JP5109982B2 - ミラー付き光伝送体の製造方法 - Google Patents

ミラー付き光伝送体の製造方法 Download PDFInfo

- Publication number

- JP5109982B2 JP5109982B2 JP2009003381A JP2009003381A JP5109982B2 JP 5109982 B2 JP5109982 B2 JP 5109982B2 JP 2009003381 A JP2009003381 A JP 2009003381A JP 2009003381 A JP2009003381 A JP 2009003381A JP 5109982 B2 JP5109982 B2 JP 5109982B2

- Authority

- JP

- Japan

- Prior art keywords

- reflection

- layer

- optical transmission

- mirror

- transmission body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000005540 biological transmission Effects 0.000 title claims description 158

- 230000003287 optical effect Effects 0.000 title claims description 146

- 238000004519 manufacturing process Methods 0.000 title claims description 31

- 238000007493 shaping process Methods 0.000 claims description 81

- 238000005520 cutting process Methods 0.000 claims description 28

- 229910052751 metal Inorganic materials 0.000 claims description 15

- 239000002184 metal Substances 0.000 claims description 15

- 229920005989 resin Polymers 0.000 claims description 15

- 239000011347 resin Substances 0.000 claims description 15

- 238000009751 slip forming Methods 0.000 claims description 8

- 229920001187 thermosetting polymer Polymers 0.000 claims description 8

- 229920005992 thermoplastic resin Polymers 0.000 claims description 6

- 239000007787 solid Substances 0.000 claims description 4

- 239000000758 substrate Substances 0.000 description 50

- 239000000463 material Substances 0.000 description 17

- 239000011162 core material Substances 0.000 description 14

- 239000013307 optical fiber Substances 0.000 description 12

- 238000009499 grossing Methods 0.000 description 10

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 6

- 229910052737 gold Inorganic materials 0.000 description 6

- 239000010931 gold Substances 0.000 description 6

- 239000004642 Polyimide Substances 0.000 description 4

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 229920001721 polyimide Polymers 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 229910052710 silicon Inorganic materials 0.000 description 4

- 239000010703 silicon Substances 0.000 description 4

- 238000007740 vapor deposition Methods 0.000 description 4

- 239000004593 Epoxy Substances 0.000 description 3

- 238000005253 cladding Methods 0.000 description 3

- 238000004891 communication Methods 0.000 description 3

- 238000000151 deposition Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 238000000016 photochemical curing Methods 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- 238000009792 diffusion process Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 230000000873 masking effect Effects 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 239000007779 soft material Substances 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000001723 curing Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 150000002222 fluorine compounds Chemical class 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000010365 information processing Effects 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/10—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings of the optical waveguide type

- G02B6/12—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings of the optical waveguide type of the integrated circuit kind

- G02B6/122—Basic optical elements, e.g. light-guiding paths

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/021—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles characterised by the shape of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/68—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts by incorporating or moulding on preformed parts, e.g. inserts or layers, e.g. foam blocks

- B29C70/74—Moulding material on a relatively small portion of the preformed part, e.g. outsert moulding

- B29C70/76—Moulding on edges or extremities of the preformed part

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2011/00—Optical elements, e.g. lenses, prisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2011/00—Optical elements, e.g. lenses, prisms

- B29L2011/0075—Light guides, optical cables

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1052—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing

- Y10T156/1062—Prior to assembly

- Y10T156/1066—Cutting to shape joining edge surfaces only

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Optical Integrated Circuits (AREA)

- Optical Elements Other Than Lenses (AREA)

Description

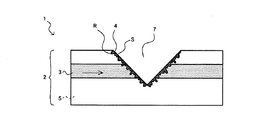

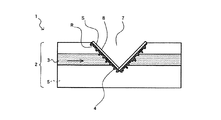

なお、光伝送方向(図示左右方向)に対して直角に交差している反射補助層4を有する図1、図3のミラー付き光伝送体1は、光伝送方向(図示左右方向)に反射補助層4とは別のミラー(図示せず)を形成することにより、レーザ発振等の共振器としての利用が可能である。

特に、フレキシブルな光導波路や光ファイバをダイシングで切削加工すると粗面Rが顕著となるが、本発明は、このような軟らかい光伝送体2にミラーを形成する場合に好適である。

2 光伝送体

3 光伝送層

4 反射補助層

5 基板

6 角溝

7 V溝

8 光反射膜

9 整形部材

R 粗面

S、SS 平滑面

Claims (5)

- 光伝送方向に連続的に形成されている光伝送層の途中にその光伝送方向に対して傾斜させてダイシングにより切削加工することによって、粗面を有するV溝を形成する第1のステップと、

上記粗面に密着させて上記粗面を覆う未固化状態の反射補助層を形成する第2のステップと、

固形の部材からなり上記V溝の傾斜に対応する傾斜角の平滑面を有する整形部材を用い、上記整形部材の平滑面を未固化状態の上記反射補助層に押し付けて、上記反射補助層に上記光伝送層からの光が反射される反射補助層の平滑面を形成する第3のステップと、

未固化状態の上記反射補助層を固化する第4のステップと、

を有することを特徴とするミラー付き光伝送体の製造方法。 - 上記整形部材を固化された上記反射補助層から剥離させる第5のステップを有する、

請求項1記載のミラー付き光伝送体の製造方法。 - 上記第3のステップにおいて、上記整形部材の平滑面にあらかじめ光反射膜を付着させておき、上記整形部材に付着された上記光反射膜を未固化状態の上記反射補助層に押し付けて、上記反射補助層の平滑面を形成し、

上記第4のステップにおいて、上記反射補助層を固化する際に、上記光反射膜が上記反射補助層に接着され、

上記第5のステップにおいて、上記光反射膜は、上記整形部材から剥離されて、上記反射補助層の平滑面に接着された状態で残る、

請求項2記載のミラー付き光伝送体の製造方法。 - 上記反射補助層は、熱硬化樹脂、光硬化樹脂、又は、熱可塑性樹脂からなる、

請求項1〜3いずれかに記載のミラー付き光伝送体の製造方法。 - 上記光反射膜は、金属膜、又は、多層膜からなる、

請求項3に記載のミラー付き光伝送体の製造方法。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009003381A JP5109982B2 (ja) | 2008-10-09 | 2009-01-09 | ミラー付き光伝送体の製造方法 |

| US12/576,258 US8335415B2 (en) | 2008-10-09 | 2009-10-09 | Mirror-embedded light transmission medium and fabrication method of same |

| CN200910178990.7A CN101718889B (zh) | 2008-10-09 | 2009-10-09 | 带镜面的光传输体及其制造方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008263042 | 2008-10-09 | ||

| JP2008263042 | 2008-10-09 | ||

| JP2009003381A JP5109982B2 (ja) | 2008-10-09 | 2009-01-09 | ミラー付き光伝送体の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010113325A JP2010113325A (ja) | 2010-05-20 |

| JP2010113325A5 JP2010113325A5 (ja) | 2011-06-23 |

| JP5109982B2 true JP5109982B2 (ja) | 2012-12-26 |

Family

ID=42098934

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009003381A Expired - Fee Related JP5109982B2 (ja) | 2008-10-09 | 2009-01-09 | ミラー付き光伝送体の製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8335415B2 (ja) |

| JP (1) | JP5109982B2 (ja) |

| CN (1) | CN101718889B (ja) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8905610B2 (en) | 2009-01-26 | 2014-12-09 | Flex Lighting Ii, Llc | Light emitting device comprising a lightguide film |

| US9651729B2 (en) | 2010-04-16 | 2017-05-16 | Flex Lighting Ii, Llc | Reflective display comprising a frontlight with extraction features and a light redirecting optical element |

| US9028123B2 (en) | 2010-04-16 | 2015-05-12 | Flex Lighting Ii, Llc | Display illumination device with a film-based lightguide having stacked incident surfaces |

| CA2829388C (en) | 2011-03-09 | 2018-09-25 | Flex Lighting Ii, Llc | Light emitting device with adjustable light output profile |

| JP5950618B2 (ja) * | 2012-02-24 | 2016-07-13 | キヤノン株式会社 | 光透過部材の形成方法および撮像装置の製造方法 |

| US9566751B1 (en) * | 2013-03-12 | 2017-02-14 | Flex Lighting Ii, Llc | Methods of forming film-based lightguides |

| US11009646B2 (en) | 2013-03-12 | 2021-05-18 | Azumo, Inc. | Film-based lightguide with interior light directing edges in a light mixing region |

| US9690032B1 (en) | 2013-03-12 | 2017-06-27 | Flex Lighting Ii Llc | Lightguide including a film with one or more bends |

| CN104516055A (zh) * | 2013-09-26 | 2015-04-15 | 上海美维科技有限公司 | 一种改善光波导切割面光学质量的方法 |

| JP2016203376A (ja) * | 2013-10-04 | 2016-12-08 | コニカミノルタ株式会社 | フィルムミラーの製造方法 |

| JP6835979B2 (ja) * | 2017-02-21 | 2021-02-24 | シグニファイ ホールディング ビー ヴィSignify Holding B.V. | 光ファイバを使用する3d印刷された照明器具 |

| WO2020047340A1 (en) | 2018-08-30 | 2020-03-05 | Flex Lighting Ii, Llc | Film-based frontlight with angularly varying diffusion film |

| WO2020123539A1 (en) | 2018-12-11 | 2020-06-18 | Flex Lighting Ii, Llc | Front illumination lightguide with a diffusely reflective release liner |

| WO2020142731A1 (en) | 2019-01-03 | 2020-07-09 | Flex Lighting Ii, Llc | Reflective display comprising a lightguide and light turning film creating multiple illumination peaks |

| CN113678036B (zh) | 2019-01-09 | 2024-02-02 | 阿祖莫公司 | 包括以不同的折叠角折叠的耦合光导的反射型显示器 |

| US11513274B2 (en) | 2019-08-01 | 2022-11-29 | Azumo, Inc. | Lightguide with a light input edge between lateral edges of a folded strip |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50155243A (ja) * | 1974-06-05 | 1975-12-15 | ||

| DE2938810A1 (de) * | 1979-09-25 | 1981-04-09 | Siemens AG, 1000 Berlin und 8000 München | Vorrichtung zum einkoppeln von strahlung in einen optischen wellenleiter |

| DE4012747A1 (de) * | 1990-04-21 | 1991-10-24 | Bodenseewerk Geraetetech | Verfahren zur herstellung von feinoptischen stirnflaechen an wellenleitern |

| KR100236432B1 (ko) * | 1996-07-31 | 1999-12-15 | 미야즈 쥰이치로 | 광학 편광기, 이의 제조 방법 및 광학 편광기 제조용 블레이드 |

| JP3753508B2 (ja) | 1996-07-31 | 2006-03-08 | 日本電信電話株式会社 | 光路変換素子の作製方法、および光路変換素子作製用のブレード |

| US6952504B2 (en) * | 2001-12-21 | 2005-10-04 | Neophotonics Corporation | Three dimensional engineering of planar optical structures |

| US6058228A (en) * | 1997-10-06 | 2000-05-02 | Nec Research Institute, Inc. | Cost-effective side-coupling polymer fiber optics for optical interconnections |

| US6684007B2 (en) * | 1998-10-09 | 2004-01-27 | Fujitsu Limited | Optical coupling structures and the fabrication processes |

| TW451084B (en) * | 1999-06-25 | 2001-08-21 | Toppan Printing Co Ltd | Optical-electro wiring board, mounted board, and manufacturing method of optical-electro wiring board |

| AU1301501A (en) * | 1999-11-11 | 2001-06-06 | Photonixnet Kabushiki Kaisha | Optical connector and optical transceiver |

| JP3762208B2 (ja) * | 2000-09-29 | 2006-04-05 | 株式会社東芝 | 光配線基板の製造方法 |

| JP2002258081A (ja) * | 2001-02-28 | 2002-09-11 | Fujitsu Ltd | 光配線基板、光配線基板の製造方法及び多層光配線 |

| JP2003240997A (ja) * | 2002-02-21 | 2003-08-27 | Fujitsu Ltd | 空間反射型構造を有する光集積回路の製造方法 |

| ATE412256T1 (de) * | 2002-06-07 | 2008-11-15 | Fujifilm Corp | Verfahren zur herstellung strukturierter schichten |

| WO2004027472A1 (ja) * | 2002-09-20 | 2004-04-01 | Toppan Printing Co., Ltd. | 光導波路及びその製造方法 |

| JP3887371B2 (ja) * | 2003-11-27 | 2007-02-28 | インターナショナル・ビジネス・マシーンズ・コーポレーション | 光伝送基板、光伝送基板製造方法、及び光電気集積回路 |

| JP2006184773A (ja) * | 2004-12-28 | 2006-07-13 | Mitsui Chemicals Inc | 光導波路およびこれを備えた光電気混載基板 |

| JP2007219143A (ja) | 2006-02-16 | 2007-08-30 | Sumitomo Bakelite Co Ltd | 光導波路構造体および電子機器 |

| JP2007293108A (ja) | 2006-04-26 | 2007-11-08 | Mitsumi Electric Co Ltd | 光学装置及び光学装置の製造方法 |

| JP5018254B2 (ja) | 2007-06-06 | 2012-09-05 | 日立電線株式会社 | ミラー付き光導波路及びその製造方法 |

-

2009

- 2009-01-09 JP JP2009003381A patent/JP5109982B2/ja not_active Expired - Fee Related

- 2009-10-09 US US12/576,258 patent/US8335415B2/en not_active Expired - Fee Related

- 2009-10-09 CN CN200910178990.7A patent/CN101718889B/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US8335415B2 (en) | 2012-12-18 |

| US20100092143A1 (en) | 2010-04-15 |

| JP2010113325A (ja) | 2010-05-20 |

| CN101718889A (zh) | 2010-06-02 |

| CN101718889B (zh) | 2013-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5109982B2 (ja) | ミラー付き光伝送体の製造方法 | |

| JP5018254B2 (ja) | ミラー付き光導波路及びその製造方法 | |

| US6944377B2 (en) | Optical communication device and laminated optical communication module | |

| US8542963B2 (en) | Method for manufacturing optical coupling element, optical transmission substrate, optical coupling component, coupling method, and optical interconnect system | |

| US8715542B2 (en) | Method of manufacturing optical waveguide | |

| US20110084047A1 (en) | Methods For Fabrication Of Large Core Hollow Waveguides | |

| JP2010535357A (ja) | フォトニックガイド装置 | |

| US6631228B2 (en) | Adhesive-free bonding method of fiber attachment for polymer optical waveguide on polymer substrate | |

| JP2007183467A (ja) | ミラー付光導波路及びその製造方法 | |

| JP2001188146A (ja) | 光結合方法及び光回路 | |

| JP4252968B2 (ja) | 光導波路ユニットの製造方法 | |

| JP2012058683A (ja) | フィルム光導波路及びその製造方法 | |

| JP4290065B2 (ja) | 光モジュールおよびその製造方法 | |

| JP3973072B2 (ja) | 金属コート光ファイバ、スリーブ付き金属コート光ファイバ、および光半導体モジュールの製造方法 | |

| JP3858683B2 (ja) | 多層光配線及びその製造方法 | |

| JP3907036B2 (ja) | 金属コート光ファイバ、スリーブ付き金属コート光ファイバ、および光半導体モジュール | |

| JP2009103860A (ja) | 光導波路および光導波路製造方法 | |

| JP2008046333A (ja) | 光送受信モジュール | |

| JP4133410B2 (ja) | 光ファイバアレイの製造方法 | |

| JP2003270461A (ja) | 光通信部品、積層型光通信モジュール、およびその製造方法 | |

| JP2009103804A (ja) | 光導波路及びその製造方法 | |

| JP2008197380A (ja) | 多チャンネル光路変換素子とその作製方法 | |

| JP2010078670A (ja) | 高分子光導波路及びその製造方法 | |

| JP2004302401A (ja) | 光路変換素子及びその作製方法、光集積回路及びその作製方法 | |

| JP4498978B2 (ja) | 平面光回路アセンブリおよびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110415 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110415 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110415 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120605 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120606 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120730 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120911 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120924 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151019 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |