JP5802391B2 - 多色容器のためのプラスチック・プリフォームとその製造方法 - Google Patents

多色容器のためのプラスチック・プリフォームとその製造方法 Download PDFInfo

- Publication number

- JP5802391B2 JP5802391B2 JP2010545334A JP2010545334A JP5802391B2 JP 5802391 B2 JP5802391 B2 JP 5802391B2 JP 2010545334 A JP2010545334 A JP 2010545334A JP 2010545334 A JP2010545334 A JP 2010545334A JP 5802391 B2 JP5802391 B2 JP 5802391B2

- Authority

- JP

- Japan

- Prior art keywords

- preform

- layer

- container

- region

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004033 plastic Substances 0.000 title claims description 24

- 229920003023 plastic Polymers 0.000 title claims description 24

- 238000004519 manufacturing process Methods 0.000 title claims description 12

- 239000000463 material Substances 0.000 claims description 131

- 239000010410 layer Substances 0.000 claims description 82

- 238000000034 method Methods 0.000 claims description 32

- 230000000694 effects Effects 0.000 claims description 31

- 238000002347 injection Methods 0.000 claims description 26

- 239000007924 injection Substances 0.000 claims description 26

- 239000012792 core layer Substances 0.000 claims description 19

- 239000000654 additive Substances 0.000 claims description 16

- 230000004888 barrier function Effects 0.000 claims description 16

- 239000000975 dye Substances 0.000 claims description 16

- 239000007788 liquid Substances 0.000 claims description 16

- 230000000996 additive effect Effects 0.000 claims description 12

- 229920000642 polymer Polymers 0.000 claims description 9

- 238000000071 blow moulding Methods 0.000 claims description 7

- 238000011049 filling Methods 0.000 claims description 5

- 238000001746 injection moulding Methods 0.000 claims description 5

- 239000000203 mixture Substances 0.000 claims description 5

- 230000001965 increasing effect Effects 0.000 claims description 4

- 238000000926 separation method Methods 0.000 claims description 4

- 229920002994 synthetic fiber Polymers 0.000 claims description 4

- 230000002411 adverse Effects 0.000 claims description 3

- 239000003153 chemical reaction reagent Substances 0.000 claims description 3

- 230000003472 neutralizing effect Effects 0.000 claims description 3

- 238000000149 argon plasma sintering Methods 0.000 claims description 2

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 239000012530 fluid Substances 0.000 claims description 2

- 239000002344 surface layer Substances 0.000 claims description 2

- 239000012620 biological material Substances 0.000 claims 1

- 238000009418 renovation Methods 0.000 claims 1

- 239000003086 colorant Substances 0.000 description 15

- 239000000047 product Substances 0.000 description 11

- 239000000049 pigment Substances 0.000 description 10

- 238000004040 coloring Methods 0.000 description 9

- 229920000139 polyethylene terephthalate Polymers 0.000 description 9

- 239000005020 polyethylene terephthalate Substances 0.000 description 9

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 8

- 239000001301 oxygen Substances 0.000 description 8

- 229910052760 oxygen Inorganic materials 0.000 description 8

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 6

- 230000008569 process Effects 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 238000009792 diffusion process Methods 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- 230000002265 prevention Effects 0.000 description 4

- 239000002356 single layer Substances 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 239000001569 carbon dioxide Substances 0.000 description 3

- 229910002092 carbon dioxide Inorganic materials 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 238000005452 bending Methods 0.000 description 2

- 238000012790 confirmation Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 235000013305 food Nutrition 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 230000005012 migration Effects 0.000 description 2

- 238000013508 migration Methods 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 238000004806 packaging method and process Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 238000004064 recycling Methods 0.000 description 2

- IKHGUXGNUITLKF-XPULMUKRSA-N acetaldehyde Chemical compound [14CH]([14CH3])=O IKHGUXGNUITLKF-XPULMUKRSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 235000013334 alcoholic beverage Nutrition 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 235000013361 beverage Nutrition 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 235000013365 dairy product Nutrition 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 239000003651 drinking water Substances 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000005670 electromagnetic radiation Effects 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 239000007850 fluorescent dye Substances 0.000 description 1

- 238000005194 fractionation Methods 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 230000004807 localization Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000004597 plastic additive Substances 0.000 description 1

- -1 polyethylene terephthalate Polymers 0.000 description 1

- 238000003908 quality control method Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000002000 scavenging effect Effects 0.000 description 1

- 239000011265 semifinished product Substances 0.000 description 1

- 235000014214 soft drink Nutrition 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B11/00—Making preforms

- B29B11/14—Making preforms characterised by structure or composition

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/071—Preforms or parisons characterised by their configuration, e.g. geometry, dimensions or physical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/16—Making multilayered or multicoloured articles

- B29C45/1642—Making multilayered or multicoloured articles having a "sandwich" structure

- B29C45/1646—Injecting parison-like articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/16—Making multilayered or multicoloured articles

- B29C45/1684—Injecting parison-like articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material, by deep-drawing operations performed on sheet material

- B65D1/02—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents

- B65D1/0207—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents characterised by material, e.g. composition, physical features

- B65D1/0215—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents characterised by material, e.g. composition, physical features multilayered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material, by deep-drawing operations performed on sheet material

- B65D1/02—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents

- B65D1/0223—Bottles or similar containers with necks or like restricted apertures, designed for pouring contents characterised by shape

- B65D1/0261—Bottom construction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/22—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor using multilayered preforms or parisons

- B29C2049/222—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor using multilayered preforms or parisons only parts of the preforms or parisons are layered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/0715—Preforms or parisons characterised by their configuration the preform having one end closed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/072—Preforms or parisons characterised by their configuration having variable wall thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/076—Preforms or parisons characterised by their configuration characterised by the shape

- B29C2949/0768—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform

- B29C2949/0769—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform characterised by the lip, i.e. very top of preform neck

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/076—Preforms or parisons characterised by their configuration characterised by the shape

- B29C2949/0768—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform

- B29C2949/077—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform characterised by the neck

- B29C2949/0772—Closure retaining means

- B29C2949/0773—Threads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/076—Preforms or parisons characterised by their configuration characterised by the shape

- B29C2949/0768—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform

- B29C2949/077—Preforms or parisons characterised by their configuration characterised by the shape characterised by the shape of specific parts of preform characterised by the neck

- B29C2949/0777—Tamper-evident band retaining ring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/20—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer

- B29C2949/22—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer at neck portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/20—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer

- B29C2949/24—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer at flange portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/20—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer

- B29C2949/26—Preforms or parisons whereby a specific part is made of only one component, e.g. only one layer at body portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3004—Preforms or parisons made of several components having longitudinally different components within one layer, e.g. tubes with longitudinal stratified layering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3006—Preforms or parisons made of several components having tangentially different components within one layer, e.g. longitudinal stripes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3016—Preforms or parisons made of several components at body portion

- B29C2949/3018—Preforms or parisons made of several components at body portion partially

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/302—Preforms or parisons made of several components at bottom portion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

- B29C2949/3028—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3024—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique

- B29C2949/3026—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components

- B29C2949/3028—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components

- B29C2949/303—Preforms or parisons made of several components characterised by the number of components or by the manufacturing technique having two or more components having three or more components having more than three components

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

- B29C2949/3036—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/30—Preforms or parisons made of several components

- B29C2949/3032—Preforms or parisons made of several components having components being injected

- B29C2949/3034—Preforms or parisons made of several components having components being injected having two or more components being injected

- B29C2949/3036—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected

- B29C2949/3038—Preforms or parisons made of several components having components being injected having two or more components being injected having three or more components being injected having more than three components being injected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/02—Combined blow-moulding and manufacture of the preform or the parison

- B29C49/06—Injection blow-moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2067/00—Use of polyesters or derivatives thereof, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0005—Condition, form or state of moulded material or of the material to be shaped containing compounding ingredients

- B29K2105/0032—Pigments, colouring agents or opacifiyng agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/25—Solid

- B29K2105/253—Preform

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/25—Solid

- B29K2105/253—Preform

- B29K2105/258—Tubular

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0018—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds having particular optical properties, e.g. fluorescent or phosphorescent

- B29K2995/002—Coloured

- B29K2995/0021—Multi-coloured

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0018—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds having particular optical properties, e.g. fluorescent or phosphorescent

- B29K2995/0025—Opaque

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0037—Other properties

- B29K2995/0068—Permeability to liquids; Adsorption

- B29K2995/0069—Permeability to liquids; Adsorption non-permeable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

- B29L2031/7158—Bottles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2203/00—Decoration means, markings, information elements, contents indicators

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/131—Glass, ceramic, or sintered, fused, fired, or calcined metal oxide or metal carbide containing [e.g., porcelain, brick, cement, etc.]

- Y10T428/1317—Multilayer [continuous layer]

- Y10T428/1321—Polymer or resin containing [i.e., natural or synthetic]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/1355—Elemental metal containing [e.g., substrate, foil, film, coating, etc.]

- Y10T428/1359—Three or more layers [continuous layer]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/1372—Randomly noninterengaged or randomly contacting fibers, filaments, particles, or flakes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/1379—Contains vapor or gas barrier, polymer derived from vinyl chloride or vinylidene chloride, or polymer containing a vinyl alcohol unit

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/13—Hollow or container type article [e.g., tube, vase, etc.]

- Y10T428/1352—Polymer or resin containing [i.e., natural or synthetic]

- Y10T428/1379—Contains vapor or gas barrier, polymer derived from vinyl chloride or vinylidene chloride, or polymer containing a vinyl alcohol unit

- Y10T428/1383—Vapor or gas barrier, polymer derived from vinyl chloride or vinylidene chloride, or polymer containing a vinyl alcohol unit is sandwiched between layers [continuous layer]

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Ceramic Engineering (AREA)

- Physics & Mathematics (AREA)

- Geometry (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Containers Having Bodies Formed In One Piece (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Description

Claims (15)

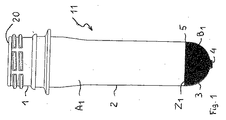

- 注ぎ口を取り囲むネック部と、隣接する壁部と、前記ネック部の反対側にあり、製造される容器の支持基部となる底部とを含む、容器をブロー成形するためのプリフォームであって、

前記プリフォームは第1の領域および少なくとも1つの第2の領域から構成され、前記第1の領域は第1のプラスチック材料からなり、前記少なくとも1つの第2の領域は少なくとも1つの第2の材料からなり、

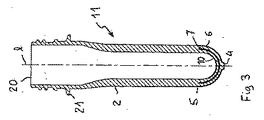

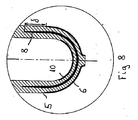

前記第1の領域および第2の領域は相互に異なる配色を有し、少なくとも前記底部の実質的な部分が、前記第1のプラスチック材料から構成される第1の層と、前記少なくとも1つの第2の材料から構成される追加の第2の層とを有する多層構造から構成され、前記第2の層が2つの表面層を含み、その内の1つが前記プリフォームに関して外側に方向付けられ、もう一方のものが内側に方向付けられ、中間の第2の層が間に位置付けられてコア層を構成し、コア層はさらに2つの前記第1の層の間に位置付けられ、および前記プリフォームが一体であり、前記第1の領域から前記第2の領域への境目に継ぎ目がなく、前記第2の領域が不透明および/または半透明でありかつ前記プリフォームの前記底部に限定されていることを特徴とするプリフォーム。 - (a)前記第1または第2の領域の内の少なくとも1つが着色されていること、および

(b)少なくとも前記第1の領域が、透明、または透明かつ着色されていないこと

から選択される少なくとも1つであることを特徴とする請求項1記載のプリフォーム。 - 前記プリフォームの前記第1および第2の領域の間の境目が、分離線に存在するか、または前記第1および第2の領域が、前記領域間の境目と比較すると極めて弱いコントラストをなす境目帯域によって分離されることを特徴とする請求項1または2記載のプリフォーム。

- 前記追加の第2の層の少なくとも1つが、着色染料と前記第2の材料としてのプラスチックとの混合物から構成されることを特徴とする請求項1〜3のいずれかに記載のプリフォーム。

- 前記着色染料が、蛍光性、燐光性または発光性染料からなるリストから選ばれることを特徴とする請求項4記載のプリフォーム。

- (a)少なくとも1つの第2の材料が、前記第1のプラスチック材料と同じであること、および

(b)前記コア層が、少なくとも局所的に前記底の厚みの半分までを占める厚み(ε)を有すること

から選択される少なくとも1つであることを特徴とする請求項1〜5のいずれかに記載のプリフォーム。 - (a)前記追加の内層および外層のそれぞれが、実質的に前記プリフォームの壁の屈曲である、底の境界まで伸張していること、および

(b)前記コア層が、前記底から、少なくとも前記内層および外層のそれぞれと同じ範囲まで伸張し、または前記コア層が、前記底から、前記内層および外層のそれぞれを、一定の距離だけ上回る高さまで伸張していること

から選択される少なくとも1つであることを特徴とする請求項1〜6のいずれかに記載のプリフォーム。 - 前記プリフォームの壁部がさらに中間壁層を含んでなる多層構造を有し、前記中間壁層が第3のプラスチック材料から構成されるバリア層として作用する請求項1〜7のいずれかに記載のプリフォーム。

- 前記材料の少なくとも1つが所定量の添加剤を含み、該添加剤が、前記容器中に含まれる製品に対し悪影響を有する試薬に対して中和効果を有し、活性を有するまたは活性のないバリアが、前記プリフォームの壁部において形成されることを特徴とする請求項1〜8のいずれかに記載のプリフォーム。

- 前記中間の層の少なくとも1つが、流体または液体からなる請求項1〜9のいずれかに記載のプリフォーム。

- 前記材料の少なくとも1つが、ポリマー中で作用する細胞および/または細胞生成物によって構成される、いわゆるポリマーバイオアグリゲートから構成されることを特徴とする請求項1〜10のいずれかに記載のプリフォーム。

- 請求項1〜11のいずれかに記載のプリフォームをブロー成形することによって得られる容器の利用法であって、

容器が、高い拡散能を有する光散乱媒体で充填され、前記媒体を充填した際に、前記底に限定された色が、前記容器の全体に渡って拡散される利用法。 - 容器中にブロー成形されることを意図されるプリフォームを射出成形するための方法であって、前記プリフォームが、注ぎ口を含むネック部と、隣接する壁部と、前記ネック部の反対側にあり、製造される容器の支持基部を形成するよう意図されている底部とを含み、前記方法が以下のステップ、すなわち、

a)最初に第2の材料を射出するステップであって、前記第2の材料が、前記プリフォームの前記底部において、外層にあるモールドの冷たい表面および内層にあるコアの冷たい表面で固化するステップと、

b)その後、実質的に前記壁部およびネック部の完全な容量を構成する、前記壁部および前記ネック部に流入し、そしてすでに固化された前記第2の材料と接触して、底部の2つの層に流入する第1の材料を射出するステップと、

c)最後に、前記底部において残っている容量を充填し、前記底部におけるコア層を構成する第2の材料を射出するステップと

を含む方法。 - 前記第2の材料のコア層が、前記壁部において他の2つの第2の層よりも距離(δ)だけさらに伸張するように、前記第1の材料の量がわずかに減らされ、最終ステップで射出される前記第2の材料の量が増やされ、第3の材料が、前記壁部において中間層を構成するように、前記第3の材料が、前記第2の材料の射出という最終段階の前に射出されることを特徴とする請求項13記載の方法。

- 射出成形において、請求項1〜11のいずれかに記載のプリフォームを製造する方法であって、最初に第2の材料が射出され、前記プリフォームの前記底部において、外層にあるモールドの冷たい表面および内層にあるコアの冷たい表面で固化され、所定量の第1の合成材料が中空のモールドスペースに射出され、そして所定量の第2もしくは第3の材料が、コア層の形成前に前記中空のモールドスペースにおいて前記射出された第1の合成材料の中に射出され、

第2もしくは第3の材料が前記第1の材料と異なることと、

前記中空のモールドスペースにおける射出が、前記第1の材料の一部と並行する射出であることと、

前記中空のモールドスペースの射出開口部の領域において並行に射出する場合、前記第2もしくは第3の材料が前記プリフォームから外側に射出され、そして前記第1の材料が前記プリフォームに関して内側に射出されることと、および/または

射出された前記材料の少なくとも1つが、生体材料を含み、以下のステップ、すなわち

a)ポリマーを選択するステップと、

b)一連の有機体を、細胞、生体および/または細胞生成物から選択するステップと、

c)前記ポリマー中で前記細胞および/または細胞生成物を作用させることにより、集合体を形成し、結果としていわゆるポリマーバイオアグリゲートを形成するステップと

を含む方法によって製造され、

作用が、選択された温度間隔から選ばれた作用温度で実行され、該温度の下限が、実質的に標準圧力条件下で実質的に100℃に設定され得ることを特徴とする方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE2008/0082A BE1018460A5 (nl) | 2008-02-12 | 2008-02-12 | Kleurvoorvorm en werkwijze voor het vervaardigen hiervan tot een polychromatische kunststofbehouder. |

| BE2008/0082 | 2008-02-12 | ||

| PCT/BE2009/000008 WO2009100506A2 (en) | 2008-02-12 | 2009-02-12 | Plastic preform and process for the manufacturing thereof to a polychromatic container |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011526546A JP2011526546A (ja) | 2011-10-13 |

| JP2011526546A5 JP2011526546A5 (ja) | 2014-06-19 |

| JP5802391B2 true JP5802391B2 (ja) | 2015-10-28 |

Family

ID=39773088

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010545334A Expired - Fee Related JP5802391B2 (ja) | 2008-02-12 | 2009-02-12 | 多色容器のためのプラスチック・プリフォームとその製造方法 |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US8895120B2 (ja) |

| EP (1) | EP2318194B1 (ja) |

| JP (1) | JP5802391B2 (ja) |

| CN (1) | CN102026793A (ja) |

| AU (1) | AU2009214840B2 (ja) |

| BE (1) | BE1018460A5 (ja) |

| CA (1) | CA2715008A1 (ja) |

| DK (1) | DK2318194T3 (ja) |

| ES (1) | ES2402069T3 (ja) |

| WO (1) | WO2009100506A2 (ja) |

| ZA (1) | ZA201006528B (ja) |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8057733B2 (en) | 2007-12-21 | 2011-11-15 | Silgan Plastics Corporation | Dosing bottle and method |

| USD769720S1 (en) | 2007-12-21 | 2016-10-25 | Silgan Plastics Llc | Preform for dosing bottle |

| WO2012134996A1 (en) * | 2011-03-25 | 2012-10-04 | Amcor Limited | Barrier system for wide mouth containers |

| US20130069268A1 (en) | 2011-09-16 | 2013-03-21 | Pepsico, Inc. | Non-Uniform Color Infusion Distribution In Plastic Containers |

| US20130069267A1 (en) | 2011-09-16 | 2013-03-21 | Pepsico, Inc. | Method And Apparatus For Forming Color Swirls In Plastic Containers |

| USD732391S1 (en) * | 2012-02-10 | 2015-06-23 | Silgan Plastics Llc | Container with ribbed neck |

| BE1020911B1 (nl) * | 2012-11-30 | 2019-09-16 | Resilux | Werkwijze van overmoulding, i.h.b. bij voorvormelingen bestemd om omgevormd te worden tot behouders. |

| AP2017009698A0 (en) * | 2014-08-01 | 2017-01-31 | Coca Cola Co | Lightweight base for carbonated beverage packaging |

| JP6415902B2 (ja) * | 2014-08-28 | 2018-10-31 | 株式会社吉野工業所 | プリフォーム及びボトルの製造方法 |

| WO2016084301A1 (ja) * | 2014-11-28 | 2016-06-02 | 株式会社吉野工業所 | 二軸延伸ブロー成形用のプリフォーム及び容器、並びに二軸延伸ブロー成形用のプリフォームの製造方法及び容器の製造方法 |

| USD817173S1 (en) * | 2014-12-25 | 2018-05-08 | Dai Nippon Printing Co., Ltd. | Preform for bottles |

| WO2017156384A1 (en) * | 2016-03-11 | 2017-09-14 | Ring Container Technologies | Method of manufacture of a container |

| US10889046B2 (en) | 2016-09-12 | 2021-01-12 | Lifetime Products, Inc. | Dual color blow molding process |

| EP3470195A1 (en) | 2017-10-12 | 2019-04-17 | The Procter & Gamble Company | Blow molded article with visual effects |

| WO2020006624A1 (en) * | 2018-07-03 | 2020-01-09 | Husky Injection Molding Systems Ltd. | A preform and mold stack |

| US11046473B2 (en) * | 2018-07-17 | 2021-06-29 | The Procter And Gamble Company | Blow molded article with visual effects |

| US11724847B2 (en) | 2018-10-19 | 2023-08-15 | The Procter & Gamble Company | Blow molded article with debossing |

| EP3898155A1 (en) * | 2018-12-19 | 2021-10-27 | The Procter & Gamble Company | Article with visual effect |

| US11634248B2 (en) | 2018-12-19 | 2023-04-25 | The Procter & Gamble Company | Mono-layer blow molded article with functional, visual, and/or tactile effects and method of making such articles |

| MX2021012431A (es) * | 2019-04-11 | 2021-11-12 | Procter & Gamble | Articulo moldeado por soplado con efectos visuales. |

| US20200354529A1 (en) * | 2019-05-08 | 2020-11-12 | The Procter & Gamble Company | One piece multilayer thermoplastic container having a colorant |

| IT201900025117A1 (it) * | 2019-12-20 | 2021-06-20 | De Longhi Appliances Srl | Metodo ed apparato di realizzazione di un componente in materiale plastico, e componente in materiale plastico |

| CN114929467A (zh) | 2020-01-08 | 2022-08-19 | 宝洁公司 | 具有颜色梯度的吹塑多层制品 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5928451B2 (ja) * | 1976-12-28 | 1984-07-13 | 株式会社吉野工業所 | 多色の横縞模様壜体成形方法 |

| JPS61219644A (ja) * | 1985-03-26 | 1986-09-30 | 東洋製罐株式会社 | 延伸多層プラスチック容器の製法 |

| GB8616460D0 (en) * | 1986-07-05 | 1986-08-13 | Metal Box Plc | Manufacture of articles |

| JPH0267117A (ja) * | 1988-09-02 | 1990-03-07 | Toyo Seikan Kaisha Ltd | 射出成形用金型 |

| US4923723A (en) * | 1988-11-01 | 1990-05-08 | Continental Pet Technologies, Inc. | Multi-layer preform, method of forming preform, and container formed from the preform |

| US4954376A (en) * | 1988-12-30 | 1990-09-04 | Continental Pet Technologies, Inc. | Two material three/five layer preform |

| US4990301A (en) | 1989-01-25 | 1991-02-05 | Continental Pet Technologies, Inc. | Method and apparatus for injection molding of multilayer preforms |

| JPH0376624A (ja) * | 1989-08-18 | 1991-04-02 | Kamaya Kagaku Kogyo Co Ltd | 容器の射出形成方法及び容器の射出成形装置及び容器 |

| DE4330451A1 (de) * | 1993-09-09 | 1995-03-16 | Werner Froer | Verfahren zur Herstellung eines spritzgegossenen Körpers und Spritzgußkörper |

| US5595799A (en) * | 1995-12-14 | 1997-01-21 | Dtl Technology Limited Partnership | Coinjection molding of decorative preforms and containers produced from such preforms |

| US5804016A (en) * | 1996-03-07 | 1998-09-08 | Continental Pet Technologies, Inc. | Multilayer container resistant to elevated temperatures and pressures, and method of making the same |

| FR2754245B1 (fr) * | 1996-10-07 | 1998-11-27 | Oreal | Recipient a bande(s) de couleur et/ou d'aspect differents |

| DE50005364D1 (de) | 1999-11-05 | 2004-03-25 | Otto Hofstetter Ag Uznach | Mehrschichtiger vorformling und verfahren zur herstellung desselben |

| CN1195620C (zh) * | 2000-10-19 | 2005-04-06 | 帝人株式会社 | 多层预成型体及其制造方法 |

| AU2002225866A1 (en) * | 2000-11-08 | 2002-05-21 | Valspar Sourcing, Inc | Multilayered package with barrier properties |

| US20020058114A1 (en) * | 2000-11-10 | 2002-05-16 | Sung Chien Min | Colored bottle blank and forming mold set with manufacturing process thereof |

| EP1559529A3 (en) * | 2004-02-02 | 2005-10-19 | The Procter & Gamble Company | Preforms made of two or more materials and processes for obtaining them |

| US7357967B2 (en) * | 2004-02-27 | 2008-04-15 | Owens-Illinois Prescription Products Inc. | Container having fluorescent indicia |

| US6988629B2 (en) * | 2004-05-13 | 2006-01-24 | Plastipak Packaging, Inc. | Hollow plastic article including a view stripe |

| WO2006012713A2 (en) * | 2004-08-06 | 2006-02-09 | Resilux | Preform for blowing a container and process for manufacturing therof |

| BE1016177A6 (nl) * | 2004-09-03 | 2006-04-04 | Resilux | Werkwijze voor het vervaardigen van hydrofobe polymeren. |

| CN101857094B (zh) | 2005-04-28 | 2012-09-19 | 株式会社吉野工业所 | 具有层次图案的瓶体以及预成型件的注射成型方法 |

| JP4692731B2 (ja) * | 2005-04-28 | 2011-06-01 | 株式会社吉野工業所 | グラデーション模様付きボトルと、ボトル成形用のプリフォーム |

-

2008

- 2008-02-12 BE BE2008/0082A patent/BE1018460A5/nl not_active IP Right Cessation

-

2009

- 2009-02-12 AU AU2009214840A patent/AU2009214840B2/en not_active Ceased

- 2009-02-12 EP EP09710251A patent/EP2318194B1/en active Active

- 2009-02-12 US US12/735,734 patent/US8895120B2/en not_active Expired - Fee Related

- 2009-02-12 WO PCT/BE2009/000008 patent/WO2009100506A2/en active Application Filing

- 2009-02-12 JP JP2010545334A patent/JP5802391B2/ja not_active Expired - Fee Related

- 2009-02-12 ES ES09710251T patent/ES2402069T3/es active Active

- 2009-02-12 CA CA2715008A patent/CA2715008A1/en not_active Abandoned

- 2009-02-12 DK DK09710251.1T patent/DK2318194T3/da active

- 2009-02-12 CN CN200980112938.XA patent/CN102026793A/zh active Pending

-

2010

- 2010-09-13 ZA ZA2010/06528A patent/ZA201006528B/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| AU2009214840B2 (en) | 2014-10-30 |

| BE1018460A5 (nl) | 2010-12-07 |

| WO2009100506A3 (en) | 2010-10-07 |

| ZA201006528B (en) | 2011-10-26 |

| EP2318194B1 (en) | 2013-01-09 |

| CN102026793A (zh) | 2011-04-20 |

| EP2318194A2 (en) | 2011-05-11 |

| JP2011526546A (ja) | 2011-10-13 |

| AU2009214840A1 (en) | 2009-08-20 |

| US20100307633A1 (en) | 2010-12-09 |

| CA2715008A1 (en) | 2009-08-20 |

| WO2009100506A2 (en) | 2009-08-20 |

| DK2318194T3 (da) | 2013-04-15 |

| ES2402069T3 (es) | 2013-04-26 |

| US8895120B2 (en) | 2014-11-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5802391B2 (ja) | 多色容器のためのプラスチック・プリフォームとその製造方法 | |

| JP2011526546A5 (ja) | ||

| RU2455209C1 (ru) | Полиэфирная емкость, изготовленная формованием с раздувом, с наформованным термопластичным слоем | |

| AU2005210653B2 (en) | Preforms made of two or more materials and processes for obtaining them. | |

| KR101319732B1 (ko) | 그라데이션 모양 부착 병체 및 프리폼의 사출성형방법 | |

| KR101105751B1 (ko) | 합성 수지 중공체 | |

| JP2014530125A (ja) | プリフォームを製造する方法 | |

| JP6415902B2 (ja) | プリフォーム及びボトルの製造方法 | |

| JP6975371B2 (ja) | プラスチック容器 | |

| JP4337395B2 (ja) | プラスチック包装体及びその加飾方法 | |

| KR20100001397A (ko) | 다색조 용기 | |

| JP2022137948A (ja) | 合成樹脂製容器 | |

| EP3243623A1 (en) | Two-layered preform | |

| MXPA06008668A (en) | Preforms made of two or more materials and processes for obtaining them |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120213 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120213 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20131024 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131029 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140128 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140204 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140227 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140306 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20140328 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20140404 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20140428 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150106 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150403 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150501 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20150605 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150702 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150804 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150831 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5802391 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |