JP6668616B2 - コンベヤベルト - Google Patents

コンベヤベルト Download PDFInfo

- Publication number

- JP6668616B2 JP6668616B2 JP2015112881A JP2015112881A JP6668616B2 JP 6668616 B2 JP6668616 B2 JP 6668616B2 JP 2015112881 A JP2015112881 A JP 2015112881A JP 2015112881 A JP2015112881 A JP 2015112881A JP 6668616 B2 JP6668616 B2 JP 6668616B2

- Authority

- JP

- Japan

- Prior art keywords

- steel

- conveyor belt

- steel cord

- core layer

- less

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910000831 Steel Inorganic materials 0.000 claims description 107

- 239000010959 steel Substances 0.000 claims description 107

- 239000012792 core layer Substances 0.000 claims description 37

- 229920001971 elastomer Polymers 0.000 claims description 29

- 239000005060 rubber Substances 0.000 claims description 29

- 239000000835 fiber Substances 0.000 claims description 8

- 239000011347 resin Substances 0.000 claims description 3

- 229920005989 resin Polymers 0.000 claims description 3

- 238000009940 knitting Methods 0.000 claims description 2

- 238000010276 construction Methods 0.000 claims 2

- 238000004519 manufacturing process Methods 0.000 description 14

- 230000002093 peripheral effect Effects 0.000 description 9

- 238000004073 vulcanization Methods 0.000 description 8

- 230000003014 reinforcing effect Effects 0.000 description 6

- 230000004048 modification Effects 0.000 description 4

- 238000012986 modification Methods 0.000 description 4

- 239000010410 layer Substances 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 229920002292 Nylon 6 Polymers 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- 229920002978 Vinylon Polymers 0.000 description 1

- 229920006231 aramid fiber Polymers 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229920003244 diene elastomer Polymers 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920006306 polyurethane fiber Polymers 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000002964 rayon Substances 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G15/00—Conveyors having endless load-conveying surfaces, i.e. belts and like continuous members, to which tractive effort is transmitted by means other than endless driving elements of similar configuration

- B65G15/30—Belts or like endless load-carriers

- B65G15/32—Belts or like endless load-carriers made of rubber or plastics

- B65G15/34—Belts or like endless load-carriers made of rubber or plastics with reinforcing layers, e.g. of fabric

- B65G15/36—Belts or like endless load-carriers made of rubber or plastics with reinforcing layers, e.g. of fabric the layers incorporating ropes, chains, or rolled steel sections

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D1/00—Woven fabrics designed to make specified articles

- D03D1/0094—Belts

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/242—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads inorganic, e.g. basalt

- D03D15/25—Metal

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/283—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads synthetic polymer-based, e.g. polyamide or polyester fibres

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/60—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the warp or weft elements other than yarns or threads

- D03D15/62—Cords or ropes

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0673—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core having a rope configuration

- D07B1/068—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core having a rope configuration characterised by the strand design

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0606—Reinforcing cords for rubber or plastic articles

- D07B1/062—Reinforcing cords for rubber or plastic articles the reinforcing cords being characterised by the strand configuration

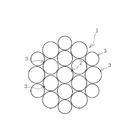

- D07B1/0626—Reinforcing cords for rubber or plastic articles the reinforcing cords being characterised by the strand configuration the reinforcing cords consisting of three core wires or filaments and at least one layer of outer wires or filaments, i.e. a 3+N configuration

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0606—Reinforcing cords for rubber or plastic articles

- D07B1/062—Reinforcing cords for rubber or plastic articles the reinforcing cords being characterised by the strand configuration

- D07B1/0633—Reinforcing cords for rubber or plastic articles the reinforcing cords being characterised by the strand configuration having a multiple-layer configuration

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2501/00—Application field

- D07B2501/20—Application field related to ropes or cables

- D07B2501/2076—Power transmissions

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2101/00—Inorganic fibres

- D10B2101/20—Metallic fibres

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2505/00—Industrial

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Belt Conveyors (AREA)

- Ropes Or Cables (AREA)

Description

2 芯線

3 側線

4 横糸

5 心体層

6 上カバーゴム

7 下カバーゴム

8 クッションゴム

9 コンベヤベルト

Claims (4)

- 横並び状態で延在する多数本のスチールコードにより構成される心体層と、この心体層を挟んで上下にそれぞれ配置される上カバーゴムおよび下カバーゴムとを備え、前記スチールコードが長手方向に延在して埋設されたコンベヤベルトにおいて、

前記スチールコードの外径が0.35mm以上6.0mm以下であり、前記スチールコードの横並びピッチが0.35mm超7.0mm以下であり、それぞれの前記スチールコードが複数本のスチールワイヤを撚り合わせて形成されていて、横並び状態の前記スチールコードの間を上下に縫うように通過して横断する複数本の横糸を備え、これら複数本の前記横糸の前記スチールコードの長手方向に隣り合うどうしが互いに前記スチールコードの長手方向に16mm以上500mm以下の間隔をあけて配置されていて、それぞれの前記横糸が前記スチールコードよりも細径の樹脂繊維であることを特徴とするコンベヤベルト。 - 前記スチールコードの構造が、1+6構成コード、3+6構成コード、1+19構成コード、1+Sew(19)構成コードのいずれか1つの構成コードであり、前記スチールコードの撚り倍数が9以上14以下である請求項1に記載のコンベヤベルト。

- 前記スチールコードを構成する側線に外径の異なる2種類のスチールワイヤが使用されていて、相対的に小径の前記スチールワイヤの外径が、相対的に大径の前記スチールワイヤの外径の60%以上90%以下に設定されている請求項2に記載のコンベヤベルト。

- それぞれの前記横糸が複数本の長繊維を編み合わせて構成され、繊度が300dtex以上5000dtex以下である請求項1〜3のいずれかに記載のコンベヤベルト。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015112881A JP6668616B2 (ja) | 2015-06-03 | 2015-06-03 | コンベヤベルト |

| AU2016269892A AU2016269892B2 (en) | 2015-06-03 | 2016-05-11 | Conveyor belt |

| CN201680027989.2A CN107614399A (zh) | 2015-06-03 | 2016-05-11 | 传送带 |

| PCT/JP2016/064051 WO2016194569A1 (ja) | 2015-06-03 | 2016-05-11 | コンベヤベルト |

| RU2017143144A RU2678945C1 (ru) | 2015-06-03 | 2016-05-11 | Транспортерная лента |

| US15/578,680 US10160600B2 (en) | 2015-06-03 | 2016-05-11 | Conveyor belt |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015112881A JP6668616B2 (ja) | 2015-06-03 | 2015-06-03 | コンベヤベルト |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2016222441A JP2016222441A (ja) | 2016-12-28 |

| JP6668616B2 true JP6668616B2 (ja) | 2020-03-18 |

Family

ID=57441004

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015112881A Active JP6668616B2 (ja) | 2015-06-03 | 2015-06-03 | コンベヤベルト |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10160600B2 (ja) |

| JP (1) | JP6668616B2 (ja) |

| CN (1) | CN107614399A (ja) |

| AU (1) | AU2016269892B2 (ja) |

| RU (1) | RU2678945C1 (ja) |

| WO (1) | WO2016194569A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6620430B2 (ja) * | 2015-06-03 | 2019-12-18 | 横浜ゴム株式会社 | ゴム製品用補強層 |

| WO2017110076A1 (ja) * | 2015-12-21 | 2017-06-29 | 日本板硝子株式会社 | ゴム補強用コード及びそれを用いたゴム製品 |

| JP6819242B2 (ja) * | 2016-11-24 | 2021-01-27 | 横浜ゴム株式会社 | コンベヤベルトでのループコイルの埋設深さの設定方法およびコンベヤベルトの製造方法 |

| FI3645442T3 (fi) * | 2017-06-27 | 2024-08-22 | Bekaert Advanced Cords Aalter Nv | Terässäikeillä vahvistettu hihna |

| JP7281573B2 (ja) * | 2021-04-06 | 2023-05-25 | 三ツ星ベルト株式会社 | 歯付ベルト |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8424086D0 (en) | 1984-09-24 | 1984-10-31 | Bekaert Sa Nv | Steel cord |

| JPH04209115A (ja) * | 1990-11-30 | 1992-07-30 | Nkk Corp | 人員輸送用ベルトおよびその製造方法 |

| US5609242A (en) * | 1995-07-12 | 1997-03-11 | The Goodyear Tire & Rubber Company | Steel cable conveyor belt with improved penetration and rip resistance |

| JP3349443B2 (ja) * | 1998-07-29 | 2002-11-25 | 住友ゴム工業株式会社 | 金属コード及びそれを用いた空気入りタイヤ |

| CN2411234Y (zh) * | 1999-12-25 | 2000-12-20 | 青岛第六橡胶厂 | 具有可拉伸变形耐冲击防撕裂增强层的输送带 |

| JP2009114592A (ja) * | 2007-11-08 | 2009-05-28 | Yokohama Rubber Co Ltd:The | ゴム補強用スチールコード及びそれを用いた空気入りラジアルタイヤ |

| ATE550462T1 (de) * | 2009-01-16 | 2012-04-15 | Teijin Fibers Ltd | Polyesterfaser, verfahren zur herstellung der polyesterfaser sowie reifencord, reifen, fasermaterial zur bandverstärkung und band, allesamt mit dieser polyesterfaser |

| JP5625604B2 (ja) | 2010-08-11 | 2014-11-19 | 横浜ゴム株式会社 | ゴム補強用スチールコード |

| JP5934005B2 (ja) * | 2012-03-27 | 2016-06-15 | 帝人株式会社 | ゴム補強用繊維コード及びそれを用いてなるゴム・繊維複合体 |

| JP5825234B2 (ja) * | 2012-09-11 | 2015-12-02 | 横浜ゴム株式会社 | ゴム補強用スチールコードおよびコンベヤベルト |

| JP2014201853A (ja) * | 2013-04-05 | 2014-10-27 | 横浜ゴム株式会社 | コンベヤベルト用繊維補強層 |

| CN104444068A (zh) * | 2013-09-17 | 2015-03-25 | 天津市天水工业用带有限公司 | 钢丝绳输送带 |

| CN203682362U (zh) * | 2014-01-23 | 2014-07-02 | 青岛华夏橡胶工业有限公司 | 轻型高强力钢丝绳芯输送带 |

-

2015

- 2015-06-03 JP JP2015112881A patent/JP6668616B2/ja active Active

-

2016

- 2016-05-11 AU AU2016269892A patent/AU2016269892B2/en not_active Ceased

- 2016-05-11 WO PCT/JP2016/064051 patent/WO2016194569A1/ja not_active Ceased

- 2016-05-11 CN CN201680027989.2A patent/CN107614399A/zh active Pending

- 2016-05-11 RU RU2017143144A patent/RU2678945C1/ru active

- 2016-05-11 US US15/578,680 patent/US10160600B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| AU2016269892B2 (en) | 2019-01-17 |

| AU2016269892A1 (en) | 2017-12-07 |

| WO2016194569A1 (ja) | 2016-12-08 |

| US20180148263A1 (en) | 2018-05-31 |

| US10160600B2 (en) | 2018-12-25 |

| JP2016222441A (ja) | 2016-12-28 |

| RU2678945C1 (ru) | 2019-02-04 |

| CN107614399A (zh) | 2018-01-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6668616B2 (ja) | コンベヤベルト | |

| CN107109786B (zh) | 电梯绳和制造所述电梯绳的方法 | |

| JP2012507440A5 (ja) | ||

| CN106957619A (zh) | 胶带、特别是用于缠绕汽车中的缆线的缠绕带 | |

| CN109281026B (zh) | 一种高渗胶性能子午钢丝帘线 | |

| JP6343872B2 (ja) | スチールコードおよびゴム製品の製造方法 | |

| KR20160043856A (ko) | 타이어 보강용 스틸코드 | |

| CN111247292B (zh) | 弹性体加强用钢帘线 | |

| CA2908763A1 (en) | Fiber reinforcement layer for conveyor belts | |

| JP6177198B2 (ja) | 歯付きベルト | |

| JP6620430B2 (ja) | ゴム製品用補強層 | |

| CN209975022U (zh) | 一种高渗胶性能子午钢丝帘线 | |

| JP6024081B2 (ja) | 空気入りラジアルタイヤ及びその製造方法 | |

| JPH083886A (ja) | スチールコードおよびタイヤ | |

| CN218951834U (zh) | 一种全钢子午胎用3×(2+3)结构的钢丝帘线 | |

| CN217266599U (zh) | 一种高强度、耐冲击超细纤维迪尼玛绳 | |

| JPH08118907A (ja) | ゴム補強用スチールコードおよびこれを使用したラジアルタイヤ | |

| JP5863712B2 (ja) | 自動車の補機駆動ベルト伝動装置及びそれに用いるvリブドベルト | |

| JP2008115974A (ja) | 動力伝動用ベルト | |

| JP5504580B2 (ja) | コンベヤベルト | |

| KR200459038Y1 (ko) | 이단 피복 로프 | |

| CN207331168U (zh) | 一种输送带用编织骨架及输送带 | |

| WO2020113605A1 (zh) | 一种2+2+8×n结构的高渗胶性能钢丝帘线 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180601 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190702 |

|

| RD07 | Notification of extinguishment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7427 Effective date: 20190731 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190805 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200128 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200210 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6668616 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |