WO2012026236A1 - ポリカーボネート系樹脂組成物 - Google Patents

ポリカーボネート系樹脂組成物 Download PDFInfo

- Publication number

- WO2012026236A1 WO2012026236A1 PCT/JP2011/066154 JP2011066154W WO2012026236A1 WO 2012026236 A1 WO2012026236 A1 WO 2012026236A1 JP 2011066154 W JP2011066154 W JP 2011066154W WO 2012026236 A1 WO2012026236 A1 WO 2012026236A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- polycarbonate

- group

- mass

- carbon atoms

- resin composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- IHOYFJWHNOJFCS-UHFFFAOYSA-N CC(C)N(C)[O](C)C Chemical compound CC(C)N(C)[O](C)C IHOYFJWHNOJFCS-UHFFFAOYSA-N 0.000 description 1

- 0 CC*(C)N(*)*(C)C Chemical compound CC*(C)N(*)*(C)C 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L69/00—Compositions of polycarbonates; Compositions of derivatives of polycarbonates

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G64/00—Macromolecular compounds obtained by reactions forming a carbonic ester link in the main chain of the macromolecule

- C08G64/18—Block or graft polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G77/00—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule

- C08G77/42—Block-or graft-polymers containing polysiloxane sequences

- C08G77/445—Block-or graft-polymers containing polysiloxane sequences containing polyester sequences

- C08G77/448—Block-or graft-polymers containing polysiloxane sequences containing polyester sequences containing polycarbonate sequences

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K9/00—Use of pretreated ingredients

- C08K9/04—Ingredients treated with organic substances

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G77/00—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule

- C08G77/04—Polysiloxanes

- C08G77/20—Polysiloxanes containing silicon bound to unsaturated aliphatic groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K7/00—Use of ingredients characterised by shape

- C08K7/02—Fibres or whiskers

- C08K7/04—Fibres or whiskers inorganic

- C08K7/14—Glass

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L83/00—Compositions of macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon only; Compositions of derivatives of such polymers

- C08L83/10—Block- or graft-copolymers containing polysiloxane sequences

Definitions

- the present invention relates to a glass fiber reinforced polycarbonate resin composition having excellent impact resistance. More specifically, the present invention relates to a glass fiber reinforced polycarbonate resin composition excellent in impact resistance, comprising a polycarbonate-polyorganosiloxane copolymer having a specific chain length and glass fibers treated with a specific sizing agent. It is.

- Polycarbonate resins are excellent in mechanical strength, electrical properties, transparency, and the like, and are widely used as engineering plastics in various fields such as the electrical / electronic equipment field and the automotive field.

- a glass fiber reinforced polycarbonate resin to which glass fiber is added is known.

- the impact resistance of the polycarbonate resin is significantly reduced.

- various methods for improving the impact resistance of a polycarbonate resin to which glass fiber is added have been studied. For example, a method of blending a polycarbonate-polyorganosiloxane copolymer with a polycarbonate resin is disclosed (Patent Documents 1 and 2).

- Patent Document 3 a polycarbonate resin composition composed of glass fiber and polycarbonate-polydimethylsiloxane treated with a sizing agent containing a polyolefin resin is treated with a sizing agent containing an epoxy resin and a urethane resin. It is shown that the resin composition is inferior in impact strength to the resin composition composed of the prepared glass fiber and polycarbonate-polydimethylsiloxane.

- Patent Document 4 it is known that the Izod impact strength of a polycarbonate resin composition can be improved by adding glass fibers treated with a coating agent containing a polyolefin wax to a mixed resin of a polycarbonate resin and a polyester resin.

- the polycarbonate resin only a homopolycarbonate derived from bisphenol A is disclosed.

- a polycarbonate resin composition obtained by blending an aromatic polycarbonate resin with a glass fiber pre-coated with a coating agent having low adhesion to the polycarbonate resin, and further blending an organic alkali metal salt or an organic phosphorus compound. (Patent Documents 5 and 6).

- the glass fibers used here are glass fibers that have been pretreated with a coating of polyolefin, preferably polyolefin wax.

- polyolefin preferably polyolefin wax.

- specific polycarbonate-polyorganosiloxane copolymer used in the present invention is not disclosed as the polycarbonate resin to be used.

- An object of the present invention is to obtain more excellent impact resistance in a polycarbonate resin composition containing glass fibers.

- the present inventors have solved the above problems by using a polycarbonate-polyorganosiloxane copolymer having a specific chain length of the polyorganosiloxane portion and glass fibers treated with a sizing agent containing polyolefin.

- the present invention was completed.

- the present invention (A): (A-1): 5 to 100 mass of a polycarbonate-polyorganosiloxane copolymer having a main chain having a repeating unit represented by the general formula (I) and a structural unit represented by the general formula (II) % And (A-2); 100 parts by mass of a polycarbonate-based resin mixture consisting of 0 to 95% by mass of an aromatic polycarbonate other than (A-1), and (B) 3 to 20 parts by mass of glass fiber treated with polyolefin It is related with the polycarbonate-type resin composition containing these.

- R 1 and R 2 each independently represents an alkyl group or alkoxy group having 1 to 6 carbon atoms, and X represents a single bond, an alkylene group having 1 to 8 carbon atoms, or an alkylidene group having 2 to 8 carbon atoms.

- n is an average number of repetitions and represents a number of 65 to 600, and a and b each independently represent an integer of 0 to 4.

- the impact resistance is further improved. It is possible to provide a glass fiber reinforced polycarbonate resin composition having a high glass fiber content.

- the present invention provides a polycarbonate-polyorganosiloxane copolymer having (A) :( A-1); a main chain having a repeating unit represented by the general formula (I) and a structural unit represented by the general formula (II) 5 to 100% by mass, and (A-2); 100 parts by mass of a polycarbonate resin mixture comprising 0 to 95% by mass of an aromatic polycarbonate other than (A-1), and (B) glass fiber 3 treated with polyolefin

- the present invention relates to a polycarbonate resin composition containing ⁇ 20 parts by mass.

- R 1 and R 2 each independently represents an alkyl group or alkoxy group having 1 to 6 carbon atoms

- X represents a single bond, an alkylene group having 1 to 8 carbon atoms, or an alkylidene group having 2 to 8 carbon atoms.

- R 3 to R 6 each independently represents a hydrogen atom, a halogen atom, an alkyl group having 1 to 6 carbon atoms, an alkoxy group having 1 to 6 carbon atoms or an aryl group having 6 to 12 carbon atoms, preferably R 3 to R 6 are all methyl groups.

- Y represents an organic residue containing an aliphatic group or an aromatic group, and is preferably an organic residue derived from allylphenol or eugenol.

- n is an average number of repetitions and represents a number of 65 to 600, and a and b each independently represent an integer of 0 to 4.

- (A-1) polycarbonate - described polyorganosiloxane copolymer the content of the polyorganosiloxane block portion containing the structural unit represented by the general formula (II) is preferably 1 to 20% by mass, The amount is preferably 1.5 to 15% by mass, more preferably 2 to 13% by mass. If it is 1% by mass or more, the effect of improving impact strength is sufficient, and if it is 20% by mass or less, sufficient heat resistance is obtained.

- the average repeating number n in the structural unit represented by the general formula (II) is from 65 to 600, more preferably from 70 to 200, still more preferably from 80 to 180.

- n is less than 65, the effect of improving the impact strength is not sufficient, and if it exceeds 600, (A-1) the handleability in producing the polyorganosiloxane-polycarbonate copolymer becomes difficult and economical.

- Mv viscosity average molecular weight

- the polycarbonate-polyorganosiloxane copolymer includes a dihydric phenol represented by the general formula (1) and a polyorganosiloxane represented by the general formula (2).

- R 3 to R 6 each independently represents a hydrogen atom, a halogen atom, an alkyl group having 1 to 6 carbon atoms, an alkoxy group having 1 to 6 carbon atoms or an aryl group having 6 to 12 carbon atoms.

- Y represents an organic residue containing aliphatic or aromatic

- Z represents halogen, —R 7 OH, —R 7 COOH, —R 7 NH 2 , —COOH or —SH

- R 7 represents a straight chain Represents a branched or cyclic alkylene group, an aryl-substituted alkylene group, an aryl-substituted alkylene group which may have an alkoxy group on the ring, or an arylene group.

- m represents 0 or 1; ] When, in which phosgene, carbonic esters, or obtained a chloroformate by copolymerizing.

- dihydric phenols represented by the general formula (1) used as a raw material for the (A-1) polycarbonate-polyorganosiloxane copolymer.

- 2,2-bis (4-hydroxyphenyl) propane [commonly called bisphenol a] is preferable.

- bisphenols other than bisphenol A include bis (4-hydroxyphenyl) methane, 1,1-bis (4-hydroxyphenyl) ethane, 2,2-bis (4-hydroxyphenyl) butane, and 2,2-bis. (4-hydroxyphenyl) octane, bis (4-hydroxyphenyl) phenylmethane, bis (4-hydroxyphenyl) diphenylmethane, 2,2-bis (4-hydroxy-3-methylphenyl) propane, bis (4-hydroxyphenyl) ) Naphthylmethane, 1,1-bis (4-hydroxy-t-butylphenyl) propane, 2,2-bis (4-hydroxy-3-bromophenyl) propane, 2,2-bis (4-hydroxy-3, 5-tetramethylphenyl) propane, 2,2-bis (4-hydroxy-3-chlorofe) Bis (hydroxyaryl) alkanes such as propane, 2,2-bis (4-hydroxy-3,5-dichlorophenyl) propane, 2,2-bis (4-hydroxy-3,5-dibrom

- the polyorganosiloxane represented by the general formula (2) is a phenol having an olefinically unsaturated carbon-carbon bond, preferably vinylphenol, allylphenol, eugenol, isopropenylphenol or the like having a predetermined polymerization degree n. It can be easily produced by hydrosilation reaction at the end of the polyorganosiloxane chain.

- the phenols are more preferably allylphenol or eugenol.

- Y in the general formula (II) of (A-1) is an organic residue derived from allylphenol or eugenol.

- Examples of the polyorganosiloxane represented by the general formula (2) include:

- R 3 to R 6 are each independently a hydrogen atom, a halogen atom or an alkyl group having 1 to 6 carbon atoms, as in the general formula (1).

- R 8 represents an alkyl, alkenyl, aryl or aralkyl group

- n represents the average number of repeating organosiloxane constituent units and represents a number of 65 to 600 C represents a positive integer.

- c is usually an integer of 1 to 6.

- Etc is usually an integer of 1 to 6.

- a phenol-modified polyorganosiloxane represented by the formula (3) is preferable from the viewpoint of easy polymerization, and ⁇ , ⁇ -bis [3- (o-hydroxyphenyl), which is one of the compounds represented by the formula (4). ) Propyl] polydimethylsiloxane or ⁇ , ⁇ -bis [3- (4-hydroxy-3-methoxyphenyl) propyl] polydimethylsiloxane, which is one of the compounds represented by formula (5), is preferred because of its availability. .

- the phenol-modified polyorganosiloxane can be prepared by known methods. Known production methods include the following, for example. Cyclotrisiloxane and disiloxane are reacted in the presence of an acidic catalyst to synthesize ⁇ , ⁇ -dihydrogenorganopolysiloxane. At this time, ⁇ , ⁇ -dihydrogenorganopolysiloxane having a desired average repeating unit can be synthesized by changing the charging ratio of cyclotrisiloxane and disiloxane.

- this ⁇ , ⁇ -dihydrogenorganopolysiloxane is subjected to an addition reaction with a phenol compound having an unsaturated aliphatic hydrocarbon group such as allylphenol or eugenol, to thereby obtain a desired compound.

- a phenol compound having an unsaturated aliphatic hydrocarbon group such as allylphenol or eugenol

- a phenol-modified polyorganosiloxane having an average repeating unit can be produced.

- low molecular weight cyclic polyorganosiloxane and an excessive amount of the phenol compound remain as impurities. Therefore, heating is performed under reduced pressure to distill off these low molecular compounds.

- the aromatic polycarbonate other than (A-2); (A-1) includes a dihydric phenol compound and phosgene in the presence of an organic solvent inert to the reaction and an alkaline aqueous solution.

- an interfacial polymerization method in which a polymerization catalyst such as a tertiary amine or a quaternary ammonium salt is added for polymerization, or a dihydric phenol compound is dissolved in pyridine or a mixed solution of pyridine and an inert solvent, Those obtained by a conventional method for producing an aromatic polycarbonate such as a pyridine method for directly producing by introducing phosgene are used.

- a terminal terminator, a molecular weight regulator, a branching agent and the like are used as necessary.

- a terminal terminator or a molecular weight modifier is usually used.

- the molecular weight regulator various types can be used as long as they are usually used for polymerization of polycarbonate resin. Specifically, as monohydric phenol, for example, phenol, on-butylphenol, mn-butylphenol, pn-butylphenol, o-isobutylphenol, m-isobutylphenol, p-isobutylphenol, ot -Butylphenol, mt-butylphenol, pt-butylphenol, on-pentylphenol, mn-pentylphenol, pn-pentylphenol, on-hexylphenol, mn-hexylphenol, pn-hexylphenol, pt-octylphenol, o-cyclohexylphenol, m-cyclohexylphenol, p-cyclohexylphenol, p-cyclohexy

- a branching polycarbonate can be obtained by using a branching agent in combination in the range of 0.01 to 3 mol%, particularly 0.1 to 1.0 mol% with respect to the dihydric phenol compound.

- the branching agent include 1,1,1-tris (4-hydroxyphenyl) ethane, 4,4 ′-[1- [4- [1- (4-hydroxyphenyl) -1-methylethyl] phenyl] ethylidene.

- the content of the polyorganosiloxane is from the viewpoint of impact resistance. it is preferably 1 to 10 mass%, more preferably 2 to 7% by mass.

- the content of (A-1) is 5 to 100% by mass, preferably 20 to 100% by mass, more preferably 40 to 100% by mass, and (A-2) The content of is 95 to 0% by mass, preferably 80 to 0% by mass, more preferably 60 to 0% by mass.

- (A-1) When the content of the polycarbonate-polyorganosiloxane copolymer is less than 5% by mass, (A-1) a polyorganosiloxane block portion containing a structural unit represented by the general formula (II) at the time of production

- (A-1) the uniformity of the reaction may be reduced in the polymerization step during production, and the polymer and the polymer may be washed in the polymer washing step. since there is the separation of water is deteriorated, greatly reduced the productivity of the (a-1).

- the content of (A-2) aromatic polycarbonate resin exceeds 95% by mass, the ratio of (A-1) becomes less than 5% by mass. It is necessary to increase the content of the polyorganosiloxane block portion including the structural unit represented by the formula (1), which is not preferable for the same reason as described above.

- glass fiber treated with polyolefin glass fiber obtained by bundling glass fiber with a bundling agent containing a polyolefin resin in advance is used.

- sizing agents such as polyurethane, epoxy resin, vinyl acetate resin, polyacrylic acid, etc., but even if glass fibers treated with these sizing agents are used, the effect of the present invention is I can't get it.

- the polyolefin sizing agent is a sizing agent comprising a polyolefin resin and an optionally functionalized silane sizing agent.

- polyolefin resin polyolefin wax is preferable.

- the polyolefin wax preferably comprises polyethylene wax or polypropylene wax or copolymers thereof, such as polyethylene-propylene wax and polyethylene-butylene wax.

- the polyolefin wax is preferably based on an olefin having 2 to 18 carbon atoms, more preferably 2 to 8 carbon atoms, even more preferably 2 to 4 carbon atoms, and particularly preferably a polyethylene wax. It is. Such glass fibers converged by polyolefin resins are commercially available.

- the glass fiber used for the sizing treatment with a sizing agent containing a polyolefin-based resin may be any of alkali-containing glass, low alkali glass, and alkali-free glass.

- a sizing agent containing a polyolefin-based resin may be any of alkali-containing glass, low alkali glass, and alkali-free glass.

- any things, such as roving, a chopped strand, a milled fiber can be used.

- the average fiber diameter of the glass fiber is 1 to 30 ⁇ m, preferably 5 to 25 ⁇ m, more preferably 8 to 20 ⁇ m.

- the glass fiber may have a cross-sectional shape other than a perfect circle, such as an elliptical shape, a cocoon shape, or a three-leaf shape. Furthermore, it may be one glass fiber of circular shape glass fiber and non-perfect circle shape is mixed.

- the glass fiber treated with the polyolefin (B) used in the present invention is one obtained by treating the glass fiber with the sizing agent and bundling it to about 100 to 1,000 strands.

- the method for bundling glass fibers using a bundling agent is not particularly limited, and any conventionally used method such as dip coating, roller coating, spray coating, flow coating, spray coating or the like is used. be able to.

- a chopped strand obtained by cutting the obtained strand into an average fiber length of 1 to 8 mm, preferably about 3 to 6 mm is used.

- Glass fibers used for sizing treatment with a sizing agent containing the polyolefin resin are silanes such as aminosilane, epoxy silane, vinyl silane, and methacryl silane, titanate, aluminum, chrome, zirconium.

- the surface treatment may be performed with a borane or borane coupling agent.

- silane coupling agents and titanate coupling agents are preferable, and silane coupling agents are particularly preferable.

- silane coupling agents include triethoxysilane, vinyltris ( ⁇ -methoxyethoxy) silane, ⁇ -methacryloxypropyltrimethoxysilane, ⁇ -glycidoxypropyltrimethoxysilane, ⁇ -(3,4-epoxycyclohexyl) ethyltrimethoxysilane, N- ⁇ - (aminoethyl) - ⁇ -aminopropylmethyldimethoxysilane, ⁇ -aminopropyltriethoxysilane, N-phenyl- ⁇ -aminopropyltrimethoxysilane , .gamma.-mercaptopropyl cytometry silane, .gamma.-chloropropyl trimethoxy silane, and the like.

- ⁇ -aminopropyltriethoxysilane and N- ⁇ - (aminoethyl) - ⁇ -aminopropyltrimethoxysilane are preferably used.

- the method conventionally used for example, Any method such as an aqueous solution method, an organic solvent method, and a spray method can be used.

- the use amount of the sizing agent and the coupling agent is not particularly limited, but is usually used so that the total amount thereof is 0.1 to 1.5% by mass with respect to the glass fiber.

- the content of the glass fiber treated with (B) polyolefin is 3 to 20 parts by mass, preferably 4 to 19 parts by mass with respect to 100 parts by mass of the (A) polycarbonate resin mixture. Part, more preferably 5 to 18 parts by weight.

- the amount is less than 3 parts by mass, the effect of improving heat resistance and rigidity by adding glass fiber is not sufficient.

- it exceeds 20 parts by mass the effect of improving the Izod impact strength obtained by using the polyolefin-based sizing agent decreases.

- the polycarbonate resin composition of the present invention may be conventionally added to the polycarbonate resin composition as necessary.

- these various additives can be blended. These include reinforcing materials, fillers, stabilizers, antioxidants, UV absorbers, antistatic agents, lubricants, mold release agents, dyes, pigments, other flame retardants and elastomers for improving impact resistance. .

- the polycarbonate resin composition of the present invention can be obtained by blending each component (A-1), (A-2), (B), and known additives as necessary, and kneading. it can.

- the blending and kneading are usually performed using a method such as a ribbon blender, a Henschel mixer, a Banbury mixer, a drum tumbler, a single screw extruder, a twin screw extruder, a kneader, a multi screw extruder or the like. It can be done by a method.

- the heating temperature of during the kneading is usually selected in the range of 250 ⁇ 320 ° C..

- various conventionally known molding methods such as injection molding, injection compression molding, extrusion molding, blow molding, press molding, etc.

- a vacuum molding method, a foam molding method, or the like can be used.

- the tubular reactor had a jacket portion, and the temperature of the reaction solution was kept at 40 ° C. or lower by passing cooling water through the jacket.

- the reaction solution exiting the tubular reactor was continuously introduced into a 40-liter baffled tank reactor equipped with a receding blade, and bisphenol A aqueous sodium hydroxide solution 2.8 L / hr, 25 mass.

- the reaction was carried out by adding 0.64 L / hr of a 0.07 L / hr aqueous sodium hydroxide solution, 17 L / hr water, and 1 wt% triethylamine aqueous solution.

- the reaction liquid overflowing from the tank reactor was continuously extracted and allowed to stand to separate and remove the aqueous phase, and the methylene chloride phase was collected.

- the polycarbonate oligomer thus obtained had a concentration of 318 g / L and a chloroformate group concentration of 0.75 mol / L.

- the weight average molecular weight (Mw) was 1190.

- the weight average molecular weight (Mw) was measured using GPC (column: TOSOH TSK-GEL MULTIPIORE HXL-M (2) + Shodex KF801 (1)), temperature 40 ° C., flow rate 1.0 ml, using THF (tetrahydrofuran) as a developing solvent. / Min, detector: RI], and measured as a standard polystyrene equivalent molecular weight (weight average molecular weight: Mw).

- Dimethylsiloxane reaction was carried out.

- methylene chloride solution of pt-butylphenol (PTBP) (137.9 g of pt-butylphenol dissolved in 2.0 L of methylene chloride)

- sodium hydroxide aqueous solution of bisphenol A (581 g of sodium hydroxide)

- a solution obtained by dissolving 1147 g of bisphenol A in an aqueous solution in which 2.3 g of sodium dithionite was dissolved in 8.5 L of water and the polymerization reaction was carried out for 50 minutes.

- the methylene chloride solution of the polycarbonate-polydimethylsiloxane copolymer obtained by washing was concentrated and pulverized, and the obtained flakes were dried at 120 ° C. under reduced pressure.

- the polycarbonate-polydimethylsiloxane copolymer obtained as described above has a polydimethylsiloxane residue content determined by NMR measurement of 6.0% by mass and a viscosity measured according to ISO 1628-4 (1999). The number was 47.4, and the viscosity average molecular weight (Mv) determined from the calculation formula described later was 17,700.

- Examples 1 to 15 and Comparative Examples 1 to 26 Polycarbonate-polydimethylsiloxane copolymers (A-1-1 to A-1-9) obtained in Production Examples 1 to 9 and aromatic polycarbonates (A-2-) at the compounding ratios shown in Table 2 and Table 3. 1 to A-2-4), glass fibers (B-1, B-2), tris (2,4-di-tert-butylphenyl) phosphite [manufactured by BASF, trade name “Irgafos168”] 0.10 mass The parts were mixed and melt-kneaded at a resin temperature of 290 ° C.

- each polycarbonate resin composition pellet using a vented twin-screw extruder [manufactured by Toshiba Machine Co., Ltd., model name “TEM-35B”] to prepare each polycarbonate resin composition pellet.

- the aromatic polycarbonates (A-2-1 to A-2-4) used are as shown below.

- A-2-1 Bisphenol A polycarbonate having a viscosity average molecular weight of 23300 [manufactured by Idemitsu Kosan Co., Ltd., trade name “Taflon FN2500A”]

- A-2-2 Bisphenol A polycarbonate having a viscosity average molecular weight of 19000 [trade name “Taflon FN1900A” manufactured by Idemitsu Kosan Co., Ltd.]

- A-2-3 Bisphenol A polycarbonate having a viscosity average molecular weight of 21100 [manufactured by Idemitsu Kosan Co., Ltd., trade name “Taflon FN2200A”]

- A-2-4 Bisphenol A polycarbonate having a viscosity average molecular weight of 26100 [trade name “Taflon FN2600A” manufactured by Idemitsu Kosan Co., Ltd.]

- B-1 Glass fiber treated with a sizing agent containing polyolefin resin [Owens Corning, 03 MA FT 415A (average fiber diameter 14 ⁇ m, average fiber length 4 mm) chopped strand]

- B-2 Glass fiber treated with a sizing agent containing urethane resin [chopped strand of 03 MA FT 737 (average fiber diameter 13 ⁇ m, average fiber length 4 mm) manufactured by Owens Corning Co., Ltd.]

- the obtained filtrate was dried on a petri dish to obtain a polycarbonate resin composition after removing glass fibers.

- the polycarbonate resin compositions of Examples 1 to 15 exhibit superior characteristics than the polycarbonate resin compositions of Comparative Examples 1 to 26. That is, the polycarbonate-based resin compositions of Examples 1 to 15 include (A-1) a composition not containing a polycarbonate-polyorganosiloxane copolymer, and a PDMS chain length in (A-1) of less than 65, that is, ( A-1) a composition using the copolymer having an average repeating number n of the organosiloxane structural unit in the general formula (II) of less than 65, and (B) a glass fiber that is not a glass fiber treated with polyolefin. It can be seen that the composition shows higher Izod impact strength as compared to the composition used and the composition in which the content of the component (B) exceeds 20 parts by mass.

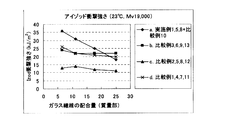

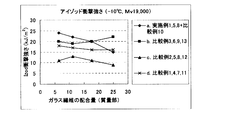

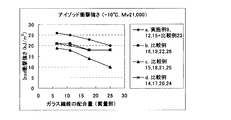

- FIG. 1 to 4 are plots of Izod impact strength (23 ° C. and ⁇ 10 ° C.) of the polycarbonate resin compositions of Examples and Comparative Examples of the present application, with the horizontal axis representing the glass fiber content.

- FIG. 1 and FIG. 2 show examples of the present application using a component (A-1) having an average number of repeating units n of 90 in the general formula (II) and having a viscosity average molecular weight (Mv) of 19,000. Izod impact strength of the polycarbonate resin composition, and its comparative example.

- FIGS. 1 a, 2 a, 3 a, and 4 a are compositions of Examples of the present application (however, a comparative example in which the glass fiber content is 25 parts by mass), FIG. 1 b, FIG. 2b, FIG. 3b, and FIG. 4b are compositions containing glass fiber (B-2) other than the component (B) of this application, and FIG. 1c, FIG.

- FIG. 1d, FIG. 2d, FIG. 3d, and FIG. 4d show the data of the composition in which n in the component (A-1) is less than 65. From comparison of a in FIGS. 1 to 4 and b to d in FIGS. 1 to 4, the polycarbonate resin composition of the example of the present application has superior Izod impact strength than the polycarbonate resin composition of the comparative example of the present application. You can see that

- a glass fiber reinforced polycarbonate resin composition having higher impact resistance can be provided.

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Polyesters Or Polycarbonates (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012530586A JP5739892B2 (ja) | 2010-08-26 | 2011-07-14 | ポリカーボネート系樹脂組成物 |

| CN201180041025.0A CN103068921B (zh) | 2010-08-26 | 2011-07-14 | 聚碳酸酯系树脂组合物 |

| KR1020137004621A KR101816500B1 (ko) | 2010-08-26 | 2011-07-14 | 폴리카보네이트계 수지 조성물 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010189952 | 2010-08-26 | ||

| JP2010-189952 | 2010-08-26 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012026236A1 true WO2012026236A1 (ja) | 2012-03-01 |

Family

ID=45723247

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/066154 Ceased WO2012026236A1 (ja) | 2010-08-26 | 2011-07-14 | ポリカーボネート系樹脂組成物 |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP5739892B2 (enExample) |

| KR (1) | KR101816500B1 (enExample) |

| CN (1) | CN103068921B (enExample) |

| TW (1) | TW201209097A (enExample) |

| WO (1) | WO2012026236A1 (enExample) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014136879A1 (ja) * | 2013-03-06 | 2014-09-12 | 出光興産株式会社 | ポリカーボネート樹脂組成物及び成形体 |

| WO2016063656A1 (ja) * | 2014-10-20 | 2016-04-28 | 出光興産株式会社 | リサイクル材を含むポリカーボネート系樹脂組成物及びその成形品 |

| EP3312241A4 (en) * | 2015-06-17 | 2018-12-26 | Idemitsu Kosan Co.,Ltd. | Polycarbonate resin composition and molded product thereof |

| JP2020189993A (ja) * | 2015-06-17 | 2020-11-26 | 出光興産株式会社 | ポリカーボネート系樹脂組成物の製造方法 |

| JP2022502525A (ja) * | 2019-09-02 | 2022-01-11 | エルジー・ケム・リミテッド | コポリカーボネートおよびこれを含むポリカーボネート組成物 |

| US20230357512A1 (en) * | 2020-06-30 | 2023-11-09 | Idemitsu Kosan Co.,Ltd. | Resin composition, molded body, and method of improving property of resin composition |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017034040A1 (ja) * | 2015-08-27 | 2017-03-02 | 出光興産株式会社 | ポリカーボネート-ポリオルガノシロキサン共重合体の製造方法 |

| US11911914B2 (en) | 2019-01-28 | 2024-02-27 | Cognex Corporation | System and method for automatic hand-eye calibration of vision system for robot motion |

| WO2021045390A1 (ko) * | 2019-09-02 | 2021-03-11 | 주식회사 엘지화학 | 코폴리카보네이트 및 이를 포함하는 폴리카보네이트 조성물 |

| CN114316237B (zh) * | 2021-07-14 | 2023-04-21 | 广州市德力塑化工科技有限公司 | 一种电容器膜用的三元聚碳酸酯及其制备方法和应用 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0726149A (ja) * | 1993-05-12 | 1995-01-27 | Idemitsu Petrochem Co Ltd | ガラス繊維強化ポリカーボネート系樹脂組成物 |

| JPH10273585A (ja) * | 1997-01-30 | 1998-10-13 | General Electric Co <Ge> | ガラス強化ポリカーボネート−ポリエステル組成物 |

| JP2003277597A (ja) * | 2002-03-25 | 2003-10-02 | Teijin Chem Ltd | ガラス繊維強化ポリカーボネート樹脂組成物 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6001929A (en) * | 1994-07-15 | 1999-12-14 | Idemitsu Petrochemical Co., Ltd. | Polycarbonate resin composition |

| EP0692522B1 (en) * | 1994-07-15 | 2002-09-11 | Idemitsu Petrochemical Co., Ltd. | Polycarbonate resin composition |

| JP5021192B2 (ja) * | 2004-12-06 | 2012-09-05 | 出光興産株式会社 | ポリカーボネート樹脂組成物及び成形体 |

-

2011

- 2011-07-14 JP JP2012530586A patent/JP5739892B2/ja active Active

- 2011-07-14 CN CN201180041025.0A patent/CN103068921B/zh active Active

- 2011-07-14 KR KR1020137004621A patent/KR101816500B1/ko active Active

- 2011-07-14 WO PCT/JP2011/066154 patent/WO2012026236A1/ja not_active Ceased

- 2011-07-20 TW TW100125673A patent/TW201209097A/zh unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0726149A (ja) * | 1993-05-12 | 1995-01-27 | Idemitsu Petrochem Co Ltd | ガラス繊維強化ポリカーボネート系樹脂組成物 |

| JPH10273585A (ja) * | 1997-01-30 | 1998-10-13 | General Electric Co <Ge> | ガラス強化ポリカーボネート−ポリエステル組成物 |

| JP2003277597A (ja) * | 2002-03-25 | 2003-10-02 | Teijin Chem Ltd | ガラス繊維強化ポリカーボネート樹脂組成物 |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014136879A1 (ja) * | 2013-03-06 | 2014-09-12 | 出光興産株式会社 | ポリカーボネート樹脂組成物及び成形体 |

| JP2014172938A (ja) * | 2013-03-06 | 2014-09-22 | Idemitsu Kosan Co Ltd | ポリカーボネート樹脂組成物及び成形体 |

| US9540511B2 (en) | 2013-03-06 | 2017-01-10 | Idemitsu Kosan Co., Ltd. | Polycarbonate resin composition and molded body |

| WO2016063656A1 (ja) * | 2014-10-20 | 2016-04-28 | 出光興産株式会社 | リサイクル材を含むポリカーボネート系樹脂組成物及びその成形品 |

| JP2016079333A (ja) * | 2014-10-20 | 2016-05-16 | 出光興産株式会社 | リサイクル材を含むポリカーボネート系樹脂組成物及びその成形品 |

| JP2020189993A (ja) * | 2015-06-17 | 2020-11-26 | 出光興産株式会社 | ポリカーボネート系樹脂組成物の製造方法 |

| EP3312241A4 (en) * | 2015-06-17 | 2018-12-26 | Idemitsu Kosan Co.,Ltd. | Polycarbonate resin composition and molded product thereof |

| US10975225B2 (en) | 2015-06-17 | 2021-04-13 | Idemitsu Kosan Co., Ltd. | Polycarbonate resin composition and molded product thereof |

| JP7081882B2 (ja) | 2015-06-17 | 2022-06-07 | 出光興産株式会社 | ポリカーボネート系樹脂組成物の製造方法 |

| JP2022502525A (ja) * | 2019-09-02 | 2022-01-11 | エルジー・ケム・リミテッド | コポリカーボネートおよびこれを含むポリカーボネート組成物 |

| JP7090804B2 (ja) | 2019-09-02 | 2022-06-24 | エルジー・ケム・リミテッド | コポリカーボネートおよびこれを含むポリカーボネート組成物 |

| US11572439B2 (en) | 2019-09-02 | 2023-02-07 | Lg Chem, Ltd. | Copolycarbonate and polycarbonate composition comprising the same |

| US20230357512A1 (en) * | 2020-06-30 | 2023-11-09 | Idemitsu Kosan Co.,Ltd. | Resin composition, molded body, and method of improving property of resin composition |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101816500B1 (ko) | 2018-01-09 |

| CN103068921A (zh) | 2013-04-24 |

| TW201209097A (en) | 2012-03-01 |

| JPWO2012026236A1 (ja) | 2013-10-28 |

| TWI563031B (enExample) | 2016-12-21 |

| KR20130100274A (ko) | 2013-09-10 |

| JP5739892B2 (ja) | 2015-06-24 |

| CN103068921B (zh) | 2015-07-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5739892B2 (ja) | ポリカーボネート系樹脂組成物 | |

| JP7081882B2 (ja) | ポリカーボネート系樹脂組成物の製造方法 | |

| JP5547953B2 (ja) | ポリカーボネート−ポリオルガノシロキサン共重合体、その製造方法及び該共重合体を含むポリカーボネート樹脂 | |

| JP5919294B2 (ja) | ポリカーボネート−ポリオルガノシロキサン共重合体及びその製造方法 | |

| CN105899607B (zh) | 聚碳酸酯树脂组合物 | |

| JP6072841B2 (ja) | ポリカーボネート樹脂組成物及びポリカーボネート樹脂成形体 | |

| TWI567105B (zh) | 共聚碳酸酯及含彼之組成物 | |

| KR20120050964A (ko) | 휴대형 전자기기 케이스 | |

| TWI663207B (zh) | Polycarbonate resin composition | |

| TWI775816B (zh) | 聚碳酸酯-聚有機矽氧烷共聚物、包含其之聚碳酸酯系樹脂組合物及其成形品 | |

| JPWO2018159781A1 (ja) | ポリカーボネート系樹脂組成物及びその成形品 | |

| JP5431751B2 (ja) | 摺動性に優れたポリカーボネート系樹脂組成物及びそれを用いた成形品 | |

| US20190002652A1 (en) | Glass-reinforced pdms copolycarbonate resins | |

| JP7129134B2 (ja) | ポリカーボネート系樹脂組成物及びその成形品 | |

| WO2018066561A1 (ja) | ポリカーボネート系樹脂組成物及び成形体 | |

| JPWO2018159779A1 (ja) | ポリカーボネート系樹脂組成物及びその成形品 | |

| WO2020158590A1 (ja) | カーボネート-オレフィン系共重合体及びその組成物 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180041025.0 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11819705 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2012530586 Country of ref document: JP Kind code of ref document: A |

|

| ENP | Entry into the national phase |

Ref document number: 20137004621 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 11819705 Country of ref document: EP Kind code of ref document: A1 |