JP5799877B2 - 熱可塑性樹脂組成物の製造方法および粉体原料用押出機 - Google Patents

熱可塑性樹脂組成物の製造方法および粉体原料用押出機 Download PDFInfo

- Publication number

- JP5799877B2 JP5799877B2 JP2012078923A JP2012078923A JP5799877B2 JP 5799877 B2 JP5799877 B2 JP 5799877B2 JP 2012078923 A JP2012078923 A JP 2012078923A JP 2012078923 A JP2012078923 A JP 2012078923A JP 5799877 B2 JP5799877 B2 JP 5799877B2

- Authority

- JP

- Japan

- Prior art keywords

- raw material

- kneading

- powder raw

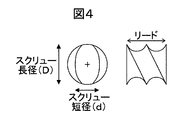

- screw

- thermoplastic resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002994 raw material Substances 0.000 title claims description 79

- 239000000843 powder Substances 0.000 title claims description 76

- 229920005992 thermoplastic resin Polymers 0.000 title claims description 44

- 239000011342 resin composition Substances 0.000 title claims description 37

- 238000004519 manufacturing process Methods 0.000 title claims description 31

- 238000004898 kneading Methods 0.000 claims description 84

- 239000000806 elastomer Substances 0.000 claims description 21

- 229920001971 elastomer Polymers 0.000 claims description 20

- 239000002245 particle Substances 0.000 claims description 10

- 239000004734 Polyphenylene sulfide Substances 0.000 claims description 8

- 229920000069 polyphenylene sulfide Polymers 0.000 claims description 8

- 239000000470 constituent Substances 0.000 claims description 5

- 229920006122 polyamide resin Polymers 0.000 claims description 4

- 229920001225 polyester resin Polymers 0.000 claims description 4

- 239000004645 polyester resin Substances 0.000 claims description 3

- 229920005989 resin Polymers 0.000 description 18

- 239000011347 resin Substances 0.000 description 18

- 238000000034 method Methods 0.000 description 14

- 239000000835 fiber Substances 0.000 description 13

- 230000000694 effects Effects 0.000 description 12

- 239000012779 reinforcing material Substances 0.000 description 9

- 230000000669 biting effect Effects 0.000 description 8

- 238000002844 melting Methods 0.000 description 7

- 230000008018 melting Effects 0.000 description 7

- 239000000945 filler Substances 0.000 description 6

- 238000011049 filling Methods 0.000 description 6

- 238000002156 mixing Methods 0.000 description 6

- -1 polyethylene terephthalate Polymers 0.000 description 6

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 238000010008 shearing Methods 0.000 description 5

- 230000006872 improvement Effects 0.000 description 4

- 238000007664 blowing Methods 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 238000001125 extrusion Methods 0.000 description 3

- 230000007935 neutral effect Effects 0.000 description 3

- 239000008188 pellet Substances 0.000 description 3

- 230000001141 propulsive effect Effects 0.000 description 3

- 239000012783 reinforcing fiber Substances 0.000 description 3

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 2

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 2

- 239000005977 Ethylene Substances 0.000 description 2

- 229920002292 Nylon 6 Polymers 0.000 description 2

- 229910021536 Zeolite Inorganic materials 0.000 description 2

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 2

- 239000004917 carbon fiber Substances 0.000 description 2

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 239000010893 paper waste Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920006324 polyoxymethylene Polymers 0.000 description 2

- 229910052604 silicate mineral Inorganic materials 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 239000000454 talc Substances 0.000 description 2

- 229910052623 talc Inorganic materials 0.000 description 2

- 238000005979 thermal decomposition reaction Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 239000010456 wollastonite Substances 0.000 description 2

- 229910052882 wollastonite Inorganic materials 0.000 description 2

- 239000010457 zeolite Substances 0.000 description 2

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 1

- 229920002972 Acrylic fiber Polymers 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 244000198134 Agave sisalana Species 0.000 description 1

- 239000005995 Aluminium silicate Substances 0.000 description 1

- 229910052582 BN Inorganic materials 0.000 description 1

- 240000008564 Boehmeria nivea Species 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 1

- 244000025254 Cannabis sativa Species 0.000 description 1

- 235000012766 Cannabis sativa ssp. sativa var. sativa Nutrition 0.000 description 1

- 235000012765 Cannabis sativa ssp. sativa var. spontanea Nutrition 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229920003043 Cellulose fiber Polymers 0.000 description 1

- 240000000491 Corchorus aestuans Species 0.000 description 1

- 235000011777 Corchorus aestuans Nutrition 0.000 description 1

- 235000010862 Corchorus capsularis Nutrition 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 241000219146 Gossypium Species 0.000 description 1

- 240000000797 Hibiscus cannabinus Species 0.000 description 1

- 240000006240 Linum usitatissimum Species 0.000 description 1

- 235000004431 Linum usitatissimum Nutrition 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 240000000907 Musa textilis Species 0.000 description 1

- 229920002302 Nylon 6,6 Polymers 0.000 description 1

- 229930040373 Paraformaldehyde Natural products 0.000 description 1

- 229930182556 Polyacetal Natural products 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 229920001131 Pulp (paper) Polymers 0.000 description 1

- 240000000111 Saccharum officinarum Species 0.000 description 1

- 235000007201 Saccharum officinarum Nutrition 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Natural products C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 1

- YKTSYUJCYHOUJP-UHFFFAOYSA-N [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] Chemical compound [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] YKTSYUJCYHOUJP-UHFFFAOYSA-N 0.000 description 1

- RJDOZRNNYVAULJ-UHFFFAOYSA-L [O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[F-].[F-].[Mg++].[Mg++].[Mg++].[Al+3].[Si+4].[Si+4].[Si+4].[K+] Chemical compound [O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[O--].[F-].[F-].[Mg++].[Mg++].[Mg++].[Al+3].[Si+4].[Si+4].[Si+4].[K+] RJDOZRNNYVAULJ-UHFFFAOYSA-L 0.000 description 1

- 229920006221 acetate fiber Polymers 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 235000012211 aluminium silicate Nutrition 0.000 description 1

- OJMOMXZKOWKUTA-UHFFFAOYSA-N aluminum;borate Chemical compound [Al+3].[O-]B([O-])[O-] OJMOMXZKOWKUTA-UHFFFAOYSA-N 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 239000010425 asbestos Substances 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000000440 bentonite Substances 0.000 description 1

- 229910000278 bentonite Inorganic materials 0.000 description 1

- SVPXDRXYRYOSEX-UHFFFAOYSA-N bentoquatam Chemical compound O.O=[Si]=O.O=[Al]O[Al]=O SVPXDRXYRYOSEX-UHFFFAOYSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 235000009120 camo Nutrition 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 235000005607 chanvre indien Nutrition 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- GUJOJGAPFQRJSV-UHFFFAOYSA-N dialuminum;dioxosilane;oxygen(2-);hydrate Chemical compound O.[O-2].[O-2].[O-2].[Al+3].[Al+3].O=[Si]=O.O=[Si]=O.O=[Si]=O.O=[Si]=O GUJOJGAPFQRJSV-UHFFFAOYSA-N 0.000 description 1

- GDVKFRBCXAPAQJ-UHFFFAOYSA-A dialuminum;hexamagnesium;carbonate;hexadecahydroxide Chemical compound [OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Al+3].[Al+3].[O-]C([O-])=O GDVKFRBCXAPAQJ-UHFFFAOYSA-A 0.000 description 1

- NJLLQSBAHIKGKF-UHFFFAOYSA-N dipotassium dioxido(oxo)titanium Chemical compound [K+].[K+].[O-][Ti]([O-])=O NJLLQSBAHIKGKF-UHFFFAOYSA-N 0.000 description 1

- 239000010459 dolomite Substances 0.000 description 1

- 229910000514 dolomite Inorganic materials 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000010433 feldspar Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- VOZRXNHHFUQHIL-UHFFFAOYSA-N glycidyl methacrylate Chemical compound CC(=C)C(=O)OCC1CO1 VOZRXNHHFUQHIL-UHFFFAOYSA-N 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000011487 hemp Substances 0.000 description 1

- 229920001903 high density polyethylene Polymers 0.000 description 1

- 229910001701 hydrotalcite Inorganic materials 0.000 description 1

- 229960001545 hydrotalcite Drugs 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- XGZVUEUWXADBQD-UHFFFAOYSA-L lithium carbonate Chemical compound [Li+].[Li+].[O-]C([O-])=O XGZVUEUWXADBQD-UHFFFAOYSA-L 0.000 description 1

- 229910052808 lithium carbonate Inorganic materials 0.000 description 1

- 229920001684 low density polyethylene Polymers 0.000 description 1

- 239000004702 low-density polyethylene Substances 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000010445 mica Substances 0.000 description 1

- 229910052618 mica group Inorganic materials 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 229910052901 montmorillonite Inorganic materials 0.000 description 1

- 239000002667 nucleating agent Substances 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920006124 polyolefin elastomer Polymers 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 229920001955 polyphenylene ether Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000004627 regenerated cellulose Substances 0.000 description 1

- 229910052895 riebeckite Inorganic materials 0.000 description 1

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical compound O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000002893 slag Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 229920002725 thermoplastic elastomer Polymers 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/505—Screws

- B29C48/57—Screws provided with kneading disc-like elements, e.g. with oval-shaped elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/46—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft

- B29B7/48—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws

- B29B7/482—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws provided with screw parts in addition to other mixing parts, e.g. paddles, gears, discs

- B29B7/483—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws provided with screw parts in addition to other mixing parts, e.g. paddles, gears, discs the other mixing parts being discs perpendicular to the screw axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/505—Screws

- B29C48/54—Screws with additional forward-feeding elements

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012078923A JP5799877B2 (ja) | 2012-03-30 | 2012-03-30 | 熱可塑性樹脂組成物の製造方法および粉体原料用押出機 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012078923A JP5799877B2 (ja) | 2012-03-30 | 2012-03-30 | 熱可塑性樹脂組成物の製造方法および粉体原料用押出機 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013208728A JP2013208728A (ja) | 2013-10-10 |

| JP2013208728A5 JP2013208728A5 (enExample) | 2014-05-15 |

| JP5799877B2 true JP5799877B2 (ja) | 2015-10-28 |

Family

ID=49527097

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012078923A Active JP5799877B2 (ja) | 2012-03-30 | 2012-03-30 | 熱可塑性樹脂組成物の製造方法および粉体原料用押出機 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5799877B2 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5660513B1 (ja) * | 2014-05-22 | 2015-01-28 | 国立大学法人九州工業大学 | バイオマスナノ繊維の製造方法およびバイオマスナノ繊維・高分子樹脂複合体の製造方法 |

| JP7371371B2 (ja) * | 2019-07-12 | 2023-10-31 | 東レ株式会社 | ポリフェニレンスルフィド樹脂組成物の製造方法 |

| CN112592534B (zh) * | 2020-11-30 | 2022-12-06 | 金发科技股份有限公司 | 一种增韧增强聚丙烯复合材料的制备方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06306285A (ja) * | 1993-04-22 | 1994-11-01 | Tonen Corp | 食器用熱可塑性樹脂組成物 |

| JP5369614B2 (ja) * | 2008-10-30 | 2013-12-18 | 東レ株式会社 | 粉体原料用押出機および熱可塑性樹脂組成物の製造方法 |

| JP5534964B2 (ja) * | 2010-06-11 | 2014-07-02 | 旭化成ケミカルズ株式会社 | ポリフェニレンエーテル樹脂組成物の製造方法 |

-

2012

- 2012-03-30 JP JP2012078923A patent/JP5799877B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013208728A (ja) | 2013-10-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5369614B2 (ja) | 粉体原料用押出機および熱可塑性樹脂組成物の製造方法 | |

| US4708623A (en) | Apparatus for producing organic filler-blended resin compositions | |

| JP2008238626A (ja) | 熱可塑性樹脂組成物の製造方法 | |

| CN113412179B (zh) | 热塑性树脂组合物的成型机和制造方法以及复合树脂组合物成型品的制造方法、注塑成型品 | |

| JP2014051088A (ja) | 熱可塑性樹脂組成物の溶融混練方法 | |

| CN101679925A (zh) | 清洗剂及使用该清洗剂清洗树脂成形机的方法 | |

| JP5799877B2 (ja) | 熱可塑性樹脂組成物の製造方法および粉体原料用押出機 | |

| CN103030891A (zh) | 一种长玻璃纤维增强聚丙烯复合材料及其制备方法 | |

| JP6608306B2 (ja) | 樹脂組成物成形機および樹脂組成物の成形方法 | |

| JP2018048227A (ja) | 熱可塑性樹脂組成物の製造方法 | |

| CN102794899A (zh) | 一种用于废旧橡塑共混体系复合改性的双螺杆挤出机的螺杆 | |

| BR102012015496B1 (pt) | Método de fabricação para composição de resina contendo pó fino de papel | |

| KR20210096363A (ko) | 경도 및 강도가 우수한 폐플라스틱 재활용 성형물 제조방법 | |

| CN107835732B (zh) | 树脂组合物的制造方法 | |

| WO2023097950A1 (zh) | 一种高抗冲木塑头盔复合材料及制备方法 | |

| JP3983056B2 (ja) | 再生pet樹脂組成物の製造方法 | |

| JP6353691B2 (ja) | ガラスウール複合熱可塑性樹脂組成物及びその製造法、成形物。 | |

| JP2010030176A (ja) | 熱可塑性樹脂組成物ペレットの製造方法 | |

| BR102012015495B1 (pt) | Método de fabricação para composição de resina contendo pó fino de papel | |

| JP5032244B2 (ja) | 繊維強化熱可塑性樹脂組成物の製造装置およびその製造方法 | |

| JP7637038B2 (ja) | 混合組成物の製造方法 | |

| CN102794900A (zh) | 一种用于废旧塑料再生加工的双螺杆挤出机的螺杆 | |

| JPH0730211B2 (ja) | 熱可塑性樹脂組成物の製造方法 | |

| JP7426451B1 (ja) | ガラス繊維強化ポリアミド樹脂組成物の製造方法 | |

| JP7426450B1 (ja) | ガラス繊維強化ポリアミド樹脂組成物の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140331 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140331 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141217 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150106 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150305 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150728 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150810 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5799877 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |