JP5559203B2 - シリコン心棒を製造する方法及び装置 - Google Patents

シリコン心棒を製造する方法及び装置 Download PDFInfo

- Publication number

- JP5559203B2 JP5559203B2 JP2011546591A JP2011546591A JP5559203B2 JP 5559203 B2 JP5559203 B2 JP 5559203B2 JP 2011546591 A JP2011546591 A JP 2011546591A JP 2011546591 A JP2011546591 A JP 2011546591A JP 5559203 B2 JP5559203 B2 JP 5559203B2

- Authority

- JP

- Japan

- Prior art keywords

- silicon

- induction coil

- mandrel

- pulling

- pulled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 title claims description 111

- 229910052710 silicon Inorganic materials 0.000 title claims description 111

- 239000010703 silicon Substances 0.000 title claims description 111

- 238000000034 method Methods 0.000 title claims description 45

- 238000004519 manufacturing process Methods 0.000 title claims description 16

- 230000006698 induction Effects 0.000 claims description 83

- 239000002994 raw material Substances 0.000 claims description 40

- 239000000155 melt Substances 0.000 claims description 19

- 230000012010 growth Effects 0.000 claims description 14

- 238000004804 winding Methods 0.000 claims description 11

- 230000001939 inductive effect Effects 0.000 claims description 7

- 238000002425 crystallisation Methods 0.000 claims description 5

- 239000012768 molten material Substances 0.000 claims description 5

- 239000002019 doping agent Substances 0.000 claims description 4

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 3

- 229910052796 boron Inorganic materials 0.000 claims description 3

- 238000010992 reflux Methods 0.000 claims 2

- 239000013078 crystal Substances 0.000 description 12

- 239000007789 gas Substances 0.000 description 8

- 239000000463 material Substances 0.000 description 7

- 230000008021 deposition Effects 0.000 description 5

- 238000010438 heat treatment Methods 0.000 description 4

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 4

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 4

- 102100027340 Slit homolog 2 protein Human genes 0.000 description 3

- 101710133576 Slit homolog 2 protein Proteins 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000001976 improved effect Effects 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 101700004678 SLIT3 Proteins 0.000 description 1

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 1

- 102100027339 Slit homolog 3 protein Human genes 0.000 description 1

- 230000003698 anagen phase Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 238000005137 deposition process Methods 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- ZDHXKXAHOVTTAH-UHFFFAOYSA-N trichlorosilane Chemical compound Cl[SiH](Cl)Cl ZDHXKXAHOVTTAH-UHFFFAOYSA-N 0.000 description 1

- 239000005052 trichlorosilane Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/02—Elements

- C30B29/06—Silicon

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B13/00—Single-crystal growth by zone-melting; Refining by zone-melting

- C30B13/16—Heating of the molten zone

- C30B13/20—Heating of the molten zone by induction, e.g. hot wire technique

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B15/00—Single-crystal growth by pulling from a melt, e.g. Czochralski method

- C30B15/005—Simultaneous pulling of more than one crystal

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1004—Apparatus with means for measuring, testing, or sensing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1004—Apparatus with means for measuring, testing, or sensing

- Y10T117/1008—Apparatus with means for measuring, testing, or sensing with responsive control means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

- Y10T117/1032—Seed pulling

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

- Y10T117/1032—Seed pulling

- Y10T117/1068—Seed pulling including heating or cooling details [e.g., shield configuration]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

- Y10T117/1076—Apparatus for crystallization from liquid or supercritical state having means for producing a moving solid-liquid-solid zone

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T117/00—Single-crystal, oriented-crystal, and epitaxy growth processes; non-coating apparatus therefor

- Y10T117/10—Apparatus

- Y10T117/1024—Apparatus for crystallization from liquid or supercritical state

- Y10T117/1076—Apparatus for crystallization from liquid or supercritical state having means for producing a moving solid-liquid-solid zone

- Y10T117/1088—Apparatus for crystallization from liquid or supercritical state having means for producing a moving solid-liquid-solid zone including heating or cooling details

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Silicon Compounds (AREA)

Description

半導体用のシリコンの原材料及び太陽電池の原材料としての多結晶シリコンの、著しく高まり、上昇し続ける需要により、相応に、約4〜10mmの直径を有するシリコン心棒の需要も高まっている。シリコン心棒の製造は、トリクロルシラン(ジーメンス法)又はモノシランからのシリコンの熱分解による堆積によってシリコン棒を生産する必須の、一部では制限要因ともなる要素である。シリコン心棒の全長が、生産されるシリコン棒の長さに相当するので、ソーラーシリコン及び半導体シリコンの生産の急激な増加に伴い、これらの心棒も相応に大量に必要とされる。

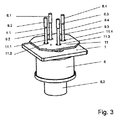

2 主スリット

3 電流供給部

4 中央開口

5.1,5.2,5.3,5.4 引き上げ開口

6 Si原料棒

6.1 融液溜

6.2 スピンドル

7.1,7.2,7.3,7.4 支持体

8.1,8.2,8.3,8.4 シリコン種棒

9.1,9.2,9.3,9.4 シリコン心棒

10 引き上げ装置

11 遮蔽板

11.1,11.2,11.3,11.4 遮蔽板に設けられた開口

LI 誘導コイルの辺長

DS Si原料棒の直径

DK 引き上げ開口が配置されている円の直径

Claims (10)

- 唯一の巻線を備え、かつ電流供給部としてのスリットを備えるディスクからなる、HF電流が通電される平たんな誘導コイルにより形成されるSi原料棒の上端の融液から、シリコン心棒を、平たんな誘導コイルを通して上方に引き上げる、るつぼなしの結晶化法によりシリコン心棒を製造する方法であって、

融液の誘導性の加熱のためだけに役立つ平たんな誘導コイル(1)が、シリコン心棒が引き上げられない、電流が環流する中央開口(4)の他に、電流が環流しない別の引き上げ開口(5.1,5.2,5.3,5.4)を備え、該引き上げ開口(5.1,5.2,5.3,5.4)を通してそれぞれ1つのシリコン心棒(9.1,9.2,9.3,9.4)を引き上げることを特徴とする、るつぼなしの結晶化法によりシリコン心棒を製造する方法。 - 開始段階において、それぞれ1つの支持体(7.1,7.2,7.3,7.4)に固定されている複数のシリコン種棒(8.1,8.2,8.3,8.4)を、Si原料棒(6)の頂部の、前記誘導コイル(1)により形成された融液(6.1)において、前記引き上げ開口(5.1,5.2,5.3,5.4)を通して融液に接触させ、その後、シリコン種棒(8.1,8.2,8.3,8.4)をそれぞれ1つの別の引き上げ開口(5.1,5.2,5.3,5.4)を通して上方に引き上げることにより、成長を行う、請求項1記載の方法。

- 前記誘導コイル(1)の上方に、結晶化したシリコン心棒(9.1,9.2,9.3,9.4)への誘導性の熱供給を抑制する手段を設ける、請求項1記載の方法。

- 前記支持体(7.1,7.2,7.3,7.4)を前記シリコン種棒(8.1,8.2,8.3,8.4)及び該シリコン種棒(8.1,8.2,8.3,8.4)において成長したシリコン心棒(9.1,9.2,9.3,9.4)とともに同期的に上方に引き上げる、請求項2記載の方法。

- 使用するSi原料棒(6)が、引き上げられるシリコン心棒(9.1,9.2,9.3,9.4)が所望のドーピングを有しているように、ホウ素及び/又は別のドーパントを含むドーピングを有している、請求項1記載の方法。

- ドーパントを融液にプロセス中に供給する、請求項1記載の方法。

- 成長したシリコン心棒(9.1,9.2,9.3,9.4)を、引き上げチャンバの上側の部分に存在するガスシールを通して、連続的に引き上げチャンバから外空間まで引き上げ、引き上げプロセスを、Si原料棒(6)の融解した材料貯留が消費されるまで持続可能とする、請求項6記載の方法。

- 請求項1から6までのいずれか1項記載の方法を実施するための装置であって、唯一の巻線を備え、かつ電流供給部としてのスリットを備えるディスクからなる平たんな誘導コイルが使用される装置において、該誘導コイル(1)が、HF電流が環流する中央開口(4)の他に、別の引き上げ開口(5.1,5.2,5.3,5.4)を備え、該引き上げ開口(5.1,5.2,5.3,5.4)が、環状電流により環流されておらず、該引き上げ開口(5.1,5.2,5.3,5.4)を通してそれぞれ1つのシリコン心棒(9.1,9.2,9.3,9.4)が引き上げ可能であることを特徴とする装置。

- 小さな間隔を置いて前記誘導コイル(1)上に遮蔽板(11)が配置されており、該遮蔽板(11)が、前記誘導コイル(1)に設けられた前記引き上げ開口(5.1,5.2,5.3,5.4)に対して合同に配置された開口(11.1,11.2,11.3,11.4)を有している、請求項8記載の装置。

- 前記装置が気密の引き上げチャンバ内に配置されており、該引き上げチャンバが該引き上げチャンバの上側の容器壁に、誘導コイル(1)に設けられた引き上げ開口(5.1,5.2,5.3,5.4)及び遮蔽板(11)に設けられた開口(11.1,11.2,11.3,11.4)の上方に、長管の形のガスシールを有しており、該ガスシールを通して前記シリコン心棒(9.1,9.2,9.3,9.4)が引き上げ可能である、請求項8記載の装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009005837A DE102009005837B4 (de) | 2009-01-21 | 2009-01-21 | Verfahren und Vorrichtung zur Herstellung von Siliziumdünnstäben |

| DE102009005837.0 | 2009-01-21 | ||

| PCT/DE2010/000070 WO2010083818A1 (de) | 2009-01-21 | 2010-01-19 | Verfahren und vorrichtung zur herstellung von siliziumdünnstäben |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012515698A JP2012515698A (ja) | 2012-07-12 |

| JP2012515698A5 JP2012515698A5 (ja) | 2012-12-20 |

| JP5559203B2 true JP5559203B2 (ja) | 2014-07-23 |

Family

ID=42109319

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011546591A Expired - Fee Related JP5559203B2 (ja) | 2009-01-21 | 2010-01-19 | シリコン心棒を製造する方法及び装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8197595B2 (ja) |

| EP (1) | EP2379783B1 (ja) |

| JP (1) | JP5559203B2 (ja) |

| CN (1) | CN102292475B (ja) |

| DE (1) | DE102009005837B4 (ja) |

| DK (1) | DK2379783T3 (ja) |

| WO (1) | WO2010083818A1 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013016823A1 (en) * | 2011-07-29 | 2013-02-07 | Ats Automation Tooling Systems Inc. | Systems and methods for producing silicon slim rods |

| RU2507318C1 (ru) * | 2012-08-14 | 2014-02-20 | Закрытое Акционерное Общество "Валенсия" | Способ получения кремниевых филаментов произвольного сечения (варианты) |

| CN103147118B (zh) * | 2013-02-25 | 2016-03-30 | 天津市环欧半导体材料技术有限公司 | 一种利用直拉区熔法制备太阳能级硅单晶的方法 |

| CN103993352A (zh) * | 2014-04-18 | 2014-08-20 | 洛阳金诺机械工程有限公司 | 一种使籽晶转动的硅芯拉制方法 |

| CN105274616B (zh) * | 2014-06-18 | 2018-03-09 | 四川永祥多晶硅有限公司 | 一种提高硅芯母料利用率的方法 |

| KR101611053B1 (ko) * | 2014-06-27 | 2016-04-11 | 오씨아이 주식회사 | 폴리실리콘 절편을 이용한 폴리실리콘 필라멘트 접합장치 |

| CN104264221A (zh) * | 2014-09-10 | 2015-01-07 | 河南协鑫光伏科技有限公司 | 一种生产原生多晶硅用方型硅芯材料及制备方法 |

| DE102014226419A1 (de) * | 2014-12-18 | 2016-06-23 | Siltronic Ag | Verfahren zum Züchten eines Einkristalls durch Kristallisieren des Einkristalls aus einer Fließzone |

| CN106757310A (zh) * | 2016-12-19 | 2017-05-31 | 洛阳金诺机械工程有限公司 | 一种硅芯拉制装置 |

| CN109576778A (zh) * | 2018-12-25 | 2019-04-05 | 内蒙古中环光伏材料有限公司 | 一种降低cz法制备单晶的杂质含量的方法 |

| CN114455587B (zh) * | 2022-01-26 | 2023-07-21 | 何良雨 | 一种高纯多晶硅生产装置和方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1544301A1 (de) * | 1966-09-28 | 1970-05-27 | Siemens Ag | Verfahren zum tiegelfreien Zonenschmelzen eines kristallinen Stabes,insbesondere Halbleiterstabes |

| DE2458490A1 (de) | 1974-12-10 | 1976-06-16 | Siemens Ag | Verfahren zum herstellen eines siliciumhalbleiterkristallstabes durch tiegelfreies zonenschmelzen |

| US4220839A (en) * | 1978-01-05 | 1980-09-02 | Topsil A/S | Induction heating coil for float zone melting of semiconductor rods |

| DD141536A1 (de) * | 1979-01-22 | 1980-05-07 | Dietmar Taenzer | Verfahren zur herstellung kristalliner staebchen aus einer schmelze |

| DE2952602A1 (de) | 1979-12-28 | 1981-07-02 | Siemens AG, 1000 Berlin und 8000 München | Verfahren und vorrichtung zum herstellen von silicium-duennstaeben |

| DD226599B1 (de) * | 1984-09-10 | 1990-10-10 | Spurenmetalle Freiberg Veb Kom | Vorrichtung zur herstellung von silizium-duennstaeben |

| ATE332990T1 (de) * | 2003-02-11 | 2006-08-15 | Topsil Semiconductor Materials | Vorrichtung und verfahren zur herstellung eines einkristallstabs |

| CN1247831C (zh) * | 2003-11-14 | 2006-03-29 | 中国科学院物理研究所 | 一种碳化硅晶体生长装置 |

| KR101300309B1 (ko) * | 2004-06-18 | 2013-08-28 | 엠이엠씨 일렉트로닉 머티리얼즈, 인크. | 용융기 어셈블리, 및 결정 형성 장치를 용융된 원재료로충전하는 방법 |

| DE102005063346B4 (de) | 2005-04-06 | 2010-10-28 | Pv Silicon Forschungs Und Produktions Gmbh | Verfahren zur Herstellung einer einkristallinen Si-Scheibe mit annähernd rundem polygonalem Querschnitt |

| US20110204044A1 (en) * | 2008-11-25 | 2011-08-25 | Chaoxuan Liu | High-frequency coil pulling holes arrangement for producing multiple silicon cores |

| KR101324582B1 (ko) | 2008-11-25 | 2013-11-04 | 루오양 진누오 메캐니컬 엔지니어링 씨오., 엘티디 | 복수 개의 실리콘 코어를 제조하기 위한 고주파 코일 인상홀 배열체 |

-

2009

- 2009-01-21 DE DE102009005837A patent/DE102009005837B4/de not_active Expired - Fee Related

-

2010

- 2010-01-19 WO PCT/DE2010/000070 patent/WO2010083818A1/de active Application Filing

- 2010-01-19 EP EP10706486.7A patent/EP2379783B1/de active Active

- 2010-01-19 JP JP2011546591A patent/JP5559203B2/ja not_active Expired - Fee Related

- 2010-01-19 US US13/143,738 patent/US8197595B2/en active Active

- 2010-01-19 DK DK10706486.7T patent/DK2379783T3/da active

- 2010-01-19 CN CN201080004883.3A patent/CN102292475B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN102292475A (zh) | 2011-12-21 |

| EP2379783B1 (de) | 2014-05-28 |

| US20110314869A1 (en) | 2011-12-29 |

| WO2010083818A1 (de) | 2010-07-29 |

| DE102009005837A1 (de) | 2010-07-22 |

| DE102009005837B4 (de) | 2011-10-06 |

| CN102292475B (zh) | 2014-05-28 |

| JP2012515698A (ja) | 2012-07-12 |

| US8197595B2 (en) | 2012-06-12 |

| EP2379783A1 (de) | 2011-10-26 |

| DK2379783T3 (da) | 2014-09-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5559203B2 (ja) | シリコン心棒を製造する方法及び装置 | |

| JP5831436B2 (ja) | シリコン単結晶の製造方法 | |

| KR100954291B1 (ko) | 고품질의 반도체 단결정 잉곳 제조장치 및 방법 | |

| JP2012515698A5 (ja) | ||

| JP5131170B2 (ja) | 単結晶製造用上部ヒーターおよび単結晶製造装置ならびに単結晶製造方法 | |

| JP5464429B2 (ja) | 四角形の断面を有する単結晶シリコンの育成方法 | |

| WO2011062092A1 (ja) | 単結晶引き上げ装置 | |

| US5556461A (en) | Method for producing a silicon single crystal by a float-zone method | |

| TW202227679A (zh) | 長晶爐 | |

| JP2014080302A (ja) | 単結晶引上装置及び単結晶引上方法 | |

| JP5372105B2 (ja) | n型シリコン単結晶およびその製造方法 | |

| JP2020037500A (ja) | 単結晶の製造方法及び装置及びシリコン単結晶インゴット | |

| JP2011006314A (ja) | 単結晶引き上げ装置 | |

| JP4555677B2 (ja) | 連続的な結晶化により、所定の横断面及び柱状の多結晶構造を有する結晶ロッドを製造するための装置 | |

| JP5477229B2 (ja) | 半導体単結晶の製造装置及び製造方法 | |

| JP5392040B2 (ja) | 単結晶製造装置及び単結晶製造方法 | |

| JPH07267776A (ja) | 結晶成長方法 | |

| CN114616361B (zh) | 硅单晶的制造方法 | |

| KR101425933B1 (ko) | 단결정 실리콘 잉곳 제조장치 | |

| JP2000247787A (ja) | 単結晶の製造方法および製造装置 | |

| CN112210819A (zh) | 一种晶棒的制备方法和设备 | |

| TWI836994B (zh) | 含有摻雜物的矽錠片 | |

| JP2011051824A (ja) | 単結晶製造装置 | |

| RU2531514C1 (ru) | Нагреватель устройства для выращивания монокристаллов из расплава методом чохральского | |

| JP3986108B2 (ja) | 石英ガラスルツボ及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121030 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20121030 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131216 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20131219 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140311 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140507 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140605 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5559203 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |