JP5656636B2 - 多成分繊維 - Google Patents

多成分繊維 Download PDFInfo

- Publication number

- JP5656636B2 JP5656636B2 JP2010522852A JP2010522852A JP5656636B2 JP 5656636 B2 JP5656636 B2 JP 5656636B2 JP 2010522852 A JP2010522852 A JP 2010522852A JP 2010522852 A JP2010522852 A JP 2010522852A JP 5656636 B2 JP5656636 B2 JP 5656636B2

- Authority

- JP

- Japan

- Prior art keywords

- fiber

- multicomponent

- pcm

- viscosity

- fibers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000835 fiber Substances 0.000 title claims description 282

- 239000000463 material Substances 0.000 claims description 170

- 239000012782 phase change material Substances 0.000 claims description 164

- 239000004034 viscosity adjusting agent Substances 0.000 claims description 53

- 229920000642 polymer Polymers 0.000 claims description 44

- -1 polyethylene Polymers 0.000 claims description 40

- 239000002250 absorbent Substances 0.000 claims description 36

- 230000002745 absorbent Effects 0.000 claims description 36

- 239000001993 wax Substances 0.000 claims description 25

- 239000004744 fabric Substances 0.000 claims description 24

- 238000002074 melt spinning Methods 0.000 claims description 22

- 239000004698 Polyethylene Substances 0.000 claims description 19

- 238000000034 method Methods 0.000 claims description 19

- 229920000573 polyethylene Polymers 0.000 claims description 19

- 239000004215 Carbon black (E152) Substances 0.000 claims description 17

- 229930195733 hydrocarbon Natural products 0.000 claims description 17

- 150000002430 hydrocarbons Chemical class 0.000 claims description 17

- 239000000155 melt Substances 0.000 claims description 17

- 238000002844 melting Methods 0.000 claims description 14

- 230000008018 melting Effects 0.000 claims description 14

- 229920000098 polyolefin Polymers 0.000 claims description 8

- 238000001125 extrusion Methods 0.000 claims description 7

- 239000004952 Polyamide Substances 0.000 claims description 5

- 229920002647 polyamide Polymers 0.000 claims description 5

- 229920006125 amorphous polymer Polymers 0.000 claims description 3

- 230000003796 beauty Effects 0.000 claims description 2

- 229920006149 polyester-amide block copolymer Polymers 0.000 claims 1

- 239000011162 core material Substances 0.000 description 49

- 239000000203 mixture Substances 0.000 description 26

- 230000004927 fusion Effects 0.000 description 20

- 239000004743 Polypropylene Substances 0.000 description 17

- 229920001155 polypropylene Polymers 0.000 description 17

- 238000009987 spinning Methods 0.000 description 14

- 238000004519 manufacturing process Methods 0.000 description 11

- 239000003094 microcapsule Substances 0.000 description 10

- 239000007787 solid Substances 0.000 description 10

- 239000004753 textile Substances 0.000 description 10

- 239000002245 particle Substances 0.000 description 9

- CBFCDTFDPHXCNY-UHFFFAOYSA-N icosane Chemical compound CCCCCCCCCCCCCCCCCCCC CBFCDTFDPHXCNY-UHFFFAOYSA-N 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 7

- 229920001903 high density polyethylene Polymers 0.000 description 7

- 239000004700 high-density polyethylene Substances 0.000 description 7

- 229920000139 polyethylene terephthalate Polymers 0.000 description 7

- 239000005020 polyethylene terephthalate Substances 0.000 description 7

- 238000012545 processing Methods 0.000 description 7

- 229920002994 synthetic fiber Polymers 0.000 description 7

- 230000000694 effects Effects 0.000 description 6

- 238000009940 knitting Methods 0.000 description 6

- 238000013508 migration Methods 0.000 description 6

- 230000005012 migration Effects 0.000 description 6

- 230000001331 thermoregulatory effect Effects 0.000 description 6

- 239000000853 adhesive Substances 0.000 description 5

- 230000001070 adhesive effect Effects 0.000 description 5

- 230000008901 benefit Effects 0.000 description 5

- 230000036760 body temperature Effects 0.000 description 5

- 239000007788 liquid Substances 0.000 description 5

- 229920000728 polyester Polymers 0.000 description 5

- 239000012209 synthetic fiber Substances 0.000 description 5

- 238000005406 washing Methods 0.000 description 5

- 229920001577 copolymer Polymers 0.000 description 4

- 238000002425 crystallisation Methods 0.000 description 4

- 230000008025 crystallization Effects 0.000 description 4

- 238000010438 heat treatment Methods 0.000 description 4

- VAMFXQBUQXONLZ-UHFFFAOYSA-N n-alpha-eicosene Natural products CCCCCCCCCCCCCCCCCCC=C VAMFXQBUQXONLZ-UHFFFAOYSA-N 0.000 description 4

- 230000001105 regulatory effect Effects 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 229920000742 Cotton Polymers 0.000 description 3

- 230000033228 biological regulation Effects 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 239000010408 film Substances 0.000 description 3

- 239000000017 hydrogel Substances 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000004745 nonwoven fabric Substances 0.000 description 3

- 230000035699 permeability Effects 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 229920003043 Cellulose fiber Polymers 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 229920002472 Starch Polymers 0.000 description 2

- 206010044565 Tremor Diseases 0.000 description 2

- 239000004699 Ultra-high molecular weight polyethylene Substances 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 230000003750 conditioning effect Effects 0.000 description 2

- 238000000113 differential scanning calorimetry Methods 0.000 description 2

- 238000009792 diffusion process Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 238000002474 experimental method Methods 0.000 description 2

- 238000010348 incorporation Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000004750 melt-blown nonwoven Substances 0.000 description 2

- 239000012802 nanoclay Substances 0.000 description 2

- LQERIDTXQFOHKA-UHFFFAOYSA-N nonadecane Chemical compound CCCCCCCCCCCCCCCCCCC LQERIDTXQFOHKA-UHFFFAOYSA-N 0.000 description 2

- RZJRJXONCZWCBN-UHFFFAOYSA-N octadecane Chemical compound CCCCCCCCCCCCCCCCCC RZJRJXONCZWCBN-UHFFFAOYSA-N 0.000 description 2

- 239000011368 organic material Substances 0.000 description 2

- 229920002401 polyacrylamide Polymers 0.000 description 2

- 229920000058 polyacrylate Polymers 0.000 description 2

- 229920006254 polymer film Polymers 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 150000003384 small molecules Chemical class 0.000 description 2

- 239000008107 starch Substances 0.000 description 2

- 235000019698 starch Nutrition 0.000 description 2

- 229920000247 superabsorbent polymer Polymers 0.000 description 2

- 210000004243 sweat Anatomy 0.000 description 2

- 230000028016 temperature homeostasis Effects 0.000 description 2

- 238000009864 tensile test Methods 0.000 description 2

- 229920000785 ultra high molecular weight polyethylene Polymers 0.000 description 2

- 238000009941 weaving Methods 0.000 description 2

- 210000002268 wool Anatomy 0.000 description 2

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 229920002972 Acrylic fiber Polymers 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- 241000196324 Embryophyta Species 0.000 description 1

- 241000590913 Euploea core Species 0.000 description 1

- 229920006798 HMWPE Polymers 0.000 description 1

- 239000004705 High-molecular-weight polyethylene Substances 0.000 description 1

- 206010021639 Incontinence Diseases 0.000 description 1

- 241000208202 Linaceae Species 0.000 description 1

- 235000004431 Linum usitatissimum Nutrition 0.000 description 1

- 241001465754 Metazoa Species 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- 229920002125 Sokalan® Polymers 0.000 description 1

- 229920010741 Ultra High Molecular Weight Polyethylene (UHMWPE) Polymers 0.000 description 1

- 229920006097 Ultramide® Polymers 0.000 description 1

- 229920002522 Wood fibre Polymers 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 210000001124 body fluid Anatomy 0.000 description 1

- 239000010839 body fluid Substances 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- DGLFSNZWRYADFC-UHFFFAOYSA-N chembl2334586 Chemical class C1CCC2=CN=C(N)N=C2C2=C1NC1=CC=C(C#CC(C)(O)C)C=C12 DGLFSNZWRYADFC-UHFFFAOYSA-N 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000009945 crocheting Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 229920006240 drawn fiber Polymers 0.000 description 1

- 230000002996 emotional effect Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000006261 foam material Substances 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 150000004676 glycans Chemical class 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 238000005338 heat storage Methods 0.000 description 1

- FNAZRRHPUDJQCJ-UHFFFAOYSA-N henicosane Chemical compound CCCCCCCCCCCCCCCCCCCCC FNAZRRHPUDJQCJ-UHFFFAOYSA-N 0.000 description 1

- 238000000265 homogenisation Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 239000002075 main ingredient Substances 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000010128 melt processing Methods 0.000 description 1

- 238000010309 melting process Methods 0.000 description 1

- 125000000325 methylidene group Chemical group [H]C([H])=* 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000003607 modifier Substances 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000012188 paraffin wax Substances 0.000 description 1

- 239000003415 peat Substances 0.000 description 1

- 239000008188 pellet Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 238000002135 phase contrast microscopy Methods 0.000 description 1

- 238000005191 phase separation Methods 0.000 description 1

- 230000037081 physical activity Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 229920000747 poly(lactic acid) Polymers 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 239000004584 polyacrylic acid Substances 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 239000004626 polylactic acid Substances 0.000 description 1

- 229920005596 polymer binder Polymers 0.000 description 1

- 239000002491 polymer binding agent Substances 0.000 description 1

- 229920005594 polymer fiber Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 229920001184 polypeptide Polymers 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 229920002215 polytrimethylene terephthalate Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 1

- 229920002717 polyvinylpyridine Polymers 0.000 description 1

- 102000004196 processed proteins & peptides Human genes 0.000 description 1

- 108090000765 processed proteins & peptides Proteins 0.000 description 1

- 230000001012 protector Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 230000033764 rhythmic process Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 230000035807 sensation Effects 0.000 description 1

- 230000008326 skin blood flow Effects 0.000 description 1

- 230000005808 skin problem Effects 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 239000008247 solid mixture Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000004747 spunlaid nonwoven Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000004583 superabsorbent polymers (SAPs) Substances 0.000 description 1

- 230000002459 sustained effect Effects 0.000 description 1

- 230000035900 sweating Effects 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000012549 training Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 229940117958 vinyl acetate Drugs 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

- 239000002759 woven fabric Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K5/00—Heat-transfer, heat-exchange or heat-storage materials, e.g. refrigerants; Materials for the production of heat or cold by chemical reactions other than by combustion

- C09K5/02—Materials undergoing a change of physical state when used

- C09K5/06—Materials undergoing a change of physical state when used the change of state being from liquid to solid or vice versa

- C09K5/063—Materials absorbing or liberating heat during crystallisation; Heat storage materials

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F1/00—General methods for the manufacture of artificial filaments or the like

- D01F1/02—Addition of substances to the spinning solution or to the melt

- D01F1/10—Other agents for modifying properties

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/06—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyolefin as constituent

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/12—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyamide as constituent

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/14—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyester as constituent

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

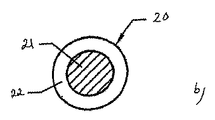

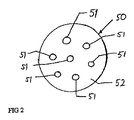

- Y10T428/2929—Bicomponent, conjugate, composite or collateral fibers or filaments [i.e., coextruded sheath-core or side-by-side type]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Textile Engineering (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Combustion & Propulsion (AREA)

- Thermal Sciences (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Nonwoven Fabrics (AREA)

- Multicomponent Fibers (AREA)

- Woven Fabrics (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/SE2007/000769 WO2009031946A1 (en) | 2007-09-03 | 2007-09-03 | Multi-component fibres |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010538171A JP2010538171A (ja) | 2010-12-09 |

| JP2010538171A5 JP2010538171A5 (enExample) | 2014-11-06 |

| JP5656636B2 true JP5656636B2 (ja) | 2015-01-21 |

Family

ID=40429111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010522852A Expired - Fee Related JP5656636B2 (ja) | 2007-09-03 | 2007-09-03 | 多成分繊維 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9725633B2 (enExample) |

| EP (1) | EP2185752B1 (enExample) |

| JP (1) | JP5656636B2 (enExample) |

| CN (1) | CN101821434B (enExample) |

| AU (1) | AU2007358683B2 (enExample) |

| BR (1) | BRPI0721980B1 (enExample) |

| MX (1) | MX2010001557A (enExample) |

| WO (1) | WO2009031946A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018051216A (ja) * | 2016-09-30 | 2018-04-05 | 日本製紙クレシア株式会社 | ローションティッシュペーパー及びローションティッシュペーパーの製造方法 |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9434869B2 (en) | 2001-09-21 | 2016-09-06 | Outlast Technologies, LLC | Cellulosic fibers having enhanced reversible thermal properties and methods of forming thereof |

| USD666421S1 (en) * | 2011-08-22 | 2012-09-04 | Vivenzio Elizabeth J | Temporary transfer sheet for an areolar tattoo |

| FI125678B (fi) * | 2011-08-26 | 2016-01-15 | Bioretec Oy | Bioabsorboituva, orientoitu, muotoiltava kiinnitysmateriaali ja -levy |

| US20120095605A1 (en) | 2011-09-17 | 2012-04-19 | Tran Bao Q | Smart building systems and methods |

| US8359750B2 (en) | 2011-12-28 | 2013-01-29 | Tran Bao Q | Smart building systems and methods |

| DE102012110330B4 (de) * | 2012-10-29 | 2014-07-24 | STS Textiles GmbH & Co. KG | Textiles Flächengebilde mit einem Latentwärmespeicher |

| JP6841811B2 (ja) * | 2015-07-14 | 2021-03-10 | ビーエイエスエフ・ソシエタス・エウロパエアBasf Se | 被覆されたコア材料をベースとするフィラメント |

| US10799390B2 (en) | 2015-08-03 | 2020-10-13 | New York Knitworks, Llc | Energy harvesting, heat managing, multi-effect therapeutic garment |

| US20170086522A1 (en) * | 2015-09-25 | 2017-03-30 | Welspun India Limited | Shawl Textile Article And Method Of Making Same |

| KR101714910B1 (ko) * | 2015-10-23 | 2017-03-10 | (주)엘지하우시스 | 다공성 단일 수지 섬유 복합재 및 다공성 단일 수지 섬유 복합재를 제조하는 방법 |

| EP3445195B1 (en) * | 2016-04-21 | 2020-01-29 | O&M Halyard International Unlimited Company | Face mask having improved comfort through cooling of microclimate through use of a phase change material |

| US20190299740A1 (en) * | 2016-06-09 | 2019-10-03 | E. I. Du Pont De Nemours And Company | Heat storage cable including closing system |

| CN106245405B (zh) * | 2016-08-31 | 2018-02-06 | 江苏理文造纸有限公司 | 用于成型网的快速脱水纤维的制造装置和制造方法 |

| CN106245406B (zh) * | 2016-08-31 | 2018-05-01 | 江苏理文造纸有限公司 | 用于快速脱水成型网的制造装置和制造方法 |

| US11339503B2 (en) | 2019-02-13 | 2022-05-24 | Rensselaer Polytechnic Institute | Methods and systems for producing beaded polymeric fibers with advanced thermoregulating properties |

| CN114569322A (zh) * | 2020-12-01 | 2022-06-03 | 中国科学院大连化学物理研究所 | 一种质地柔软降温时间长的降温护理袋 |

| JPWO2022244848A1 (enExample) * | 2021-05-21 | 2022-11-24 | ||

| CN115748051A (zh) * | 2021-09-02 | 2023-03-07 | 青岛正恒祥科技有限公司 | 一种持续冷感调温纱及其制造方法 |

| WO2023156874A1 (en) * | 2022-02-15 | 2023-08-24 | 3M Innovative Properties Company | Cluster of polymeric columns and method of making same |

| CN115404564A (zh) * | 2022-09-30 | 2022-11-29 | 许昌鸿洋生化实业发展有限公司 | 一种pcm技术包覆相变材料智能调温假发纤维 |

| JP7340821B1 (ja) | 2023-04-11 | 2023-09-08 | 青島紗支紡織科技有限公司 | 冷感生地用複合繊維、その製造方法、冷感生地、及び繊維製品 |

| CN117626470A (zh) * | 2023-11-07 | 2024-03-01 | 华南理工大学 | 一种超高分子量聚乙烯基同轴相变储能纤维及其制备方法 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4908166A (en) * | 1985-11-22 | 1990-03-13 | University Of Dayton | Method for preparing polyolefin composites containing a phase change material |

| US4923549A (en) * | 1987-10-30 | 1990-05-08 | Kimberly-Clark Corporation | Method of making a multilayer polymeric film having dead bend characteristics |

| JP2804147B2 (ja) | 1990-03-28 | 1998-09-24 | 帝人株式会社 | 熱接着性複合繊維 |

| JP2761094B2 (ja) | 1990-10-26 | 1998-06-04 | 松下電工株式会社 | 蓄熱繊維 |

| JP2537313B2 (ja) | 1991-07-02 | 1996-09-25 | 大和紡績株式会社 | ポリプロピレン繊維および複合繊維 |

| ES2113280B1 (es) * | 1994-11-10 | 1999-04-01 | Repsol Quimica Sa | Modificaciones polimericas para aplicaciones de termoconformado. |

| JPH08311716A (ja) * | 1995-05-12 | 1996-11-26 | Nippon Ester Co Ltd | 吸発熱性複合繊維 |

| US6855422B2 (en) * | 2000-09-21 | 2005-02-15 | Monte C. Magill | Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof |

| JP5902365B2 (ja) | 2000-09-21 | 2016-04-20 | アウトラスト テクノロジーズ,リミテッド ライアビリティ カンパニー | 可逆的熱特性を有する複合繊維 |

| US7160612B2 (en) * | 2000-09-21 | 2007-01-09 | Outlast Technologies, Inc. | Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof |

| US7113520B1 (en) * | 2001-04-11 | 2006-09-26 | Adl Llc | Local protocol server |

| JP2002317329A (ja) | 2001-04-24 | 2002-10-31 | Idemitsu Technofine Co Ltd | 蓄熱性繊維、その製造方法および蓄熱性布部材 |

| EP1484378A4 (en) * | 2002-03-12 | 2006-08-30 | Idemitsu Kosan Co | HEAT-STORING MATERIAL, COMPOSITION AND BOTH USE |

| JP4339006B2 (ja) | 2002-04-08 | 2009-10-07 | 出光テクノファイン株式会社 | 蓄熱性複合繊維及び蓄熱性布部材 |

| JP2004011032A (ja) * | 2002-06-03 | 2004-01-15 | Idemitsu Technofine Co Ltd | 温度コントロール繊維、および温度コントロール布部材 |

| JP2004043676A (ja) | 2002-07-12 | 2004-02-12 | Idemitsu Kosan Co Ltd | ポリエーテル蓄熱材料 |

| JP2005060896A (ja) | 2003-08-14 | 2005-03-10 | Japan Polyolefins Co Ltd | 複合繊維、その製造方法およびこれを用いた不織布 |

| CN101292064A (zh) * | 2005-09-15 | 2008-10-22 | 纤维创新技术公司 | 包含相变材料的多组分纤维 |

| EP1795542A1 (en) * | 2005-12-07 | 2007-06-13 | Borealis Technology Oy | Polymer |

| JP5145911B2 (ja) | 2007-12-07 | 2013-02-20 | 東ソー株式会社 | ポリエチレン系樹脂組成物及びそれよりなるブロー容器 |

| JP2009143079A (ja) | 2007-12-13 | 2009-07-02 | Japan Polyethylene Corp | 中空成形体、その成形装置及び方法 |

| JP2009154332A (ja) | 2007-12-25 | 2009-07-16 | Japan Polyethylene Corp | 積層体 |

-

2007

- 2007-09-03 US US12/673,839 patent/US9725633B2/en not_active Expired - Fee Related

- 2007-09-03 CN CN200780100407.XA patent/CN101821434B/zh not_active Expired - Fee Related

- 2007-09-03 BR BRPI0721980-6A patent/BRPI0721980B1/pt not_active IP Right Cessation

- 2007-09-03 AU AU2007358683A patent/AU2007358683B2/en not_active Ceased

- 2007-09-03 WO PCT/SE2007/000769 patent/WO2009031946A1/en not_active Ceased

- 2007-09-03 MX MX2010001557A patent/MX2010001557A/es active IP Right Grant

- 2007-09-03 JP JP2010522852A patent/JP5656636B2/ja not_active Expired - Fee Related

- 2007-09-03 EP EP07808789.7A patent/EP2185752B1/en not_active Not-in-force

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018051216A (ja) * | 2016-09-30 | 2018-04-05 | 日本製紙クレシア株式会社 | ローションティッシュペーパー及びローションティッシュペーパーの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| MX2010001557A (es) | 2010-06-01 |

| CN101821434A (zh) | 2010-09-01 |

| EP2185752A1 (en) | 2010-05-19 |

| EP2185752B1 (en) | 2017-12-20 |

| BRPI0721980A2 (pt) | 2014-02-25 |

| US9725633B2 (en) | 2017-08-08 |

| JP2010538171A (ja) | 2010-12-09 |

| WO2009031946A1 (en) | 2009-03-12 |

| AU2007358683B2 (en) | 2012-05-24 |

| BRPI0721980B1 (pt) | 2017-12-26 |

| EP2185752A4 (en) | 2013-10-16 |

| CN101821434B (zh) | 2015-04-01 |

| US20110027568A1 (en) | 2011-02-03 |

| AU2007358683A1 (en) | 2009-03-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5656636B2 (ja) | 多成分繊維 | |

| JP6659936B2 (ja) | 温度調節セルロース系繊維及びその用途 | |

| ES2377833T3 (es) | Fibras celulósicas que tienen propiedades térmicas reversibles mejoradas y métodos para su fabricación | |

| US20080118727A1 (en) | Process for producing elastic and/or water degradable webs from composite filaments | |

| US20030194552A1 (en) | Binder fiber and nonwoven web | |

| JP2011058157A (ja) | ソフト性に優れたスパンボンド不織布及びその製造方法 | |

| JP2013511628A (ja) | 耐火性と増強された可逆的熱特性の組合せを有する繊維および物品 | |

| CN101668501A (zh) | 用作吸收性物品中的面向身体层片的无纺材料 | |

| BR112019020760B1 (pt) | Pano de fibra de celulose não tecido com diferentes conjuntos de poros, método para fabricar um pano de fibra de celulose não tecido, dispositivo para fabricar pano de fibra de celulose não tecido, método para controlar liberação de um agente ativo, método para uso de um pano de fibra de celulose não tecido e produto ou compósito | |

| CN1946896A (zh) | 包含具有不同水平或组合的添加剂的层的非织造织物及其制备方法 | |

| CN113748234B (zh) | 复合纤维、其制造方法、热粘合无纺布、吸收性物品用表面片材以及吸收性物品 | |

| Wei et al. | Micro–nanofiber three-dimensional antibacterial sponge with wetting/pore dual gradient for rapid liquid infiltration and uniform retention in diapers | |

| RU2444583C2 (ru) | Многокомпонентные волокна | |

| JP2024518171A (ja) | 強度促進不織布 | |

| JP2006057200A (ja) | 吸収性物品 | |

| WO2007006421A1 (en) | Hygiene article | |

| JP4785596B2 (ja) | 複合繊維とその製造方法及びこれを用いた繊維構造物 | |

| JP2002138359A (ja) | ポリエチレン系複合長繊維不織布 | |

| CN102586911A (zh) | 具有湿度调节功能的纤维及其制造方法和用途 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120305 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120313 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120608 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130312 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130711 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20130812 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20130913 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20140901 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20140901 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20141125 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5656636 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |