JP5335028B2 - 樹脂製ボトルの製造方法 - Google Patents

樹脂製ボトルの製造方法 Download PDFInfo

- Publication number

- JP5335028B2 JP5335028B2 JP2011116864A JP2011116864A JP5335028B2 JP 5335028 B2 JP5335028 B2 JP 5335028B2 JP 2011116864 A JP2011116864 A JP 2011116864A JP 2011116864 A JP2011116864 A JP 2011116864A JP 5335028 B2 JP5335028 B2 JP 5335028B2

- Authority

- JP

- Japan

- Prior art keywords

- preform

- blow molding

- inspection

- thickness

- molding process

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/78—Measuring, controlling or regulating

- B29C49/783—Measuring, controlling or regulating blowing pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/78—Measuring, controlling or regulating

- B29C49/786—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/78—Measuring, controlling or regulating

- B29C49/786—Temperature

- B29C2049/7867—Temperature of the heating or cooling means

- B29C2049/78675—Temperature of the heating or cooling means of the heating means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/78—Measuring, controlling or regulating

- B29C2049/787—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2795/00—Printing on articles made from plastics or substances in a plastic state

- B29C2795/002—Printing on articles made from plastics or substances in a plastic state before shaping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2949/00—Indexing scheme relating to blow-moulding

- B29C2949/07—Preforms or parisons characterised by their configuration

- B29C2949/0715—Preforms or parisons characterised by their configuration the preform having one end closed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/02—Combined blow-moulding and manufacture of the preform or the parison

- B29C49/06—Injection blow-moulding

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

Description

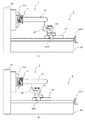

2 切断装置

3 ナイロンチャック

3A スリット

4 PETボトル(樹脂製ボトル)

5 ブロー成形機

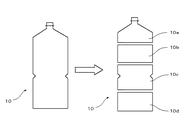

11 首部

12 胴部

12a−12c 検査部位

21 基礎

22 主軸台

22A チャック

23 スライダ

23A ハンドル

24 刃物台

24A ハンドル

25 カッター

51 ブロー成形用ヒータ

52 金型

53 延伸棒

Claims (5)

- 原型となるプリフォームからブロー成形工程によって形成される樹脂製ボトルの製造方法において、

前記プリフォームの胴部に設定された複数の検査部位のそれぞれの重量または肉厚を計測する第1のステップと、

前記第1のステップにて計測された重量または肉厚のそれぞれを予め設定された設定値と比較することによって、前記第1のステップにて計測された重量または肉厚と、前記設定値との差異を前記検査部位毎に検査する第2のステップと、

前記検査部位毎の検査結果に応じて、前記ブロー成形工程におけるブロー成形の条件を調整する第3のステップと

を有することを特徴とする樹脂製ボトルの製造方法。 - 前記第3のステップでは、前記検査部位毎の温度を調整することによって、前記ブロー成形工程におけるブロー成形の条件を調整することを特徴とする請求項1に記載された樹脂製ボトルの製造方法。

- 前記第3のステップでは、前記プリフォームに導入する空気の圧力を調整することによって、前記ブロー成形工程におけるブロー成形の条件を調整することを特徴とする請求項1に記載された樹脂製ボトルの製造方法。

- 前記第3のステップでは、前記プリフォームに空気を導入するタイミングを調整することによって、前記ブロー成形工程におけるブロー成形の条件を調整することを特徴とする請求項1に記載された樹脂製ボトルの製造方法。

- 前記第1のステップでは、前記プリフォームの胴部を前記検査部位毎に切断した後、前記検査部位毎に重量または肉厚を計測することを特徴とする請求項1から4のいずれかに記載された樹脂製ボトルの製造方法。

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011116864A JP5335028B2 (ja) | 2011-05-25 | 2011-05-25 | 樹脂製ボトルの製造方法 |

| TW101118182A TWI503220B (zh) | 2011-05-25 | 2012-05-22 | Method for manufacturing resin bottles |

| SG2013086004A SG195074A1 (en) | 2011-05-25 | 2012-05-22 | Method for producing resin bottles |

| ES12789773.4T ES2608154T3 (es) | 2011-05-25 | 2012-05-22 | Método para producir botellas de resina |

| EP12789773.4A EP2716431B1 (en) | 2011-05-25 | 2012-05-22 | Method for producing resin bottles |

| NZ616760A NZ616760B2 (en) | 2011-05-25 | 2012-05-22 | Method for producing resin bottles |

| PCT/JP2012/062989 WO2012161171A1 (ja) | 2011-05-25 | 2012-05-22 | 樹脂製ボトルの製造方法 |

| US14/112,560 US9555576B2 (en) | 2011-05-25 | 2012-05-22 | Method for producing resin bottles |

| CN2012101638129A CN102794903A (zh) | 2011-05-25 | 2012-05-23 | 树脂制瓶的制造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011116864A JP5335028B2 (ja) | 2011-05-25 | 2011-05-25 | 樹脂製ボトルの製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012245636A JP2012245636A (ja) | 2012-12-13 |

| JP5335028B2 true JP5335028B2 (ja) | 2013-11-06 |

Family

ID=47194320

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011116864A Active JP5335028B2 (ja) | 2011-05-25 | 2011-05-25 | 樹脂製ボトルの製造方法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9555576B2 (ja) |

| EP (1) | EP2716431B1 (ja) |

| JP (1) | JP5335028B2 (ja) |

| CN (1) | CN102794903A (ja) |

| ES (1) | ES2608154T3 (ja) |

| SG (1) | SG195074A1 (ja) |

| TW (1) | TWI503220B (ja) |

| WO (1) | WO2012161171A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023126406A1 (fr) * | 2021-12-30 | 2023-07-06 | Sidel Participations | Procédé de fabrication de récipients et installation pour sa mise en œuvre |

| EP4275866A1 (de) * | 2022-05-09 | 2023-11-15 | Krones AG | Verfahren und vorrichtung zur herstellung von kunststoffbehältnissen mit zonenweiser inspektion von kunststoffvorformlingen |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106626325B (zh) * | 2016-11-30 | 2019-05-03 | 蔡怀峰 | 斜口包装筒的加工方法 |

| KR102002149B1 (ko) * | 2017-04-26 | 2019-07-24 | 에이테크솔루션(주) | 헤드업 디스플레이용 광학 미러 제작방법 |

| DE102021128918A1 (de) * | 2021-11-05 | 2023-05-11 | Krones Aktiengesellschaft | Vorrichtung und Verfahren zum Herstellen von Kunststoffbehältnissen mit Inspektion |

| CN115401900A (zh) * | 2022-08-25 | 2022-11-29 | 张家港市绿环机械有限公司 | 一种注拉吹机的测厚调温系统及测厚调温工艺 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3950459A (en) * | 1972-12-27 | 1976-04-13 | Phillips Petroleum Company | Continuous process for producing, reheating, and blow molding parisons |

| JPS6230020A (ja) | 1985-08-01 | 1987-02-09 | Ishikawajima Harima Heavy Ind Co Ltd | プラスチツク吹込成形方法 |

| DE3816273C3 (de) * | 1988-05-12 | 1996-03-21 | Harald Feuerherm | Verfahren zum Extrusionsblasformen eines Hohlkörpers und Vorrichtung zur Durchführung des Verfahrens |

| JPH0464411A (ja) * | 1990-07-04 | 1992-02-28 | Ishikawajima Harima Heavy Ind Co Ltd | パリソンの形状制御方法 |

| JPH0813498B2 (ja) | 1992-02-29 | 1996-02-14 | 日精エー・エス・ビー機械株式会社 | 耐熱性容器の成形方法 |

| JP3233980B2 (ja) * | 1992-04-27 | 2001-12-04 | 本田技研工業株式会社 | ブロー成形の成形制御システムおよび成形制御方法 |

| DE19544634A1 (de) * | 1995-11-30 | 1997-06-05 | Feuerherm Harald | Verfahren zum Blasformen von Hohlkörpern aus thermoplastischem Kunststoff |

| JP3799788B2 (ja) | 1997-12-25 | 2006-07-19 | 凸版印刷株式会社 | プラスチックボトルの成形方法 |

| DE19813668C2 (de) * | 1998-03-27 | 2003-04-30 | Ossberger Gmbh & Co | Herstellvorrichtung mit Kontrolleinrichtungen für einen Kunststoff-Hohlkörper |

| EP1719970A3 (en) * | 2000-03-01 | 2009-11-18 | Plastic Technologies, Inc. | Method and apparatus for measuring wall thickness of a plastic container |

| US6985221B2 (en) | 2000-03-01 | 2006-01-10 | Petwall, Llc | Method and apparatus for measuring wall thickness of plastic container |

| JP3597508B2 (ja) * | 2001-02-06 | 2004-12-08 | 花王株式会社 | プリフォームの設計方法および装置 |

| TW564218B (en) * | 2001-02-06 | 2003-12-01 | Kao Corp | Design method and device for preform |

| JP2003062896A (ja) * | 2001-08-24 | 2003-03-05 | Lion Corp | 容器肉厚設計システム及び容器肉厚設計方法 |

| US20060058911A1 (en) * | 2004-09-13 | 2006-03-16 | Graham Packaging Company, L.P. | System and method for phase monitoring during blow molding |

| CN101249721B (zh) | 2008-03-13 | 2010-09-08 | 华南理工大学 | 一种基于图像识别技术的挤出吹塑制品壁厚在线控制系统及其方法 |

| DE102008052611B3 (de) * | 2008-10-21 | 2010-04-08 | Feuerherm, Harald, Dipl.-Ing. | Verfahren zur Herstellung von Kunststoffhohlkörpern durch Blasformen |

| DE102008057999A1 (de) * | 2008-11-13 | 2010-05-20 | Khs Corpoplast Gmbh & Co. Kg | Verfahren und Vorrichtung zur Blasformung von Behältern |

| DE102009035868A1 (de) * | 2009-07-31 | 2011-02-03 | Krones Ag | Vorrichtung zum Umformen von Kunststoffvorformlingen mit synchroner Erwärmung und Reckung |

| JP5738070B2 (ja) * | 2011-05-25 | 2015-06-17 | サントリーホールディングス株式会社 | プリフォームの切断装置 |

-

2011

- 2011-05-25 JP JP2011116864A patent/JP5335028B2/ja active Active

-

2012

- 2012-05-22 SG SG2013086004A patent/SG195074A1/en unknown

- 2012-05-22 ES ES12789773.4T patent/ES2608154T3/es active Active

- 2012-05-22 TW TW101118182A patent/TWI503220B/zh not_active IP Right Cessation

- 2012-05-22 WO PCT/JP2012/062989 patent/WO2012161171A1/ja not_active Ceased

- 2012-05-22 EP EP12789773.4A patent/EP2716431B1/en active Active

- 2012-05-22 US US14/112,560 patent/US9555576B2/en active Active

- 2012-05-23 CN CN2012101638129A patent/CN102794903A/zh active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023126406A1 (fr) * | 2021-12-30 | 2023-07-06 | Sidel Participations | Procédé de fabrication de récipients et installation pour sa mise en œuvre |

| FR3131557A1 (fr) * | 2021-12-30 | 2023-07-07 | Sidel Participations | Procédé de fabrication de récipients et installation pour sa mise en œuvre |

| EP4275866A1 (de) * | 2022-05-09 | 2023-11-15 | Krones AG | Verfahren und vorrichtung zur herstellung von kunststoffbehältnissen mit zonenweiser inspektion von kunststoffvorformlingen |

Also Published As

| Publication number | Publication date |

|---|---|

| SG195074A1 (en) | 2013-12-30 |

| TWI503220B (zh) | 2015-10-11 |

| JP2012245636A (ja) | 2012-12-13 |

| ES2608154T3 (es) | 2017-04-06 |

| US9555576B2 (en) | 2017-01-31 |

| NZ616760A (en) | 2014-09-26 |

| US20140077404A1 (en) | 2014-03-20 |

| WO2012161171A1 (ja) | 2012-11-29 |

| CN102794903A (zh) | 2012-11-28 |

| EP2716431B1 (en) | 2016-12-07 |

| EP2716431A1 (en) | 2014-04-09 |

| TW201313446A (zh) | 2013-04-01 |

| EP2716431A4 (en) | 2015-09-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5335028B2 (ja) | 樹脂製ボトルの製造方法 | |

| RU2577270C2 (ru) | Вытяжное стержневое приспособление для жидкостного или гидравлического формования с раздувом | |

| JP6736124B2 (ja) | 耐圧容器の製造方法並びに当該製造方法に用いる予備成形体および容器 | |

| RU2627858C2 (ru) | Способ и устройство для изготовления оптимизированного контура дна на заготовке | |

| EP2463079A1 (en) | A process for single-step forming and filling of containers | |

| JP6130792B2 (ja) | 機械の衛生管理および加工のための逆延伸ロッド | |

| JP6712259B2 (ja) | プラスチック材料からなる容器のブロー成形方法の制御方法 | |

| EP3159137B1 (en) | Manufacturing method and manufacturing apparatus for hollow container | |

| AU775363B2 (en) | Method for producing tubular containers | |

| JP7561908B2 (ja) | 延伸ブロー成形ピペットならびに延伸ブロー成形ピペットを成形するためのシステムおよび方法 | |

| JP6359829B2 (ja) | ハイドロブロー(HYDROBLOW)予備成形品(preform)の設計 | |

| EP3928952B1 (en) | Method for manufacturing eccentric container, and temperature adjustment mold | |

| EP3059069B1 (en) | A method for manufacturing bent-neck bottles, and a machine for implementing said method | |

| US12343922B2 (en) | Die unit, blow molding device, and blow molding method | |

| CN107405818A (zh) | 带内表面螺旋条的容器、带内表面螺旋条的容器的制造方法及其制造装置 | |

| JP5738070B2 (ja) | プリフォームの切断装置 | |

| EP2633977B1 (en) | Production method for hollow container | |

| JP2024164288A (ja) | 樹脂製容器の製造装置、樹脂製容器の製造方法、および金型 | |

| JP4748475B2 (ja) | 射出成形プリフォーム | |

| CN203844213U (zh) | 一种塑料制品余料切割刀具 | |

| NZ616760B2 (en) | Method for producing resin bottles | |

| WO2023157863A1 (ja) | 温度調整用金型、温度調整方法および樹脂製容器の製造装置 | |

| Berezanskii et al. | Experience in planning and manufacture of equipment for the production of extrusion blow moulded products | |

| KR20160072362A (ko) | 블로우 성형기용 넥 지그 | |

| JP2009298087A (ja) | 中空樹脂成形品の製造装置及び製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130704 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20130704 |

|

| TRDD | Decision of grant or rejection written | ||

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20130719 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130723 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130730 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5335028 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |