JP5827235B2 - 残留物を清浄する方法および装置 - Google Patents

残留物を清浄する方法および装置 Download PDFInfo

- Publication number

- JP5827235B2 JP5827235B2 JP2012538809A JP2012538809A JP5827235B2 JP 5827235 B2 JP5827235 B2 JP 5827235B2 JP 2012538809 A JP2012538809 A JP 2012538809A JP 2012538809 A JP2012538809 A JP 2012538809A JP 5827235 B2 JP5827235 B2 JP 5827235B2

- Authority

- JP

- Japan

- Prior art keywords

- plasma

- residue

- ion

- gas

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004140 cleaning Methods 0.000 title claims description 69

- 238000000034 method Methods 0.000 title claims description 64

- 239000007789 gas Substances 0.000 claims description 109

- 150000002500 ions Chemical class 0.000 claims description 88

- 238000005468 ion implantation Methods 0.000 claims description 26

- 238000010884 ion-beam technique Methods 0.000 claims description 23

- 239000002019 doping agent Substances 0.000 claims description 18

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 15

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 14

- 229910052799 carbon Inorganic materials 0.000 claims description 14

- 229910052796 boron Inorganic materials 0.000 claims description 13

- 230000003287 optical effect Effects 0.000 claims description 8

- 238000000605 extraction Methods 0.000 claims description 7

- 229910052731 fluorine Inorganic materials 0.000 claims description 6

- 239000011737 fluorine Substances 0.000 claims description 6

- 238000004611 spectroscopical analysis Methods 0.000 claims description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 4

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 claims description 4

- 238000004949 mass spectrometry Methods 0.000 claims description 4

- 229910052760 oxygen Inorganic materials 0.000 claims description 4

- 239000001301 oxygen Substances 0.000 claims description 4

- 238000009529 body temperature measurement Methods 0.000 claims description 3

- 238000004891 communication Methods 0.000 claims description 2

- 239000012530 fluid Substances 0.000 claims description 2

- 230000000116 mitigating effect Effects 0.000 claims description 2

- 229910052594 sapphire Inorganic materials 0.000 claims description 2

- 239000010980 sapphire Substances 0.000 claims description 2

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 claims 2

- 150000001875 compounds Chemical class 0.000 claims 2

- 230000008569 process Effects 0.000 description 14

- 238000001514 detection method Methods 0.000 description 9

- 238000004458 analytical method Methods 0.000 description 7

- 239000007943 implant Substances 0.000 description 7

- 238000002513 implantation Methods 0.000 description 6

- 238000002347 injection Methods 0.000 description 6

- 239000007924 injection Substances 0.000 description 6

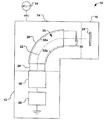

- 238000010586 diagram Methods 0.000 description 5

- 235000012431 wafers Nutrition 0.000 description 5

- 125000004429 atom Chemical group 0.000 description 4

- 150000002605 large molecules Chemical class 0.000 description 4

- 229920002521 macromolecule Polymers 0.000 description 4

- 239000004065 semiconductor Substances 0.000 description 4

- 150000001722 carbon compounds Chemical class 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- 230000006698 induction Effects 0.000 description 3

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 2

- XYFCBTPGUUZFHI-UHFFFAOYSA-N Phosphine Chemical compound P XYFCBTPGUUZFHI-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- WTEOIRVLGSZEPR-UHFFFAOYSA-N boron trifluoride Chemical compound FB(F)F WTEOIRVLGSZEPR-UHFFFAOYSA-N 0.000 description 2

- 150000001793 charged compounds Chemical class 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 238000000752 ionisation method Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- -1 small molecule ion Chemical class 0.000 description 2

- 150000003384 small molecules Chemical class 0.000 description 2

- 229910015900 BF3 Inorganic materials 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- RBFQJDQYXXHULB-UHFFFAOYSA-N arsane Chemical compound [AsH3] RBFQJDQYXXHULB-UHFFFAOYSA-N 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000005422 blasting Methods 0.000 description 1

- 150000001639 boron compounds Chemical class 0.000 description 1

- 238000000451 chemical ionisation Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 125000001153 fluoro group Chemical group F* 0.000 description 1

- 238000004868 gas analysis Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 229910000073 phosphorus hydride Inorganic materials 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000013139 quantization Methods 0.000 description 1

- 238000005215 recombination Methods 0.000 description 1

- 230000006798 recombination Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/30—Electron-beam or ion-beam tubes for localised treatment of objects

- H01J37/317—Electron-beam or ion-beam tubes for localised treatment of objects for changing properties of the objects or for applying thin layers thereon, e.g. for ion implantation

- H01J37/3171—Electron-beam or ion-beam tubes for localised treatment of objects for changing properties of the objects or for applying thin layers thereon, e.g. for ion implantation for ion implantation

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/48—Ion implantation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/02—Details

- H01J37/04—Arrangements of electrodes and associated parts for generating or controlling the discharge, e.g. electron-optical arrangement or ion-optical arrangement

- H01J37/08—Ion sources; Ion guns

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/30—Electron-beam or ion-beam tubes for localised treatment of objects

- H01J37/317—Electron-beam or ion-beam tubes for localised treatment of objects for changing properties of the objects or for applying thin layers thereon, e.g. for ion implantation

- H01J37/3174—Particle-beam lithography, e.g. electron beam lithography

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/02—Details

- H01J2237/022—Avoiding or removing foreign or contaminating particles, debris or deposits on sample or tube

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/02—Details

- H01J2237/022—Avoiding or removing foreign or contaminating particles, debris or deposits on sample or tube

- H01J2237/0225—Detecting or monitoring foreign particles

Landscapes

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electron Sources, Ion Sources (AREA)

- Plasma Technology (AREA)

- Physical Vapour Deposition (AREA)

- Cleaning In General (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/616,662 | 2009-11-11 | ||

| US12/616,662 US20110108058A1 (en) | 2009-11-11 | 2009-11-11 | Method and apparatus for cleaning residue from an ion source component |

| PCT/US2010/002969 WO2011059504A2 (en) | 2009-11-11 | 2010-11-12 | Method and apparatus for cleaning residue from an ion source component |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013511128A JP2013511128A (ja) | 2013-03-28 |

| JP2013511128A5 JP2013511128A5 (enExample) | 2015-07-02 |

| JP5827235B2 true JP5827235B2 (ja) | 2015-12-02 |

Family

ID=43735816

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012538809A Expired - Fee Related JP5827235B2 (ja) | 2009-11-11 | 2010-11-12 | 残留物を清浄する方法および装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US20110108058A1 (enExample) |

| EP (1) | EP2499653A2 (enExample) |

| JP (1) | JP5827235B2 (enExample) |

| KR (1) | KR101741405B1 (enExample) |

| CN (1) | CN102612731B (enExample) |

| TW (1) | TWI500064B (enExample) |

| WO (1) | WO2011059504A2 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120235058A1 (en) * | 2010-09-15 | 2012-09-20 | Ashwini Sinha | Method for extending lifetime of an ion source |

| US9653327B2 (en) * | 2011-05-12 | 2017-05-16 | Applied Materials, Inc. | Methods of removing a material layer from a substrate using water vapor treatment |

| RU2522662C2 (ru) * | 2011-08-03 | 2014-07-20 | Федеральное государственное бюджетное учреждение "Государственный научный центр Российской Федерации - Институт Теоретической и Экспериментальной Физики" (ФГБУ "ГНЦ РФ ИТЭФ") | Способ нерпрерываемого производства пучка ионов карборана с постоянной самоочисткой ионного источника и компонент системы экстракции ионного имплантатора |

| US20130250293A1 (en) * | 2012-03-20 | 2013-09-26 | Fei Company | Method and Apparatus for Actively Monitoring an Inductively-Coupled Plasma Ion Source using an Optical Spectrometer |

| US9142392B2 (en) * | 2013-04-29 | 2015-09-22 | Varian Semiconductor Equipment Associates, Inc. | Self-cleaning radio frequency plasma source |

| US9006690B2 (en) * | 2013-05-03 | 2015-04-14 | Axcelis Technologies, Inc. | Extraction electrode assembly voltage modulation in an ion implantation system |

| JP6461186B2 (ja) * | 2014-03-11 | 2019-01-30 | レッド ヒル バイオファーマ リミテッドRedHill Biopharma Ltd. | 悪心、嘔吐または下痢の症状を処置するためのオンダンセトロン徐放固形製剤 |

| JP6439620B2 (ja) * | 2015-07-28 | 2018-12-19 | 株式会社ニューフレアテクノロジー | 電子源のクリーニング方法及び電子ビーム描画装置 |

| US10062548B2 (en) * | 2015-08-31 | 2018-08-28 | Varian Semiconductor Equipment Associates, Inc. | Gas injection system for ion beam device |

| US10141161B2 (en) | 2016-09-12 | 2018-11-27 | Varian Semiconductor Equipment Associates, Inc. | Angle control for radicals and reactive neutral ion beams |

| US10161034B2 (en) | 2017-04-21 | 2018-12-25 | Lam Research Corporation | Rapid chamber clean using concurrent in-situ and remote plasma sources |

| US10676370B2 (en) * | 2017-06-05 | 2020-06-09 | Axcelis Technologies, Inc. | Hydrogen co-gas when using aluminum iodide as an ion source material |

| US10580632B2 (en) * | 2017-12-18 | 2020-03-03 | Agilent Technologies, Inc. | In-situ conditioning in mass spectrometry systems |

| CN111069188B (zh) * | 2018-10-18 | 2021-09-14 | 汉辰科技股份有限公司 | 离子布植机内部的氟化表面的清理 |

| CN109447013B (zh) * | 2018-11-06 | 2022-02-15 | 重庆工程职业技术学院 | 计算机用户身份识别设备 |

| JP7385809B2 (ja) * | 2019-09-05 | 2023-11-24 | 日新イオン機器株式会社 | イオンビーム照射装置のクリーニング方法 |

| US20250046586A1 (en) * | 2023-07-31 | 2025-02-06 | Veeco Instruments Inc. | Plasma vessel cleaning for ion beam system |

Family Cites Families (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2631258B1 (fr) * | 1988-05-10 | 1991-04-05 | Prestations Services Sps | Procede de nettoyage en surface par plasma differe |

| US5200023A (en) * | 1991-08-30 | 1993-04-06 | International Business Machines Corp. | Infrared thermographic method and apparatus for etch process monitoring and control |

| JPH06176724A (ja) * | 1992-01-23 | 1994-06-24 | Tokyo Electron Ltd | イオン源装置 |

| JP2618817B2 (ja) * | 1993-07-09 | 1997-06-11 | 岩谷産業株式会社 | 半導体製造装置でのノンプラズマクリーニング方法 |

| JPH0786242A (ja) * | 1993-09-10 | 1995-03-31 | Fujitsu Ltd | 半導体装置の製造方法 |

| US5554854A (en) * | 1995-07-17 | 1996-09-10 | Eaton Corporation | In situ removal of contaminants from the interior surfaces of an ion beam implanter |

| US5661308A (en) * | 1996-05-30 | 1997-08-26 | Eaton Corporation | Method and apparatus for ion formation in an ion implanter |

| US5812403A (en) * | 1996-11-13 | 1998-09-22 | Applied Materials, Inc. | Methods and apparatus for cleaning surfaces in a substrate processing system |

| US5814823A (en) * | 1997-07-12 | 1998-09-29 | Eaton Corporation | System and method for setecing neutral particles in an ion bean |

| US6135128A (en) * | 1998-03-27 | 2000-10-24 | Eaton Corporation | Method for in-process cleaning of an ion source |

| US6182603B1 (en) * | 1998-07-13 | 2001-02-06 | Applied Komatsu Technology, Inc. | Surface-treated shower head for use in a substrate processing chamber |

| US6355933B1 (en) * | 1999-01-13 | 2002-03-12 | Advanced Micro Devices, Inc. | Ion source and method for using same |

| US6221169B1 (en) * | 1999-05-10 | 2001-04-24 | Axcelis Technologies, Inc. | System and method for cleaning contaminated surfaces in an ion implanter |

| US6420275B1 (en) * | 1999-08-30 | 2002-07-16 | Micron Technology, Inc. | System and method for analyzing a semiconductor surface |

| US6228563B1 (en) * | 1999-09-17 | 2001-05-08 | Gasonics International Corporation | Method and apparatus for removing post-etch residues and other adherent matrices |

| US20030056388A1 (en) * | 2000-07-18 | 2003-03-27 | Hiromoto Ohno | Cleaning gas for semiconductor production equipment |

| US6635144B2 (en) * | 2001-04-11 | 2003-10-21 | Applied Materials, Inc | Apparatus and method for detecting an end point of chamber cleaning in semiconductor equipment |

| GB0128913D0 (en) * | 2001-12-03 | 2002-01-23 | Applied Materials Inc | Improvements in ion sources for ion implantation apparatus |

| US7106438B2 (en) * | 2002-12-12 | 2006-09-12 | Perkinelmer Las, Inc. | ICP-OES and ICP-MS induction current |

| US20040235299A1 (en) * | 2003-05-22 | 2004-11-25 | Axcelis Technologies, Inc. | Plasma ashing apparatus and endpoint detection process |

| US20080223409A1 (en) * | 2003-12-12 | 2008-09-18 | Horsky Thomas N | Method and apparatus for extending equipment uptime in ion implantation |

| WO2005060602A2 (en) * | 2003-12-12 | 2005-07-07 | Semequip, Inc. | Controlling the flow of vapors sublimated from solids |

| US7791047B2 (en) * | 2003-12-12 | 2010-09-07 | Semequip, Inc. | Method and apparatus for extracting ions from an ion source for use in ion implantation |

| GB2412488B (en) * | 2004-03-26 | 2007-03-28 | Applied Materials Inc | Ion sources |

| US7819981B2 (en) * | 2004-10-26 | 2010-10-26 | Advanced Technology Materials, Inc. | Methods for cleaning ion implanter components |

| US7109085B2 (en) * | 2005-01-11 | 2006-09-19 | Taiwan Semiconductor Manufacturing Co., Ltd. | Etching process to avoid polysilicon notching |

| US8278222B2 (en) * | 2005-11-22 | 2012-10-02 | Air Products And Chemicals, Inc. | Selective etching and formation of xenon difluoride |

| KR101455404B1 (ko) * | 2005-12-09 | 2014-10-27 | 세미이큅, 인코포레이티드 | 탄소 클러스터의 주입에 의한 반도체 디바이스의 제조를위한 시스템 및 방법 |

| US7531819B2 (en) * | 2005-12-20 | 2009-05-12 | Axcelis Technologies, Inc. | Fluorine based cleaning of an ion source |

| EP2021528A4 (en) * | 2006-04-26 | 2011-03-23 | Advanced Tech Materials | CLEANING OF SEMICONDUCTOR PROCESSING SYSTEMS |

| US8110815B2 (en) * | 2006-06-12 | 2012-02-07 | Semequip, Inc. | Vapor delivery to devices under vacuum |

| US8013312B2 (en) * | 2006-11-22 | 2011-09-06 | Semequip, Inc. | Vapor delivery system useful with ion sources and vaporizer for use in such system |

| KR20090127366A (ko) * | 2007-03-30 | 2009-12-10 | 어드밴스드 테크놀러지 머티리얼즈, 인코포레이티드 | 반도체 디바이스용 극저 접합 형성 방법 |

| US7947966B2 (en) * | 2007-07-31 | 2011-05-24 | Axcelis Technologies, Inc. | Double plasma ion source |

| WO2009102762A2 (en) * | 2008-02-11 | 2009-08-20 | Sweeney Joseph D | Ion source cleaning in semiconductor processing systems |

| US8158017B2 (en) * | 2008-05-12 | 2012-04-17 | Lam Research Corporation | Detection of arcing events in wafer plasma processing through monitoring of trace gas concentrations |

| US8809800B2 (en) * | 2008-08-04 | 2014-08-19 | Varian Semicoductor Equipment Associates, Inc. | Ion source and a method for in-situ cleaning thereof |

| US8263944B2 (en) * | 2008-12-22 | 2012-09-11 | Varian Semiconductor Equipment Associates, Inc. | Directional gas injection for an ion source cathode assembly |

| US7999479B2 (en) * | 2009-04-16 | 2011-08-16 | Varian Semiconductor Equipment Associates, Inc. | Conjugated ICP and ECR plasma sources for wide ribbon ion beam generation and control |

| US8003959B2 (en) * | 2009-06-26 | 2011-08-23 | Varian Semiconductor Equipment Associates, Inc. | Ion source cleaning end point detection |

-

2009

- 2009-11-11 US US12/616,662 patent/US20110108058A1/en not_active Abandoned

-

2010

- 2010-11-11 TW TW099138796A patent/TWI500064B/zh not_active IP Right Cessation

- 2010-11-12 EP EP10787593A patent/EP2499653A2/en not_active Withdrawn

- 2010-11-12 CN CN201080051134.6A patent/CN102612731B/zh not_active Expired - Fee Related

- 2010-11-12 WO PCT/US2010/002969 patent/WO2011059504A2/en not_active Ceased

- 2010-11-12 KR KR1020127015073A patent/KR101741405B1/ko not_active Expired - Fee Related

- 2010-11-12 JP JP2012538809A patent/JP5827235B2/ja not_active Expired - Fee Related

-

2013

- 2013-07-23 US US13/948,280 patent/US20130305989A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| CN102612731A (zh) | 2012-07-25 |

| KR101741405B1 (ko) | 2017-05-30 |

| US20110108058A1 (en) | 2011-05-12 |

| WO2011059504A3 (en) | 2011-10-27 |

| JP2013511128A (ja) | 2013-03-28 |

| EP2499653A2 (en) | 2012-09-19 |

| CN102612731B (zh) | 2016-03-16 |

| TWI500064B (zh) | 2015-09-11 |

| US20130305989A1 (en) | 2013-11-21 |

| WO2011059504A2 (en) | 2011-05-19 |

| TW201137920A (en) | 2011-11-01 |

| KR20120098774A (ko) | 2012-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5827235B2 (ja) | 残留物を清浄する方法および装置 | |

| US9984855B2 (en) | Implementation of co-gases for germanium and boron ion implants | |

| KR100559197B1 (ko) | 플라즈마 침지 이온 주입을 위한 전처리 공정 | |

| JP4126634B2 (ja) | イオン源とイオン処理工程中の洗浄方法 | |

| US7994487B2 (en) | Control of particles on semiconductor wafers when implanting boron hydrides | |

| US20080121811A1 (en) | Method and apparatus for extending equipment uptime in ion implantation | |

| JP5652582B2 (ja) | ハイブリッドイオン源 | |

| US20110143527A1 (en) | Techniques for generating uniform ion beam | |

| US8003959B2 (en) | Ion source cleaning end point detection | |

| TWI576900B (zh) | 離子植入系統、用於離子植入器之設備以及用於離子植入器之方法 | |

| US7488958B2 (en) | High conductance ion source | |

| CN112335012B (zh) | 处理系统与离子植入及沉积材料及刻蚀及处理工件的方法 | |

| US10170286B2 (en) | In-situ cleaning using hydrogen peroxide as co-gas to primary dopant or purge gas for minimizing carbon deposits in an ion source | |

| JP5652771B2 (ja) | 分子イオンを生成する方法および装置 | |

| Horsky et al. | Boron Beam Performance and in‐situ Cleaning of the ClusterIon® Source |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20131018 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140618 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140624 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140919 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150210 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20150511 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150915 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20151015 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5827235 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |