JP6869552B2 - 無加湿系プロトン伝導膜,その製法及び燃料電池 - Google Patents

無加湿系プロトン伝導膜,その製法及び燃料電池 Download PDFInfo

- Publication number

- JP6869552B2 JP6869552B2 JP2018513087A JP2018513087A JP6869552B2 JP 6869552 B2 JP6869552 B2 JP 6869552B2 JP 2018513087 A JP2018513087 A JP 2018513087A JP 2018513087 A JP2018513087 A JP 2018513087A JP 6869552 B2 JP6869552 B2 JP 6869552B2

- Authority

- JP

- Japan

- Prior art keywords

- proton

- group

- substance

- proton conductive

- site

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000446 fuel Substances 0.000 title claims description 17

- 238000004519 manufacturing process Methods 0.000 title claims description 6

- 239000000126 substance Substances 0.000 claims description 58

- 229920000642 polymer Polymers 0.000 claims description 57

- 239000012528 membrane Substances 0.000 claims description 39

- 239000002904 solvent Substances 0.000 claims description 31

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 claims description 28

- 125000000524 functional group Chemical group 0.000 claims description 22

- 239000002253 acid Substances 0.000 claims description 18

- 125000000542 sulfonic acid group Chemical group 0.000 claims description 18

- 125000003158 alcohol group Chemical group 0.000 claims description 16

- 230000009477 glass transition Effects 0.000 claims description 14

- 125000005463 sulfonylimide group Chemical group 0.000 claims description 13

- HXQQNYSFSLBXQJ-UHFFFAOYSA-N COC1=C(NC(CO)C(O)=O)CC(O)(CO)CC1=NCC(O)=O Chemical compound COC1=C(NC(CO)C(O)=O)CC(O)(CO)CC1=NCC(O)=O HXQQNYSFSLBXQJ-UHFFFAOYSA-N 0.000 claims description 12

- 239000006185 dispersion Substances 0.000 claims description 12

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical group OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 claims description 11

- 238000002844 melting Methods 0.000 claims description 10

- 230000008018 melting Effects 0.000 claims description 10

- 230000002378 acidificating effect Effects 0.000 claims description 7

- 125000002843 carboxylic acid group Chemical group 0.000 claims description 3

- 150000002222 fluorine compounds Chemical class 0.000 claims description 3

- 239000007788 liquid Substances 0.000 claims description 3

- 239000011259 mixed solution Substances 0.000 claims description 3

- 125000003368 amide group Chemical group 0.000 claims description 2

- 125000004185 ester group Chemical group 0.000 claims description 2

- 125000000468 ketone group Chemical group 0.000 claims description 2

- 238000002156 mixing Methods 0.000 claims description 2

- 238000001704 evaporation Methods 0.000 claims 1

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 57

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 38

- UWHCKJMYHZGTIT-UHFFFAOYSA-N Tetraethylene glycol, Natural products OCCOCCOCCOCCO UWHCKJMYHZGTIT-UHFFFAOYSA-N 0.000 description 31

- 229920001223 polyethylene glycol Polymers 0.000 description 31

- 239000012071 phase Substances 0.000 description 29

- 229920000557 Nafion® Polymers 0.000 description 26

- 229920001971 elastomer Polymers 0.000 description 23

- 239000000806 elastomer Substances 0.000 description 22

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 19

- -1 tert-butylphenyl Chemical group 0.000 description 18

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 17

- 239000000203 mixture Substances 0.000 description 17

- CERQOIWHTDAKMF-UHFFFAOYSA-M Methacrylate Chemical compound CC(=C)C([O-])=O CERQOIWHTDAKMF-UHFFFAOYSA-M 0.000 description 16

- 238000006116 polymerization reaction Methods 0.000 description 16

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 15

- 239000004793 Polystyrene Substances 0.000 description 15

- 229920002223 polystyrene Polymers 0.000 description 15

- 239000007789 gas Substances 0.000 description 14

- 229920000885 poly(2-vinylpyridine) Polymers 0.000 description 14

- 239000000243 solution Substances 0.000 description 14

- 239000012046 mixed solvent Substances 0.000 description 12

- 229920000075 poly(4-vinylpyridine) Polymers 0.000 description 12

- 239000000178 monomer Substances 0.000 description 11

- 125000004076 pyridyl group Chemical group 0.000 description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 11

- 239000003054 catalyst Substances 0.000 description 10

- 238000002847 impedance measurement Methods 0.000 description 10

- 238000005259 measurement Methods 0.000 description 10

- 229920001577 copolymer Polymers 0.000 description 9

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 8

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 8

- 238000010586 diagram Methods 0.000 description 8

- 238000009792 diffusion process Methods 0.000 description 8

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 8

- 239000002737 fuel gas Substances 0.000 description 6

- ZIUHHBKFKCYYJD-UHFFFAOYSA-N n,n'-methylenebisacrylamide Chemical compound C=CC(=O)NCNC(=O)C=C ZIUHHBKFKCYYJD-UHFFFAOYSA-N 0.000 description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 5

- 239000007864 aqueous solution Substances 0.000 description 5

- 229920001400 block copolymer Polymers 0.000 description 5

- 229910052799 carbon Inorganic materials 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- OZAIFHULBGXAKX-UHFFFAOYSA-N 2-(2-cyanopropan-2-yldiazenyl)-2-methylpropanenitrile Chemical compound N#CC(C)(C)N=NC(C)(C)C#N OZAIFHULBGXAKX-UHFFFAOYSA-N 0.000 description 4

- 125000000954 2-hydroxyethyl group Chemical group [H]C([*])([H])C([H])([H])O[H] 0.000 description 4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 239000004809 Teflon Substances 0.000 description 4

- 229920006362 Teflon® Polymers 0.000 description 4

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 4

- 230000003247 decreasing effect Effects 0.000 description 4

- 150000002148 esters Chemical class 0.000 description 4

- JBTWLSYIZRCDFO-UHFFFAOYSA-N ethyl methyl carbonate Chemical compound CCOC(=O)OC JBTWLSYIZRCDFO-UHFFFAOYSA-N 0.000 description 4

- 239000001257 hydrogen Substances 0.000 description 4

- 229910052739 hydrogen Inorganic materials 0.000 description 4

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 4

- 230000003647 oxidation Effects 0.000 description 4

- 238000007254 oxidation reaction Methods 0.000 description 4

- 229910052697 platinum Inorganic materials 0.000 description 4

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 4

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 239000004693 Polybenzimidazole Substances 0.000 description 3

- 230000009471 action Effects 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 229920000359 diblock copolymer Polymers 0.000 description 3

- 150000002170 ethers Chemical class 0.000 description 3

- 239000003921 oil Substances 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 3

- 229920002480 polybenzimidazole Polymers 0.000 description 3

- 238000010248 power generation Methods 0.000 description 3

- 150000003457 sulfones Chemical class 0.000 description 3

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 3

- 150000003568 thioethers Chemical class 0.000 description 3

- DNIAPMSPPWPWGF-VKHMYHEASA-N (+)-propylene glycol Chemical compound C[C@H](O)CO DNIAPMSPPWPWGF-VKHMYHEASA-N 0.000 description 2

- MYRTYDVEIRVNKP-UHFFFAOYSA-N 1,2-Divinylbenzene Chemical compound C=CC1=CC=CC=C1C=C MYRTYDVEIRVNKP-UHFFFAOYSA-N 0.000 description 2

- YPFDHNVEDLHUCE-UHFFFAOYSA-N 1,3-propanediol Substances OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 2

- RYHBNJHYFVUHQT-UHFFFAOYSA-N 1,4-Dioxane Chemical compound C1COCCO1 RYHBNJHYFVUHQT-UHFFFAOYSA-N 0.000 description 2

- PIQRVDNQKLJRJM-UHFFFAOYSA-N 3-[3-(3-sulfopropoxy)propoxy]propane-1-sulfonic acid Chemical compound OS(=O)(=O)CCCOCCCOCCCS(O)(=O)=O PIQRVDNQKLJRJM-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 2

- XPDWGBQVDMORPB-UHFFFAOYSA-N Fluoroform Chemical compound FC(F)F XPDWGBQVDMORPB-UHFFFAOYSA-N 0.000 description 2

- 101100337414 Mus musculus Golga3 gene Proteins 0.000 description 2

- 239000002202 Polyethylene glycol Substances 0.000 description 2

- 125000005073 adamantyl group Chemical group C12(CC3CC(CC(C1)C3)C2)* 0.000 description 2

- 239000004917 carbon fiber Substances 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 125000004802 cyanophenyl group Chemical group 0.000 description 2

- 125000001995 cyclobutyl group Chemical group [H]C1([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 230000009881 electrostatic interaction Effects 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- UQSQSQZYBQSBJZ-UHFFFAOYSA-N fluorosulfonic acid Chemical compound OS(F)(=O)=O UQSQSQZYBQSBJZ-UHFFFAOYSA-N 0.000 description 2

- 238000005227 gel permeation chromatography Methods 0.000 description 2

- 125000000623 heterocyclic group Chemical group 0.000 description 2

- 125000002883 imidazolyl group Chemical group 0.000 description 2

- 238000010551 living anionic polymerization reaction Methods 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000004899 motility Effects 0.000 description 2

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 2

- 125000004430 oxygen atom Chemical group O* 0.000 description 2

- 239000010702 perfluoropolyether Substances 0.000 description 2

- 229920000166 polytrimethylene carbonate Polymers 0.000 description 2

- 229920002717 polyvinylpyridine Polymers 0.000 description 2

- 238000001556 precipitation Methods 0.000 description 2

- 239000003586 protic polar solvent Substances 0.000 description 2

- 239000007784 solid electrolyte Substances 0.000 description 2

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 2

- DTGKSKDOIYIVQL-WEDXCCLWSA-N (+)-borneol Chemical group C1C[C@@]2(C)[C@@H](O)C[C@@H]1C2(C)C DTGKSKDOIYIVQL-WEDXCCLWSA-N 0.000 description 1

- ZXMGHDIOOHOAAE-UHFFFAOYSA-N 1,1,1-trifluoro-n-(trifluoromethylsulfonyl)methanesulfonamide Chemical compound FC(F)(F)S(=O)(=O)NS(=O)(=O)C(F)(F)F ZXMGHDIOOHOAAE-UHFFFAOYSA-N 0.000 description 1

- 125000001731 2-cyanoethyl group Chemical group [H]C([H])(*)C([H])([H])C#N 0.000 description 1

- KGIGUEBEKRSTEW-UHFFFAOYSA-N 2-vinylpyridine Chemical group C=CC1=CC=CC=N1 KGIGUEBEKRSTEW-UHFFFAOYSA-N 0.000 description 1

- DXIJHCSGLOHNES-UHFFFAOYSA-N 3,3-dimethylbut-1-enylbenzene Chemical compound CC(C)(C)C=CC1=CC=CC=C1 DXIJHCSGLOHNES-UHFFFAOYSA-N 0.000 description 1

- DPZYLEIWHTWHCU-UHFFFAOYSA-N 3-ethenylpyridine Chemical compound C=CC1=CC=CN=C1 DPZYLEIWHTWHCU-UHFFFAOYSA-N 0.000 description 1

- INZLZTHXPOJSCN-UHFFFAOYSA-N 3-fluoroprop-1-enylbenzene Chemical compound FCC=CC1=CC=CC=C1 INZLZTHXPOJSCN-UHFFFAOYSA-N 0.000 description 1

- KFDVPJUYSDEJTH-UHFFFAOYSA-N 4-ethenylpyridine Chemical group C=CC1=CC=NC=C1 KFDVPJUYSDEJTH-UHFFFAOYSA-N 0.000 description 1

- SXIFAEWFOJETOA-UHFFFAOYSA-N 4-hydroxy-butyl Chemical group [CH2]CCCO SXIFAEWFOJETOA-UHFFFAOYSA-N 0.000 description 1

- 238000005481 NMR spectroscopy Methods 0.000 description 1

- 108091034117 Oligonucleotide Proteins 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 125000001164 benzothiazolyl group Chemical group S1C(=NC2=C1C=CC=C2)* 0.000 description 1

- 125000004541 benzoxazolyl group Chemical group O1C(=NC2=C1C=CC=C2)* 0.000 description 1

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 238000012711 chain transfer polymerization Methods 0.000 description 1

- 238000003776 cleavage reaction Methods 0.000 description 1

- 239000000084 colloidal system Substances 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000000640 cyclooctyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C([H])([H])C1([H])[H] 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 125000001153 fluoro group Chemical group F* 0.000 description 1

- 125000003709 fluoroalkyl group Chemical group 0.000 description 1

- 125000004216 fluoromethyl group Chemical group [H]C([H])(F)* 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 1

- 150000003949 imides Chemical class 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 125000000959 isobutyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 229920002521 macromolecule Polymers 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 125000001624 naphthyl group Chemical group 0.000 description 1

- 150000002825 nitriles Chemical class 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 125000001715 oxadiazolyl group Chemical group 0.000 description 1

- 125000005010 perfluoroalkyl group Chemical group 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 125000000714 pyrimidinyl group Chemical group 0.000 description 1

- 125000005493 quinolyl group Chemical group 0.000 description 1

- 229920005604 random copolymer Polymers 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 230000007017 scission Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 125000000472 sulfonyl group Chemical group *S(*)(=O)=O 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- TXEYQDLBPFQVAA-UHFFFAOYSA-N tetrafluoromethane Chemical compound FC(F)(F)F TXEYQDLBPFQVAA-UHFFFAOYSA-N 0.000 description 1

- 125000001113 thiadiazolyl group Chemical group 0.000 description 1

- 125000002256 xylenyl group Chemical group C1(C(C=CC=C1)C)(C)* 0.000 description 1

- 239000004711 α-olefin Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/20—Manufacture of shaped structures of ion-exchange resins

- C08J5/22—Films, membranes or diaphragms

- C08J5/2206—Films, membranes or diaphragms based on organic and/or inorganic macromolecular compounds

- C08J5/2218—Synthetic macromolecular compounds

- C08J5/2231—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds

- C08J5/2237—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds containing fluorine

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/1016—Fuel cells with solid electrolytes characterised by the electrolyte material

- H01M8/1018—Polymeric electrolyte materials

- H01M8/1041—Polymer electrolyte composites, mixtures or blends

- H01M8/1044—Mixtures of polymers, of which at least one is ionically conductive

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F293/00—Macromolecular compounds obtained by polymerisation on to a macromolecule having groups capable of inducing the formation of new polymer chains bound exclusively at one or both ends of the starting macromolecule

- C08F293/005—Macromolecular compounds obtained by polymerisation on to a macromolecule having groups capable of inducing the formation of new polymer chains bound exclusively at one or both ends of the starting macromolecule using free radical "living" or "controlled" polymerisation, e.g. using a complexing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/20—Manufacture of shaped structures of ion-exchange resins

- C08J5/22—Films, membranes or diaphragms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/20—Manufacture of shaped structures of ion-exchange resins

- C08J5/22—Films, membranes or diaphragms

- C08J5/2206—Films, membranes or diaphragms based on organic and/or inorganic macromolecular compounds

- C08J5/2218—Synthetic macromolecular compounds

- C08J5/2231—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/20—Manufacture of shaped structures of ion-exchange resins

- C08J5/22—Films, membranes or diaphragms

- C08J5/2206—Films, membranes or diaphragms based on organic and/or inorganic macromolecular compounds

- C08J5/2218—Synthetic macromolecular compounds

- C08J5/2231—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds

- C08J5/2243—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds obtained by introduction of active groups capable of ion-exchange into compounds of the type C08J5/2231

- C08J5/225—Synthetic macromolecular compounds based on macromolecular compounds obtained by reactions involving unsaturated carbon-to-carbon bonds obtained by introduction of active groups capable of ion-exchange into compounds of the type C08J5/2231 containing fluorine

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/06—Ethers; Acetals; Ketals; Ortho-esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/36—Sulfur-, selenium-, or tellurium-containing compounds

- C08K5/41—Compounds containing sulfur bound to oxygen

- C08K5/42—Sulfonic acids; Derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L101/00—Compositions of unspecified macromolecular compounds

- C08L101/02—Compositions of unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups

- C08L101/06—Compositions of unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups containing oxygen atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L101/00—Compositions of unspecified macromolecular compounds

- C08L101/12—Compositions of unspecified macromolecular compounds characterised by physical features, e.g. anisotropy, viscosity or electrical conductivity

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L27/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Compositions of derivatives of such polymers

- C08L27/22—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Compositions of derivatives of such polymers modified by chemical after-treatment

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L33/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L33/04—Homopolymers or copolymers of esters

- C08L33/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, which oxygen atoms are present only as part of the carboxyl radical

- C08L33/062—Copolymers with monomers not covered by C08L33/06

- C08L33/066—Copolymers with monomers not covered by C08L33/06 containing -OH groups

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/04—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of carbon-silicon compounds, carbon or silicon

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/02—Details

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/1016—Fuel cells with solid electrolytes characterised by the electrolyte material

- H01M8/1018—Polymeric electrolyte materials

- H01M8/1041—Polymer electrolyte composites, mixtures or blends

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/1016—Fuel cells with solid electrolytes characterised by the electrolyte material

- H01M8/1018—Polymeric electrolyte materials

- H01M8/1041—Polymer electrolyte composites, mixtures or blends

- H01M8/1046—Mixtures of at least one polymer and at least one additive

- H01M8/1048—Ion-conducting additives, e.g. ion-conducting particles, heteropolyacids, metal phosphate or polybenzimidazole with phosphoric acid

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M8/1016—Fuel cells with solid electrolytes characterised by the electrolyte material

- H01M8/1018—Polymeric electrolyte materials

- H01M8/1069—Polymeric electrolyte materials characterised by the manufacturing processes

- H01M8/1081—Polymeric electrolyte materials characterised by the manufacturing processes starting from solutions, dispersions or slurries exclusively of polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F212/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring

- C08F212/02—Monomers containing only one unsaturated aliphatic radical

- C08F212/04—Monomers containing only one unsaturated aliphatic radical containing one ring

- C08F212/06—Hydrocarbons

- C08F212/08—Styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2438/00—Living radical polymerisation

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2438/00—Living radical polymerisation

- C08F2438/03—Use of a di- or tri-thiocarbonylthio compound, e.g. di- or tri-thioester, di- or tri-thiocarbamate, or a xanthate as chain transfer agent, e.g . Reversible Addition Fragmentation chain Transfer [RAFT] or Macromolecular Design via Interchange of Xanthates [MADIX]

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2327/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers

- C08J2327/02—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers not modified by chemical after-treatment

- C08J2327/12—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers not modified by chemical after-treatment containing fluorine atoms

- C08J2327/18—Homopolymers or copolymers of tetrafluoroethylene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2327/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers

- C08J2327/22—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers modified by chemical after-treatment

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/14—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing halogen, nitrogen, sulfur, or oxygen atoms in addition to the carboxy oxygen

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2355/00—Characterised by the use of homopolymers or copolymers, obtained by polymerisation reactions only involving carbon-to-carbon unsaturated bonds, not provided for in groups C08J2323/00 - C08J2353/00

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2453/00—Characterised by the use of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2455/00—Characterised by the use of homopolymers or copolymers, obtained by polymerisation reactions only involving carbon-to-carbon unsaturated bonds, not provided for in groups C08J2423/00 - C08J2453/00

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M8/00—Fuel cells; Manufacture thereof

- H01M8/10—Fuel cells with solid electrolytes

- H01M2008/1095—Fuel cells with polymeric electrolytes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2300/00—Electrolytes

- H01M2300/0017—Non-aqueous electrolytes

- H01M2300/0065—Solid electrolytes

- H01M2300/0082—Organic polymers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2300/00—Electrolytes

- H01M2300/0088—Composites

- H01M2300/0091—Composites in the form of mixtures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Manufacturing & Machinery (AREA)

- Engineering & Computer Science (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Inorganic Chemistry (AREA)

- Composite Materials (AREA)

- Dispersion Chemistry (AREA)

- Fuel Cell (AREA)

- Conductive Materials (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Description

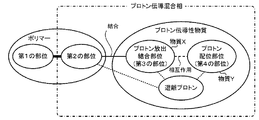

ガラス転移温度又は融解温度が前記プロトン伝導膜の使用温度よりも高いガラス状又は結晶性の第1の部位と非共有結合可能な官能基を有する第2の部位とを含むポリマーと、

プロトンを放出可能で前記ポリマーの第2の部位に非共有結合可能な官能基を有するプロトン放出・結合部位(第3の部位)とプロトンに配位可能なプロトン配位部位(第4の部位)とを相互作用し合う異なる分子に別々に含むか同一分子内に含むプロトン伝導性物質と、

を備え、

前記プロトン伝導性物質の前記プロトン放出・結合部位が結合した前記第2の部位と前記プロトン伝導性物質とを含むプロトン伝導混合相のガラス転移温度は、前記プロトン伝導膜の使用温度より低く、

前記プロトン放出・結合部位は、前記ポリマーの第2の部位よりも過多に存在している、

ものである。

[1]プロトン伝導性ソフトエラストマー膜の調製

リビングアニオン重合により合成されたポリスチレン−b−ポリ(4−ビニルピリジン)ブロック共重合体(S4VPと称することとする)をポリマーソース社(Polymer Source Inc)より購入した。ポリスチレンの平均重合度は2115、ポリ(4−ビニルピリジン)の平均重合度が143であった。このS4VP51mgを重量比7/3のテトラヒドロフラン(THF)/メタノール(MeOH)混合溶媒2.0gに溶解した。一方で、アルドリッチ社(Aldrich)より購入した10wt%のナフィオン(等価質量=1000)分散水溶液2.30gを10mL容量のテフロンビーカー(テフロンは登録商標)中に入れ、70℃のホットプレート上に48時間載せておくことで水を蒸発させ、これにテトラエチレングリコール(TEG)を240mg加え、さらに重量比6/4のTHF/MeOH混合溶媒2.0gを添加することで、ナフィオンをTEG/THF/MeOH中に溶解させた。S4VP/THF/MeOHの溶液と、ナフィオン/TEG/THF/MeOHの溶液を混合したところ、沈殿は生じず、混合液を60℃のホットプレート上に2日間載せておくことでTHF/MeOHを蒸発させてキャストし、ナフィオン/TEG/S4VPの重量比がおおよそ4.5/4.5/1のプロトン伝導性ソフトエラストマー膜を得た。ナフィオンのスルホン酸基は、S4VPのピリジル基に対して計算上、約7.4倍存在していることになる。

厚さ0.1mm程度の白金網を電極として用いた。電極間距離を0.50cmとし、プロトン伝導性ソフトエラストマー膜を電極で挟み込んだ。膜の厚みは0.04cm、膜の幅は0.32cmであった。電極で挟み込んだ状態の測定用試料を自然対流式定温恒温乾燥器中に入れて設定温度を60℃とし、6時間程度試料を乾燥させた。その後乾燥器の設定温度(測定温度)を80℃として乾燥器内温度を安定させ、電圧を80mV、周波数を1000000Hzから1Hzで変化させて無加湿条件下で交流インピーダンス測定を行った。測定装置はエフアールエー(FRA)オプション付きのポテンショ/ガルバノスタットVERSASTAT4−400(プリンストン・アプライド・リサーチ(Prinston Applied Research))を用いた。測定試料の抵抗値をCole−ColeプロットのX軸の切片から読み取ったところ、5.0×104Ωであった。プロトン伝導率=電極間距離/(膜の厚み×膜の幅×抵抗値)の関係式よりプロトン伝導率を求めたところ、7.8×10-4S/cmであった。次に、交流インピーダンス測定の測定温度を95℃としたところ、抵抗値は3.1×104S/cmであり、プロトン伝導率は1.3×10-3S/cmであった。温度を80℃から95℃に上げることでプロトン伝導率が大きくなったが、これは温度を上げることにより溶融状態のプロトン伝導混合相の粘度が下がってプロトン伝導性が向上したことによると考えられる。なお、得られたプロトン伝導性ソフトエラストマー膜は、測定中、全体としては流動せず形状を維持していた。

10wt%のナフィオン(等価質量=1000)分散水溶液2.52gを10mL容量のテフロンビーカー中に入れ、70℃のホットプレート上に48時間載せておくことで、水を蒸発させた。これにTEGを240mg加え、さらに重量比6/4のTHF/MeOH混合溶媒2.0gを添加することでナフィオンをTEG/THF/MeOH中に溶解させた。この溶液を60℃のホットプレート上に2日間載せてTHF/MeOHを蒸発させてキャストしたところ、ナフィオンとTEGのみからなる、室温において均一な粘土状混合物が得られた。無加湿条件下での交流インピーダンス測定のために上記粘土状混合物を50℃の自然対流式定温恒温乾燥器中に入れたところ流動し、固体状態でのプロトン伝導率を決定することができなかった。比較例1では、プロトン伝導混合相は、ナフィオンとTEGとの混合物であるが、このプロトン伝導混合相を支える固体相がなかっため、50℃では流動してしまったと考えられる。

ポリマーソース社より購入した、ポリスチレンの平均重合度が2115、ポリ(4−ビニルピリジン)の平均重合度が143のS4VP75mgを重量比7/3のTHF/MeOH混合溶媒2.0gで溶解した。一方で、10wt%のナフィオン(等価質量=1000)分散水溶液1.53gを10mL容量のテフロンビーカー中に入れ、70℃のホットプレート上に48時間載せておくことで水を蒸発させ、これに重量比6/4のTHF/MeOH混合溶媒2.0gを添加することでナフィオンをTHF/MeOH中に溶解させた。S4VP/THF/MeOH溶液と、ナフィオン/THF/MeOH溶液を混合したところ、沈殿は生じず、混合液を60℃のホットプレート上に2日間載せておくことで、THF/MeOHを蒸発させてキャストし、固体膜を得た。交流インピーダンス測定のために、厚みが0.04cm、幅が0.32cmの膜を用意し、電極間距離を0.50cmとして、膜を上下から電極で挟み込んで自然対流式定温恒温乾燥器中に入れた。設定温度を80℃として乾燥器内温度を安定させ、電圧を80mV、周波数を1000000Hzから1Hzで変化させて無加湿条件下で交流インピーダンス測定を行った。抵抗値は極めて大きく、プロトン伝導率は極めて低いことが分かった。比較例2では、プロトン伝導混合相に相当するのはナフィオンとポリ(4−ビニルピリジン)との混合物である。ナフィオンとポリ(4−ビニルピリジン)との混合物のTgは理論上両物質のTg以上、すなわち130℃以上であり、無加湿で80℃という条件では溶融状態ではなく固体状態であるため、ほとんどプロトンを伝導しなかったと考えられる。

実施例2では、実施例1の[1]において、S4VPを101mg使用し、10wt%のナフィオン(等価質量=1000)分散水溶液を2.00g使用し、TEGを199mg使用したこと以外は、実施例1と同様にしてプロトン伝導性ソフトエラストマー膜を作製した(ナフィオン/TEG/S4VPの重量比がおおよそ4/4/2)。ナフィオンのスルホン酸基は、S4VPのピリジル基に対して計算上、約3.3倍存在していることになる。実施例1の[2]において、膜の厚みを0.06cm、膜の幅を0.33cmとした以外は実施例1と同様にして交流インピーダンス測定を行った。80℃での抵抗値は1.2×105Ωであり、プロトン伝導率は2.3×10-4S/cmであった。95℃での抵抗値は8.3×104Ωであり、プロトン伝導率は3.3×10-4S/cmであった。実施例2では、プロトン伝導混合相は、実施例1と同様、ナフィオンとTEGとポリ(4−ビニルピリジン)との混合物であり、ポリスチレンに固定化されている。このプロトン伝導混合相は、Tgが室温以下であり、交流インピーダンス測定の温度(80℃や95℃)では溶融状態である。実施例2で得られたプロトン伝導性ソフトエラストマー膜も、測定中、全体としては流動せず形状を維持していた。

実施例3では、実施例1の[1]において、S4VPを50mg使用し、10wt%のナフィオン(等価質量=1000)分散水溶液を3.03g使用し、TEGを150mg使用したこと以外は、実施例1と同様にしてプロトン伝導性ソフトエラストマー膜を作製した(ナフィオン/TEG/S4VPの重量比がおおよそ6/3/1)。ナフィオンのスルホン酸基は、S4VPのピリジル基に対して計算上、約9.8倍存在していることになる。実施例1の[2]において、膜の厚みを0.04cm、膜の幅を0.21cmとした以外は、実施例1と同様にして交流インピーダンス測定を行った。80℃での抵抗値は8.3×104Ωであり、プロトン伝導率は6.9×10-4S/cmであった。95℃での抵抗値は5.6×104Ωであり、プロトン伝導率は1.0×10-3S/cmであった。この実施例3では、プロトン伝導混合相は、実施例1と同様、ナフィオンとTEGとポリ(4−ビニルピリジン)との混合物であり、ポリスチレンに固定化されている。このプロトン伝導混合相は、Tgが室温以下であり、交流インピーダンス測定の温度(80℃や95℃)では溶融状態である。実施例3で得られたプロトン伝導性ソフトエラストマー膜も、測定中、全体としては流動せず形状を維持していた。

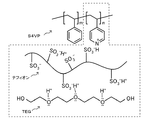

実施例4では、実施例1の[1]において、S4VPの代わりにリビングアニオン重合により合成されたポリスチレン−b−ポリ(2−ビニルピリジン)ブロック共重合体(S2VPと称する)を用いた。ポリスチレンの平均重合度は1250、ポリ(2−ビニルピリジン)の平均重合度が1285であった。またナフィオン/TEGの代わりに3,3’−(プロパン−1,3−ジイルビス(オキシ))ビス(プロパン−1−スルホン酸)(BSAと称する)/1,3−プロパンジオール(PDと称する)を用いた。BSAについてはソリッドステイトアイオニクス(Solid State Ionics),1995年,80巻,201頁−212頁及びコロイドポリマーサイエンス(Colloid Polymer Science),2014年,292巻、1261頁−1268頁 で報告されているスキームと類似の方法で合成した。S2VPを97mg、重量比7/3のTHF/MeOH混合溶媒を1.0g、ナフィオンの代わりにBSAを191mg、TEGの代わりにPDを191mg、重量比6/4のTHF/MeOH混合溶媒2.0gの代わりに重量比7/3のTHF/MeOH混合溶媒0.9gとした以外は、実施例1と同様にしてプロトン伝導性ソフトエラストマー膜を得た(BSA/PD/S2VPの重量比がおおよそ4/4/2)。BSAのスルホン酸基は、S2VPのピリジル基に対して計算上、約2.5倍存在していることになる。このプロトン伝導性ソフトエラストマー膜の模式図を図5に示す。図5中、ポリスチレン部位がポリマーの第1の部位に相当し、ポリ(2−ビニルピリジン)部位がポリマーの第2の部位に相当し、BSAがプロトン放出・結合部位とプロトン配位部位の両方を同一分子に含む単一のプロトン伝導性物質に相当する。PDはあってもなくてもよい。ポリスチレンのTg(ガラス転移温度)は約100℃、ポリ(2−ビニルピリジン)のTgは約100℃、BSAの融点は室温以下、PDの融点は−59℃である。ポリ(2−ビニルピリジン)のピリジル基とBSAのスルホン酸基とはイオン結合している。実施例4では、プロトン伝導混合相であるBSAとPDとポリ(2−ビニルピリジン)とからなる混合物は、ポリスチレンに固定化されている。またPDはBSAと静電相互作用していると考えられる。ポリ(2−ビニルピリジン)を含有したプロトン伝導混合相(図5の1点鎖線で囲んだ部分)のTgは室温以下であり、交流インピーダンス測定の温度(47℃〜95℃)では溶融状態である。

ABジブロック共重合体として、ポリスチレン−b−ポリ(2−ビニルピリジン)(以下、S2VPという)を、Macromolecules 45, 8013-8020(2012)に記載のブロック共重合体合成法(可逆的付加開裂連鎖移動重合法)を参考にして合成した。ゲル浸透クロマトグラフィー(GPC)、核磁気共鳴分光法により、平均重合度、分子量分布(Mw/Mn)を決定した。ポリスチレンの平均重合度は307、ポリ(2−ビニルピリジン)の平均重合度は390、分子量分布Mw/Mnは1.39であった。

Claims (10)

- 無加湿な状態でプロトン伝導性を示すプロトン伝導膜であって、

ガラス転移温度又は融解温度が前記プロトン伝導膜の使用温度より高いガラス状又は結晶性の第1の部位と他の分子に非共有結合可能な官能基を有する第2の部位とを含むポリマーと、

プロトンを放出可能で前記ポリマーの第2の部位に非共有結合可能な官能基を有するプロトン放出・結合部位とプロトンに配位可能なプロトン配位部位とを相互作用し合う異なる分子に別々に含むか同一分子内に含むプロトン伝導性物質と、

を備え、

前記プロトン伝導性物質の前記プロトン放出・結合部位が結合した前記第2の部位と前記プロトン伝導性物質とを含むプロトン伝導混合相のガラス転移温度は、前記プロトン伝導膜の使用温度より低く、

前記プロトン放出・結合部位は、前記ポリマーの第2の部位よりも過多に存在している、

無加湿系プロトン伝導膜。 - 前記第2の部位は前記官能基として塩基性基を有し、前記プロトン放出・結合部位は前記官能基として酸性基を有する、

請求項1に記載の無加湿系プロトン伝導膜。 - 前記塩基性基は含窒素複素環であり、前記酸性基はカルボン酸基、リン酸基、スルホン酸基及びスルホニルイミド基の少なくとも1つである、

請求項2に記載の無加湿系プロトン伝導膜。 - 前記酸性基はスルホン酸基及びスルホニルイミド基の少なくとも1つである、

請求項3に記載の無加湿系プロトン伝導膜。 - 前記プロトン配位部位は、エーテル結合、エステル基、アルコール基、ケトン基及びアミド基の少なくとも1つである、

請求項1〜4のいずれか1項に記載の無加湿系プロトン伝導膜。 - 前記プロトン配位部位は、エーテル結合及びアルコール基の少なくとも1つである、

請求項1〜5のいずれか1項に記載の無加湿系プロトン伝導膜。 - 前記プロトン伝導性物質は、前記プロトン放出・結合部位を含む物質Xと、前記プロトン配位部位を含み前記物質Xと相互作用し合う非水の物質Yとを混合した物質であり、

前記物質Xは、スルホン酸基を側鎖に有するポリマー及びスルホニルイミド基を有するフッ素化合物の少なくとも一つであり、

前記物質Yは、エーテル結合を有するプロトン性溶媒及びアルコール基を有する重合体の少なくとも一つである、

請求項1〜6のいずれか1項に記載の無加湿系プロトン伝導膜。 - 前記プロトン伝導性物質は、前記プロトン放出・結合部位と前記プロトン配位部位とを同一分子内に含む単一の純物質であり、エーテル結合を有するジスルホン酸である、

請求項1〜6のいずれか1項に記載の無加湿系プロトン伝導膜。 - 請求項1〜8のいずれか1項に記載の無加湿系プロトン伝導膜を製造する方法であって、

(a)前記ポリマーと前記プロトン伝導性物質とを溶媒に溶解又は分散させることにより混合溶液又は分散液を得る工程と、

(b)前記混合溶液中又は前記分散液中の溶媒を蒸発させることにより前記無加湿系プロトン伝導膜を得る工程と、

を含む無加湿系プロトン伝導膜の製法。 - アノードとカソードとの間に請求項1〜8のいずれか1項に記載の無加湿系プロトン伝導膜が配置された、燃料電池。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016085786 | 2016-04-22 | ||

| JP2016085786 | 2016-04-22 | ||

| PCT/JP2017/012358 WO2017183397A1 (ja) | 2016-04-22 | 2017-03-27 | 無加湿系プロトン伝導膜,その製法及び燃料電池 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2017183397A1 JPWO2017183397A1 (ja) | 2019-02-28 |

| JP6869552B2 true JP6869552B2 (ja) | 2021-05-12 |

Family

ID=60116074

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018513087A Active JP6869552B2 (ja) | 2016-04-22 | 2017-03-27 | 無加湿系プロトン伝導膜,その製法及び燃料電池 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US10749200B2 (ja) |

| JP (1) | JP6869552B2 (ja) |

| WO (1) | WO2017183397A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7103912B2 (ja) * | 2018-10-24 | 2022-07-20 | トヨタ自動車株式会社 | 橋架け構造を有するプロトン伝導膜及び燃料電池 |

| JP7636291B2 (ja) | 2021-08-04 | 2025-02-26 | トヨタ自動車株式会社 | プロトン伝導材料 |

| WO2023120731A1 (ja) | 2021-12-24 | 2023-06-29 | 国立大学法人東海国立大学機構 | 酸性官能基を高密度で有するポリマーをベースとした高分子電解質膜 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5525436A (en) | 1994-11-01 | 1996-06-11 | Case Western Reserve University | Proton conducting polymers used as membranes |

| CN1439032A (zh) * | 2000-06-02 | 2003-08-27 | Sri国际公司 | 聚合物组合物 |

| JP5021864B2 (ja) | 2001-02-21 | 2012-09-12 | パナソニック株式会社 | 固体高分子電解質型燃料電池用膜・電極接合体および固体高分子電解質膜 |

| WO2002058178A1 (en) * | 2001-01-19 | 2002-07-25 | Matsushita Electric Industrial Co., Ltd. | Method for manufacturing fuel cell elecrolyte film-electrode bond |

| WO2003062493A1 (en) * | 2002-01-23 | 2003-07-31 | Polyfuel, Inc. | Acid-base proton conducting polymer blend membrane |

| JP3978493B2 (ja) * | 2003-05-06 | 2007-09-19 | 国立大学法人長岡技術科学大学 | 固体高分子電解質及びその製造方法 |

| JP4798974B2 (ja) * | 2004-08-17 | 2011-10-19 | 旭化成イーマテリアルズ株式会社 | 高分子固体電解質膜の製造方法 |

| KR100657939B1 (ko) * | 2004-12-24 | 2006-12-14 | 삼성에스디아이 주식회사 | 프로톤 전도체, 이를 포함한 고분자 전해질 및 이를채용한 연료전지 |

| JP2007200794A (ja) * | 2006-01-30 | 2007-08-09 | Matsushita Electric Ind Co Ltd | 酸塩基複合電解質とその製造方法、およびそれを含む膜電極複合体、燃料電池 |

| KR101381149B1 (ko) * | 2012-07-20 | 2014-04-10 | 한국에너지기술연구원 | 나피온 이오노머 용액에서 테트라에톡시실란의 인시튜 졸-겔 반응을 통한 촉매층 제조방법 |

-

2017

- 2017-03-27 JP JP2018513087A patent/JP6869552B2/ja active Active

- 2017-03-27 WO PCT/JP2017/012358 patent/WO2017183397A1/ja not_active Ceased

- 2017-03-27 US US16/095,588 patent/US10749200B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| WO2017183397A1 (ja) | 2017-10-26 |

| JPWO2017183397A1 (ja) | 2019-02-28 |

| US20190109343A1 (en) | 2019-04-11 |

| US10749200B2 (en) | 2020-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Liu et al. | Multifunctional poly (ionic liquid) s cross-linked polybenzimidazole membrane with excellent long-term stability for high temperature-proton exchange membranes fuel cells | |

| Jangu et al. | Sulfonimide-containing triblock copolymers for improved conductivity and mechanical performance | |

| Li et al. | A new class of highly-conducting polymer electrolyte membranes: Aromatic ABA triblock copolymers | |

| US8182949B2 (en) | Polymer electrolyte membrane and process for preparation thereof, and membrane-electrode assembly and polymer electrolyte fuel cell | |

| EP1798795B1 (en) | Polyelectrolyte material, polyelectrolyte component, membrane electrode composite body, and polyelectrolyte type fuel cell | |

| US8455141B2 (en) | Polymer electrolyte as well as polymer electrolyte membrane, membrane electrode assembly and polymer electrolyte fuel cell using the same | |

| Lee et al. | Fluorinated aromatic polyether ionomers containing perfluorocyclobutyl as cross-link groups for fuel cell applications | |

| Ghorai et al. | Chemically stable sulfonated polytriazoles containing trifluoromethyl and phosphine oxide moieties for proton exchange membranes | |

| WO2006068279A1 (ja) | イオン伝導性バインダー、膜−電極接合体及び燃料電池 | |

| WO2008143303A1 (en) | Polymer electrolyte composite film, membrane-electrode assembly and fuel cell | |

| Xu et al. | Performance dependence of swelling-filling treated Nafion membrane on nano-structure of macromolecular filler | |

| JP6869552B2 (ja) | 無加湿系プロトン伝導膜,その製法及び燃料電池 | |

| JP2020068130A (ja) | 橋架け構造を有するプロトン伝導膜及び燃料電池 | |

| JP2017216187A (ja) | 複合ナノファイバーおよび該ナノファイバーを含む電解質膜 | |

| Kalamaras et al. | Thermal crosslinking of aromatic polyethers bearing pyridine groups for use as high temperature polymer electrolytes | |

| Shin et al. | Effect of crosslinking on the durability and electrochemical performance of sulfonated aromatic polymer membranes at elevated temperatures | |

| JP5764956B2 (ja) | 固体電解質膜およびその製造方法 | |

| KR101350382B1 (ko) | 스타이렌-부타디엔 삼중 블록 공중합체, 및 이의 제조 방법 | |

| KR100843569B1 (ko) | 수소이온 전도성 복합 트리블록 공중합체 전해질막 및 그제조방법 | |

| Yin et al. | Enhancement in proton conductivity by blending poly (polyoxometalate)-b-poly (hexanoic acid) block copolymers with sulfonated polysulfone | |

| Anley et al. | Polybenzimidazole membranes doped with sulfonic acid-containing covalent organic frameworks and polymers for enhanced performance in vanadium redox flow batteries | |

| EP1691440A1 (en) | Solid electrolyte, method for producing the solid electrolyte, membrane, membrane electrode assembly and fuel cell comprising the solid electrolyte | |

| CN100463263C (zh) | 固体高分子电解质膜、其制造方法以及固体高分子型燃料电池 | |

| JP2006244994A (ja) | 固体電解質、固体電解質の製造方法、電極膜接合体および燃料電池 | |

| JP2022098788A (ja) | フィラーを含有するプロトン伝導性電解質膜及び燃料電池 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200316 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210323 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210407 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6869552 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |