RU2541573C9 - Способ получения полиуретановой пены с помощью порообразователя, находящегося в сверхкритическом или околокритическом состоянии - Google Patents

Способ получения полиуретановой пены с помощью порообразователя, находящегося в сверхкритическом или околокритическом состоянии Download PDFInfo

- Publication number

- RU2541573C9 RU2541573C9 RU2012123133/04A RU2012123133A RU2541573C9 RU 2541573 C9 RU2541573 C9 RU 2541573C9 RU 2012123133/04 A RU2012123133/04 A RU 2012123133/04A RU 2012123133 A RU2012123133 A RU 2012123133A RU 2541573 C9 RU2541573 C9 RU 2541573C9

- Authority

- RU

- Russia

- Prior art keywords

- mixture

- component

- polyurethane foam

- components

- blowing agent

- Prior art date

Links

- 239000004604 Blowing Agent Substances 0.000 title claims abstract description 50

- 238000000034 method Methods 0.000 title claims abstract description 43

- 229920005830 Polyurethane Foam Polymers 0.000 title claims abstract description 26

- 239000011496 polyurethane foam Substances 0.000 title claims abstract description 26

- 239000000203 mixture Substances 0.000 claims abstract description 61

- 239000004094 surface-active agent Substances 0.000 claims abstract description 37

- 125000004432 carbon atom Chemical group C* 0.000 claims abstract description 23

- 239000012948 isocyanate Substances 0.000 claims abstract description 22

- 150000002513 isocyanates Chemical class 0.000 claims abstract description 22

- 239000003599 detergent Substances 0.000 claims abstract description 18

- 239000005056 polyisocyanate Substances 0.000 claims abstract description 16

- 229920001228 polyisocyanate Polymers 0.000 claims abstract description 16

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 claims abstract description 6

- 230000009471 action Effects 0.000 claims abstract description 5

- 150000001924 cycloalkanes Chemical class 0.000 claims abstract description 4

- 229910052786 argon Inorganic materials 0.000 claims abstract description 3

- 125000004122 cyclic group Chemical group 0.000 claims abstract description 3

- 229920005862 polyol Polymers 0.000 claims description 47

- 150000003077 polyols Chemical class 0.000 claims description 42

- 239000011148 porous material Substances 0.000 claims description 38

- 239000006260 foam Substances 0.000 claims description 35

- -1 polyethylene Polymers 0.000 claims description 28

- 125000002887 hydroxy group Chemical group [H]O* 0.000 claims description 22

- 239000000463 material Substances 0.000 claims description 17

- 239000012530 fluid Substances 0.000 claims description 15

- 238000004519 manufacturing process Methods 0.000 claims description 12

- 238000002156 mixing Methods 0.000 claims description 12

- UPMLOUAZCHDJJD-UHFFFAOYSA-N 4,4'-Diphenylmethane Diisocyanate Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=C(N=C=O)C=C1 UPMLOUAZCHDJJD-UHFFFAOYSA-N 0.000 claims description 11

- 150000001875 compounds Chemical group 0.000 claims description 11

- 229920005906 polyester polyol Polymers 0.000 claims description 11

- 229920000728 polyester Polymers 0.000 claims description 8

- 238000002360 preparation method Methods 0.000 claims description 3

- 239000004698 Polyethylene Substances 0.000 claims description 2

- 229920000573 polyethylene Polymers 0.000 claims description 2

- 239000000126 substance Substances 0.000 abstract description 6

- 230000000694 effects Effects 0.000 abstract 1

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 22

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 20

- 238000006243 chemical reaction Methods 0.000 description 19

- 239000004530 micro-emulsion Substances 0.000 description 17

- 239000011541 reaction mixture Substances 0.000 description 17

- 239000002253 acid Substances 0.000 description 16

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 15

- 239000004814 polyurethane Substances 0.000 description 13

- 239000004721 Polyphenylene oxide Substances 0.000 description 11

- 150000002009 diols Chemical class 0.000 description 11

- 239000007789 gas Substances 0.000 description 11

- 229920000570 polyether Polymers 0.000 description 11

- 239000003795 chemical substances by application Substances 0.000 description 10

- 235000011187 glycerol Nutrition 0.000 description 9

- 230000015572 biosynthetic process Effects 0.000 description 8

- KPUWHANPEXNPJT-UHFFFAOYSA-N disiloxane Chemical class [SiH3]O[SiH3] KPUWHANPEXNPJT-UHFFFAOYSA-N 0.000 description 8

- 150000002430 hydrocarbons Chemical class 0.000 description 8

- 229920001296 polysiloxane Polymers 0.000 description 8

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 7

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 7

- 229930195733 hydrocarbon Natural products 0.000 description 7

- 239000007858 starting material Substances 0.000 description 7

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 6

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 6

- 238000011049 filling Methods 0.000 description 6

- 238000005755 formation reaction Methods 0.000 description 6

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 6

- XNGIFLGASWRNHJ-UHFFFAOYSA-N phthalic acid Chemical compound OC(=O)C1=CC=CC=C1C(O)=O XNGIFLGASWRNHJ-UHFFFAOYSA-N 0.000 description 6

- 229920002635 polyurethane Polymers 0.000 description 6

- 239000004215 Carbon black (E152) Substances 0.000 description 5

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 5

- OFBQJSOFQDEBGM-UHFFFAOYSA-N Pentane Chemical class CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 description 5

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 5

- 150000007513 acids Chemical class 0.000 description 5

- 125000002947 alkylene group Chemical group 0.000 description 5

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 5

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 5

- 239000004417 polycarbonate Substances 0.000 description 5

- 229920000515 polycarbonate Polymers 0.000 description 5

- AFABGHUZZDYHJO-UHFFFAOYSA-N 2-Methylpentane Chemical compound CCCC(C)C AFABGHUZZDYHJO-UHFFFAOYSA-N 0.000 description 4

- RGSFGYAAUTVSQA-UHFFFAOYSA-N Cyclopentane Chemical compound C1CCCC1 RGSFGYAAUTVSQA-UHFFFAOYSA-N 0.000 description 4

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 4

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 4

- 150000001298 alcohols Chemical class 0.000 description 4

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 4

- 239000000839 emulsion Substances 0.000 description 4

- 150000002148 esters Chemical class 0.000 description 4

- 238000009413 insulation Methods 0.000 description 4

- NNPPMTNAJDCUHE-UHFFFAOYSA-N isobutane Chemical compound CC(C)C NNPPMTNAJDCUHE-UHFFFAOYSA-N 0.000 description 4

- QQVIHTHCMHWDBS-UHFFFAOYSA-N isophthalic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 4

- 239000000178 monomer Substances 0.000 description 4

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 4

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 description 4

- 235000013772 propylene glycol Nutrition 0.000 description 4

- CXMXRPHRNRROMY-UHFFFAOYSA-N sebacic acid Chemical compound OC(=O)CCCCCCCCC(O)=O CXMXRPHRNRROMY-UHFFFAOYSA-N 0.000 description 4

- TYFQFVWCELRYAO-UHFFFAOYSA-N suberic acid Chemical compound OC(=O)CCCCCCC(O)=O TYFQFVWCELRYAO-UHFFFAOYSA-N 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- DNIAPMSPPWPWGF-VKHMYHEASA-N (+)-propylene glycol Chemical compound C[C@H](O)CO DNIAPMSPPWPWGF-VKHMYHEASA-N 0.000 description 3

- PUPZLCDOIYMWBV-UHFFFAOYSA-N (+/-)-1,3-Butanediol Chemical compound CC(O)CCO PUPZLCDOIYMWBV-UHFFFAOYSA-N 0.000 description 3

- DNIAPMSPPWPWGF-GSVOUGTGSA-N (R)-(-)-Propylene glycol Chemical compound C[C@@H](O)CO DNIAPMSPPWPWGF-GSVOUGTGSA-N 0.000 description 3

- YPFDHNVEDLHUCE-UHFFFAOYSA-N 1,3-propanediol Substances OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 3

- OTMSDBZUPAUEDD-UHFFFAOYSA-N Ethane Chemical compound CC OTMSDBZUPAUEDD-UHFFFAOYSA-N 0.000 description 3

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 3

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 3

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 3

- 150000008064 anhydrides Chemical class 0.000 description 3

- 239000001569 carbon dioxide Substances 0.000 description 3

- 229910002092 carbon dioxide Inorganic materials 0.000 description 3

- 239000003054 catalyst Substances 0.000 description 3

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 3

- 150000001991 dicarboxylic acids Chemical class 0.000 description 3

- 235000014113 dietary fatty acids Nutrition 0.000 description 3

- 229930195729 fatty acid Natural products 0.000 description 3

- 239000000194 fatty acid Substances 0.000 description 3

- 150000004665 fatty acids Chemical class 0.000 description 3

- 239000006261 foam material Substances 0.000 description 3

- 238000009472 formulation Methods 0.000 description 3

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 3

- 239000003999 initiator Substances 0.000 description 3

- 150000002596 lactones Chemical class 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- BDJRBEYXGGNYIS-UHFFFAOYSA-N nonanedioic acid Chemical compound OC(=O)CCCCCCCC(O)=O BDJRBEYXGGNYIS-UHFFFAOYSA-N 0.000 description 3

- 230000006911 nucleation Effects 0.000 description 3

- 238000010899 nucleation Methods 0.000 description 3

- 229920000768 polyamine Polymers 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 229920000166 polytrimethylene carbonate Polymers 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000011342 resin composition Substances 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- 238000003786 synthesis reaction Methods 0.000 description 3

- RTBFRGCFXZNCOE-UHFFFAOYSA-N 1-methylsulfonylpiperidin-4-one Chemical compound CS(=O)(=O)N1CCC(=O)CC1 RTBFRGCFXZNCOE-UHFFFAOYSA-N 0.000 description 2

- ZFFMLCVRJBZUDZ-UHFFFAOYSA-N 2,3-dimethylbutane Chemical compound CC(C)C(C)C ZFFMLCVRJBZUDZ-UHFFFAOYSA-N 0.000 description 2

- OHJDDRJXKMWSFJ-UHFFFAOYSA-N 2,4-diethyl-5-methylbenzene-1,3-diamine Chemical compound CCC1=C(C)C=C(N)C(CC)=C1N OHJDDRJXKMWSFJ-UHFFFAOYSA-N 0.000 description 2

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 2

- HZAXFHJVJLSVMW-UHFFFAOYSA-N 2-Aminoethan-1-ol Chemical compound NCCO HZAXFHJVJLSVMW-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 2

- GHPVDCPCKSNJDR-UHFFFAOYSA-N 2-hydroxydecanoic acid Chemical compound CCCCCCCCC(O)C(O)=O GHPVDCPCKSNJDR-UHFFFAOYSA-N 0.000 description 2

- WXUAQHNMJWJLTG-UHFFFAOYSA-N 2-methylbutanedioic acid Chemical compound OC(=O)C(C)CC(O)=O WXUAQHNMJWJLTG-UHFFFAOYSA-N 0.000 description 2

- QWGRWMMWNDWRQN-UHFFFAOYSA-N 2-methylpropane-1,3-diol Chemical compound OCC(C)CO QWGRWMMWNDWRQN-UHFFFAOYSA-N 0.000 description 2

- VEORPZCZECFIRK-UHFFFAOYSA-N 3,3',5,5'-tetrabromobisphenol A Chemical compound C=1C(Br)=C(O)C(Br)=CC=1C(C)(C)C1=CC(Br)=C(O)C(Br)=C1 VEORPZCZECFIRK-UHFFFAOYSA-N 0.000 description 2

- FZQMJOOSLXFQSU-UHFFFAOYSA-N 3-[3,5-bis[3-(dimethylamino)propyl]-1,3,5-triazinan-1-yl]-n,n-dimethylpropan-1-amine Chemical compound CN(C)CCCN1CN(CCCN(C)C)CN(CCCN(C)C)C1 FZQMJOOSLXFQSU-UHFFFAOYSA-N 0.000 description 2

- IBOFVQJTBBUKMU-UHFFFAOYSA-N 4,4'-methylene-bis-(2-chloroaniline) Chemical compound C1=C(Cl)C(N)=CC=C1CC1=CC=C(N)C(Cl)=C1 IBOFVQJTBBUKMU-UHFFFAOYSA-N 0.000 description 2

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 2

- HHDUMDVQUCBCEY-UHFFFAOYSA-N 4-[10,15,20-tris(4-carboxyphenyl)-21,23-dihydroporphyrin-5-yl]benzoic acid Chemical compound OC(=O)c1ccc(cc1)-c1c2ccc(n2)c(-c2ccc(cc2)C(O)=O)c2ccc([nH]2)c(-c2ccc(cc2)C(O)=O)c2ccc(n2)c(-c2ccc(cc2)C(O)=O)c2ccc1[nH]2 HHDUMDVQUCBCEY-UHFFFAOYSA-N 0.000 description 2

- SOGAXMICEFXMKE-UHFFFAOYSA-N Butylmethacrylate Chemical compound CCCCOC(=O)C(C)=C SOGAXMICEFXMKE-UHFFFAOYSA-N 0.000 description 2

- XDTMQSROBMDMFD-UHFFFAOYSA-N Cyclohexane Chemical compound C1CCCCC1 XDTMQSROBMDMFD-UHFFFAOYSA-N 0.000 description 2

- PIICEJLVQHRZGT-UHFFFAOYSA-N Ethylenediamine Chemical compound NCCN PIICEJLVQHRZGT-UHFFFAOYSA-N 0.000 description 2

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 description 2

- WLJVNTCWHIRURA-UHFFFAOYSA-N Heptanedioic acid Natural products OC(=O)CCCCCC(O)=O WLJVNTCWHIRURA-UHFFFAOYSA-N 0.000 description 2

- 229920000877 Melamine resin Polymers 0.000 description 2

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 2

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 2

- 229910018557 Si O Inorganic materials 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- KDYFGRWQOYBRFD-UHFFFAOYSA-N Succinic acid Natural products OC(=O)CCC(O)=O KDYFGRWQOYBRFD-UHFFFAOYSA-N 0.000 description 2

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical compound OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 description 2

- ISKQADXMHQSTHK-UHFFFAOYSA-N [4-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=C(CN)C=C1 ISKQADXMHQSTHK-UHFFFAOYSA-N 0.000 description 2

- UKLDJPRMSDWDSL-UHFFFAOYSA-L [dibutyl(dodecanoyloxy)stannyl] dodecanoate Chemical compound CCCCCCCCCCCC(=O)O[Sn](CCCC)(CCCC)OC(=O)CCCCCCCCCCC UKLDJPRMSDWDSL-UHFFFAOYSA-L 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- WNLRTRBMVRJNCN-UHFFFAOYSA-N adipic acid Chemical compound OC(=O)CCCCC(O)=O WNLRTRBMVRJNCN-UHFFFAOYSA-N 0.000 description 2

- 150000001335 aliphatic alkanes Chemical class 0.000 description 2

- 125000001931 aliphatic group Chemical group 0.000 description 2

- 125000000217 alkyl group Chemical group 0.000 description 2

- XXROGKLTLUQVRX-UHFFFAOYSA-N allyl alcohol Chemical compound OCC=C XXROGKLTLUQVRX-UHFFFAOYSA-N 0.000 description 2

- JFCQEDHGNNZCLN-UHFFFAOYSA-N anhydrous glutaric acid Natural products OC(=O)CCCC(O)=O JFCQEDHGNNZCLN-UHFFFAOYSA-N 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- WPYMKLBDIGXBTP-UHFFFAOYSA-N benzoic acid Chemical compound OC(=O)C1=CC=CC=C1 WPYMKLBDIGXBTP-UHFFFAOYSA-N 0.000 description 2

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 2

- CDQSJQSWAWPGKG-UHFFFAOYSA-N butane-1,1-diol Chemical compound CCCC(O)O CDQSJQSWAWPGKG-UHFFFAOYSA-N 0.000 description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical class OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000012975 dibutyltin dilaurate Substances 0.000 description 2

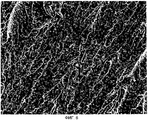

- 238000001493 electron microscopy Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 150000002334 glycols Chemical class 0.000 description 2

- DMEGYFMYUHOHGS-UHFFFAOYSA-N heptamethylene Natural products C1CCCCCC1 DMEGYFMYUHOHGS-UHFFFAOYSA-N 0.000 description 2

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 239000001282 iso-butane Substances 0.000 description 2

- 235000013847 iso-butane Nutrition 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- IJDNQMDRQITEOD-UHFFFAOYSA-N n-butane Chemical compound CCCC IJDNQMDRQITEOD-UHFFFAOYSA-N 0.000 description 2

- 239000002736 nonionic surfactant Substances 0.000 description 2

- 238000010587 phase diagram Methods 0.000 description 2

- LGRFSURHDFAFJT-UHFFFAOYSA-N phthalic anhydride Chemical compound C1=CC=C2C(=O)OC(=O)C2=C1 LGRFSURHDFAFJT-UHFFFAOYSA-N 0.000 description 2

- 229920000233 poly(alkylene oxides) Polymers 0.000 description 2

- 229920001515 polyalkylene glycol Polymers 0.000 description 2

- 239000011495 polyisocyanurate Substances 0.000 description 2

- 229920000582 polyisocyanurate Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 229920001451 polypropylene glycol Polymers 0.000 description 2

- 229920006295 polythiol Polymers 0.000 description 2

- 239000001294 propane Substances 0.000 description 2

- KIDHWZJUCRJVML-UHFFFAOYSA-N putrescine Chemical compound NCCCCN KIDHWZJUCRJVML-UHFFFAOYSA-N 0.000 description 2

- 238000010526 radical polymerization reaction Methods 0.000 description 2

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Inorganic materials [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 2

- 125000005373 siloxane group Chemical group [SiH2](O*)* 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 2

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 2

- ARCGXLSVLAOJQL-UHFFFAOYSA-N trimellitic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 ARCGXLSVLAOJQL-UHFFFAOYSA-N 0.000 description 2

- XFNJVJPLKCPIBV-UHFFFAOYSA-N trimethylenediamine Chemical compound NCCCN XFNJVJPLKCPIBV-UHFFFAOYSA-N 0.000 description 2

- 150000004072 triols Chemical class 0.000 description 2

- JXPOLSKBTUYKJB-UHFFFAOYSA-N xi-2,3-Dimethylhexane Chemical compound CCCC(C)C(C)C JXPOLSKBTUYKJB-UHFFFAOYSA-N 0.000 description 2

- WGECXQBGLLYSFP-UHFFFAOYSA-N (+-)-2,3-dimethyl-pentane Natural products CCC(C)C(C)C WGECXQBGLLYSFP-UHFFFAOYSA-N 0.000 description 1

- NIDNOXCRFUCAKQ-UMRXKNAASA-N (1s,2r,3s,4r)-bicyclo[2.2.1]hept-5-ene-2,3-dicarboxylic acid Chemical compound C1[C@H]2C=C[C@@H]1[C@H](C(=O)O)[C@@H]2C(O)=O NIDNOXCRFUCAKQ-UMRXKNAASA-N 0.000 description 1

- JNYAEWCLZODPBN-JGWLITMVSA-N (2r,3r,4s)-2-[(1r)-1,2-dihydroxyethyl]oxolane-3,4-diol Chemical compound OC[C@@H](O)[C@H]1OC[C@H](O)[C@H]1O JNYAEWCLZODPBN-JGWLITMVSA-N 0.000 description 1

- PSGCQDPCAWOCSH-UHFFFAOYSA-N (4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl) prop-2-enoate Chemical compound C1CC2(C)C(OC(=O)C=C)CC1C2(C)C PSGCQDPCAWOCSH-UHFFFAOYSA-N 0.000 description 1

- ORTVZLZNOYNASJ-UPHRSURJSA-N (z)-but-2-ene-1,4-diol Chemical compound OC\C=C/CO ORTVZLZNOYNASJ-UPHRSURJSA-N 0.000 description 1

- AZYRZNIYJDKRHO-UHFFFAOYSA-N 1,3-bis(2-isocyanatopropan-2-yl)benzene Chemical compound O=C=NC(C)(C)C1=CC=CC(C(C)(C)N=C=O)=C1 AZYRZNIYJDKRHO-UHFFFAOYSA-N 0.000 description 1

- RTTZISZSHSCFRH-UHFFFAOYSA-N 1,3-bis(isocyanatomethyl)benzene Chemical compound O=C=NCC1=CC=CC(CN=C=O)=C1 RTTZISZSHSCFRH-UHFFFAOYSA-N 0.000 description 1

- HNSDLXPSAYFUHK-UHFFFAOYSA-N 1,4-bis(2-ethylhexyl) sulfosuccinate Chemical compound CCCCC(CC)COC(=O)CC(S(O)(=O)=O)C(=O)OCC(CC)CCCC HNSDLXPSAYFUHK-UHFFFAOYSA-N 0.000 description 1

- AGJCSCSSMFRMFQ-UHFFFAOYSA-N 1,4-bis(2-isocyanatopropan-2-yl)benzene Chemical compound O=C=NC(C)(C)C1=CC=C(C(C)(C)N=C=O)C=C1 AGJCSCSSMFRMFQ-UHFFFAOYSA-N 0.000 description 1

- ALQLPWJFHRMHIU-UHFFFAOYSA-N 1,4-diisocyanatobenzene Chemical compound O=C=NC1=CC=C(N=C=O)C=C1 ALQLPWJFHRMHIU-UHFFFAOYSA-N 0.000 description 1

- OVBFMUAFNIIQAL-UHFFFAOYSA-N 1,4-diisocyanatobutane Chemical compound O=C=NCCCCN=C=O OVBFMUAFNIIQAL-UHFFFAOYSA-N 0.000 description 1

- CDMDQYCEEKCBGR-UHFFFAOYSA-N 1,4-diisocyanatocyclohexane Chemical compound O=C=NC1CCC(N=C=O)CC1 CDMDQYCEEKCBGR-UHFFFAOYSA-N 0.000 description 1

- SBJCUZQNHOLYMD-UHFFFAOYSA-N 1,5-Naphthalene diisocyanate Chemical compound C1=CC=C2C(N=C=O)=CC=CC2=C1N=C=O SBJCUZQNHOLYMD-UHFFFAOYSA-N 0.000 description 1

- DFPJRUKWEPYFJT-UHFFFAOYSA-N 1,5-diisocyanatopentane Chemical compound O=C=NCCCCCN=C=O DFPJRUKWEPYFJT-UHFFFAOYSA-N 0.000 description 1

- 229940043375 1,5-pentanediol Drugs 0.000 description 1

- QGLRLXLDMZCFBP-UHFFFAOYSA-N 1,6-diisocyanato-2,4,4-trimethylhexane Chemical compound O=C=NCC(C)CC(C)(C)CCN=C=O QGLRLXLDMZCFBP-UHFFFAOYSA-N 0.000 description 1

- TURGQPDWYFJEDY-UHFFFAOYSA-N 1-hydroperoxypropane Chemical compound CCCOO TURGQPDWYFJEDY-UHFFFAOYSA-N 0.000 description 1

- ULQISTXYYBZJSJ-UHFFFAOYSA-N 12-hydroxyoctadecanoic acid Chemical compound CCCCCCC(O)CCCCCCCCCCC(O)=O ULQISTXYYBZJSJ-UHFFFAOYSA-N 0.000 description 1

- JCTXKRPTIMZBJT-UHFFFAOYSA-N 2,2,4-trimethylpentane-1,3-diol Chemical compound CC(C)C(O)C(C)(C)CO JCTXKRPTIMZBJT-UHFFFAOYSA-N 0.000 description 1

- GOHPTLYPQCTZSE-UHFFFAOYSA-N 2,2-dimethylsuccinic acid Chemical compound OC(=O)C(C)(C)CC(O)=O GOHPTLYPQCTZSE-UHFFFAOYSA-N 0.000 description 1

- CEUQYYYUSUCFKP-UHFFFAOYSA-N 2,3-bis(2-sulfanylethylsulfanyl)propane-1-thiol Chemical compound SCCSCC(CS)SCCS CEUQYYYUSUCFKP-UHFFFAOYSA-N 0.000 description 1

- VOZKAJLKRJDJLL-UHFFFAOYSA-N 2,4-diaminotoluene Chemical compound CC1=CC=C(N)C=C1N VOZKAJLKRJDJLL-UHFFFAOYSA-N 0.000 description 1

- OAYXUHPQHDHDDZ-UHFFFAOYSA-N 2-(2-butoxyethoxy)ethanol Chemical compound CCCCOCCOCCO OAYXUHPQHDHDDZ-UHFFFAOYSA-N 0.000 description 1

- CNDCQWGRLNGNNO-UHFFFAOYSA-N 2-(2-sulfanylethoxy)ethanethiol Chemical compound SCCOCCS CNDCQWGRLNGNNO-UHFFFAOYSA-N 0.000 description 1

- GOXQRTZXKQZDDN-UHFFFAOYSA-N 2-Ethylhexyl acrylate Chemical compound CCCCC(CC)COC(=O)C=C GOXQRTZXKQZDDN-UHFFFAOYSA-N 0.000 description 1

- KIHBGTRZFAVZRV-UHFFFAOYSA-N 2-Hydroxyoctadecanoic acid Natural products CCCCCCCCCCCCCCCCC(O)C(O)=O KIHBGTRZFAVZRV-UHFFFAOYSA-N 0.000 description 1

- YAUNWJSAHTXBCF-UHFFFAOYSA-N 2-[3-(2-aminopropan-2-yl)phenyl]propan-2-amine Chemical compound CC(C)(N)C1=CC=CC(C(C)(C)N)=C1 YAUNWJSAHTXBCF-UHFFFAOYSA-N 0.000 description 1

- DSKYSDCYIODJPC-UHFFFAOYSA-N 2-butyl-2-ethylpropane-1,3-diol Chemical compound CCCCC(CC)(CO)CO DSKYSDCYIODJPC-UHFFFAOYSA-N 0.000 description 1

- OMIGHNLMNHATMP-UHFFFAOYSA-N 2-hydroxyethyl prop-2-enoate Chemical compound OCCOC(=O)C=C OMIGHNLMNHATMP-UHFFFAOYSA-N 0.000 description 1

- JZUHIOJYCPIVLQ-UHFFFAOYSA-N 2-methylpentane-1,5-diamine Chemical compound NCC(C)CCCN JZUHIOJYCPIVLQ-UHFFFAOYSA-N 0.000 description 1

- RNWKAIFTTVGWLK-UHFFFAOYSA-N 3,3-diethylpentanedioic acid Chemical compound OC(=O)CC(CC)(CC)CC(O)=O RNWKAIFTTVGWLK-UHFFFAOYSA-N 0.000 description 1

- RNLHGQLZWXBQNY-UHFFFAOYSA-N 3-(aminomethyl)-3,5,5-trimethylcyclohexan-1-amine Chemical compound CC1(C)CC(N)CC(C)(CN)C1 RNLHGQLZWXBQNY-UHFFFAOYSA-N 0.000 description 1

- FNVOFDGAASRDQY-UHFFFAOYSA-N 3-amino-2,2-dimethylpropan-1-ol Chemical compound NCC(C)(C)CO FNVOFDGAASRDQY-UHFFFAOYSA-N 0.000 description 1

- RDFQSFOGKVZWKF-UHFFFAOYSA-N 3-hydroxy-2,2-dimethylpropanoic acid Chemical compound OCC(C)(C)C(O)=O RDFQSFOGKVZWKF-UHFFFAOYSA-N 0.000 description 1

- ALRHLSYJTWAHJZ-UHFFFAOYSA-N 3-hydroxypropionic acid Chemical compound OCCC(O)=O ALRHLSYJTWAHJZ-UHFFFAOYSA-N 0.000 description 1

- QZPSOSOOLFHYRR-UHFFFAOYSA-N 3-hydroxypropyl prop-2-enoate Chemical class OCCCOC(=O)C=C QZPSOSOOLFHYRR-UHFFFAOYSA-N 0.000 description 1

- SXFJDZNJHVPHPH-UHFFFAOYSA-N 3-methylpentane-1,5-diol Chemical compound OCCC(C)CCO SXFJDZNJHVPHPH-UHFFFAOYSA-N 0.000 description 1

- DZIHTWJGPDVSGE-UHFFFAOYSA-N 4-[(4-aminocyclohexyl)methyl]cyclohexan-1-amine Chemical compound C1CC(N)CCC1CC1CCC(N)CC1 DZIHTWJGPDVSGE-UHFFFAOYSA-N 0.000 description 1

- SJZRECIVHVDYJC-UHFFFAOYSA-N 4-hydroxybutyric acid Chemical compound OCCCC(O)=O SJZRECIVHVDYJC-UHFFFAOYSA-N 0.000 description 1

- HRPVXLWXLXDGHG-UHFFFAOYSA-N Acrylamide Chemical compound NC(=O)C=C HRPVXLWXLXDGHG-UHFFFAOYSA-N 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 239000005711 Benzoic acid Substances 0.000 description 1

- FBPFZTCFMRRESA-FSIIMWSLSA-N D-Glucitol Natural products OC[C@H](O)[C@H](O)[C@@H](O)[C@H](O)CO FBPFZTCFMRRESA-FSIIMWSLSA-N 0.000 description 1

- FBPFZTCFMRRESA-JGWLITMVSA-N D-glucitol Chemical compound OC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-JGWLITMVSA-N 0.000 description 1

- RPNUMPOLZDHAAY-UHFFFAOYSA-N Diethylenetriamine Chemical compound NCCNCCN RPNUMPOLZDHAAY-UHFFFAOYSA-N 0.000 description 1

- BRLQWZUYTZBJKN-UHFFFAOYSA-N Epichlorohydrin Chemical compound ClCC1CO1 BRLQWZUYTZBJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004386 Erythritol Substances 0.000 description 1

- UNXHWFMMPAWVPI-UHFFFAOYSA-N Erythritol Natural products OCC(O)C(O)CO UNXHWFMMPAWVPI-UHFFFAOYSA-N 0.000 description 1

- JIGUQPWFLRLWPJ-UHFFFAOYSA-N Ethyl acrylate Chemical compound CCOC(=O)C=C JIGUQPWFLRLWPJ-UHFFFAOYSA-N 0.000 description 1

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 239000005057 Hexamethylene diisocyanate Substances 0.000 description 1

- WOBHKFSMXKNTIM-UHFFFAOYSA-N Hydroxyethyl methacrylate Chemical compound CC(=C)C(=O)OCCO WOBHKFSMXKNTIM-UHFFFAOYSA-N 0.000 description 1

- 239000004640 Melamine resin Substances 0.000 description 1

- VVQNEPGJFQJSBK-UHFFFAOYSA-N Methyl methacrylate Chemical compound COC(=O)C(C)=C VVQNEPGJFQJSBK-UHFFFAOYSA-N 0.000 description 1

- GYCMBHHDWRMZGG-UHFFFAOYSA-N Methylacrylonitrile Chemical compound CC(=C)C#N GYCMBHHDWRMZGG-UHFFFAOYSA-N 0.000 description 1

- 241001112258 Moca Species 0.000 description 1

- 238000001016 Ostwald ripening Methods 0.000 description 1

- ALQSHHUCVQOPAS-UHFFFAOYSA-N Pentane-1,5-diol Chemical compound OCCCCCO ALQSHHUCVQOPAS-UHFFFAOYSA-N 0.000 description 1

- YGYAWVDWMABLBF-UHFFFAOYSA-N Phosgene Chemical compound ClC(Cl)=O YGYAWVDWMABLBF-UHFFFAOYSA-N 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- WUGQZFFCHPXWKQ-UHFFFAOYSA-N Propanolamine Chemical compound NCCCO WUGQZFFCHPXWKQ-UHFFFAOYSA-N 0.000 description 1

- 239000005700 Putrescine Substances 0.000 description 1

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical group [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 1

- AWMVMTVKBNGEAK-UHFFFAOYSA-N Styrene oxide Chemical compound C1OC1C1=CC=CC=C1 AWMVMTVKBNGEAK-UHFFFAOYSA-N 0.000 description 1

- CZMRCDWAGMRECN-UGDNZRGBSA-N Sucrose Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 CZMRCDWAGMRECN-UGDNZRGBSA-N 0.000 description 1

- 229930006000 Sucrose Natural products 0.000 description 1

- UWHCKJMYHZGTIT-UHFFFAOYSA-N Tetraethylene glycol, Natural products OCCOCCOCCOCCO UWHCKJMYHZGTIT-UHFFFAOYSA-N 0.000 description 1

- IAXXETNIOYFMLW-COPLHBTASA-N [(1s,3s,4s)-4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl] 2-methylprop-2-enoate Chemical compound C1C[C@]2(C)[C@@H](OC(=O)C(=C)C)C[C@H]1C2(C)C IAXXETNIOYFMLW-COPLHBTASA-N 0.000 description 1

- DQJJXEZXOYPSNJ-UHFFFAOYSA-N [2,3-bis(hydroxymethyl)phenyl]methanol Chemical compound OCC1=CC=CC(CO)=C1CO DQJJXEZXOYPSNJ-UHFFFAOYSA-N 0.000 description 1

- JOBBTVPTPXRUBP-UHFFFAOYSA-N [3-(3-sulfanylpropanoyloxy)-2,2-bis(3-sulfanylpropanoyloxymethyl)propyl] 3-sulfanylpropanoate Chemical compound SCCC(=O)OCC(COC(=O)CCS)(COC(=O)CCS)COC(=O)CCS JOBBTVPTPXRUBP-UHFFFAOYSA-N 0.000 description 1

- FDLQZKYLHJJBHD-UHFFFAOYSA-N [3-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=CC(CN)=C1 FDLQZKYLHJJBHD-UHFFFAOYSA-N 0.000 description 1

- OXIKYYJDTWKERT-UHFFFAOYSA-N [4-(aminomethyl)cyclohexyl]methanamine Chemical compound NCC1CCC(CN)CC1 OXIKYYJDTWKERT-UHFFFAOYSA-N 0.000 description 1

- YIMQCDZDWXUDCA-UHFFFAOYSA-N [4-(hydroxymethyl)cyclohexyl]methanol Chemical compound OCC1CCC(CO)CC1 YIMQCDZDWXUDCA-UHFFFAOYSA-N 0.000 description 1

- 150000008065 acid anhydrides Chemical class 0.000 description 1

- 239000013543 active substance Substances 0.000 description 1

- 230000002730 additional effect Effects 0.000 description 1

- 239000001361 adipic acid Substances 0.000 description 1

- 235000011037 adipic acid Nutrition 0.000 description 1

- 239000002671 adjuvant Substances 0.000 description 1

- 239000004964 aerogel Substances 0.000 description 1

- 125000002723 alicyclic group Chemical group 0.000 description 1

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 1

- 125000002877 alkyl aryl group Chemical group 0.000 description 1

- 150000008051 alkyl sulfates Chemical class 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 150000001414 amino alcohols Chemical class 0.000 description 1

- LHIJANUOQQMGNT-UHFFFAOYSA-N aminoethylethanolamine Chemical compound NCCNCCO LHIJANUOQQMGNT-UHFFFAOYSA-N 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 235000010233 benzoic acid Nutrition 0.000 description 1

- HIFVAOIJYDXIJG-UHFFFAOYSA-N benzylbenzene;isocyanic acid Chemical class N=C=O.N=C=O.C=1C=CC=CC=1CC1=CC=CC=C1 HIFVAOIJYDXIJG-UHFFFAOYSA-N 0.000 description 1

- OHJMTUPIZMNBFR-UHFFFAOYSA-N biuret Chemical compound NC(=O)NC(N)=O OHJMTUPIZMNBFR-UHFFFAOYSA-N 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- DLDJFQGPPSQZKI-UHFFFAOYSA-N but-2-yne-1,4-diol Chemical compound OCC#CCO DLDJFQGPPSQZKI-UHFFFAOYSA-N 0.000 description 1

- 239000001273 butane Substances 0.000 description 1

- KDYFGRWQOYBRFD-NUQCWPJISA-N butanedioic acid Chemical compound O[14C](=O)CC[14C](O)=O KDYFGRWQOYBRFD-NUQCWPJISA-N 0.000 description 1

- JHIWVOJDXOSYLW-UHFFFAOYSA-N butyl 2,2-difluorocyclopropane-1-carboxylate Chemical compound CCCCOC(=O)C1CC1(F)F JHIWVOJDXOSYLW-UHFFFAOYSA-N 0.000 description 1

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 1

- 229930188620 butyrolactone Natural products 0.000 description 1

- 150000001718 carbodiimides Chemical class 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 150000004649 carbonic acid derivatives Chemical class 0.000 description 1

- 150000001735 carboxylic acids Chemical class 0.000 description 1

- 125000002091 cationic group Chemical group 0.000 description 1

- 230000001413 cellular effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 238000004581 coalescence Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- IFDVQVHZEKPUSC-UHFFFAOYSA-N cyclohex-3-ene-1,2-dicarboxylic acid Chemical compound OC(=O)C1CCC=CC1C(O)=O IFDVQVHZEKPUSC-UHFFFAOYSA-N 0.000 description 1

- QYQADNCHXSEGJT-UHFFFAOYSA-N cyclohexane-1,1-dicarboxylate;hydron Chemical compound OC(=O)C1(C(O)=O)CCCCC1 QYQADNCHXSEGJT-UHFFFAOYSA-N 0.000 description 1

- QSAWQNUELGIYBC-UHFFFAOYSA-N cyclohexane-1,2-dicarboxylic acid Chemical compound OC(=O)C1CCCCC1C(O)=O QSAWQNUELGIYBC-UHFFFAOYSA-N 0.000 description 1

- OIWOHHBRDFKZNC-UHFFFAOYSA-N cyclohexyl 2-methylprop-2-enoate Chemical compound CC(=C)C(=O)OC1CCCCC1 OIWOHHBRDFKZNC-UHFFFAOYSA-N 0.000 description 1

- FOTKYAAJKYLFFN-UHFFFAOYSA-N decane-1,10-diol Chemical compound OCCCCCCCCCCO FOTKYAAJKYLFFN-UHFFFAOYSA-N 0.000 description 1

- LSXWFXONGKSEMY-UHFFFAOYSA-N di-tert-butyl peroxide Chemical compound CC(C)(C)OOC(C)(C)C LSXWFXONGKSEMY-UHFFFAOYSA-N 0.000 description 1

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 1

- 125000005442 diisocyanate group Chemical group 0.000 description 1

- IEJIGPNLZYLLBP-UHFFFAOYSA-N dimethyl carbonate Chemical compound COC(=O)OC IEJIGPNLZYLLBP-UHFFFAOYSA-N 0.000 description 1

- ROORDVPLFPIABK-UHFFFAOYSA-N diphenyl carbonate Chemical compound C=1C=CC=CC=1OC(=O)OC1=CC=CC=C1 ROORDVPLFPIABK-UHFFFAOYSA-N 0.000 description 1

- SZXQTJUDPRGNJN-UHFFFAOYSA-N dipropylene glycol Chemical compound OCCCOCCCO SZXQTJUDPRGNJN-UHFFFAOYSA-N 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000000635 electron micrograph Methods 0.000 description 1

- 238000004945 emulsification Methods 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- UNXHWFMMPAWVPI-ZXZARUISSA-N erythritol Chemical compound OC[C@H](O)[C@H](O)CO UNXHWFMMPAWVPI-ZXZARUISSA-N 0.000 description 1

- 229940009714 erythritol Drugs 0.000 description 1

- 235000019414 erythritol Nutrition 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- 238000005886 esterification reaction Methods 0.000 description 1

- 125000001033 ether group Chemical group 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- SUPCQIBBMFXVTL-UHFFFAOYSA-N ethyl 2-methylprop-2-enoate Chemical compound CCOC(=O)C(C)=C SUPCQIBBMFXVTL-UHFFFAOYSA-N 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 239000001530 fumaric acid Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- SXCBDZAEHILGLM-UHFFFAOYSA-N heptane-1,7-diol Chemical compound OCCCCCCCO SXCBDZAEHILGLM-UHFFFAOYSA-N 0.000 description 1

- NAQMVNRVTILPCV-UHFFFAOYSA-N hexane-1,6-diamine Chemical compound NCCCCCCN NAQMVNRVTILPCV-UHFFFAOYSA-N 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- LMHJFKYQYDSOQO-UHFFFAOYSA-N hydroxydecanoic acid Natural products CCCCCC(O)CCCC(O)=O LMHJFKYQYDSOQO-UHFFFAOYSA-N 0.000 description 1

- 230000033444 hydroxylation Effects 0.000 description 1

- 238000005805 hydroxylation reaction Methods 0.000 description 1

- 229940119545 isobornyl methacrylate Drugs 0.000 description 1

- ZFSLODLOARCGLH-UHFFFAOYSA-N isocyanuric acid Chemical compound OC1=NC(O)=NC(O)=N1 ZFSLODLOARCGLH-UHFFFAOYSA-N 0.000 description 1

- NIMLQBUJDJZYEJ-UHFFFAOYSA-N isophorone diisocyanate Chemical compound CC1(C)CC(N=C=O)CC(C)(CN=C=O)C1 NIMLQBUJDJZYEJ-UHFFFAOYSA-N 0.000 description 1

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 1

- 239000011976 maleic acid Substances 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 125000000956 methoxy group Chemical group [H]C([H])([H])O* 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- SWGZAKPJNWCPRY-UHFFFAOYSA-N methyl-bis(trimethylsilyloxy)silicon Chemical compound C[Si](C)(C)O[Si](C)O[Si](C)(C)C SWGZAKPJNWCPRY-UHFFFAOYSA-N 0.000 description 1

- 150000002763 monocarboxylic acids Chemical class 0.000 description 1

- KVKFRMCSXWQSNT-UHFFFAOYSA-N n,n'-dimethylethane-1,2-diamine Chemical compound CNCCNC KVKFRMCSXWQSNT-UHFFFAOYSA-N 0.000 description 1

- SYSQUGFVNFXIIT-UHFFFAOYSA-N n-[4-(1,3-benzoxazol-2-yl)phenyl]-4-nitrobenzenesulfonamide Chemical class C1=CC([N+](=O)[O-])=CC=C1S(=O)(=O)NC1=CC=C(C=2OC3=CC=CC=C3N=2)C=C1 SYSQUGFVNFXIIT-UHFFFAOYSA-N 0.000 description 1

- 238000002429 nitrogen sorption measurement Methods 0.000 description 1

- OEIJHBUUFURJLI-UHFFFAOYSA-N octane-1,8-diol Chemical compound OCCCCCCCCO OEIJHBUUFURJLI-UHFFFAOYSA-N 0.000 description 1

- HXSACZWWBYWLIS-UHFFFAOYSA-N oxadiazine-4,5,6-trione Chemical group O=C1ON=NC(=O)C1=O HXSACZWWBYWLIS-UHFFFAOYSA-N 0.000 description 1

- MTMMGZCTRGFZAH-UHFFFAOYSA-N pent-1-ene-1,5-diol Chemical compound OCCCC=CO MTMMGZCTRGFZAH-UHFFFAOYSA-N 0.000 description 1

- PNJWIWWMYCMZRO-UHFFFAOYSA-N pent‐4‐en‐2‐one Natural products CC(=O)CC=C PNJWIWWMYCMZRO-UHFFFAOYSA-N 0.000 description 1

- 150000002978 peroxides Chemical class 0.000 description 1

- 238000005191 phase separation Methods 0.000 description 1

- 229940067626 phosphatidylinositols Drugs 0.000 description 1

- 150000003905 phosphatidylinositols Chemical class 0.000 description 1

- 229920002401 polyacrylamide Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- AOHJOMMDDJHIJH-UHFFFAOYSA-N propylenediamine Chemical compound CC(N)CN AOHJOMMDDJHIJH-UHFFFAOYSA-N 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000007142 ring opening reaction Methods 0.000 description 1

- 238000004626 scanning electron microscopy Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 239000008259 solid foam Substances 0.000 description 1

- 239000000600 sorbitol Substances 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000005720 sucrose Substances 0.000 description 1

- 150000005846 sugar alcohols Polymers 0.000 description 1

- 150000000000 tetracarboxylic acids Chemical class 0.000 description 1

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 1

- UFDHBDMSHIXOKF-UHFFFAOYSA-N tetrahydrophthalic acid Natural products OC(=O)C1=C(C(O)=O)CCCC1 UFDHBDMSHIXOKF-UHFFFAOYSA-N 0.000 description 1

- RUELTTOHQODFPA-UHFFFAOYSA-N toluene 2,6-diisocyanate Chemical compound CC1=C(N=C=O)C=CC=C1N=C=O RUELTTOHQODFPA-UHFFFAOYSA-N 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 238000000844 transformation Methods 0.000 description 1

- 150000003628 tricarboxylic acids Chemical class 0.000 description 1

- UFTFJSFQGQCHQW-UHFFFAOYSA-N triformin Chemical compound O=COCC(OC=O)COC=O UFTFJSFQGQCHQW-UHFFFAOYSA-N 0.000 description 1

- KVMPUXDNESXNOH-UHFFFAOYSA-N tris(1-chloropropan-2-yl) phosphate Chemical compound ClCC(C)OP(=O)(OC(C)CCl)OC(C)CCl KVMPUXDNESXNOH-UHFFFAOYSA-N 0.000 description 1

- AVWRKZWQTYIKIY-UHFFFAOYSA-N urea-1-carboxylic acid Chemical compound NC(=O)NC(O)=O AVWRKZWQTYIKIY-UHFFFAOYSA-N 0.000 description 1

- PAPBSGBWRJIAAV-UHFFFAOYSA-N ε-Caprolactone Chemical compound O=C1CCCCCO1 PAPBSGBWRJIAAV-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

- C08J9/12—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a physical blowing agent

- C08J9/14—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a physical blowing agent organic

- C08J9/141—Hydrocarbons

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/14—Manufacture of cellular products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C44/00—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles

- B29C44/34—Auxiliary operations

- B29C44/3469—Cell or pore nucleation

- B29C44/348—Cell or pore nucleation by regulating the temperature and/or the pressure, e.g. suppression of foaming until the pressure is rapidly decreased

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C44/00—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles

- B29C44/34—Auxiliary operations

- B29C44/60—Measuring, controlling or regulating

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/65—Low-molecular-weight compounds having active hydrogen with high-molecular-weight compounds having active hydrogen

- C08G18/66—Compounds of groups C08G18/42, C08G18/48, or C08G18/52

- C08G18/6633—Compounds of group C08G18/42

- C08G18/6637—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38

- C08G18/664—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3203

- C08G18/6644—Compounds of group C08G18/42 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3203 having at least three hydroxy groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G81/00—Macromolecular compounds obtained by interreacting polymers in the absence of monomers, e.g. block polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/02—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by the reacting monomers or modifying agents during the preparation or modification of macromolecules

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

- C08J9/12—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a physical blowing agent

- C08J9/122—Hydrogen, oxygen, CO2, nitrogen or noble gases

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/04—Condition, form or state of moulded material or of the material to be shaped cellular or porous

- B29K2105/041—Microporous

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G2110/00—Foam properties

- C08G2110/0025—Foam properties rigid

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G2110/00—Foam properties

- C08G2110/0041—Foam properties having specified density

- C08G2110/005—< 50kg/m3

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2203/00—Foams characterized by the expanding agent

- C08J2203/08—Supercritical fluid

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2375/00—Characterised by the use of polyureas or polyurethanes; Derivatives of such polymers

- C08J2375/04—Polyurethanes

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Polyurethanes Or Polyureas (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009053218A DE102009053218A1 (de) | 2009-11-06 | 2009-11-06 | Verfahren zur Herstellung eines Polyurethanschaums mittels über- oder nahekritischen Treibmittels |

| DE102009053218.8 | 2009-11-06 | ||

| PCT/EP2010/066744 WO2011054873A2 (de) | 2009-11-06 | 2010-11-03 | Verfahren zur herstellung eines polyurethanschaums mittels über- oder nahekritischen treibmittels |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| RU2012123133A RU2012123133A (ru) | 2013-12-20 |

| RU2541573C2 RU2541573C2 (ru) | 2015-02-20 |

| RU2541573C9 true RU2541573C9 (ru) | 2015-11-10 |

Family

ID=43970450

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2012123133/04A RU2541573C9 (ru) | 2009-11-06 | 2010-11-03 | Способ получения полиуретановой пены с помощью порообразователя, находящегося в сверхкритическом или околокритическом состоянии |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US9139683B2 (OSRAM) |

| EP (1) | EP2496624B1 (OSRAM) |

| JP (1) | JP5629778B2 (OSRAM) |

| KR (1) | KR101761953B1 (OSRAM) |

| CN (1) | CN102712737B (OSRAM) |

| BR (1) | BR112012010624A2 (OSRAM) |

| CA (1) | CA2779979C (OSRAM) |

| DE (1) | DE102009053218A1 (OSRAM) |

| DK (1) | DK2496624T3 (OSRAM) |

| ES (1) | ES2523996T3 (OSRAM) |

| MX (1) | MX349772B (OSRAM) |

| PL (1) | PL2496624T3 (OSRAM) |

| RU (1) | RU2541573C9 (OSRAM) |

| WO (1) | WO2011054873A2 (OSRAM) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011144728A1 (de) * | 2010-05-21 | 2011-11-24 | Basf Se | Nanoporöse polymerschaumstoffe |

| WO2012026368A1 (ja) * | 2010-08-23 | 2012-03-01 | 日東電工株式会社 | W/o型エマルション、発泡体、および機能性発泡体 |

| DE102010060386A1 (de) * | 2010-11-05 | 2012-05-10 | Bayer Materialscience Aktiengesellschaft | Verfahren zur Herstellung eines geschäumten Materials, hierbei eingesetzte emulsionsförmige Zusammensetzung und hieraus erhältliches geschäumtes Material |

| DE102010060390A1 (de) * | 2010-11-05 | 2012-05-10 | Bayer Materialscience Aktiengesellschaft | Emulsionsförmige Reaktionsmischung und Verfahren zur Herstellung von Polyurethanschäumen aus einer solchen Reaktionsmischung |

| CN104619736B (zh) * | 2012-07-31 | 2017-08-18 | 科思创德国股份有限公司 | 使用乳化发泡剂制备聚氨酯泡沫的方法 |

| US10414921B1 (en) | 2013-09-04 | 2019-09-17 | Virfex, LLC | Polyurethane foam based ballistic armor |

| MX2016005916A (es) * | 2013-11-08 | 2016-07-13 | Covestro Deutschland Ag | Espuma de poliuretano y proceso para producirla. |

| DE102013223391A1 (de) | 2013-11-15 | 2015-05-21 | Universität Zu Köln | Herstellung von porösen Materialien durch Expansion von Polymergelen |

| US10626290B2 (en) * | 2013-12-16 | 2020-04-21 | Ppg Industries Ohio, Inc. | Method of extending pot life of coating compositions |

| MX2016009155A (es) | 2014-01-23 | 2016-09-09 | Dow Global Technologies Llc | Espuma rigida de poliuretano que tiene un tamaño de celula pequeño. |

| CN106457629B (zh) * | 2014-05-28 | 2019-04-12 | 陶氏环球技术有限责任公司 | 用于生产纳米泡沫的模具方法 |

| JP6438568B2 (ja) | 2014-08-15 | 2018-12-12 | ダウ グローバル テクノロジーズ エルエルシー | ポリジメチルシロキサングラフト化ポリエチレン発泡体 |

| CN104388073B (zh) * | 2014-11-27 | 2017-07-28 | 中国石油化工股份有限公司 | 超临界二氧化碳固体增稠剂及其制备方法和用途 |

| CN105070819B (zh) * | 2015-06-30 | 2017-12-08 | 厦门大学 | 一种调控氧化物材料热导率的方法 |

| SG11201806874QA (en) | 2016-02-26 | 2018-09-27 | Solvay | Process for the preparation of a polyurethane foam |

| US10577801B2 (en) * | 2016-07-15 | 2020-03-03 | Firestone Building Products Company, Llc | Silicone membranes |

| US11104777B2 (en) | 2016-07-29 | 2021-08-31 | Dow Global Technologies Llc | Insulative apparatus |

| KR20190038809A (ko) * | 2016-07-29 | 2019-04-09 | 코베스트로 도이칠란트 아게 | 발포 중합체를 제조하기 위한 시스템 및 방법 |

| CN108219097A (zh) * | 2016-12-14 | 2018-06-29 | 上海东大化学有限公司 | 一种单组份聚氨酯发泡胶及其制备方法 |

| EP3372625A1 (de) * | 2017-03-07 | 2018-09-12 | Covestro Deutschland AG | Polyurethanschaum und verfahren zu seiner herstellung |

| WO2019043043A1 (en) | 2017-08-29 | 2019-03-07 | Solvay Sa | PROCESS FOR THE PREPARATION OF POLYURETHANE FOAM |

| WO2019063562A1 (en) | 2017-09-27 | 2019-04-04 | Solvay Sa | PROCESS FOR THE PREPARATION OF POLYURETHANE FOAM |

| KR101902441B1 (ko) * | 2017-11-28 | 2018-10-01 | 주식회사 지아이테크 | 배치형 발포 공정을 이용한 다경도 다탄성 폴리우레탄 폼 제조 방법 |

| EP3749431A4 (en) * | 2018-02-07 | 2021-10-27 | Cidra Corporate Services LLC | OPEN-CELL OR CROSS-LINKED FOAM WITH A THREE-DIMENSIONAL OPEN NETWORK STRUCTURE CONSISTING OF A HYDROPHOBIC MATERIAL FOR THE SELECTIVE SEPARATION OF MINERAL PARTICLES |

| EP3560970A1 (de) | 2018-04-25 | 2019-10-30 | Covestro Deutschland AG | Offenzelliger polyurethanhartschaum und dessen verwendung |

| EP3564283A1 (de) | 2018-04-30 | 2019-11-06 | Covestro Deutschland AG | Verfahren zur herstellung von geschlossenzelligem polyurethanschaum |

| DE102019200446A1 (de) | 2019-01-16 | 2020-07-16 | Evonik Operations Gmbh | Poly-OH-funktionelle Trisiloxane, deren Herstellung sowie deren Verwendung zur Herstellung von Polyurethanschäumen |

| FR3095207B1 (fr) * | 2019-04-16 | 2021-04-23 | Commissariat Energie Atomique | Procédé de fonctionnalisation de surface en milieu fluide supercritique |

| CN110409553B (zh) * | 2019-08-06 | 2021-06-15 | 长江水利委员会长江科学院 | 一种高寒高海拔地区太阳能光伏供水系统 |

| EP3789417A1 (de) | 2019-09-06 | 2021-03-10 | Covestro Deutschland AG | Polyurethan-basierter isolationskörper und verfahren zu seiner herstellung |

| EP3838545A1 (de) | 2019-12-17 | 2021-06-23 | Covestro Deutschland AG | Polyolmischungen und deren verwendung in der herstellung feinzelliger polyurethanschäume |

| KR102397310B1 (ko) * | 2020-04-08 | 2022-05-12 | 에이치디씨현대이피 주식회사 | 용매를 사용하지 않는 고발포 폴리우레탄 폼 제조방법 및 이 제조방법에 의해 제조된 폴리우레탄 폼 |

| US20230132681A1 (en) * | 2020-06-11 | 2023-05-04 | Dow Global Technologies Llc | Isocyanate-reactive composition and method of preparing polyurethane and polyisocyanurate foams |

| CN112795174A (zh) * | 2020-12-31 | 2021-05-14 | 平湖华申汽车内饰件有限公司 | 一种汽车内饰聚氨酯自动发泡一体化工艺 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0353061A2 (en) * | 1988-07-29 | 1990-01-31 | Pmc, Inc. | Blowing agents for polyurethane foam |

| RU97115776A (ru) * | 1995-12-22 | 1999-07-10 | Оси Спешиэлтиз, Инк. | Способ получения полиуретановой пены и полиуретановая пена |

| RU2312112C2 (ru) * | 2001-06-21 | 2007-12-10 | Байер Антверпен Н.Ф. | Способ получения смесей полиолов |

| RU2007112444A (ru) * | 2006-04-05 | 2008-10-10 | Байер МатириальСайенс ЛЛСИ (US) | Эластичная полиуретановая пена и способ ее получения |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4604090A (en) | 1983-11-22 | 1986-08-05 | Consolidated Controls Corporation | Compact implantable medication infusion device |

| WO1989004858A1 (en) * | 1987-11-27 | 1989-06-01 | Battelle Memorial Institute | Supercritical fluid reverse micelle separation |

| CN1181769A (zh) | 1995-12-22 | 1998-05-13 | 格伦A·米尔勒 | 烯醇-醚封端的聚醚以及由其制得的表面活性剂 |

| TW568921B (en) * | 1998-08-07 | 2004-01-01 | Huntsman Int Llc | Process for preparing a moulded flexible polyurethane foam |

| AU774491B2 (en) * | 1999-12-24 | 2004-07-01 | Huntsman International Llc | Gas assisted injection moulding |

| DE10030384A1 (de) | 2000-06-21 | 2002-01-03 | Hennecke Gmbh | Verfahren zur Herstellung von Blockschaum |

| US6294107B1 (en) | 2000-07-26 | 2001-09-25 | Basf Corporation | Alkylene oxide modified silicone glycol compatibilizing agents for stable polyester polyol compositions |

| JP4154654B2 (ja) * | 2002-09-13 | 2008-09-24 | アキレス株式会社 | 硬質ポリウレタンフォームの製造方法 |

| DE10260815B4 (de) | 2002-12-23 | 2008-07-03 | Universität Zu Köln | Aufgeschäumtes Material und Herstellverfahren für das aufgeschäumte Material |

| JP4217895B2 (ja) | 2003-12-01 | 2009-02-04 | 株式会社ブリヂストン | ポリウレタン発泡成形体の製造方法 |

| US7183330B2 (en) | 2003-12-15 | 2007-02-27 | Air Products And Chemicals, Inc. | Silicone surfactants for rigid polyurethane foam made with hydrocarbon blowing agents |

| JP5266756B2 (ja) * | 2005-04-21 | 2013-08-21 | 旭硝子株式会社 | 低反発性軟質ポリウレタンフォームおよびその製造方法 |

| DE102005025970A1 (de) | 2005-06-03 | 2006-12-07 | Basf Ag | Poröse Polyisocyanat-Polyadditionsprodukte |

| ATE494316T1 (de) | 2006-02-15 | 2011-01-15 | Stepan Co | Verträglichmachende tenside für polyurethanpolyole und harze |

| US20090062414A1 (en) * | 2007-08-28 | 2009-03-05 | David Picheng Huang | System and method for producing damping polyurethane CMP pads |

| US20090099273A1 (en) * | 2007-10-12 | 2009-04-16 | Williams David J | Non-silicone surfactants for polyurethane or polyisocyanurate foam containing halogenated olefins as blowing agents |

| JP5388471B2 (ja) | 2008-04-07 | 2014-01-15 | 株式会社イノアックコーポレーション | 金属粉末を含有するポリウレタン発泡体 |

-

2009

- 2009-11-06 DE DE102009053218A patent/DE102009053218A1/de not_active Ceased

-

2010

- 2010-11-03 WO PCT/EP2010/066744 patent/WO2011054873A2/de not_active Ceased

- 2010-11-03 US US13/505,769 patent/US9139683B2/en not_active Expired - Fee Related

- 2010-11-03 KR KR1020127014600A patent/KR101761953B1/ko not_active Expired - Fee Related

- 2010-11-03 EP EP10775804.7A patent/EP2496624B1/de active Active

- 2010-11-03 JP JP2012537389A patent/JP5629778B2/ja not_active Expired - Fee Related

- 2010-11-03 PL PL10775804T patent/PL2496624T3/pl unknown

- 2010-11-03 MX MX2012005242A patent/MX349772B/es active IP Right Grant

- 2010-11-03 BR BR112012010624A patent/BR112012010624A2/pt not_active Application Discontinuation

- 2010-11-03 CA CA2779979A patent/CA2779979C/en not_active Expired - Fee Related

- 2010-11-03 CN CN201080061627.8A patent/CN102712737B/zh not_active Expired - Fee Related

- 2010-11-03 RU RU2012123133/04A patent/RU2541573C9/ru active

- 2010-11-03 ES ES10775804.7T patent/ES2523996T3/es active Active

- 2010-11-03 DK DK10775804.7T patent/DK2496624T3/da active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0353061A2 (en) * | 1988-07-29 | 1990-01-31 | Pmc, Inc. | Blowing agents for polyurethane foam |

| RU97115776A (ru) * | 1995-12-22 | 1999-07-10 | Оси Спешиэлтиз, Инк. | Способ получения полиуретановой пены и полиуретановая пена |

| RU2312112C2 (ru) * | 2001-06-21 | 2007-12-10 | Байер Антверпен Н.Ф. | Способ получения смесей полиолов |

| RU2007112444A (ru) * | 2006-04-05 | 2008-10-10 | Байер МатириальСайенс ЛЛСИ (US) | Эластичная полиуретановая пена и способ ее получения |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20120094009A (ko) | 2012-08-23 |

| JP5629778B2 (ja) | 2014-11-26 |

| CA2779979A1 (en) | 2011-05-12 |

| WO2011054873A3 (de) | 2011-11-24 |

| CN102712737B (zh) | 2014-07-09 |

| PL2496624T3 (pl) | 2015-01-30 |

| CN102712737A (zh) | 2012-10-03 |

| JP2013510209A (ja) | 2013-03-21 |

| EP2496624B1 (de) | 2014-09-17 |

| DK2496624T3 (da) | 2014-11-03 |

| RU2012123133A (ru) | 2013-12-20 |

| MX349772B (es) | 2017-08-10 |

| US9139683B2 (en) | 2015-09-22 |

| WO2011054873A2 (de) | 2011-05-12 |

| RU2541573C2 (ru) | 2015-02-20 |

| KR101761953B1 (ko) | 2017-07-26 |

| ES2523996T3 (es) | 2014-12-03 |

| US20120245243A1 (en) | 2012-09-27 |

| CA2779979C (en) | 2017-10-24 |

| MX2012005242A (es) | 2012-06-13 |

| BR112012010624A2 (pt) | 2016-03-29 |

| DE102009053218A1 (de) | 2011-07-14 |

| EP2496624A2 (de) | 2012-09-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2541573C9 (ru) | Способ получения полиуретановой пены с помощью порообразователя, находящегося в сверхкритическом или околокритическом состоянии | |

| RU2566502C9 (ru) | Способ изготовления полиуретановой пены и получаемая при этом полиуретановая пена | |

| RU2601447C2 (ru) | Способ получения вспененного материала, используемая при этом композиция в виде эмульсии и вспененный материал, который может быть получен указанным способом | |

| RU2586883C2 (ru) | Реакционная смесь в форме эмульсии и получение полиуретановых пен из такой реакционной смеси | |

| CN103492468B (zh) | 聚氨酯泡沫及其制造方法 | |

| CN104703768B (zh) | 用于制备含层状硅酸盐的pur和pir硬质泡沫的反应体系 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| TH4A | Reissue of patent specification |