JP5921798B2 - 積層ナノモールドおよびその製造方法 - Google Patents

積層ナノモールドおよびその製造方法 Download PDFInfo

- Publication number

- JP5921798B2 JP5921798B2 JP2009540277A JP2009540277A JP5921798B2 JP 5921798 B2 JP5921798 B2 JP 5921798B2 JP 2009540277 A JP2009540277 A JP 2009540277A JP 2009540277 A JP2009540277 A JP 2009540277A JP 5921798 B2 JP5921798 B2 JP 5921798B2

- Authority

- JP

- Japan

- Prior art keywords

- pfpe

- layer

- curable

- pet

- laminate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/3842—Manufacturing moulds, e.g. shaping the mould surface by machining

- B29C33/3857—Manufacturing moulds, e.g. shaping the mould surface by machining by making impressions of one or more parts of models, e.g. shaped articles and including possible subsequent assembly of the parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/3807—Resin-bonded materials, e.g. inorganic particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/40—Plastics, e.g. foam or rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/42—Moulds or cores; Details thereof or accessories therefor characterised by the shape of the moulding surface, e.g. ribs or grooves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

- B29C43/222—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length characterised by the shape of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

- B29C43/28—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

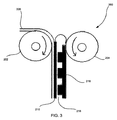

- B29C43/3697—Moulds for making articles of definite length, i.e. discrete articles comprising rollers or belts cooperating with non-rotating mould parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/16—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating

- B32B37/18—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of discrete sheets or panels only

- B32B37/182—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of discrete sheets or panels only one or more of the layers being plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0012—Mechanical treatment, e.g. roughening, deforming, stretching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82B—NANOSTRUCTURES FORMED BY MANIPULATION OF INDIVIDUAL ATOMS, MOLECULES, OR LIMITED COLLECTIONS OF ATOMS OR MOLECULES AS DISCRETE UNITS; MANUFACTURE OR TREATMENT THEREOF

- B82B3/00—Manufacture or treatment of nanostructures by manipulation of individual atoms or molecules, or limited collections of atoms or molecules as discrete units

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y10/00—Nanotechnology for information processing, storage or transmission, e.g. quantum computing or single electron logic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/0002—Lithographic processes using patterning methods other than those involving the exposure to radiation, e.g. by stamping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/38—Moulds or cores; Details thereof or accessories therefor characterised by the material or the manufacturing process

- B29C33/3842—Manufacturing moulds, e.g. shaping the mould surface by machining

- B29C2033/385—Manufacturing moulds, e.g. shaping the mould surface by machining by laminating a plurality of layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2067/00—Use of polyesters or derivatives thereof, as moulding material

- B29K2067/003—PET, i.e. poylethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2071/00—Use of polyethers, e.g. PEEK, i.e. polyether-etherketone or PEK, i.e. polyetherketone or derivatives thereof, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2667/00—Use of polyesters or derivatives thereof for preformed parts, e.g. for inserts

- B29K2667/003—PET, i.e. poylethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2867/00—Use of polyesters or derivatives thereof as mould material

- B29K2867/003—PET, i.e. polyethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2871/00—Use of polyethers, e.g. PEEK, i.e. polyether-etherketone or PEK, i.e. polyetherketone or derivatives thereof, as mould material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/756—Microarticles, nanoarticles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S425/00—Plastic article or earthenware shaping or treating: apparatus

- Y10S425/81—Sound record

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/26—Web or sheet containing structurally defined element or component, the element or component having a specified physical dimension

- Y10T428/263—Coating layer not in excess of 5 mils thick or equivalent

- Y10T428/264—Up to 3 mils

- Y10T428/265—1 mil or less

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/3154—Of fluorinated addition polymer from unsaturated monomers

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Nanotechnology (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Mathematical Physics (AREA)

- Theoretical Computer Science (AREA)

- Inorganic Chemistry (AREA)

- Laminated Bodies (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Magnetic Record Carriers (AREA)

- Manufacturing Of Magnetic Record Carriers (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/633,763 US8128393B2 (en) | 2006-12-04 | 2006-12-04 | Methods and materials for fabricating laminate nanomolds and nanoparticles therefrom |

| US11/633,763 | 2006-12-04 | ||

| PCT/US2007/024910 WO2008143650A2 (en) | 2006-12-04 | 2007-12-04 | Methods and materials for fabricating laminate nanomolds and nanoparticles therefrom |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012185449A Division JP5680597B2 (ja) | 2006-12-04 | 2012-08-24 | ナノモールドシステム |

| JP2014180817A Division JP6069272B2 (ja) | 2006-12-04 | 2014-09-05 | 積層モールドシステム |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010511544A JP2010511544A (ja) | 2010-04-15 |

| JP2010511544A5 JP2010511544A5 (cg-RX-API-DMAC7.html) | 2011-02-03 |

| JP5921798B2 true JP5921798B2 (ja) | 2016-05-24 |

Family

ID=39476167

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009540277A Active JP5921798B2 (ja) | 2006-12-04 | 2007-12-04 | 積層ナノモールドおよびその製造方法 |

| JP2012185449A Active JP5680597B2 (ja) | 2006-12-04 | 2012-08-24 | ナノモールドシステム |

| JP2014180817A Active JP6069272B2 (ja) | 2006-12-04 | 2014-09-05 | 積層モールドシステム |

| JP2016004104A Pending JP2016128258A (ja) | 2006-12-04 | 2016-01-13 | 積層ナノモールドの製造方法および材料、ならびにそれによって得られたナノ粒子 |

Family Applications After (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012185449A Active JP5680597B2 (ja) | 2006-12-04 | 2012-08-24 | ナノモールドシステム |

| JP2014180817A Active JP6069272B2 (ja) | 2006-12-04 | 2014-09-05 | 積層モールドシステム |

| JP2016004104A Pending JP2016128258A (ja) | 2006-12-04 | 2016-01-13 | 積層ナノモールドの製造方法および材料、ならびにそれによって得られたナノ粒子 |

Country Status (7)

| Country | Link |

|---|---|

| US (7) | US8128393B2 (cg-RX-API-DMAC7.html) |

| EP (2) | EP2117725B1 (cg-RX-API-DMAC7.html) |

| JP (4) | JP5921798B2 (cg-RX-API-DMAC7.html) |

| KR (3) | KR101507805B1 (cg-RX-API-DMAC7.html) |

| CN (2) | CN103831914B (cg-RX-API-DMAC7.html) |

| HK (1) | HK1253730A1 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2008143650A2 (cg-RX-API-DMAC7.html) |

Families Citing this family (80)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5931855A (en) | 1997-05-21 | 1999-08-03 | Frank Hoffman | Surgical methods using one-way suture |

| AU2004276302B2 (en) * | 2003-09-23 | 2011-02-03 | California Institute Of Technology | Photocurable perfluoropolyethers for use as novel materials in microfluidic devices |

| WO2005112787A2 (en) | 2004-05-14 | 2005-12-01 | Quill Medical, Inc. | Suture methods and devices |

| US8944804B2 (en) * | 2006-01-04 | 2015-02-03 | Liquidia Technologies, Inc. | Nanostructured surfaces for biomedical/biomaterial applications and processes thereof |

| WO2008027571A2 (en) * | 2006-08-30 | 2008-03-06 | Liquidia Technologies, Inc. | Nanoparticles having functional additives for self and directed assembly and methods of fabricating same |

| US8128393B2 (en) | 2006-12-04 | 2012-03-06 | Liquidia Technologies, Inc. | Methods and materials for fabricating laminate nanomolds and nanoparticles therefrom |

| WO2008127455A2 (en) * | 2006-12-05 | 2008-10-23 | Liquidia Technologies, Inc. | Nanoarrays and methods and materials for fabricating same |

| US8915943B2 (en) | 2007-04-13 | 2014-12-23 | Ethicon, Inc. | Self-retaining systems for surgical procedures |

| US7763484B2 (en) * | 2007-06-13 | 2010-07-27 | Sumitomo Electric Industries, Ltd. | Method to form an optical grating and to form a distributed feedback laser diode with the optical grating |

| EP2197501B8 (en) | 2007-09-27 | 2012-10-03 | Ethicon, LLC | Self-retaining sutures including tissue retainers having improved strength |

| US7976759B2 (en) * | 2007-10-12 | 2011-07-12 | Liquidia Technologies, Inc. | System and method for producing particles and patterned films |

| JP5518737B2 (ja) | 2007-12-19 | 2014-06-11 | エシコン・エルエルシー | 熱接触媒介リテーナを備えた留置縫合糸 |

| US8916077B1 (en) | 2007-12-19 | 2014-12-23 | Ethicon, Inc. | Self-retaining sutures with retainers formed from molten material |

| US8118834B1 (en) | 2007-12-20 | 2012-02-21 | Angiotech Pharmaceuticals, Inc. | Composite self-retaining sutures and method |

| WO2009097556A2 (en) | 2008-01-30 | 2009-08-06 | Angiotech Pharmaceuticals, Inc. | Appartaus and method for forming self-retaining sutures |

| US8615856B1 (en) | 2008-01-30 | 2013-12-31 | Ethicon, Inc. | Apparatus and method for forming self-retaining sutures |

| ES2706295T3 (es) | 2008-02-21 | 2019-03-28 | Ethicon Llc | Método y aparato para elevar retenedores en suturas de auto-retención |

| US8641732B1 (en) | 2008-02-26 | 2014-02-04 | Ethicon, Inc. | Self-retaining suture with variable dimension filament and method |

| SG188784A1 (en) | 2008-04-15 | 2013-04-30 | Ethicon Llc | Self-retaining sutures with bi-directional retainers or uni-directional retainers |

| US8961560B2 (en) | 2008-05-16 | 2015-02-24 | Ethicon, Inc. | Bidirectional self-retaining sutures with laser-marked and/or non-laser marked indicia and methods |

| BRPI0921810B8 (pt) | 2008-11-03 | 2021-06-22 | Angiotech Pharm Inc | montagem para inserir um comprimento de sutura no interior do corpo de um mamífero |

| BRPI0923282B1 (pt) | 2008-12-05 | 2019-09-03 | Liquidia Tech Inc | método para a produção de materiais padronizados |

| EP3243631B1 (en) | 2009-01-20 | 2019-10-23 | Gerald Rocha | Method for producing projections on a substrate |

| US8288482B2 (en) * | 2009-06-17 | 2012-10-16 | E I Du Pont De Nemours And Company | Curable fluoroelastomer compositions |

| JP5168510B2 (ja) * | 2009-08-20 | 2013-03-21 | 信越化学工業株式会社 | ナノインプリント用部材又は曲面印刷用パッド材もしくはオフセット印刷用ブランケット材 |

| US8899957B2 (en) | 2009-09-25 | 2014-12-02 | HGST Netherlands B.V. | System, method and apparatus for manufacturing magnetic recording media |

| NZ702869A (en) | 2010-05-04 | 2016-05-27 | Ethicon Llc | Self-retaining systems having laser-cut retainers |

| WO2011156733A2 (en) | 2010-06-11 | 2011-12-15 | Angiotech Pharmaceuticals, Inc. | Suture delivery tools for endoscopic and robot-assisted surgery and methods |

| MX2013005072A (es) | 2010-11-03 | 2013-12-02 | Tissuegen Inc | Hilos de sutura de autorretención eluyentes de fármacos y métodos relacionados con estos. |

| JP6013352B2 (ja) | 2010-11-09 | 2016-10-25 | エシコン・エルエルシーEthicon LLC | 緊急留置縫合糸及びパッケージ |

| KR101215299B1 (ko) * | 2010-12-30 | 2012-12-26 | 포항공과대학교 산학협력단 | 나노 임프린트 몰드 제조방법, 이 방법에 의해 제조된 나노 임프린트 몰드를 이용한 발광다이오드 제조방법 및 이 방법에 의해 제조된 발광다이오드 |

| PL2665538T3 (pl) * | 2011-01-18 | 2015-08-31 | Amazon Filters Spolka Z Ograniczona Odpowiedzialnoscia | Kompozytowe struktury filtracyjne i sposób otrzymywania kompozytowych struktur filtracyjnych |

| WO2012129534A2 (en) | 2011-03-23 | 2012-09-27 | Angiotech Pharmaceuticals, Inc. | Self-retaining variable loop sutures |

| US20130172931A1 (en) | 2011-06-06 | 2013-07-04 | Jeffrey M. Gross | Methods and devices for soft palate tissue elevation procedures |

| US10126648B2 (en) | 2012-05-25 | 2018-11-13 | Micro Resist Technology Gesellschaft Für Chemische Materialien Spezieller Protoresistsysteme Gmbh | Composition suitable for use as a release-optimized material for nanoimprint processes and uses thereof |

| EP2945687A4 (en) * | 2013-01-18 | 2016-09-14 | Univ North Carolina | PRODUCTION OF MICRONED PINS WITH HIGH THROUGHPUT |

| CN103464686B (zh) * | 2013-09-27 | 2016-04-27 | 无锡市众鑫机械制造有限公司 | 一种成型模具 |

| MX2016007345A (es) | 2013-12-06 | 2016-12-09 | Envisia Therapeutics Inc | Implante intracameral para el tratamiento de una condicion ocular. |

| WO2015095291A1 (en) * | 2013-12-19 | 2015-06-25 | Illumina, Inc. | Substrates comprising nano-patterning surfaces and methods of preparing thereof |

| KR20170018451A (ko) | 2014-06-23 | 2017-02-17 | 카본, 인크. | 다중 경화 메커니즘을 갖는 물질로부터 3차원 물체를 제조하는 방법 |

| US9575226B2 (en) * | 2014-09-22 | 2017-02-21 | The Chinese University Of Hong Kong | Positive microcontact printing |

| CA2974982A1 (en) | 2015-02-05 | 2016-08-11 | David Moore | Method of additive manufacturing by intermittent exposure |

| US10391711B2 (en) | 2015-03-05 | 2019-08-27 | Carbon, Inc. | Fabrication of three dimensional objects with multiple operating modes |

| EP4566638A3 (en) | 2015-05-29 | 2025-08-27 | Allergan, Inc. | Implant for treatment of an ocular condition |

| TWI556942B (zh) * | 2015-07-23 | 2016-11-11 | Aurotek Corp | Roller imprinting system |

| WO2017015675A1 (en) | 2015-07-23 | 2017-01-26 | Envisia Therapeutics, Inc. | Glaucoma treatment via intracameral ocular implants |

| TWI584938B (zh) * | 2015-07-23 | 2017-06-01 | Aurotek Corp | Roller imprinting system |

| TW201722965A (zh) | 2015-08-16 | 2017-07-01 | 葛蘭素史密斯克藍智慧財產發展有限公司 | 用於抗菌應用之化合物 |

| WO2017040883A1 (en) | 2015-09-04 | 2017-03-09 | Carbon, Inc. | Cyanate ester dual cure resins for additive manufacturing |

| US10975193B2 (en) | 2015-09-09 | 2021-04-13 | Carbon, Inc. | Epoxy dual cure resins for additive manufacturing |

| US10647873B2 (en) * | 2015-10-30 | 2020-05-12 | Carbon, Inc. | Dual cure article of manufacture with portions of differing solubility |

| WO2017079502A1 (en) | 2015-11-05 | 2017-05-11 | Carbon, Inc. | Silicone dual cure resins for additive manufacturing |

| EP3377045A1 (en) | 2015-11-18 | 2018-09-26 | Glaxosmithkline Intellectual Property (No. 2) Limited | Pharmaceutical compositions of ribavirin |

| EP3394673A1 (en) | 2015-12-22 | 2018-10-31 | Carbon, Inc. | Fabrication of compound products from multiple intermediates by additive manufacturing with dual cure resins |

| US10647054B2 (en) | 2015-12-22 | 2020-05-12 | Carbon, Inc. | Accelerants for additive manufacturing with dual cure resins |

| CN115195104B (zh) | 2015-12-22 | 2023-12-05 | 卡本有限公司 | 用于用双重固化树脂的增材制造的双重前体树脂系统 |

| US10501572B2 (en) | 2015-12-22 | 2019-12-10 | Carbon, Inc. | Cyclic ester dual cure resins for additive manufacturing |

| WO2017112571A1 (en) | 2015-12-22 | 2017-06-29 | Carbon, Inc. | Dual cure additive manufacturing of rigid intermediates that generate semi-rigid, flexible, or elastic final products |

| US10787583B2 (en) | 2015-12-22 | 2020-09-29 | Carbon, Inc. | Method of forming a three-dimensional object comprised of a silicone polymer or co-polymer |

| US10343331B2 (en) | 2015-12-22 | 2019-07-09 | Carbon, Inc. | Wash liquids for use in additive manufacturing with dual cure resins |

| CA3016860A1 (en) | 2016-03-07 | 2017-09-14 | Glaxosmithkline Biologicals Sa | Drug delivery particles |

| IL310250B2 (en) | 2016-05-05 | 2025-09-01 | Liquidia Tech Inc | Terpostinil in dry powder form for the treatment of pulmonary hypertension |

| US10603486B2 (en) | 2016-06-13 | 2020-03-31 | Galvani Bioelectronics Limited | Neural interface fabrication |

| US10500786B2 (en) | 2016-06-22 | 2019-12-10 | Carbon, Inc. | Dual cure resins containing microwave absorbing materials and methods of using the same |

| CN108475621A (zh) * | 2016-07-05 | 2018-08-31 | 松下知识产权经营株式会社 | 模具、压印装置及压印方法 |

| CN110023056B (zh) * | 2016-11-21 | 2021-08-24 | 卡本有限公司 | 通过递送反应性组分用于后续固化来制造三维物体的方法 |

| IL267443B2 (en) * | 2016-12-22 | 2023-10-01 | Illumina Inc | Imprinting apparatus |

| WO2018165090A1 (en) | 2017-03-09 | 2018-09-13 | Carbon, Inc. | Tough, high temperature polymers produced by stereolithography |

| WO2018237038A1 (en) | 2017-06-21 | 2018-12-27 | Carbon, Inc. | Method of additive manufacturing |

| CN107573531B (zh) * | 2017-07-13 | 2020-08-14 | 大连理工大学 | 一种液滴饼状弹跳的大尺寸超疏水圆柱阵列的热压加工方法 |

| CN107643652A (zh) | 2017-10-31 | 2018-01-30 | 武汉华星光电技术有限公司 | 纳米压印模板及其制作方法和应用 |

| CN109942806A (zh) * | 2018-03-09 | 2019-06-28 | 深圳怡钛积科技股份有限公司 | 全氟聚醚改性的树枝状硅烷衍生物及其制备方法和应用 |

| US11249393B2 (en) | 2018-05-09 | 2022-02-15 | Facebook Technologies, Llc | Nanoimprint lithography processes for switching mechanical properties of imprint materials |

| CN109177134A (zh) * | 2018-08-15 | 2019-01-11 | 信利光电股份有限公司 | 一种制备扩散片的压印模具和一种扩散片 |

| US11504903B2 (en) | 2018-08-28 | 2022-11-22 | Carbon, Inc. | 1K alcohol dual cure resins for additive manufacturing |

| WO2020247708A1 (en) * | 2019-06-06 | 2020-12-10 | Qolibri, Inc. | Liquid filter apparatus for gas/solid separation for semiconductor processes |

| KR102286438B1 (ko) * | 2020-04-01 | 2021-08-05 | 연세대학교 산학협력단 | 패턴화된 금속 나노구 어레이층의 제조방법, 이를 포함하는 전자 소자의 제조방법 및 이에 의해 제조된 전자 소자 |

| US12268633B2 (en) | 2020-11-04 | 2025-04-08 | Alcon Inc. | Medical implant |

| EP4279655B1 (de) * | 2022-05-19 | 2024-05-08 | Fritz Egger GmbH & Co. OG | Verfahren zur herstellung eines strukturgebers zum texturieren einer prägefähigen materialoberfläche, insbesondere harzhaltigen laminatoberfläche, und derartiger strukturgeber |

| AU2023355823A1 (en) | 2022-10-05 | 2025-04-17 | Mireca Medicines Gmbh | MICROPARTICLE AND IMPLANT FORMULATIONS FOR cGMP ANALOG THERAPY |

Family Cites Families (61)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3810874A (en) | 1969-03-10 | 1974-05-14 | Minnesota Mining & Mfg | Polymers prepared from poly(perfluoro-alkylene oxide) compounds |

| US3707529A (en) | 1970-09-04 | 1972-12-26 | Du Pont | Elastomeric vinylidene fluoride polymers with 55-95 percent non-ionic end groups |

| US4818801A (en) | 1982-01-18 | 1989-04-04 | Minnesota Mining And Manufacturing Company | Ophthalmic device comprising a polymer of a telechelic perfluoropolyether |

| US4694045A (en) | 1985-12-11 | 1987-09-15 | E. I. Du Pont De Nemours And Company | Base resistant fluoroelastomers |

| US4937147A (en) * | 1989-04-10 | 1990-06-26 | Monsanto Company | Transparent polymeric laminate |

| JPH04288305A (ja) | 1991-03-15 | 1992-10-13 | Nippon Mektron Ltd | パーオキサイド加硫可能な含フッ素エラストマ−の製造方法 |

| DE4114598A1 (de) | 1991-05-04 | 1992-11-05 | Bayer Ag | Unvernetzte copolymerisate mit reaktiven doppelbindungen aus fluormonomeren und nicht konjugierten dienen und verfahren zu ihrer herstellung |

| JPH05124111A (ja) * | 1991-11-07 | 1993-05-21 | Toppan Printing Co Ltd | 包装用ラミネートフイルムの製造方法 |

| IT1265461B1 (it) | 1993-12-29 | 1996-11-22 | Ausimont Spa | Fluoroelastomeri comprendenti unita' monomeriche derivanti da una bis-olefina |

| US5512374A (en) | 1994-05-09 | 1996-04-30 | Texas Instruments Incorporated | PFPE coatings for micro-mechanical devices |

| IT1269514B (it) | 1994-05-18 | 1997-04-01 | Ausimont Spa | Fluoroelastomeri vulcanizzabili per via perossidica,particolarmente adatti per la fabbricazione di o-ring |

| JP3327016B2 (ja) | 1994-12-06 | 2002-09-24 | ダイキン工業株式会社 | 低温シール性に優れたフッ素ゴム共重合体及びその硬化用組成物 |

| US5630902A (en) | 1994-12-30 | 1997-05-20 | Honeywell Inc. | Apparatus for use in high fidelty replication of diffractive optical elements |

| EP0784542B1 (en) | 1995-08-04 | 2001-11-28 | International Business Machines Corporation | Stamp for a lithographic process |

| US20040137734A1 (en) | 1995-11-15 | 2004-07-15 | Princeton University | Compositions and processes for nanoimprinting |

| JPH09151357A (ja) | 1995-11-28 | 1997-06-10 | Toray Dow Corning Silicone Co Ltd | コーティング剤組成物 |

| US6166157A (en) | 1995-12-20 | 2000-12-26 | E. I. Du Pont De Nemours And Company | Iodonitriles as chain transfer agents in the manufacture of perfluoropolymers |

| CA2721172C (en) | 1999-06-28 | 2012-04-10 | California Institute Of Technology | Microfabricated elastomeric valve and pump systems |

| US6512063B2 (en) | 2000-10-04 | 2003-01-28 | Dupont Dow Elastomers L.L.C. | Process for producing fluoroelastomers |

| US7294294B1 (en) * | 2000-10-17 | 2007-11-13 | Seagate Technology Llc | Surface modified stamper for imprint lithography |

| US6422528B1 (en) | 2001-01-17 | 2002-07-23 | Sandia National Laboratories | Sacrificial plastic mold with electroplatable base |

| JP4116314B2 (ja) * | 2001-04-09 | 2008-07-09 | 出光興産株式会社 | マイクロエンボスシートの製造方法 |

| US20030071016A1 (en) | 2001-10-11 | 2003-04-17 | Wu-Sheng Shih | Patterned structure reproduction using nonsticking mold |

| US7037457B2 (en) * | 2001-11-05 | 2006-05-02 | 3M Innovative Properties Company | Systems and methods for composite webs with structured discrete polymeric regions |

| EP1333680A3 (fr) | 2002-01-16 | 2007-06-13 | Koninklijke Philips Electronics N.V. | Procédé de traitement d'une image numérique |

| US6979419B2 (en) * | 2002-03-07 | 2005-12-27 | Robert Cameron | Method of manufacturing a print pad having a surface textured for printing on a highly polished surface such as a contact lens or a contact lens mold |

| KR100537722B1 (ko) | 2002-10-11 | 2005-12-20 | 강신일 | 미세형상 구조물의 연속 성형장치 및 방법 그리고 그 미세형상의 성형을 위한 스탬퍼 제작방법 |

| US20040202865A1 (en) | 2003-04-08 | 2004-10-14 | Andrew Homola | Release coating for stamper |

| KR100568581B1 (ko) | 2003-04-14 | 2006-04-07 | 주식회사 미뉴타텍 | 미세패턴 형성 몰드용 조성물 및 이로부터 제작된 몰드 |

| US6808646B1 (en) | 2003-04-29 | 2004-10-26 | Hewlett-Packard Development Company, L.P. | Method of replicating a high resolution three-dimensional imprint pattern on a compliant media of arbitrary size |

| US7070406B2 (en) | 2003-04-29 | 2006-07-04 | Hewlett-Packard Development Company, L.P. | Apparatus for embossing a flexible substrate with a pattern carried by an optically transparent compliant media |

| US6860956B2 (en) | 2003-05-23 | 2005-03-01 | Agency For Science, Technology & Research | Methods of creating patterns on substrates and articles of manufacture resulting therefrom |

| US7063994B2 (en) | 2003-07-11 | 2006-06-20 | Organic Vision Inc. | Organic semiconductor devices and methods of fabrication including forming two parts with polymerisable groups and bonding the parts |

| US20050084613A1 (en) | 2003-08-19 | 2005-04-21 | Jian Wang | Sub-micron-scale patterning method and system |

| JP2005066836A (ja) * | 2003-08-22 | 2005-03-17 | Three M Innovative Properties Co | 可とう性成形型及びその製造方法ならびに微細構造体の製造方法 |

| AU2004276302B2 (en) | 2003-09-23 | 2011-02-03 | California Institute Of Technology | Photocurable perfluoropolyethers for use as novel materials in microfluidic devices |

| KR101376715B1 (ko) | 2003-12-19 | 2014-03-27 | 더 유니버시티 오브 노쓰 캐롤라이나 엣 채플 힐 | 소프트 또는 임프린트 리소그래피를 이용하여 분리된 마이크로- 및 나노- 구조를 제작하는 방법 |

| WO2007030698A2 (en) | 2005-09-07 | 2007-03-15 | The University Of North Carolina At Chapel Hill | Materials and methods for fabricating isolated micro-and nano-structures having chemical functionality |

| JP2005193473A (ja) * | 2004-01-06 | 2005-07-21 | Three M Innovative Properties Co | 転写用成形型及びその製造方法ならびに微細構造体の製造方法 |

| US8158728B2 (en) | 2004-02-13 | 2012-04-17 | The University Of North Carolina At Chapel Hill | Methods and materials for fabricating microfluidic devices |

| JP2005288933A (ja) * | 2004-04-01 | 2005-10-20 | Three M Innovative Properties Co | 可とう性成形型及びその製造方法 |

| JP4322161B2 (ja) * | 2004-04-12 | 2009-08-26 | 出光興産株式会社 | 転写シートの製造方法及び転写シートの製造装置 |

| JP2005302576A (ja) * | 2004-04-13 | 2005-10-27 | Toyo Tire & Rubber Co Ltd | バリアリブ形成用樹脂シート |

| JP2008507114A (ja) | 2004-04-27 | 2008-03-06 | ザ ボード オブ トラスティーズ オブ ザ ユニヴァーシティー オブ イリノイ | ソフトリソグラフィ用複合パターニングデバイス |

| US20060021533A1 (en) | 2004-07-30 | 2006-02-02 | Jeans Albert H | Imprint stamp |

| US7368171B2 (en) * | 2004-09-03 | 2008-05-06 | H.B. Fuller Licensing & Financing, Inc. | Laminating adhesive, laminate including the same, and method of making a laminate |

| JP2006110997A (ja) * | 2004-09-16 | 2006-04-27 | Asahi Glass Co Ltd | 転写体の製造方法、光硬化性組成物、および微細構造体の製造方法 |

| JP2006137021A (ja) * | 2004-11-10 | 2006-06-01 | Asahi Glass Co Ltd | 転写体の製造方法 |

| JP2006137504A (ja) * | 2004-11-10 | 2006-06-01 | Tadano Ltd | クレーンの格納解除制御装置 |

| JP2006182011A (ja) | 2004-11-30 | 2006-07-13 | Asahi Glass Co Ltd | 光硬化性樹脂成型用モールドおよび該モールドを用いる硬化物の製造方法 |

| JP2006182001A (ja) | 2004-12-27 | 2006-07-13 | Koichi Takemaru | 経文の分割書写兼日記用紙 |

| EP1700680A1 (en) | 2005-03-09 | 2006-09-13 | EPFL Ecole Polytechnique Fédérale de Lausanne | Easy release fluoropolymer molds for micro- and nano-pattern replication |

| MX2007016039A (es) | 2005-06-17 | 2008-10-27 | Univ North Carolina | Metodos, sistemas y materiales de fabricacion de nanoparticulas. |

| WO2007021763A2 (en) | 2005-08-11 | 2007-02-22 | Packaging Progressions, Inc. | Interleaver stacker and loading system |

| JP2007307752A (ja) * | 2006-05-17 | 2007-11-29 | Asahi Glass Co Ltd | モールドおよびその製造方法 |

| US20080000373A1 (en) | 2006-06-30 | 2008-01-03 | Maria Petrucci-Samija | Printing form precursor and process for preparing a stamp from the precursor |

| US20080047930A1 (en) | 2006-08-23 | 2008-02-28 | Graciela Beatriz Blanchet | Method to form a pattern of functional material on a substrate |

| US20080083484A1 (en) * | 2006-09-28 | 2008-04-10 | Graciela Beatriz Blanchet | Method to form a pattern of functional material on a substrate |

| US8128393B2 (en) * | 2006-12-04 | 2012-03-06 | Liquidia Technologies, Inc. | Methods and materials for fabricating laminate nanomolds and nanoparticles therefrom |

| US20080251976A1 (en) * | 2007-04-13 | 2008-10-16 | Liquidia Technologies, Inc. | Micro and nano-spacers having highly uniform size and shape |

| EP2690650B1 (en) * | 2011-06-23 | 2017-08-09 | Asahi Kasei Kabushiki Kaisha | Laminate for forming fine pattern, and method for producing laminate for forming fine pattern |

-

2006

- 2006-12-04 US US11/633,763 patent/US8128393B2/en active Active

-

2007

- 2007-12-04 KR KR1020147011301A patent/KR101507805B1/ko active Active

- 2007-12-04 CN CN201410061019.7A patent/CN103831914B/zh active Active

- 2007-12-04 EP EP07874162.6A patent/EP2117725B1/en active Active

- 2007-12-04 CN CN200780050904.3A patent/CN101668594B/zh active Active

- 2007-12-04 WO PCT/US2007/024910 patent/WO2008143650A2/en not_active Ceased

- 2007-12-04 KR KR1020097013846A patent/KR101507816B1/ko active Active

- 2007-12-04 JP JP2009540277A patent/JP5921798B2/ja active Active

- 2007-12-04 KR KR1020147033229A patent/KR101557030B1/ko active Active

- 2007-12-04 EP EP17194942.3A patent/EP3306395B1/en active Active

-

2012

- 2012-01-19 US US13/354,046 patent/US8439666B2/en active Active

- 2012-08-24 JP JP2012185449A patent/JP5680597B2/ja active Active

-

2013

- 2013-03-15 US US13/834,454 patent/US8662878B2/en active Active

-

2014

- 2014-01-17 US US14/157,971 patent/US8945441B2/en active Active

- 2014-09-05 JP JP2014180817A patent/JP6069272B2/ja active Active

- 2014-12-18 US US14/574,543 patent/US9340001B2/en active Active

-

2016

- 2016-01-13 JP JP2016004104A patent/JP2016128258A/ja active Pending

- 2016-04-26 US US15/138,831 patent/US9662809B2/en active Active

-

2017

- 2017-05-25 US US15/605,746 patent/US10717209B2/en active Active

-

2018

- 2018-10-10 HK HK18112880.8A patent/HK1253730A1/en unknown

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5921798B2 (ja) | 積層ナノモールドおよびその製造方法 | |

| US9314548B2 (en) | Nanostructured surfaces for biomedical/biomaterial applications and processes thereof | |

| US20090027603A1 (en) | Low Surface Energy Polymeric Material for Use in Liquid Crystal Displays | |

| US20070178133A1 (en) | Medical device, materials, and methods | |

| HK1198474B (en) | Methods and materials for fabricating laminate nanomolds and nanoparticles therefrom |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101202 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101202 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120326 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120328 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120622 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120629 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120725 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120801 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120824 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130517 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130815 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130822 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130917 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140507 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160413 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5921798 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |