JP6326257B2 - 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 - Google Patents

燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 Download PDFInfo

- Publication number

- JP6326257B2 JP6326257B2 JP2014060080A JP2014060080A JP6326257B2 JP 6326257 B2 JP6326257 B2 JP 6326257B2 JP 2014060080 A JP2014060080 A JP 2014060080A JP 2014060080 A JP2014060080 A JP 2014060080A JP 6326257 B2 JP6326257 B2 JP 6326257B2

- Authority

- JP

- Japan

- Prior art keywords

- exhaust gas

- catalyst

- combustion exhaust

- denitration

- zeolite

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/064—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof containing iron group metals, noble metals or copper

- B01J29/072—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

- B01D53/9413—Processes characterised by a specific catalyst

- B01D53/9418—Processes characterised by a specific catalyst for removing nitrogen oxides by selective catalytic reduction [SCR] using a reducing agent in a lean exhaust gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/74—Iron group metals

- B01J23/75—Cobalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/40—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively

- B01J29/42—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively containing iron group metals, noble metals or copper

- B01J29/46—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/65—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the ferrierite type, e.g. types ZSM-21, ZSM-35 or ZSM-38, as exemplified by patent documents US4046859, US4016245 and US4046859, respectively

- B01J29/66—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the ferrierite type, e.g. types ZSM-21, ZSM-35 or ZSM-38, as exemplified by patent documents US4046859, US4016245 and US4046859, respectively containing iron group metals, noble metals or copper

- B01J29/68—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/19—Catalysts containing parts with different compositions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/0009—Use of binding agents; Moulding; Pressing; Powdering; Granulating; Addition of materials ameliorating the mechanical properties of the product catalyst

- B01J37/0018—Addition of a binding agent or of material, later completely removed among others as result of heat treatment, leaching or washing,(e.g. forming of pores; protective layer, desintegrating by heat)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0201—Impregnation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/16—Reducing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2251/00—Reactants

- B01D2251/20—Reductants

- B01D2251/208—Hydrocarbons

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20746—Cobalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/50—Zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/50—Zeolites

- B01D2255/504—ZSM 5 zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/10—After treatment, characterised by the effect to be obtained

- B01J2229/18—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself

- B01J2229/186—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself not in framework positions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/30—After treatment, characterised by the means used

- B01J2229/40—Special temperature treatment, i.e. other than just for template removal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2235/00—Indexing scheme associated with group B01J35/00, related to the analysis techniques used to determine the catalysts form or properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2235/00—Indexing scheme associated with group B01J35/00, related to the analysis techniques used to determine the catalysts form or properties

- B01J2235/15—X-ray diffraction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/024—Multiple impregnation or coating

- B01J37/0246—Coatings comprising a zeolite

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2370/00—Selection of materials for exhaust purification

- F01N2370/02—Selection of materials for exhaust purification used in catalytic reactors

- F01N2370/04—Zeolitic material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2570/00—Exhaust treating apparatus eliminating, absorbing or adsorbing specific elements or compounds

- F01N2570/14—Nitrogen oxides

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Environmental & Geological Engineering (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Biomedical Technology (AREA)

- Toxicology (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

- Catalysts (AREA)

- Exhaust Gas After Treatment (AREA)

Description

(Co/MFIゼオライト触媒の調製)

本発明の燃焼排ガス浄化用脱硝触媒として、MFI(ZSM−5)型ゼオライトにコバルト(Co)を担持させた触媒を製造した。

上記実施例1の場合と同様にして、本発明の燃焼排ガス浄化用脱硝触媒を製造するが、上記実施例1の場合と異なる点は、実施例2では、市販のMFI型ゼオライトの焼成条件を、700℃で12時間とし、実施例3では、市販のMFI型ゼオライトの焼成条件を、700℃で24時間とし、実施例4では、市販のMFI型ゼオライトの焼成条件を、700℃で36時間とした点にある。

上記実施例2の場合と同様にして、本発明の燃焼排ガス浄化用脱硝触媒を製造するが、上記実施例2の場合と異なる点は、ゼオライトとして市販のフェリエライト(FER)型ゼオライト(商品名HSZ−720NHA、東ソー株式会社製)を用い、Co/FERゼオライトの脱硝触媒を製造して使用した点にある。

比較のために、上記実施例1の場合と同様にして、燃焼排ガスの浄化用脱硝触媒を製造するが、上記実施例1の場合と異なる点は、市販のMFI型ゼオライトの焼成を行わず、未焼成のMFI型ゼオライトを使用した点にある。

比較のために、上記実施例5の場合と同様にして、燃焼排ガスの浄化用脱硝触媒を製造するが、上記実施例5の場合と異なる点は、市販のフェリエライト(FER)型ゼオライトの焼成を行わず、未焼成のFER型ゼオライトを使用した点にある。

比較のために、上記実施例1の場合と同様にして、燃焼排ガスの浄化用脱硝触媒を製造するが、上記実施例1の場合と異なる点は、比較例3では、市販のMFI型ゼオライトの焼成条件を、600℃で12時間とし、比較例4では、市販のMFI型ゼオライトの焼成条件を、800℃で12時間とした点にある。

得られた脱硝触媒性能の評価試験の結果を、上記の表1にあわせて示した。

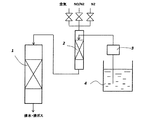

2:蒸発器

3:定量送液ポンプ

4:アルコール水溶液槽

Claims (4)

- 還元剤としてアルコールを添加した燃焼排ガスに接触させて、該排ガス中の窒素酸化物を除去する燃焼排ガスの浄化方法に用いられる脱硝触媒であって、前記脱硝触媒が、担体であるゼオライトに触媒金属が担持されたものであり、かつ前記脱硝触媒の粉末X線回折測定において回折角(2θ)=7.8〜10.0°の回折ピーク高さIと、同回折角(2θ)=28.0〜31.0°の回折ピーク高さJとの比r=I/Jが、3.0〜5.0の範囲にあることを特徴とする、燃焼排ガス浄化用触媒。

- 触媒金属が、コバルト(Co)であることを特徴とする、請求項1に記載の燃焼排ガス浄化用触媒。

- 還元剤としてのアルコールが、メタノール、またはエタノールであることを特徴とする、請求項1または2に記載の燃焼排ガス浄化用触媒。

- 燃焼排ガスの浄化方法であって、ゼオライトよりなる担体に触媒金属が担持されかつ粉末X線回折測定において回折角(2θ)=7.8〜10.0°の回折ピーク高さIと、同回折角(2θ)=28.0〜31.0°の回折ピーク高さJとの比r=I/Jが、3.0〜5.0の範囲にある脱硝触媒に、還元剤としてアルコールを添加した燃焼排ガスを接触させることにより、排ガス中の窒素酸化物を除去することを特徴とする、燃焼排ガスの浄化方法。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014060080A JP6326257B2 (ja) | 2014-03-24 | 2014-03-24 | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 |

| CN201580015047.8A CN106132539B (zh) | 2014-03-24 | 2015-03-23 | 燃烧废气净化用催化剂和燃烧废气的净化方法 |

| EP15769841.6A EP3124113A4 (en) | 2014-03-24 | 2015-03-23 | Combustion exhaust gas purifying catalyst and method for purifying combustion exhaust gas |

| KR1020167024714A KR102363752B1 (ko) | 2014-03-24 | 2015-03-23 | 연소배기가스 정화용 촉매 및 연소배기가스의 정화방법 |

| US15/125,730 US10112183B2 (en) | 2014-03-24 | 2015-03-23 | Catalyst for purifying combustion exhaust gas, and method for purifying combustion exhaust gas |

| PCT/JP2015/058742 WO2015146913A1 (ja) | 2014-03-24 | 2015-03-23 | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014060080A JP6326257B2 (ja) | 2014-03-24 | 2014-03-24 | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015182005A JP2015182005A (ja) | 2015-10-22 |

| JP2015182005A5 JP2015182005A5 (ja) | 2017-02-09 |

| JP6326257B2 true JP6326257B2 (ja) | 2018-05-16 |

Family

ID=54195426

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014060080A Active JP6326257B2 (ja) | 2014-03-24 | 2014-03-24 | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10112183B2 (ja) |

| EP (1) | EP3124113A4 (ja) |

| JP (1) | JP6326257B2 (ja) |

| KR (1) | KR102363752B1 (ja) |

| CN (1) | CN106132539B (ja) |

| WO (1) | WO2015146913A1 (ja) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6232223B2 (ja) * | 2013-07-25 | 2017-11-15 | 日立造船株式会社 | 排ガス浄化方法 |

| CN120054605A (zh) * | 2023-11-22 | 2025-05-30 | 陈海军 | 含钒fer型沸石及其应用 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0543222A (ja) * | 1991-08-16 | 1993-02-23 | Tosoh Corp | Co3O4含有ゼオライト及びその製造方法 |

| JPH0543221A (ja) * | 1991-08-16 | 1993-02-23 | Tosoh Corp | コバルト化合物含有ゼオライト及びその製造方法 |

| JPH07303820A (ja) * | 1994-03-14 | 1995-11-21 | Sekiyu Sangyo Kasseika Center | 窒素酸化物の接触還元方法 |

| JP4172828B2 (ja) * | 1996-07-24 | 2008-10-29 | 株式会社明電舎 | 脱硝剤および排気ガス中の窒素酸化物の除去方法 |

| JP2004358454A (ja) | 2003-04-11 | 2004-12-24 | Sumitomo Metal Mining Co Ltd | 排ガス浄化触媒及び浄化方法 |

| JP2006220107A (ja) | 2005-02-14 | 2006-08-24 | Sumitomo Metal Mining Co Ltd | 排ガスの脱硝浄化方法及びその装置 |

| CN101723404A (zh) | 2008-10-24 | 2010-06-09 | 北京化工大学 | 一种高过渡金属含量分子筛的制备方法 |

| MX2012003978A (es) * | 2009-10-14 | 2012-05-08 | Basf Catalysts Llc | Tamiz molecular de levyne que contiene cobre para la reduccion selectiva de nox. |

| JP6051084B2 (ja) * | 2012-03-30 | 2016-12-21 | 日立造船株式会社 | 燃焼排ガスの浄化方法、および脱硝触媒 |

| JP6185598B2 (ja) * | 2012-12-07 | 2017-08-23 | エクソンモービル リサーチ アンド エンジニアリング カンパニーExxon Research And Engineering Company | 改善された形態を有するzsm−5結晶の合成 |

-

2014

- 2014-03-24 JP JP2014060080A patent/JP6326257B2/ja active Active

-

2015

- 2015-03-23 CN CN201580015047.8A patent/CN106132539B/zh active Active

- 2015-03-23 WO PCT/JP2015/058742 patent/WO2015146913A1/ja not_active Ceased

- 2015-03-23 US US15/125,730 patent/US10112183B2/en active Active

- 2015-03-23 KR KR1020167024714A patent/KR102363752B1/ko active Active

- 2015-03-23 EP EP15769841.6A patent/EP3124113A4/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| KR20160137995A (ko) | 2016-12-02 |

| US20170001181A1 (en) | 2017-01-05 |

| JP2015182005A (ja) | 2015-10-22 |

| KR102363752B1 (ko) | 2022-02-15 |

| US10112183B2 (en) | 2018-10-30 |

| WO2015146913A1 (ja) | 2015-10-01 |

| EP3124113A1 (en) | 2017-02-01 |

| CN106132539B (zh) | 2019-02-19 |

| EP3124113A4 (en) | 2017-09-27 |

| CN106132539A (zh) | 2016-11-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6572133B2 (ja) | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 | |

| KR101950670B1 (ko) | 금속 도핑된 제올라이트 및 제오타입의 제조 방법 및 질소 산화물의 촉매 정화에 대한 이들의 적용 | |

| JP5431160B2 (ja) | ジルコニウムおよびケイ素の酸化物とならびにチタン、アルミニウム、タングステン、モリブデン、セリウム、鉄、スズ、亜鉛およびマンガンから選択される少なくとも1種類の他の元素の酸化物とを含有する高酸性度組成物 | |

| CN102166522B (zh) | 一种烟气脱硝催化剂及其制备和应用 | |

| JP5987010B2 (ja) | ジルコニウム、セリウムおよびニオブを含む組成物を触媒として用いて、酸化窒素(NOx)を含有するガスを処理する方法 | |

| EP3487620A1 (en) | Catalyst composite and use thereof in the selective catalytic reduction of nox | |

| KR101629483B1 (ko) | 바나듐계 탈질촉매 및 그 제조방법 | |

| CN104941630A (zh) | 一种低温高活性烟气脱硝催化剂及其制备 | |

| CN104772162A (zh) | 低温NH3还原NOx的Zr-Ce-Mn-Fe/ZSM-5复合氧化物催化剂及其制备方法 | |

| JP2022529175A (ja) | NOxの選択的還元のための、AFX構造を有するゼオライトと少なくとも1つの遷移金属を含む触媒の急速合成 | |

| JP6326257B2 (ja) | 燃焼排ガス浄化用触媒、および燃焼排ガスの浄化方法 | |

| JP6886776B2 (ja) | 排ガス浄化触媒 | |

| JPWO2012086413A1 (ja) | 脱硝触媒用担体、脱硝触媒及び脱硝装置 | |

| JP5164821B2 (ja) | 窒素酸化物選択的接触還元用触媒 | |

| KR20080113565A (ko) | 선택적 촉매 환원 반응용 철 담지 제올라이트 촉매의제조방법 | |

| JP6051084B2 (ja) | 燃焼排ガスの浄化方法、および脱硝触媒 | |

| JP6134552B2 (ja) | 燃焼排ガスの浄化方法、および脱硝触媒 | |

| CN112188929B (zh) | 用于nox选择性还原的包含afx结构沸石和bea结构沸石的混合物以及至少一种过渡金属的催化剂 | |

| KR101629487B1 (ko) | 저온에서의 질소산화물 제거용 망간-세리아-텅스텐-티타니아 촉매 및 그 제조방법 | |

| JP6051083B2 (ja) | 燃焼排ガスの浄化方法、および脱硝触媒 | |

| RU2647847C1 (ru) | Катализатор, способ его приготовления и способ очистки отходящих газов от оксидов азота | |

| WO2014087910A1 (ja) | 燃焼排ガス浄化用触媒およびこの触媒を用いる脱硝浄化方法 | |

| PL246810B1 (pl) | Zeolitowy katalizator do selektywnej redukcji NOx amoniakiem i sposób jego wytwarzania | |

| JPH11342336A (ja) | 窒素酸化物の分解除去用触媒a及び窒素酸化物の分解除去方法 | |

| WO2013069713A1 (ja) | 燃焼排ガス中の窒素酸化物の除去触媒および同触媒を用いる窒素酸化物の除去方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161226 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20161226 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170829 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171030 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180320 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180416 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6326257 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |