KR20110095386A - 액체 금속을 운반하기 위한 래들 파이프용 운송 및 보관 장치 - Google Patents

액체 금속을 운반하기 위한 래들 파이프용 운송 및 보관 장치 Download PDFInfo

- Publication number

- KR20110095386A KR20110095386A KR1020117014228A KR20117014228A KR20110095386A KR 20110095386 A KR20110095386 A KR 20110095386A KR 1020117014228 A KR1020117014228 A KR 1020117014228A KR 20117014228 A KR20117014228 A KR 20117014228A KR 20110095386 A KR20110095386 A KR 20110095386A

- Authority

- KR

- South Korea

- Prior art keywords

- shroud

- ladle

- rack

- transport

- casting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 229910001338 liquidmetal Inorganic materials 0.000 title claims abstract description 20

- 238000005058 metal casting Methods 0.000 claims abstract description 5

- 238000005266 casting Methods 0.000 claims description 50

- 238000000034 method Methods 0.000 claims description 19

- 238000004140 cleaning Methods 0.000 claims description 10

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 6

- 229910052760 oxygen Inorganic materials 0.000 claims description 6

- 239000001301 oxygen Substances 0.000 claims description 6

- 230000000295 complement effect Effects 0.000 claims description 4

- 230000003100 immobilizing effect Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000008929 regeneration Effects 0.000 description 3

- 238000011069 regeneration method Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 239000011343 solid material Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 230000003111 delayed effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000004062 sedimentation Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

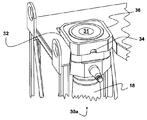

- B22D41/00—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like

- B22D41/50—Pouring-nozzles

- B22D41/56—Means for supporting, manipulating or changing a pouring-nozzle

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

- Warehouses Or Storage Devices (AREA)

- Load-Engaging Elements For Cranes (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP08169505 | 2008-11-20 | ||

| EP08169505.8 | 2008-11-20 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20110095386A true KR20110095386A (ko) | 2011-08-24 |

Family

ID=40219422

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020117014228A Withdrawn KR20110095386A (ko) | 2008-11-20 | 2009-11-19 | 액체 금속을 운반하기 위한 래들 파이프용 운송 및 보관 장치 |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US8820592B2 (enExample) |

| EP (1) | EP2367650A1 (enExample) |

| JP (1) | JP5336603B2 (enExample) |

| KR (1) | KR20110095386A (enExample) |

| CN (1) | CN102281971B (enExample) |

| AU (1) | AU2009317512B2 (enExample) |

| BR (1) | BRPI0922003A2 (enExample) |

| CA (1) | CA2743102A1 (enExample) |

| EG (1) | EG26344A (enExample) |

| MX (1) | MX2011005341A (enExample) |

| NZ (1) | NZ593477A (enExample) |

| RU (1) | RU2526353C2 (enExample) |

| UA (1) | UA103063C2 (enExample) |

| WO (1) | WO2010057645A1 (enExample) |

| ZA (1) | ZA201104534B (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AR074355A1 (es) * | 2008-11-20 | 2011-01-12 | Vesuvius Group Sa | Elemento de colada reutilizable y procedimiento de colada |

| EP2367649B1 (fr) * | 2008-11-20 | 2013-01-02 | Vesuvius Group S.A | Tete de support pour la manipulation d'un tube de poche |

| US10239114B2 (en) | 2016-01-29 | 2019-03-26 | Honda Motor Co., Ltd. | Systems and methods for transporting material |

| JP6953965B2 (ja) * | 2017-09-29 | 2021-10-27 | 信越化学工業株式会社 | 抗菌・抗カビ性を有する光触媒・合金微粒子分散液、その製造方法、及び光触媒・合金薄膜を表面に有する部材 |

| CN108817370A (zh) * | 2018-07-17 | 2018-11-16 | 江苏泰瑞耐火有限公司 | 底盘模具 |

| CN108714687A (zh) * | 2018-07-17 | 2018-10-30 | 江苏泰瑞耐火有限公司 | 子母口定位胶套 |

| CN108968524A (zh) * | 2018-07-19 | 2018-12-11 | 佛山市业鹏机械有限公司 | 一种线缆管材样品立体展示装置 |

| CN109332621B (zh) * | 2018-10-15 | 2023-08-04 | 哈尔滨博实自动化股份有限公司 | 一种适用于连铸台上智能自动化作业的装置 |

| CN216656332U (zh) * | 2020-03-31 | 2022-06-03 | 维苏威集团有限公司 | 金属浇铸设备 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU1752496A1 (ru) * | 1990-12-10 | 1992-08-07 | Всесоюзный научно-исследовательский и проектно-конструкторский институт металлургического машиностроения | Устройство дл замены удлиненного погружного стакана |

| FR2672526B1 (fr) | 1991-02-07 | 1993-05-28 | Lorraine Laminage | Dispositif d'ejection de support de tube protecteur de jet dans une installation de coulee continue. |

| BE1007317A3 (fr) * | 1993-07-27 | 1995-05-16 | Int Ind Eng Sa | Dispositif d'amenee et d'echange d'un tube de coulee dans une installation de coulee continue a brames minces. |

| JP3250771B2 (ja) * | 1993-12-16 | 2002-01-28 | 黒崎播磨株式会社 | 溶融金属流出用耐火物の支持金物 |

| JP2927186B2 (ja) | 1994-07-06 | 1999-07-28 | 東芝セラミックス株式会社 | 使用済ノズルの廃却ポット |

| JP2798610B2 (ja) * | 1994-08-10 | 1998-09-17 | 品川白煉瓦株式会社 | 浸漬ノズルの取付け取外し装置 |

| JP3212071B2 (ja) * | 1995-10-20 | 2001-09-25 | 東芝セラミックス株式会社 | 浸漬ノズルのハンドリング装置 |

| JP3168157B2 (ja) * | 1996-01-23 | 2001-05-21 | 住友重機械工業株式会社 | 連続鋳造機のロングノズル着脱装置 |

| US5819844A (en) * | 1996-07-31 | 1998-10-13 | Vesuvius Crucible Company | Beaver-tail tube assembly and tube changing method |

| KR19980070518A (ko) * | 1997-01-17 | 1998-10-26 | 오자와미또시 | 침지노즐 교환장치를 구비한 슬래브용 연속주조기 및침지노즐의 교환방법 |

| KR100916101B1 (ko) | 2002-09-06 | 2009-09-11 | 주식회사 포스코 | 쉬라우드 노즐과 콜렉타 노즐의 자동 연결장치 |

| AT502058B1 (de) * | 2005-06-20 | 2007-11-15 | Voest Alpine Ind Anlagen | Stranggiessanlage mit mindestens einem multifunktions-roboter |

-

2009

- 2009-11-19 MX MX2011005341A patent/MX2011005341A/es active IP Right Grant

- 2009-11-19 AU AU2009317512A patent/AU2009317512B2/en not_active Ceased

- 2009-11-19 JP JP2011536778A patent/JP5336603B2/ja not_active Expired - Fee Related

- 2009-11-19 WO PCT/EP2009/008254 patent/WO2010057645A1/fr not_active Ceased

- 2009-11-19 CN CN200980155166.8A patent/CN102281971B/zh not_active Expired - Fee Related

- 2009-11-19 BR BRPI0922003A patent/BRPI0922003A2/pt not_active IP Right Cessation

- 2009-11-19 US US13/130,323 patent/US8820592B2/en not_active Expired - Fee Related

- 2009-11-19 NZ NZ593477A patent/NZ593477A/xx not_active IP Right Cessation

- 2009-11-19 CA CA2743102A patent/CA2743102A1/fr not_active Abandoned

- 2009-11-19 KR KR1020117014228A patent/KR20110095386A/ko not_active Withdrawn

- 2009-11-19 EP EP09763842A patent/EP2367650A1/fr not_active Withdrawn

- 2009-11-19 UA UAA201107605A patent/UA103063C2/ru unknown

- 2009-11-19 RU RU2011124583/02A patent/RU2526353C2/ru not_active IP Right Cessation

-

2011

- 2011-05-17 EG EG2011050774A patent/EG26344A/en active

- 2011-06-20 ZA ZA2011/04534A patent/ZA201104534B/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| AU2009317512B2 (en) | 2014-03-27 |

| RU2011124583A (ru) | 2012-12-27 |

| JP2012509187A (ja) | 2012-04-19 |

| ZA201104534B (en) | 2012-09-26 |

| CN102281971B (zh) | 2014-10-08 |

| NZ593477A (en) | 2012-11-30 |

| US8820592B2 (en) | 2014-09-02 |

| WO2010057645A1 (fr) | 2010-05-27 |

| CN102281971A (zh) | 2011-12-14 |

| MX2011005341A (es) | 2011-06-16 |

| JP5336603B2 (ja) | 2013-11-06 |

| RU2526353C2 (ru) | 2014-08-20 |

| EP2367650A1 (fr) | 2011-09-28 |

| CA2743102A1 (fr) | 2010-05-27 |

| EG26344A (en) | 2013-08-20 |

| UA103063C2 (ru) | 2013-09-10 |

| US20110240246A1 (en) | 2011-10-06 |

| AU2009317512A1 (en) | 2011-07-07 |

| BRPI0922003A2 (pt) | 2015-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20110095386A (ko) | 액체 금속을 운반하기 위한 래들 파이프용 운송 및 보관 장치 | |

| CN110892057B (zh) | 基因测序反应设备、基因测序系统和基因测序反应方法 | |

| JP2012509187A5 (enExample) | ||

| KR101699150B1 (ko) | 로스트왁스 주물 탈사장치 및 그 방법 | |

| US12042856B2 (en) | Robotized ladle transportation device system with embedded manipulator | |

| EP4106934B1 (en) | Robotized ladle turret system | |

| US10239114B2 (en) | Systems and methods for transporting material | |

| RU2683670C1 (ru) | Установка для литья и способ литья | |

| SK286318B6 (en) | Storage, handling and transport device for workpieces during a surface treatment | |

| AU2015226002B2 (en) | System for carrying out operations linked to the use of cells of a facility for producing aluminium by means of electrolysis | |

| KR101765028B1 (ko) | 로스트왁스 주물 탈사장치 및 그 방법 | |

| JP5164750B2 (ja) | 鋳造アノードの取り出し装置及び鋳造アノードの取り出し方法 | |

| JP3273427B2 (ja) | 溶融金属容器用耐火物の交換方法及び溶融金属容器用耐火物の交換装置 | |

| JP3554609B2 (ja) | 原子炉内核計装管の取り扱い方法及び装置 | |

| JP3975187B2 (ja) | 溶鋼処理ライン | |

| CN222801430U (zh) | 废旧工业钴60再利用源棒的倒装源装置 | |

| RU2818157C1 (ru) | Роботизированная система устройства для транспортировки разливочного ковша со встроенным манипулятором | |

| JP2003326349A (ja) | 遠心鋳造設備におけるパレット内の中子及び中敷取出し装置 | |

| JPH0819854A (ja) | 使用済ノズルの廃却ポット | |

| JP2005211904A (ja) | 金属溶湯供給装置 | |

| JPH09295131A (ja) | 掛堰供給・回収装置 | |

| JPH1034291A (ja) | 連続鋳造設備のタンディッシュ保守装置 | |

| JP2006117969A (ja) | 転炉への溶銑供給方法 | |

| JPH0197900A (ja) | 制御棒駆動装置の交換方法および装置 | |

| JPH09323154A (ja) | 掛堰カバー着脱機能を有する掛堰供給・回収装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20110620 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20140929 Comment text: Request for Examination of Application |

|

| PC1202 | Submission of document of withdrawal before decision of registration |

Comment text: [Withdrawal of Procedure relating to Patent, etc.] Withdrawal (Abandonment) Patent event code: PC12021R01D Patent event date: 20150729 |

|

| WITB | Written withdrawal of application |