KR20180098689A - 코일의 권선 방법 및 권선 장치 - Google Patents

코일의 권선 방법 및 권선 장치 Download PDFInfo

- Publication number

- KR20180098689A KR20180098689A KR1020187024382A KR20187024382A KR20180098689A KR 20180098689 A KR20180098689 A KR 20180098689A KR 1020187024382 A KR1020187024382 A KR 1020187024382A KR 20187024382 A KR20187024382 A KR 20187024382A KR 20180098689 A KR20180098689 A KR 20180098689A

- Authority

- KR

- South Korea

- Prior art keywords

- winding

- unit

- shaft

- coil

- wire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/04—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing coils

- H01F41/06—Coil winding

- H01F41/064—Winding non-flat conductive wires, e.g. rods, cables or cords

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/28—Coils; Windings; Conductive connections

- H01F27/2823—Wires

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21F—WORKING OR PROCESSING OF METAL WIRE

- B21F3/00—Coiling wire into particular forms

- B21F3/10—Coiling wire into particular forms to spirals other than flat, e.g. conical

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/04—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing coils

- H01F41/06—Coil winding

- H01F41/082—Devices for guiding or positioning the winding material on the former

- H01F41/086—Devices for guiding or positioning the winding material on the former in a special configuration on the former, e.g. orthocyclic coils or open mesh coils

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/04—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets for manufacturing coils

- H01F41/06—Coil winding

- H01F41/098—Mandrels; Formers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F5/00—Coils

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Manufacture Of Motors, Generators (AREA)

- Coil Winding Methods And Apparatuses (AREA)

- Coils Of Transformers For General Uses (AREA)

- Manufacturing Cores, Coils, And Magnets (AREA)

- Wire Processing (AREA)

- Coiling Of Filamentary Materials In General (AREA)

Abstract

Description

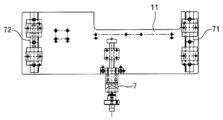

도 2는 상기 권선 장치의 전체를 도시하는 정면도이다.

도 3은 제1 왕복대의 평면도이다.

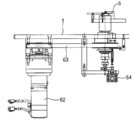

도 4는 축체 및 그 주변 기구의 정면도이다.

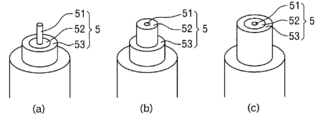

도 5는 축체의 단면도이다.

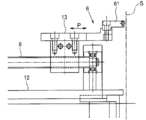

도 6은 축체 및 그 주변 기구의 평면도이다.

도 7은 굽힘 기구의 정면도이다.

도 8은 축체 및 굽힘 기구의 사시도이다.

도 9는 축체의 동작을 설명하는 사시도이다.

도 10은 축체와 코일 중간 제품의 치수 관계를 설명하는 단면도이다.

도 11은 코일 중간 제품의 코너부를 확대하여 도시하는 평면도이다.

도 12는 코일의 권선 공정의 제1 단계를 설명하는 일련의 평면도이다.

도 13은 코일의 권선 공정의 제2 단계를 설명하는 일련의 평면도이다.

도 14는 코일의 권선 공정의 제3 단계를 설명하는 일련의 평면도이다.

도 15는 코일의 권선 공정의 제4 단계를 설명하는 일련의 평면도이다.

도 16은 코일의 권선 공정의 제5 단계를 설명하는 일련의 평면도이다.

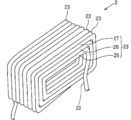

도 17은 코일의 완성 상태의 사시도이다.

도 18은 코일의 중간 제품으로부터 완성품을 얻는 압축 공정을 도시하는 도면이다.

20 : 중간 제품

21 : 완성품

22 : 도선

23 : 단위 코일부

25 : 제1 단위 권취부

26 : 제2 단위 권취부

27 : 제3 단위 권취부

1 : 베이스

11 : 제1 왕복대

12 : 회전대

13 : 제2 왕복대

3 : 도선 조출 기구

4 : 도선 이송 기구

5 : 축체

51 : 제1 축부

52 : 제2 축부

53 : 제3 축부

6 : 굽힘 기구

61 : 압박 부재

62 : 모터

7 : 제1 왕복 구동 기구

8 : 제2 왕복 구동 기구

9 : 가이드판

S : 권취축

Claims (1)

- 권취축을 중심으로 하여 1개의 도선을 권회하여 형성되는 복수의 단위 코일부가, 상기 권취축 방향으로 배열되어 있고, 각 단위 코일부는, 서로 다른 내주 길이를 갖는 복수의 단위 권취부로 구성되고, 내주 길이가 큰 단위 권취부의 내측에 내주 길이가 작은 단위 권취부의 적어도 일부가 압입됨으로써, 각 단위 코일부가 적어도 일부에서 다층화되어 있고, 각 단위 권취부는, 각각 원호 형상의 복수의 코너부를 갖는 루프 형상의 권선 경로를 따라 권회되어 있는 코일에 있어서,

각 단위 코일부를 구성하는 복수의 단위 권취부에 있어서 상기 권취축에 대해 동일한 위상 각도로 형성되는 복수의 코너부는, 동일한 위치에 곡률 중심을 갖고 반경이 다른 복수의 원호선을 따라 연장되고, 내측의 단위 권취부의 코너부와 외측의 단위 권취부의 코너부가 서로 밀착하고 있는 것을 특징으로 하는, 코일.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2011-151444 | 2011-07-08 | ||

| JP2011151444A JP5535141B2 (ja) | 2011-07-08 | 2011-07-08 | 空芯コイルの巻線方法及び巻線装置 |

| PCT/JP2012/066327 WO2013008621A1 (ja) | 2011-07-08 | 2012-06-27 | コイルの巻線方法及び巻線装置 |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147000739A Division KR101910225B1 (ko) | 2011-07-08 | 2012-06-27 | 코일의 권선 방법 및 권선 장치 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098689A true KR20180098689A (ko) | 2018-09-04 |

| KR101948499B1 KR101948499B1 (ko) | 2019-02-14 |

Family

ID=47505918

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187024382A Active KR101948499B1 (ko) | 2011-07-08 | 2012-06-27 | 코일의 권선 방법 및 권선 장치 |

| KR1020147000739A Active KR101910225B1 (ko) | 2011-07-08 | 2012-06-27 | 코일의 권선 방법 및 권선 장치 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147000739A Active KR101910225B1 (ko) | 2011-07-08 | 2012-06-27 | 코일의 권선 방법 및 권선 장치 |

Country Status (6)

| Country | Link |

|---|---|

| US (2) | US20140184379A1 (ko) |

| JP (1) | JP5535141B2 (ko) |

| KR (2) | KR101948499B1 (ko) |

| CN (1) | CN103843088B (ko) |

| TW (1) | TWI552177B (ko) |

| WO (1) | WO2013008621A1 (ko) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5490186B2 (ja) * | 2012-05-31 | 2014-05-14 | 株式会社エス・エッチ・ティ | コイルの巻線方法及び変圧器 |

| JP5499349B2 (ja) * | 2012-11-02 | 2014-05-21 | 福井県 | 巻線構造及びそれを用いた電気機器 |

| CN104347263A (zh) * | 2013-07-25 | 2015-02-11 | 安徽一变变压器制造有限公司 | 壳式变压器绕线机 |

| WO2015155899A1 (ja) * | 2014-04-12 | 2015-10-15 | 福井県 | 巻線構造及びそれを用いた電気機器 |

| CN110310821A (zh) * | 2019-07-22 | 2019-10-08 | 成都玖锦科技有限公司 | 一种微型精密金丝线圈绕制装置 |

| DE102023129768A1 (de) * | 2023-10-27 | 2025-04-30 | Wafios Aktiengesellschaft | Verfahren und Umformmaschine zur Herstellung von Formteilen |

| KR20250156298A (ko) | 2024-04-25 | 2025-11-03 | 경북대학교 산학협력단 | 금속 나노입자가 전착된 초친수성 티타늄 산화물 나노튜브 전극, 이의 제조방법 및 이를 이용한 음이온 교환막 수전해 장치 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003086438A (ja) | 2001-07-03 | 2003-03-20 | Sht:Kk | 空芯コイル、コイル装置及びそれらの製造方法 |

| JP2006339407A (ja) | 2005-06-02 | 2006-12-14 | Sht Corp Ltd | 自動巻線機及びこれを用いた空心コイルの製造方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3787766A (en) * | 1972-02-22 | 1974-01-22 | Duncan Electric Co Inc | Meter magnet with strip-wound current coil |

| US3989200A (en) * | 1975-04-22 | 1976-11-02 | Bachi, Inc. | Non-circular perfect layer electrical coils |

| US4924201A (en) * | 1988-08-29 | 1990-05-08 | General Electric Company | Core and coil assembly for a transformer having an amorphous steel core |

| JPH07183152A (ja) * | 1993-12-22 | 1995-07-21 | Toshiba Corp | コイル巻線装置 |

| EP1414051B1 (en) * | 2001-07-03 | 2013-02-13 | SHT Corporation Limited | Method for manufacturing coil device |

| JP3621676B2 (ja) * | 2001-11-29 | 2005-02-16 | 昭和電線電纜株式会社 | 電気コイルの巻線加工装置 |

| US7317372B2 (en) | 2002-06-11 | 2008-01-08 | Sht Corporation Limited | Air-core coil and process for fabricating the same |

| JP4059888B2 (ja) * | 2005-03-31 | 2008-03-12 | 三映電子工業株式会社 | 矩形状コイルの製造方法及び矩形状コイルの製造装置 |

| JP5155732B2 (ja) * | 2008-05-15 | 2013-03-06 | 株式会社日立産機システム | 変圧器用多段コイル、並びにそれを製作するための巻線方法及び装置 |

| JP4278700B1 (ja) * | 2008-06-12 | 2009-06-17 | 日特エンジニアリング株式会社 | エッジワイズコイルの巻線方法及び巻線装置 |

| JP5935478B2 (ja) * | 2012-04-19 | 2016-06-15 | 株式会社豊田自動織機 | コイル巻取り装置の芯金 |

-

2011

- 2011-07-08 JP JP2011151444A patent/JP5535141B2/ja active Active

-

2012

- 2012-06-27 KR KR1020187024382A patent/KR101948499B1/ko active Active

- 2012-06-27 KR KR1020147000739A patent/KR101910225B1/ko active Active

- 2012-06-27 CN CN201280033950.3A patent/CN103843088B/zh active Active

- 2012-06-27 WO PCT/JP2012/066327 patent/WO2013008621A1/ja not_active Ceased

- 2012-07-03 TW TW101123852A patent/TWI552177B/zh active

-

2014

- 2014-01-07 US US14/149,778 patent/US20140184379A1/en not_active Abandoned

-

2016

- 2016-09-16 US US15/268,358 patent/US10418173B2/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003086438A (ja) | 2001-07-03 | 2003-03-20 | Sht:Kk | 空芯コイル、コイル装置及びそれらの製造方法 |

| JP2006339407A (ja) | 2005-06-02 | 2006-12-14 | Sht Corp Ltd | 自動巻線機及びこれを用いた空心コイルの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201308375A (zh) | 2013-02-16 |

| CN103843088A (zh) | 2014-06-04 |

| KR20140037211A (ko) | 2014-03-26 |

| US20140184379A1 (en) | 2014-07-03 |

| TWI552177B (zh) | 2016-10-01 |

| KR101910225B1 (ko) | 2018-10-19 |

| US10418173B2 (en) | 2019-09-17 |

| JP5535141B2 (ja) | 2014-07-02 |

| US20170069424A1 (en) | 2017-03-09 |

| KR101948499B1 (ko) | 2019-02-14 |

| CN103843088B (zh) | 2016-08-31 |

| WO2013008621A1 (ja) | 2013-01-17 |

| JP2013021041A (ja) | 2013-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101948499B1 (ko) | 코일의 권선 방법 및 권선 장치 | |

| JP5131560B2 (ja) | コイル製造方法及びコイル製造装置 | |

| JP5131561B2 (ja) | コイル製造方法、コイル製造装置、及びコイル | |

| KR101715991B1 (ko) | 자동 권선기, 공심 코일 및 그 권선 방법 | |

| JP4600580B2 (ja) | 固定子コイルの製造方法 | |

| JP3932084B2 (ja) | 回転電機のコイル導体の製造方法 | |

| CN112020818A (zh) | 电气设备用线圈的制造方法及制造装置 | |

| JP5785117B2 (ja) | 巻線装置および巻線方法 | |

| JP2019195845A (ja) | コイル成形装置およびコイル成形方法 | |

| US9242830B2 (en) | Coil winding method and transformer | |

| JP5369160B2 (ja) | 空芯コイルの巻線装置 | |

| JP6741148B2 (ja) | コイルの形成方法およびステータの製造方法 | |

| JP5499349B2 (ja) | 巻線構造及びそれを用いた電気機器 | |

| JP5146778B2 (ja) | 線材成形装置及びコイル製造装置 | |

| JP5244223B2 (ja) | 空芯コイル及びその巻線方法 | |

| JP2015019439A (ja) | 連続波型コイルの成形方法 | |

| KR20250116358A (ko) | 모터의 헤어핀 성형장치 및 성형방법 | |

| CN120770109A (zh) | 用于制造电机的转子或定子的绕组垫的弯曲装置 | |

| CN111525760A (zh) | 电机绕组线圈的绕制工艺和电机绕组线圈 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A107 | Divisional application of patent | ||

| PA0104 | Divisional application for international application |

St.27 status event code: A-0-1-A10-A18-div-PA0104 St.27 status event code: A-0-1-A10-A16-div-PA0104 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| A201 | Request for examination | ||

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PN2301 | Change of applicant |

St.27 status event code: A-5-5-R10-R13-asn-PN2301 St.27 status event code: A-5-5-R10-R11-asn-PN2301 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 7 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |