JP5809837B2 - 複雑な形状寸法を有する複合積層材を形成及び適用するための方法と装置 - Google Patents

複雑な形状寸法を有する複合積層材を形成及び適用するための方法と装置 Download PDFInfo

- Publication number

- JP5809837B2 JP5809837B2 JP2011095584A JP2011095584A JP5809837B2 JP 5809837 B2 JP5809837 B2 JP 5809837B2 JP 2011095584 A JP2011095584 A JP 2011095584A JP 2011095584 A JP2011095584 A JP 2011095584A JP 5809837 B2 JP5809837 B2 JP 5809837B2

- Authority

- JP

- Japan

- Prior art keywords

- tool

- bag

- laminate

- bladder

- composite

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 66

- 239000002131 composite material Substances 0.000 title claims description 60

- 238000000465 moulding Methods 0.000 claims description 14

- 239000000758 substrate Substances 0.000 claims description 14

- 230000008878 coupling Effects 0.000 claims description 3

- 238000010168 coupling process Methods 0.000 claims description 3

- 238000005859 coupling reaction Methods 0.000 claims description 3

- 239000000835 fiber Substances 0.000 description 15

- 239000002648 laminated material Substances 0.000 description 14

- 238000004519 manufacturing process Methods 0.000 description 10

- 238000007596 consolidation process Methods 0.000 description 8

- 239000004616 structural foam Substances 0.000 description 6

- 238000003475 lamination Methods 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000010030 laminating Methods 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000003672 processing method Methods 0.000 description 2

- 238000009419 refurbishment Methods 0.000 description 2

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 238000013475 authorization Methods 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/30—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core

- B29C70/38—Automated lay-up, e.g. using robots, laying filaments according to predetermined patterns

- B29C70/382—Automated fiber placement [AFP]

- B29C70/384—Fiber placement heads, e.g. component parts, details or accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/44—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using isostatic pressure, e.g. pressure difference-moulding, vacuum bag-moulding, autoclave-moulding or expanding rubber-moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/30—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core

- B29C70/38—Automated lay-up, e.g. using robots, laying filaments according to predetermined patterns

- B29C70/382—Automated fiber placement [AFP]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/54—Component parts, details or accessories; Auxiliary operations, e.g. feeding or storage of prepregs or SMC after impregnation or during ageing

- B29C70/541—Positioning reinforcements in a mould, e.g. using clamping means for the reinforcement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C73/00—Repairing of articles made from plastics or substances in a plastic state, e.g. of articles shaped or produced by using techniques covered by this subclass or subclass B29D

- B29C73/04—Repairing of articles made from plastics or substances in a plastic state, e.g. of articles shaped or produced by using techniques covered by this subclass or subclass B29D using preformed elements

- B29C73/10—Repairing of articles made from plastics or substances in a plastic state, e.g. of articles shaped or produced by using techniques covered by this subclass or subclass B29D using preformed elements using patches sealing on the surface of the article

- B29C73/12—Apparatus therefor, e.g. for applying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C73/00—Repairing of articles made from plastics or substances in a plastic state, e.g. of articles shaped or produced by using techniques covered by this subclass or subclass B29D

- B29C73/24—Apparatus or accessories not otherwise provided for

- B29C73/30—Apparatus or accessories not otherwise provided for for local pressing or local heating

- B29C73/32—Apparatus or accessories not otherwise provided for for local pressing or local heating using an elastic element, e.g. inflatable bag

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/10—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the pressing technique, e.g. using action of vacuum or fluid pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C2037/90—Measuring, controlling or regulating

- B29C2037/903—Measuring, controlling or regulating by means of a computer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/36—Moulds for making articles of definite length, i.e. discrete articles

- B29C43/3642—Bags, bleeder sheets or cauls for isostatic pressing

- B29C2043/3649—Inflatable bladders using gas or fluid and related details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3076—Aircrafts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3076—Aircrafts

- B29L2031/3082—Fuselages

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/17—Surface bonding means and/or assemblymeans with work feeding or handling means

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Robotics (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Moulding By Coating Moulds (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Description

部品表面の外形とほぼ一致する、ツールのマルチ外形面上に、真空バッグを引き付けること、

バッグの上からツール面上に複合プライを積み上げること、

部品の表面に対するツール面の位置を表わす一組の位置データを生成すること、

位置データとマニピュレータとを使用して、自動的にツールを部品の近くへと移動させ、部品表面に対して積層材を配置すること、並びに

バッグを膨張させることにより、部品表面に対して積層材を圧密化すること

を含む。

バッグを真空引きすることにより、圧密化された積層材からバッグを引き離すこと

を含むことができる。

バッグとツール面との間でブラダーを膨張させることにより、部品に対して積層材を圧密化すること

を含むことができる。

部品表面の外形とほぼ一致するツールのマルチ外形面上に柔軟なバッグを引き付けること、

バッグで覆われたツール面の上に、複合積層材を配置すること、

部品の近くにツールを移動させ、ツールを使用して部品表面上に積層材を配置すること、

バッグを膨張させることにより、部品表面に対して積層材を圧密化すること、並びに

バッグを真空引きすることにより、圧密化された積層材からバッグを引き離すこと

を含む。

ツール面とバッグとの間でブラダーを膨張させることにより、部品表面に対して積層材を圧密化すること

を含むことができる。

ツール面上にバッグを引き付けることが、バッグを真空引きすることを含むことができ、且つ

部品の近くにツールを移動させることが、空間内において部品の位置をツール面の位置に関連付ける一組のデータによりプログラムされたコントローラによって操作されるマニピュレータを用いて実行することができる。

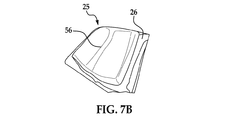

部品表面の外形とほぼ一致するマルチ外形面を有するツール、

ツール面の外形を覆ってそのような外形に適合するツール上の柔軟なバッグであって、その上に積層材が配置されて、与圧されると部品表面に対して積層材を圧密化するバッグ、

ツールを部品の近くへと動かして、部品表面上に積層材を配置するマニピュレータ、並びに

マニピュレータの動作及びバッグの与圧を制御するコントローラ

を備えている。

部品表面に対して積層材を圧密化するための、ツール面とバッグとの間に配置されて膨張させることが可能なブラダー

を備えることができる。

部品表面の外形とほぼ一致するマルチ外形面を有するツール、

その上に搭載されたツールを操作するためのロボットマニピュレータ、

ツール面上にマルチプライ複合積層材を形成するための繊維配置ヘッドを含む複合繊維自動積層成形装置、

繊維配置ヘッド、ツール面、及び部品表面を、共通の空間座標系内で互いに対して位置決めする一組の位置データを生成するためのロケータシステム、

部品表面に対して積層材を圧密化するための、ツール上のコンパクタ、並びに

位置データに基づいて、マニピュレータ、自動積層成形装置、及びコンパクタの動作を制御する制御手段

を備えている。

ツール面と、積層材に圧密化のための圧力を印加するバッグとの間に配置された、バッグを介して与圧可能なツール上のブラダー

を含むことができる。

圧力源、

真空源、並びに

制御手段により動作されて、バッグ及びブラダーの各々と、圧力源及び真空源とを選択的に連結する一組のバルブ

を含むことができる。

部品表面の外形とほぼ一致するマルチ外形面を有する構造用発泡材ツール、

ツールを操作するためのロボットマニピュレータ、

マニピュレータ上にツールを取り外し可能に取り付けて、マニピュレータ上のツールの交換を可能にする取り付けアダプタ、

ツール面上にマルチプライ複合積層材を形成するための繊維配置ヘッドを含む複合繊維自動積層成形装置、

繊維配置ヘッド、ツール面、及び部品表面を共通の空間座標系に位置決めする一組の位置データを生成するためのロケータシステム、

ツール面を覆い、且つツールに対してシールされた、部品表面に対して積層材を圧密化するための、膨張させることが可能なバッグ、

部品表面に対して積層材を圧密化するための、ツール面上及びバッグ内部において膨張させることが可能なブラダー、

圧力源、

真空源、

圧力源及び真空源の各々をバッグ及びブラダーと選択的に連結するためのバルブシステムを含む、バッグ及びブラダーの各々を別々に膨張及び減圧する手段、並びに

マニピュレータ、自動積層成形装置、及びバルブシステムの動作を調節及び制御するためのコントローラ

を備えている。

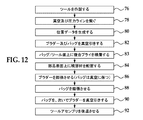

部品表面の外形にほぼ一致する、ツールのマルチ外形面上に、柔軟なバッグを配置すること、

ツールに対してバッグをシールして、ほぼ気密なチャンバを形成すること、

真空チャンバを真空引きすることにより、ツール面上にバッグを引き付けること、

自動積層成形装置を使用して、バッグの上に複合積層材を形成し、ツール面の外形に適合させること、

自動制御されるマニピュレータにツールを取り付けること、

3D空間座標系において部品表面に対してツール面を位置決めする一組の位置データを生成すること、

マニピュレータを使用して、部品の近くへとツールを動かし、部品表面上に積層材を配置すること、

ツール面とバッグとの間でバッグを膨張させて、部品表面に対して積層材を圧密化すること、

部品表面に対して積層材を更に圧密化するために、バッグを膨張させること、

バッグを真空引きすることによりバッグを減圧すること、並びに、

プログラムされたコントローラを使用して、自動積層成形装置、バッグ、ブラダー、及びマニピュレータの動作を調節及び制御すること

を含む。

(態様1)

外形を有する部品の上に複合積層材を形成及び配置する方法であって、

部品の外形とほぼ一致する外形を有するツールの上に、外形を有する複合積層材を形成すること、

ツールに対する部品の位置を表わす一組の位置データを生成すること、並びに

マニピュレータ及び位置データを使用して、部品の近くへとツールを動かし、外形を有する部品の上に、外形を有する積層材を配置すること

を含む方法。

(態様2)

外形を有する複合積層材を形成することを、ツール上に複合材料を自動的に配置する自動積層成形装置を使用して実行する、態様1に記載の方法。

(態様3)

ツール上でブラダーを膨張させることにより、部品に対して積層材を圧密化すること

を更に含む、態様1に記載の方法。

(態様4)

ツール上でバッグを膨張させることにより、部品に対して積層材を更に圧密化すること

を更に含む、態様3に記載の方法。

(態様5)

バッグを減圧することにより、圧密化された積層材からバッグを後退させること

を更に含む、態様4に記載の方法。

(態様6)

位置データを生成することを、共通の三次元(3D)座標系において、部品の外形の3D位置に対するツールの外形の3D位置を決定することにより実行する、態様1に記載の方法。

(態様7)

外形を有する基板上に複合積層材を適用するための装置であって、

基板の近くへとツールを動かすためのマニピュレータに取り付けられるツールであって、基板の外形とほぼ一致する外形を有するツール面を含むツール、

基板上に積層材を圧密化するための、ツール上の第1の柔軟なコンパクタであって、ツール面を覆い、上に複合積層材が配置されるよう適合された第1の柔軟なコンパクタ、並びに

第1及び第2のコンパクタを制御する手段

を備える装置。

(態様8)

第1のコンパクタと、基板上に積層材を圧密化するためのツール面との間に配置される、ツール上の第2の柔軟なコンパクタ

を更に備える、態様7に記載の装置。

(態様9)

第1のコンパクタが、ツールにシールされた真空バッグを含んでおり、

第2のコンパクタが、柔軟で膨張させることが可能なブラダーを含んでおり、且つ

第1及び第2のコンパクタを制御する手段が、圧力源と、真空源と、圧力源及び真空源をバッグ及びブラダーと選択的に連結させるためのコントローラとを含んでいる、

態様7に記載の装置。

Claims (6)

- 外形を有する部品(24)の上に複合積層材(20)を形成及び配置する方法であって、

部品の外形とほぼ一致する外形を有し、面上にブラダー(54)及びバッグ(56)を順次設けたツール(25)のバッグ(56)上に、部品の外形とほぼ一致する外形を有する複合積層材を形成すること、

ツールに対する部品の位置を表わす一組の位置データ(45a)を生成すること、

マニピュレータ(36)及び位置データを使用して、部品の近くへとツールを動かし、外形を有する部品の上に、該複合積層材を配置すること、

該ツール上で該ブラダー(54)を膨張させることにより、部品に対して該複合積層材を圧密化すること、及び

該ツール上で該バッグ(56)を膨張させることにより、部品に対して該複合積層材を更に圧密化すること

を含む方法。 - バッグを減圧することにより、圧密化された積層材からバッグを後退させること

を更に含む、請求項1に記載の方法。 - まずバッグを、それからブラダーを真空引きすることにより、バッグ及びブラダーを減圧し複合積層材(20)から引き離すことを含む、請求項1に記載の方法。

- 外形を有する複合積層材を形成することを、ツール上に複合材料を自動的に配置する自動積層成形装置(42)を使用して実行する、請求項1に記載の方法。

- 位置データを生成することを、共通の三次元(3D)座標系(55)において、部品の外形の3D位置に対するツールの外形の3D位置を決定することにより実行する、請求項1に記載の方法。

- 外形を有する基板(22)上に複合積層材(20)を適用するための装置であって、

基板の近くへとツールを動かすためのマニピュレータ(36)に取り付けられるツールであって、基板の外形とほぼ一致する外形を有するツール面(28)を含むツール(25)、

基板上に積層材を圧密化するための第1の柔軟なコンパクタであって、ツールにシールされた真空バッグ(56)を含み、ツール面を覆い、上に複合積層材が配置されるよう適合された第1の柔軟なコンパクタ、

第1のコンパクタと基板上に積層材を圧密化するためのツール面との間に配置され、柔軟で膨張させることが可能なブラダーを(54)含む、ツール上の第2の柔軟なコンパクタ、及び

圧力源(62)と、真空源(64)と、圧力源及び真空源をバッグ及びブラダーと選択的に連結させるためのコントローラ(74)とを含んでいる、第1及び第2のコンパクタを制御する手段

を備える装置。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/768,007 | 2010-04-27 | ||

| US12/768,007 US8936695B2 (en) | 2007-07-28 | 2010-04-27 | Method for forming and applying composite layups having complex geometries |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011251525A JP2011251525A (ja) | 2011-12-15 |

| JP2011251525A5 JP2011251525A5 (ja) | 2015-05-14 |

| JP5809837B2 true JP5809837B2 (ja) | 2015-11-11 |

Family

ID=44487206

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011095584A Active JP5809837B2 (ja) | 2010-04-27 | 2011-04-22 | 複雑な形状寸法を有する複合積層材を形成及び適用するための方法と装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (2) | US8936695B2 (ja) |

| EP (1) | EP2383106B1 (ja) |

| JP (1) | JP5809837B2 (ja) |

| CN (1) | CN102233708B (ja) |

| CA (1) | CA2731324C (ja) |

| ES (1) | ES2421624T3 (ja) |

Families Citing this family (70)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7849729B2 (en) | 2006-12-22 | 2010-12-14 | The Boeing Company | Leak detection in vacuum bags |

| US8568551B2 (en) | 2007-05-22 | 2013-10-29 | The Boeing Company | Pre-patterned layup kit and method of manufacture |

| US9770871B2 (en) | 2007-05-22 | 2017-09-26 | The Boeing Company | Method and apparatus for layup placement |

| US8936695B2 (en) | 2007-07-28 | 2015-01-20 | The Boeing Company | Method for forming and applying composite layups having complex geometries |

| US8707766B2 (en) | 2010-04-21 | 2014-04-29 | The Boeing Company | Leak detection in vacuum bags |

| US8333864B2 (en) | 2008-09-30 | 2012-12-18 | The Boeing Company | Compaction of prepreg plies on composite laminate structures |

| US8916010B2 (en) * | 2007-12-07 | 2014-12-23 | The Boeing Company | Composite manufacturing method |

| US8752293B2 (en) | 2007-12-07 | 2014-06-17 | The Boeing Company | Method of fabricating structures using composite modules and structures made thereby |

| US8556618B2 (en) * | 2011-04-07 | 2013-10-15 | Spirit Aerosystems, Inc. | Method and bladder apparatus for forming composite parts |

| US9969131B2 (en) * | 2011-06-22 | 2018-05-15 | The Boeing Company | Automated ply layup system |

| JP5649125B2 (ja) * | 2011-07-01 | 2015-01-07 | Necエンジニアリング株式会社 | テープ貼付装置 |

| BR112014018031B1 (pt) | 2012-01-25 | 2020-12-01 | Safran | processo e ferramenta para a fabricação de uma pá de hélice |

| FR2985939B1 (fr) * | 2012-01-25 | 2014-02-14 | Snecma | Procede de fabrication d'une pale d'helice a structure composite, comprenant un ajustement de position entre deux parties |

| US8714226B2 (en) * | 2012-02-27 | 2014-05-06 | The Boeing Company | Automated fiber placement including layup mandrel tool |

| US9878503B2 (en) | 2012-08-23 | 2018-01-30 | Bombardier Inc. | Method for preparing composite structures and consumable assembly therefor |

| US8826957B2 (en) * | 2012-08-31 | 2014-09-09 | General Electric Company | Methods and systems for automated ply layup for composites |

| US8741084B2 (en) * | 2012-10-05 | 2014-06-03 | The Boeing Company | Method of composite tape lamination over convex radii |

| US9162396B2 (en) * | 2012-10-12 | 2015-10-20 | The Boeing Company | Method for forming fuselage stringers |

| US8974618B1 (en) * | 2012-12-04 | 2015-03-10 | The Boeing Company | Systems and methods for assembling a skin of a composite structure |

| JP6366611B2 (ja) * | 2013-03-12 | 2018-08-01 | ディーフェンバッハー ゲゼルシャフト ミット ベシュレンクテル ハフツング マシーネン− ウント アンラーゲンバウDieffenbacher GmbH Maschinen− und Anlagenbau | 先進複合構成部材を製造する方法及びシステム |

| US20140265058A1 (en) * | 2013-03-13 | 2014-09-18 | North Thin Ply Technology Llc | System and method for maneuvering thin ply technology complexes |

| US9511537B2 (en) * | 2013-06-25 | 2016-12-06 | Sikorsky Aircraft Corporation | Bonding tool, system to apply pressure during a bonding process and method to apply pressure during a bonding process |

| DE102014201060A1 (de) * | 2014-01-22 | 2015-07-23 | Broetje-Automation Gmbh | Faserlegemaschine und Verfahren zur Herstellung von Fasergelegen |

| US10112349B2 (en) * | 2014-03-20 | 2018-10-30 | The Boeing Company | Placement of prepreg tows in high angle transition regions |

| US9782938B2 (en) * | 2014-03-21 | 2017-10-10 | The Boeing Company | Manufacturing system for composite structures |

| US9375884B2 (en) * | 2014-04-15 | 2016-06-28 | The Boeing Company | Optical scanner and projection apparatus for thermal management of composite repairs |

| US9873230B1 (en) * | 2014-08-19 | 2018-01-23 | The Boeing Company | Mobile system for automated layup and compaction of composite laminates |

| US9770873B2 (en) * | 2014-08-22 | 2017-09-26 | The Boeing Company | System and method for optimizing composite laminate structures |

| CN105522724B (zh) * | 2014-10-24 | 2019-06-04 | 波音公司 | 真空压实装置和对丝束进行压实的方法 |

| FR3027843B1 (fr) * | 2014-11-03 | 2016-12-23 | Aircelle Sa | Procede pour la reparation d'une peau perforee d'un panneau au moyen d'un doubleur |

| US10222353B2 (en) * | 2015-03-18 | 2019-03-05 | The Boeing Company | Method and assembly for inspecting a partially cured repair patch prior to installation |

| US10144185B2 (en) * | 2015-04-01 | 2018-12-04 | The Boeing Company | Method and apparatus for high-temperature post-curing of UV-cured photopolymers |

| US9902091B2 (en) * | 2015-04-21 | 2018-02-27 | Rohr, Inc. | Composite bonding tool with high thermal conductivity and low coefficient of thermal expansion |

| US10800111B2 (en) | 2015-06-16 | 2020-10-13 | The Boeing Company | Composite structure fabrication systems and methods |

| DE102015008312A1 (de) * | 2015-06-30 | 2017-01-05 | Airbus Defence and Space GmbH | Verfahren und Vorrichtung zum Reparieren von Bauteilen |

| US10456960B2 (en) * | 2015-07-24 | 2019-10-29 | The Boeing Company | Systems and methods for incrementally forming a composite part |

| WO2017047711A1 (ja) * | 2015-09-18 | 2017-03-23 | 本田技研工業株式会社 | 貼り付け装置及び貼り付け方法 |

| EP3153309B1 (en) * | 2015-10-05 | 2018-12-12 | Airbus Operations S.L. | System for out of autoclave bonded repairs |

| US10155367B2 (en) * | 2015-12-29 | 2018-12-18 | The Boeing Company | Coordinated composite tape laying |

| US10780614B2 (en) | 2016-05-24 | 2020-09-22 | General Electric Company | System and method for forming stacked materials |

| US10611097B2 (en) | 2016-05-24 | 2020-04-07 | General Electric Company | Methods and systems including pressurized housings for forming materials |

| EP3471949B1 (en) * | 2016-06-15 | 2020-08-12 | Vestas Wind Systems A/S | Method and apparatus for making a shear web |

| CN106182749A (zh) * | 2016-07-13 | 2016-12-07 | 道生天合材料科技(上海)有限公司 | 玻璃纤维布粘接方法 |

| US10259176B2 (en) * | 2016-08-03 | 2019-04-16 | The Boeing Company | System and method associated with drape forming |

| AU2016222309B2 (en) * | 2016-08-29 | 2022-09-29 | The Boeing Company | Actuatable flow media |

| US10773902B2 (en) | 2016-12-22 | 2020-09-15 | General Electric Company | Adaptive apparatus and system for automated handling of components |

| US10781056B2 (en) | 2016-12-22 | 2020-09-22 | General Electric Company | Adaptive apparatus and system for automated handling of components |

| US10889073B2 (en) * | 2017-03-13 | 2021-01-12 | The Boeing Company | Controllable multi-celled bladders for composites |

| CN107161355B (zh) * | 2017-05-23 | 2019-06-18 | 浙江大学 | 一种飞机机翼壁板数控定位器 |

| DE102017117383A1 (de) * | 2017-08-01 | 2019-02-07 | Airbus Operations Gmbh | Verfahren und Vorrichtung zum Reparieren eines aus einem Schichtverbundwerkstoff in mehreren Schichten aufgebauten Bauteils |

| JP6946143B2 (ja) * | 2017-10-17 | 2021-10-06 | 三菱重工業株式会社 | 修理パッチ、修理パッチの成形方法、複合材の修理方法及び成形治具 |

| FR3073448B1 (fr) * | 2017-11-16 | 2022-02-04 | Safran Nacelles | Procede de reparation d'un profile composite |

| WO2019115522A1 (en) * | 2017-12-14 | 2019-06-20 | Lm Wind Power International Technology Ii Aps | A method of manufacturing at least two preforms for moulding a wind turbine blade |

| US10843449B2 (en) | 2017-12-14 | 2020-11-24 | The Boeing Company | Method and apparatus for forming composite plies on contoured tool surfaces |

| US10830062B2 (en) * | 2018-03-20 | 2020-11-10 | Raytheon Technologies Corporation | Single ply having plurality of fiber angles |

| US10960620B2 (en) | 2018-03-29 | 2021-03-30 | Rohr, Inc. | Double vacuum bag method and adjustable support structure |

| US11628624B2 (en) * | 2018-08-07 | 2023-04-18 | University Of Southern California | Hybrid formation of multi-layer prepreg composite sheet layup |

| US10882262B2 (en) * | 2018-08-22 | 2021-01-05 | The Boeing Company | Flexible mandrel for forming composite structures |

| EP3867047A1 (en) | 2018-10-15 | 2021-08-25 | General Electric Company | Systems and methods of automated film removal |

| US11247413B2 (en) | 2018-12-17 | 2022-02-15 | The Boeing Company | Composite parts including hybrid plies, methods of forming the composite parts, and systems for forming the composite parts |

| FR3094265B1 (fr) * | 2019-03-27 | 2022-01-28 | Safran Aircraft Engines | Outillage de preformage d’une preforme fibreuse et procede de preformage d’une preforme fibreuse |

| DE102019003020B4 (de) | 2019-04-26 | 2021-11-25 | LSl Ludwig Schleicher Ingenium GmbH & Co. KG | Vorrichtung zum Festkleben eines Dekorflächenelementes auf einem Bauteil |

| US11559954B2 (en) | 2020-01-16 | 2023-01-24 | The Boeing Company | Multi-chamber conformable bladder for composite part tooling |

| US11953880B2 (en) | 2020-11-18 | 2024-04-09 | The Boeing Company | Dynamic indexing for moving parts in a fabrication environment |

| EP4000894A1 (en) * | 2020-11-18 | 2022-05-25 | The Boeing Company | Dynamic indexing for moving parts in a fabrication environment |

| NL2027422B1 (en) * | 2021-01-26 | 2022-08-26 | Boeing Co | Dynamic indexing for moving parts in a fabrication environment |

| US11826904B2 (en) * | 2020-11-25 | 2023-11-28 | The Boeing Company | End effector, system and method for picking up and placing an object |

| US20220176654A1 (en) * | 2020-12-07 | 2022-06-09 | The Boeing Company | Forming apparatus, method, and system |

| US11691356B2 (en) | 2021-02-08 | 2023-07-04 | General Electric Company | System and method for forming stacked materials |

| FR3139749B1 (fr) * | 2022-09-21 | 2024-08-30 | Safran Nacelles | Outillage de mise en pression d’une zone de travail d’une piece en materiau composite, robot equipe d’un tel outillage et procede de reparation d’une telle piece en materiau composite avec un tel outillage |

Family Cites Families (186)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2374894A (en) | 1943-06-16 | 1945-05-01 | Ford Motor Co | Method and apparatus for assembling aircraft fuselages |

| US2679278A (en) | 1951-01-13 | 1954-05-25 | Brown Steel Tank Company | Apparatus for assembling tank bodies |

| US3101290A (en) | 1957-04-01 | 1963-08-20 | Pneumatiques & Caoutchous Manu | Method of joining the ends of a multi-ply laminated belt |

| US3377096A (en) * | 1967-06-02 | 1968-04-09 | Wood S Powr Grip Co Inc | Vacuum gripping pad |

| US3739166A (en) | 1971-12-30 | 1973-06-12 | Gen Electric | Photoflash device |

| US4120632A (en) | 1972-01-12 | 1978-10-17 | Klepper-Werke Kommanditgesellschaft | Molds for production of plastics material boats |

| US3983282A (en) | 1972-05-15 | 1976-09-28 | Seemann Iii William H | Fabric constructions useful as building bases in forming compound-curved structures |

| US3885071A (en) | 1972-08-10 | 1975-05-20 | Lockheed Aircraft Corp | Fiber-reinforced epoxy composite joints |

| US4015035A (en) | 1972-08-10 | 1977-03-29 | Lockheed Aircraft Corporation | Method of forming fiber-reinforced epoxy composite joints, and product thereof |

| FR2234130B1 (ja) | 1973-05-14 | 1976-04-30 | Kamov Nikolai | |

| GB1526933A (en) | 1974-09-13 | 1978-10-04 | Johnson Matthey Co Ltd | Vacuum head for handling transfers |

| US4016022A (en) | 1975-12-30 | 1977-04-05 | The United States Of America As Represented By The Secretary Of The Air Force | Low flow, vacuum bag curable prepreg material for high performance composite systems |

| US4287015A (en) | 1976-10-18 | 1981-09-01 | Danner Harold J Jun | Vacuum bag used in making laminated products |

| US4208238A (en) | 1977-07-11 | 1980-06-17 | Grumman Aerospace Corporation | Gantry for use in the manufacture of laminar structures |

| US4132755A (en) | 1977-07-22 | 1979-01-02 | Jay Johnson | Process for manufacturing resin-impregnated, reinforced articles without the presence of resin fumes |

| US4238539A (en) | 1979-05-29 | 1980-12-09 | Celanese Corporation | Fiber reinforced composite shaft with metallic connector sleeves mounted by a knurl interlock |

| DE3152072C2 (de) | 1980-06-04 | 1985-08-08 | Anatolij Borisovič Averbuch | Verfahren zur Montage von Blocksektionen von Schiffsrümpfen und Vorrichtung zur Durchführung dieses Verfahrens |

| US4491081A (en) | 1980-06-04 | 1985-01-01 | Ivanov Jury P | Method for assembling a complete module of multideck ship hull |

| US4491493A (en) | 1983-04-08 | 1985-01-01 | Eaton Homer L | Composite tape preparation and application |

| US4496412A (en) | 1984-01-03 | 1985-01-29 | The Boeing Company | Multiple lap-joint for thermoplastic laminates and method of making the lap-joint |

| US4564543A (en) | 1984-01-03 | 1986-01-14 | The Boeing Company | Multiple lap-joint for thermoplastic laminates |

| US4554036A (en) | 1984-05-07 | 1985-11-19 | Newsom Cosby M | Portable vacuum device and method of using same |

| JPS60252235A (ja) | 1984-05-29 | 1985-12-12 | Dainippon Printing Co Ltd | パツケ−ジの改ざん判定方法 |

| US4698115A (en) | 1984-09-28 | 1987-10-06 | The Boeing Company | Silicone rubber vacuum bag tool and method of fabricating same |

| US4824513A (en) | 1984-09-28 | 1989-04-25 | The Boeing Company | Silicone rubber vacuum bag tool |

| US4548859A (en) | 1984-10-12 | 1985-10-22 | The Boeing Company | Breather material and method of coating fabric with silicone rubber |

| US5034254A (en) | 1984-10-29 | 1991-07-23 | The Boeing Company | Blind-side panel repair patch |

| US4588626A (en) | 1984-10-29 | 1986-05-13 | The Boeing Company | Blind-side panel repair patch |

| US4961799A (en) | 1984-10-29 | 1990-10-09 | The Boeing Company | Blind-side panel repair method |

| US4622091A (en) | 1984-11-29 | 1986-11-11 | The Boeing Company | Resin film infusion process and apparatus |

| US4741943A (en) | 1985-12-30 | 1988-05-03 | The Boeing Company | Aerodynamic structures of composite construction |

| JPH07101216B2 (ja) | 1986-04-25 | 1995-11-01 | 三菱瓦斯化学株式会社 | 酸素インジケ−タ− |

| US5123985A (en) | 1986-09-02 | 1992-06-23 | Patricia Evans | Vacuum bagging apparatus and method including a thermoplastic elastomer film vacuum bag |

| GB8629267D0 (en) | 1986-12-08 | 1987-02-11 | Westland Plc | Laying pre-impregnated fibre reinforced material on surface |

| US5033014A (en) | 1987-04-14 | 1991-07-16 | Northrop Corporation | Integrated manufacturing system |

| US4945488A (en) | 1987-04-14 | 1990-07-31 | Northrop Corporation | Integrated aircraft manufacturing system |

| US5071338A (en) | 1987-09-08 | 1991-12-10 | United Technologies Corporation | Tool for forming complex composite articles |

| US5217669A (en) | 1987-09-08 | 1993-06-08 | United Technologies Corporation | Method for forming complex composite articles |

| EP0319449B1 (en) | 1987-12-03 | 1993-11-18 | United Technologies Corporation | Tooling and method for forming complex composite articles |

| US4934199A (en) | 1988-03-25 | 1990-06-19 | Boeing Company | Method and apparatus for preparing specimens for destructive testing of graphite epoxy composite material |

| US4902215A (en) | 1988-06-08 | 1990-02-20 | Seemann Iii William H | Plastic transfer molding techniques for the production of fiber reinforced plastic structures |

| DE3821941A1 (de) | 1988-06-29 | 1990-02-08 | Weigel Angela | Verfahren und vorrichtung zur herstellung von formteilen aus aushaertbarem werkstoff |

| US4917353A (en) | 1988-11-15 | 1990-04-17 | The Boeing Company | Vacuum probe and method |

| US4987700A (en) | 1988-12-13 | 1991-01-29 | The Boeing Company | Mechanical scarfing apparatus |

| US5207541A (en) | 1988-12-13 | 1993-05-04 | The Boeing Company | Scarfing apparatus |

| US4942013A (en) | 1989-03-27 | 1990-07-17 | Mcdonnell Douglas Corporation | Vacuum resin impregnation process |

| US5052906A (en) | 1989-03-30 | 1991-10-01 | Seemann Composite Systems, Inc. | Plastic transfer molding apparatus for the production of fiber reinforced plastic structures |

| US5038291A (en) | 1989-04-03 | 1991-08-06 | General Electric Company | Computerized ply pattern generation |

| GB2244364B (en) | 1990-05-24 | 1994-03-09 | Coin Controls | Coin discrimination apparatus |

| US5087193A (en) * | 1990-08-09 | 1992-02-11 | Herbert Jr Kenneth H | Apparatus for forming a composite article |

| JPH0483714U (ja) * | 1990-11-30 | 1992-07-21 | ||

| CA2057201C (en) | 1990-12-19 | 1998-05-19 | Vernon M. Benson | Multiple axes fiber placement machine |

| JPH04223140A (ja) * | 1990-12-26 | 1992-08-13 | Fuji Heavy Ind Ltd | 複合材の成形方法 |

| US5129813A (en) | 1991-02-11 | 1992-07-14 | Shepherd G Maury | Embossed vacuum bag, methods for producing and using said bag |

| US5190611A (en) | 1991-02-13 | 1993-03-02 | The Boeing Company | Bearing load restoration method for composite structures |

| US5116216A (en) | 1991-02-28 | 1992-05-26 | The United States Of America As Represented By The Secretary Of The Navy | Apparatus for preparing thermoplastic composites |

| US5747179A (en) | 1991-04-05 | 1998-05-05 | The Boeing Company | Pack for inductively consolidating an organic matrix composite |

| US5209804A (en) | 1991-04-30 | 1993-05-11 | United Technologies Corporation | Integrated, automted composite material manufacturing system for pre-cure processing of preimpregnated composite materials |

| US5167742A (en) | 1991-05-29 | 1992-12-01 | Westinghouse Electric Corp. | Method and device for producing a tapered scarf joint |

| US5350614A (en) | 1991-07-25 | 1994-09-27 | United Technologies Corporation | All composite article of manufacture including first and second composite members joined by a composite hinge |

| US5932635A (en) | 1991-07-30 | 1999-08-03 | Cytec Technology Corp. | Tackified prepreg systems |

| JPH05116169A (ja) | 1991-10-25 | 1993-05-14 | Mitsubishi Kasei Corp | 繊維強化樹脂成形体の製造方法 |

| DE69304689T2 (de) | 1992-04-24 | 1997-04-30 | United Technologies Corp | Verbinden von thermoplastischen und wärmehärtenden verbundstrukturen mit metallischen strukturen |

| FR2693146B1 (fr) * | 1992-07-02 | 1994-08-19 | Snecma | Installation pour la fabrication par drapage de structures multicouches en matériaux composites. |

| US5429326A (en) | 1992-07-09 | 1995-07-04 | Structural Laminates Company | Spliced laminate for aircraft fuselage |

| US5359887A (en) | 1992-08-03 | 1994-11-01 | Mc Donnell Douglas Corp | Pressure sensitive paint formulations and methods |

| US5366684A (en) | 1992-12-31 | 1994-11-22 | Grumman Aerospace Corporation | Molding composite method using an inflatable bladder pressurized in an autoclave |

| JPH06242087A (ja) | 1993-02-16 | 1994-09-02 | Hitachi Constr Mach Co Ltd | 超音波探傷装置 |

| US5439635A (en) | 1993-02-18 | 1995-08-08 | Scrimp Systems, Llc | Unitary vacuum bag for forming fiber reinforced composite articles and process for making same |

| US5316462A (en) | 1993-02-18 | 1994-05-31 | William Seemann | Unitary vacuum bag for forming fiber reinforced composite articles |

| US5427725A (en) | 1993-05-07 | 1995-06-27 | The Dow Chemical Company | Process for resin transfer molding and preform used in the process |

| GB9311427D0 (en) | 1993-06-03 | 1993-07-21 | Trigon Ind Ltd | A multi-wall film |

| US5514232A (en) | 1993-11-24 | 1996-05-07 | Burns; Marshall | Method and apparatus for automatic fabrication of three-dimensional objects |

| US5879489A (en) | 1993-11-24 | 1999-03-09 | Burns; Marshall | Method and apparatus for automatic fabrication of three-dimensional objects |

| US5441692A (en) | 1994-02-14 | 1995-08-15 | Thermal Equipment Corporation | Process and apparatus for autoclave resin transfer molding |

| US5954898A (en) | 1994-05-13 | 1999-09-21 | Lockheed Fort Worth Company | Method and system for fabricating parts from composite materials |

| US5772950A (en) * | 1994-08-31 | 1998-06-30 | The Boeing Company | Method of vacuum forming a composite |

| US6406659B1 (en) | 1995-03-28 | 2002-06-18 | Eric Lang | Composite molding method and apparatus |

| US6919039B2 (en) | 1995-03-28 | 2005-07-19 | Eric J. Lang | Channel assisted resin transfer molding |

| US5683646A (en) | 1995-05-10 | 1997-11-04 | Mcdonnell Douglas Corporation | Fabrication of large hollow composite structure with precisely defined outer surface |

| US5667881A (en) | 1995-06-06 | 1997-09-16 | Hughes Missile Systems Company | Integral thermoset/thermoplastic composite joint |

| US5612492A (en) | 1995-06-07 | 1997-03-18 | Mcdonnell Douglas Corporation | Formulations and method of use of pressure sensitive paint |

| US5958325A (en) | 1995-06-07 | 1999-09-28 | Tpi Technology, Inc. | Large composite structures and a method for production of large composite structures incorporating a resin distribution network |

| US5904972A (en) | 1995-06-07 | 1999-05-18 | Tpi Technology Inc. | Large composite core structures formed by vacuum assisted resin transfer molding |

| US5576030A (en) | 1995-10-02 | 1996-11-19 | Lockheed Corporation | Apparatus for fabricating composite parts |

| US5820894A (en) | 1995-10-06 | 1998-10-13 | Mcdonnell Douglas Corporation | Method and apparatus for consolidating a workpiece at elevated temperature |

| US5868886A (en) | 1995-12-22 | 1999-02-09 | Alston; Mark S. | Z-pin reinforced bonded composite repairs |

| AU2584497A (en) | 1996-03-22 | 1997-10-10 | Boeing Company, The | Determinant spar assembly |

| US5759325A (en) | 1996-03-29 | 1998-06-02 | Sikorsky Aircraft Corporation | Method for controlling thickness during lay-up and fabrication of press-cured composite articles |

| US5780721A (en) | 1996-06-03 | 1998-07-14 | Minnesota Mining And Manufacturing Company | Composite construction for detection chemical leaks |

| SE9602818D0 (sv) | 1996-07-19 | 1996-07-19 | Pharmacia & Upjohn Ab | Colored composition |

| US5932256A (en) | 1996-09-27 | 1999-08-03 | Mandish; Theodore O. | Vacuum molding apparatus |

| FI111352B (fi) | 1996-11-08 | 2003-07-15 | Valtion Teknillinen | Pakkaus pilaantuvia elintarvikkeita varten |

| JPH10146898A (ja) | 1996-11-15 | 1998-06-02 | Honda Motor Co Ltd | 繊維強化複合材の成形方法 |

| US6230963B1 (en) | 1997-01-28 | 2001-05-15 | Eric L. Hertz | Method and apparatus using colored foils for placing conductive preforms |

| US6692681B1 (en) | 1997-01-29 | 2004-02-17 | Raytheon Aircraft Company | Method and apparatus for manufacturing composite structures |

| JPH10219853A (ja) | 1997-01-31 | 1998-08-18 | Toho Rayon Co Ltd | 繊維強化樹脂製パネルの結合構造 |

| FR2763882B1 (fr) | 1997-05-29 | 1999-08-20 | Aerospatiale | Outillage de reparation sur site d'une structure composite presentant une zone endommagee et procede correspondant |

| US5939013A (en) | 1997-08-25 | 1999-08-17 | Florida State University | Process and apparatus for the production of high strength polymer composite structures |

| US6284089B1 (en) | 1997-12-23 | 2001-09-04 | The Boeing Company | Thermoplastic seam welds |

| US6435242B1 (en) * | 1998-03-23 | 2002-08-20 | Northrop Grumman Corp | Repair pressure applicator |

| FR2777496B1 (fr) | 1998-04-17 | 2000-08-04 | Sunkiss Aeronautique | Procede d'obtention, reparation ou reconstruction d'un objet avec une piece ou materiau composite |

| DE69913737T3 (de) | 1998-05-20 | 2009-05-14 | Cytec Technology Corp., Wilmington | Herstellung von blasenfreien Laminaten und Verwendung derselben |

| US6299819B1 (en) | 1998-07-27 | 2001-10-09 | The University Of Dayton | Double-chamber vacuum resin transfer molding |

| US6280573B1 (en) | 1998-08-12 | 2001-08-28 | Kimberly-Clark Worldwide, Inc. | Leakage control system for treatment of moving webs |

| US6090335A (en) | 1999-01-08 | 2000-07-18 | Northrop Grumman Corporation | Process of forming fiber reinforced composite articles using an insitu cured resin infusion port |

| EP1038656A1 (en) | 1999-03-02 | 2000-09-27 | LS Technologies, Inc. A Pennsylvania Corporation | Vacuum resin impregnation process |

| DE19929471C1 (de) | 1999-06-26 | 2001-01-18 | Eads Airbus Gmbh | Verfahren und Vorrichtung zur Herstellung eines dreidimensionalen Großbauteiles |

| DE60018455T3 (de) | 1999-12-07 | 2009-02-19 | The Boeing Company, Seattle | Doppelfolien vakuuminjektionsverfahren zur herstellung eines verbundwerkstoffes und damit hergestellter verbundwerkstoff |

| US6298896B1 (en) | 2000-03-28 | 2001-10-09 | Northrop Grumman Corporation | Apparatus for constructing a composite structure |

| EP1272363A1 (en) | 2000-04-11 | 2003-01-08 | AlliedSignal Inc. | Composite comprising organic fibers having a low twist multiplier and improved compressive modulus |

| US6551091B1 (en) | 2000-09-14 | 2003-04-22 | The Boeing Company | Flexible inflatable support structure for use with a reusable compaction bag |

| US6589472B1 (en) | 2000-09-15 | 2003-07-08 | Lockheed Martin Corporation | Method of molding using a thermoplastic conformal mandrel |

| US6533985B1 (en) | 2000-09-22 | 2003-03-18 | Washington State University Research Foundation | Methods and apparatus for molding composite materials |

| US6638466B1 (en) | 2000-12-28 | 2003-10-28 | Raytheon Aircraft Company | Methods of manufacturing separable structures |

| JP2002254429A (ja) | 2001-03-06 | 2002-09-11 | Toyota Industries Corp | 複合材及びその製造方法 |

| US6689438B2 (en) | 2001-06-06 | 2004-02-10 | Cryovac, Inc. | Oxygen detection system for a solid article |

| GB0121444D0 (en) | 2001-09-05 | 2001-10-24 | Univ Strathclyde | Sensor |

| US6696690B2 (en) | 2001-12-17 | 2004-02-24 | The Boeing Company | Method and apparatus to correct for the temperature sensitivity of pressure sensitive paint |

| JP2003270145A (ja) | 2002-03-14 | 2003-09-25 | National Aerospace Laboratory Of Japan | 感圧色素を担持した機能性高分子並びにそれを用いた感圧塗料及び感圧素子 |

| US6761783B2 (en) | 2002-04-09 | 2004-07-13 | The Boeing Company | Process method to repair bismaleimide (BMI) composite structures |

| US6860957B2 (en) | 2002-06-13 | 2005-03-01 | Kawasaki Jukogyo Kabushiki Kaisha | Automatic prepreg laminating method and apparatus for carrying out the same |

| US6871684B2 (en) | 2002-08-13 | 2005-03-29 | The Boeing Company | System for identifying defects in a composite structure |

| AU2002328731A1 (en) | 2002-10-02 | 2004-04-23 | Carleton University | Oxygen sensing compounds, methods for production thereof and their uses |

| US7137182B2 (en) | 2002-11-22 | 2006-11-21 | The Boeing Company | Parallel configuration composite material fabricator |

| KR101207575B1 (ko) | 2002-12-17 | 2012-12-03 | 카자크 컴포지츠, 인코포레이티드 | 대규모 복합재료 구조물 및 대규모 복합재료 구조물의 제조방법 |

| DE04775802T1 (de) | 2003-02-24 | 2006-05-18 | Bell Helicopter Textron, Inc., Fort Worth | Eingriffszahnverbindung zum zusammenfügen von faserverbundlaminaten |

| DK1603735T3 (da) | 2003-03-06 | 2007-07-09 | Vestas Wind Sys As | Forbindelse imellem kompositter med ikke-kompatible egenskaber samt fremgangsmåde til fremstilling |

| GB0305602D0 (en) | 2003-03-12 | 2003-04-16 | Univ Strathclyde | Indicator |

| GB0307225D0 (en) | 2003-03-28 | 2003-04-30 | Arx Ltd | Automated dispensing system |

| JP2004309379A (ja) | 2003-04-09 | 2004-11-04 | Toshiba Corp | 気体漏洩検出装置 |

| US7141191B2 (en) | 2003-05-02 | 2006-11-28 | The Boeing Company | Triple purpose lay-up tool |

| US6830079B1 (en) | 2003-08-27 | 2004-12-14 | General Electric Company | Integrated apparatus and method for filling porous composite preforms |

| JP2005105160A (ja) | 2003-09-30 | 2005-04-21 | Japan Aerospace Exploration Agency | 低酸素圧用感圧塗料及びその製造方法 |

| US7294220B2 (en) | 2003-10-16 | 2007-11-13 | Toyota Motor Sales, U.S.A., Inc. | Methods of stabilizing and/or sealing core material and stabilized and/or sealed core material |

| US7029267B2 (en) | 2003-10-23 | 2006-04-18 | Saint- Gobain Technical Fabrics Canada, Ltd | Reusable vacuum bag and methods of its use |

| JP5284587B2 (ja) | 2003-11-05 | 2013-09-11 | イノヴェイティブ サイエンティフィック ソリューションズ,インコーポレイテッド | 表面接触力を判定するための方法 |

| US7228611B2 (en) | 2003-11-18 | 2007-06-12 | The Boeing Company | Method of transferring large uncured composite laminates |

| US20050112772A1 (en) | 2003-11-20 | 2005-05-26 | Farone William A. | Measurement of oxidation-reduction potential of a solution |

| US20070272582A1 (en) | 2003-12-08 | 2007-11-29 | Sentronic Gmbh Gesellschaft Fur Optische Messssysteme | Packaging |

| WO2005059500A1 (en) | 2003-12-12 | 2005-06-30 | Cryovac, Inc. | Process for detecting leaks in sealed packages |

| WO2005105415A2 (en) | 2004-04-21 | 2005-11-10 | Ingersoll Machine Tools, Inc. | Forming a composite structure by filament placement on a tool surface of a tablet |

| US7186367B2 (en) | 2004-05-13 | 2007-03-06 | The United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Double vacuum bag process for resin matrix composite manufacturing |

| US7622066B2 (en) | 2004-07-26 | 2009-11-24 | The Boeing Company | Methods and systems for manufacturing composite parts with female tools |

| CN1993616B (zh) | 2004-08-06 | 2010-12-29 | 保德科技股份有限公司 | 氧检测剂薄片及使用该薄片的氧检测剂、氧检测剂薄片的制造方法 |

| DK200401225A (da) | 2004-08-13 | 2006-02-14 | Lm Glasfiber As | Metode til afskæring af laminatlag, eksempelvis et glasfiber- eller kulfiber-laminatlag i en vindmöllevinge |

| US7306450B2 (en) | 2004-09-29 | 2007-12-11 | The Boeing Company | Apparatuses, systems, and methods for manufacturing composite parts |

| JP4670313B2 (ja) * | 2004-10-29 | 2011-04-13 | 東レ株式会社 | Frp成形用強化繊維基材の賦形方法 |

| US7503368B2 (en) | 2004-11-24 | 2009-03-17 | The Boeing Company | Composite sections for aircraft fuselages and other structures, and methods and systems for manufacturing such sections |

| US7534615B2 (en) | 2004-12-03 | 2009-05-19 | Cryovac, Inc. | Process for detecting leaks in sealed packages |

| US7624488B2 (en) | 2004-12-07 | 2009-12-01 | The Boeing Company | One-piece barrel assembly cart |

| FR2879496B1 (fr) * | 2004-12-16 | 2008-12-12 | Eurocopter France | Procede et dispositif de fabrication d'une carene de rotor d'helicoptere, et carene obtenue |

| US20090064425A1 (en) | 2005-04-08 | 2009-03-12 | University Of South Carolina | Polymer/Clay Nanocomposite Films with Improved Light Fastness Properties and Process for Producing Same |

| US7527759B2 (en) | 2005-04-13 | 2009-05-05 | The Boeing Company | Method and apparatus for forming structural members |

| US8601694B2 (en) | 2008-06-13 | 2013-12-10 | The Boeing Company | Method for forming and installing stringers |

| US7766063B2 (en) | 2005-04-28 | 2010-08-03 | The Boeing Company | Machine assisted laminator and method |

| JP2007030336A (ja) * | 2005-07-27 | 2007-02-08 | Mitsubishi Heavy Ind Ltd | 繊維強化プラスチックの積層成形方法及び積層成形装置 |

| US20070035070A1 (en) * | 2005-08-15 | 2007-02-15 | Essilor International Compagnie Generale D'optique | Inflatable membrane pressing apparatus for a film or coating application or lamination process |

| US7398586B2 (en) | 2005-11-01 | 2008-07-15 | The Boeing Company | Methods and systems for manufacturing a family of aircraft wings and other composite structures |

| US7398698B2 (en) | 2005-11-03 | 2008-07-15 | The Boeing Company | Smart repair patch and associated method |

| US7655168B2 (en) | 2006-01-31 | 2010-02-02 | The Boeing Company | Tools for manufacturing composite parts and methods for using such tools |

| JP2007253441A (ja) * | 2006-03-23 | 2007-10-04 | Shin Meiwa Ind Co Ltd | プリプレグ積層体の成形装置及び成形方法 |

| US7762122B2 (en) | 2006-05-01 | 2010-07-27 | University Of Delaware | System and method of detecting air leakage in a VARTM process |

| US7587258B2 (en) | 2006-05-10 | 2009-09-08 | The Boeing Company | Merged laser and photogrammetry measurement using precise camera placement |

| US7837148B2 (en) | 2006-06-13 | 2010-11-23 | The Boeing Company | Composite wing-body joint |

| US7887249B2 (en) | 2006-06-15 | 2011-02-15 | The Boeing Company | Internal finger joint |

| US7964049B2 (en) | 2006-07-28 | 2011-06-21 | E. I. Du Pont De Nemours And Company | Processes for making fiber-on-end materials |

| US20080023015A1 (en) | 2006-07-28 | 2008-01-31 | E. I. Dupont De Nemours And Company | Processes for making fiber-on-end materials |

| US7871040B2 (en) | 2006-11-10 | 2011-01-18 | The Boeing Company | Composite aircraft structures with hat stiffeners |

| US8438909B2 (en) | 2006-12-22 | 2013-05-14 | The Boeing Company | Device and method for detecting an air leak in a tool |

| US7849729B2 (en) | 2006-12-22 | 2010-12-14 | The Boeing Company | Leak detection in vacuum bags |

| JP4921194B2 (ja) * | 2007-01-31 | 2012-04-25 | トヨタ紡織株式会社 | 表皮材の接着装置、及び、表皮材の接着方法 |

| US8568551B2 (en) | 2007-05-22 | 2013-10-29 | The Boeing Company | Pre-patterned layup kit and method of manufacture |

| US9770871B2 (en) | 2007-05-22 | 2017-09-26 | The Boeing Company | Method and apparatus for layup placement |

| US9669593B2 (en) | 2007-06-14 | 2017-06-06 | The Boeing Company | Light weight thermoplastic flex foam and hybrid duct system |

| US8936695B2 (en) | 2007-07-28 | 2015-01-20 | The Boeing Company | Method for forming and applying composite layups having complex geometries |

| US8707766B2 (en) | 2010-04-21 | 2014-04-29 | The Boeing Company | Leak detection in vacuum bags |

| US8333864B2 (en) | 2008-09-30 | 2012-12-18 | The Boeing Company | Compaction of prepreg plies on composite laminate structures |

| US7628879B2 (en) | 2007-08-23 | 2009-12-08 | The Boeing Company | Conductive scrim embedded structural adhesive films |

| US8361262B2 (en) | 2007-11-08 | 2013-01-29 | The Boeing Company | Method and apparatus for low-bulk toughened fabrics for low-pressure molding processes |

| US8916010B2 (en) | 2007-12-07 | 2014-12-23 | The Boeing Company | Composite manufacturing method |

| US8752293B2 (en) | 2007-12-07 | 2014-06-17 | The Boeing Company | Method of fabricating structures using composite modules and structures made thereby |

| JP5278790B2 (ja) * | 2008-01-11 | 2013-09-04 | 東レ株式会社 | 繊維強化樹脂複合材料の製造方法および製造装置 |

| US8557074B2 (en) | 2008-02-27 | 2013-10-15 | The Boeing Company | Reduced complexity automatic fiber placement apparatus and method |

| US9873501B2 (en) | 2010-02-05 | 2018-01-23 | Learjet Inc. | System and method for fabricating a composite material assembly |

| US8936965B2 (en) | 2010-11-26 | 2015-01-20 | Semiconductor Energy Laboratory Co., Ltd. | Semiconductor device and manufacturing method thereof |

-

2010

- 2010-04-27 US US12/768,007 patent/US8936695B2/en active Active

-

2011

- 2011-02-08 CA CA 2731324 patent/CA2731324C/en active Active

- 2011-02-24 CN CN201110047522.3A patent/CN102233708B/zh active Active

- 2011-04-01 EP EP11160866.7A patent/EP2383106B1/en active Active

- 2011-04-01 ES ES11160866T patent/ES2421624T3/es active Active

- 2011-04-22 JP JP2011095584A patent/JP5809837B2/ja active Active

-

2015

- 2015-01-05 US US14/589,996 patent/US10052827B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2383106B1 (en) | 2013-07-10 |

| US20160263842A1 (en) | 2016-09-15 |

| US20110259515A1 (en) | 2011-10-27 |

| CN102233708B (zh) | 2015-07-22 |

| US10052827B2 (en) | 2018-08-21 |

| CN102233708A (zh) | 2011-11-09 |

| US8936695B2 (en) | 2015-01-20 |

| EP2383106A1 (en) | 2011-11-02 |

| ES2421624T3 (es) | 2013-09-04 |

| CA2731324A1 (en) | 2011-10-27 |

| CA2731324C (en) | 2015-04-14 |

| JP2011251525A (ja) | 2011-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5809837B2 (ja) | 複雑な形状寸法を有する複合積層材を形成及び適用するための方法と装置 | |

| JP2011251525A5 (ja) | ||

| US10974464B2 (en) | Method for forming contoured composite laminates | |

| US8613301B2 (en) | Compaction of prepreg plies on composite laminate structures | |

| US20090320292A1 (en) | Method and apparatus for forming and installing stringers | |

| US10399284B2 (en) | Method and apparatus for forming contoured composite laminates | |

| JP6892227B2 (ja) | 起伏のある補強材を形成するための方法及び装置 | |

| US20130340928A1 (en) | Method and Apparatus for Fabricating Variable Gauge, Contoured Composite Stiffeners | |

| US9314976B2 (en) | Systems and methods for compacting a charge of composite material | |

| JP7541173B2 (ja) | 複合積層体形成装置およびその方法 | |

| US10173371B1 (en) | System and method for forming a bonded joint | |

| US9862154B2 (en) | Apparatuses and methods for efficient sealing of vacuum bag seams | |

| CN111347752B (zh) | 层板输送和压实设备及其方法 | |

| JP2020114665A (ja) | 複合材プライのレイアップを製作するためのシステム及び方法 | |

| JP6426414B2 (ja) | 補強付き複合材料パネルの製造 | |

| US20240227326A1 (en) | Composite Compaction System Supported by a Number of Morphable Bag Supports | |

| JP2020029088A (ja) | 複合構造を形成するための可撓性マンドレル | |

| EP3023231B1 (en) | Systems and methods for compacting a charge of composite material | |

| US11660828B2 (en) | Composite fabrication system with alternating air pressure control | |

| US11826970B2 (en) | Forming apparatus, method, and system | |

| US11964442B2 (en) | Forming apparatus, method, and system | |

| JP2022076461A (ja) | 高度輪郭付け複合構造体を形成するための成形装置及び方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140203 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140203 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141219 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20141224 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20150323 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150818 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150914 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5809837 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |