JP4696147B2 - ターボ機械 - Google Patents

ターボ機械 Download PDFInfo

- Publication number

- JP4696147B2 JP4696147B2 JP2008169773A JP2008169773A JP4696147B2 JP 4696147 B2 JP4696147 B2 JP 4696147B2 JP 2008169773 A JP2008169773 A JP 2008169773A JP 2008169773 A JP2008169773 A JP 2008169773A JP 4696147 B2 JP4696147 B2 JP 4696147B2

- Authority

- JP

- Japan

- Prior art keywords

- rotor

- segments

- labyrinth seal

- turbomachine

- comb

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/08—Sealings

- F04D29/10—Shaft sealings

- F04D29/102—Shaft sealings especially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/001—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between stator blade and rotor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/02—Preventing or minimising internal leakage of working-fluid, e.g. between stages by non-contact sealings, e.g. of labyrinth type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/44—Free-space packings

- F16J15/441—Free-space packings with floating ring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/44—Free-space packings

- F16J15/447—Labyrinth packings

- F16J15/4472—Labyrinth packings with axial path

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2250/00—Geometry

- F05D2250/10—Two-dimensional

- F05D2250/18—Two-dimensional patterned

- F05D2250/182—Two-dimensional patterned crenellated, notched

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49229—Prime mover or fluid pump making

- Y10T29/49297—Seal or packing making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Sealing Using Fluids, Sealing Without Contact, And Removal Of Oil (AREA)

Description

と、ロータを保持し、流路を形成するステータと、該ステータとロータ間における流体漏

洩を低減する櫛歯構造のラビリンスシールを有するターボ機械において、円周方向にセグ

メント分割し、櫛歯高さの異なるセグメントを組み合わせて溝部底部に段差を形成したラビリンスシールを有することを特徴とするものである。

2 ラビリンスシール

3 ロータ

4 ステータ

5 櫛歯

6 溝部

7 セグメント

7a 櫛歯高さの高いセグメント

7b 櫛歯高さの低いセグメント

8 溝部底部

9 溝部底部の段差

Claims (3)

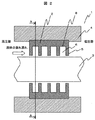

- 回転羽根車を有するロータと、ロータを保持し、流路を形成するステータと、このステ

ータと前記ロータ間における流体漏洩を低減する櫛歯構造のラビリンスシールと、を有す

るターボ機械において、前記ラビリンスシールは、円周方向にセグメントに分かれていて

、櫛歯高さの異なるセグメントを組み合わせて溝部底部に段差を形成したことを特徴とするターボ機械。 - 回転羽根車を有するロータと、ロータを保持し、流路を形成するステータと、このステ

ータと前記ロータ間における流体漏洩を低減する櫛歯構造のラビリンスシールと、を有す

るターボ機械において、前記ラビリンスシールは、円周方向にセグメントに分かれていて

、櫛歯高さの異なる2種類の前記セグメントを有し、前記ロータの直角断面上のある基準方向及びその反対方向に櫛歯高さの高いセグメントを配置し、前記基準方向に直角な方向とその反対方向に櫛歯高さの低いセグメントを配置したラビリンスシールを有するターボ機械。 - 請求項1記載のターボ機械において、前記セグメントは、櫛歯高さの異なるセグメント

が並んで配置しているターボ機械。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008169773A JP4696147B2 (ja) | 2008-06-30 | 2008-06-30 | ターボ機械 |

| US12/491,391 US8388311B2 (en) | 2008-06-30 | 2009-06-25 | Turbomachinery |

| EP09164093A EP2141363B1 (en) | 2008-06-30 | 2009-06-30 | Seal for turbomachine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008169773A JP4696147B2 (ja) | 2008-06-30 | 2008-06-30 | ターボ機械 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010007611A JP2010007611A (ja) | 2010-01-14 |

| JP4696147B2 true JP4696147B2 (ja) | 2011-06-08 |

Family

ID=40873232

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008169773A Expired - Fee Related JP4696147B2 (ja) | 2008-06-30 | 2008-06-30 | ターボ機械 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8388311B2 (ja) |

| EP (1) | EP2141363B1 (ja) |

| JP (1) | JP4696147B2 (ja) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5147885B2 (ja) | 2010-03-26 | 2013-02-20 | 株式会社日立製作所 | ロータ振動防止構造、およびそれを用いた蒸気タービン |

| GB2480680B (en) * | 2010-05-28 | 2012-10-03 | Alstom Technology Ltd | Labyrinth seal |

| JP2012102831A (ja) * | 2010-11-12 | 2012-05-31 | Hitachi Ltd | ラビリンスシール装置、およびそれを用いたターボ機械 |

| JP2014020509A (ja) * | 2012-07-20 | 2014-02-03 | Toshiba Corp | シール装置、軸流タービン、および発電プラント |

| JP6049385B2 (ja) * | 2012-10-04 | 2016-12-21 | 株式会社日立製作所 | 遠心圧縮機 |

| JP5931708B2 (ja) * | 2012-12-04 | 2016-06-08 | 三菱重工業株式会社 | シール装置及び回転機械 |

| CN103090012A (zh) * | 2013-01-18 | 2013-05-08 | 沈阳航空航天大学 | 一种新型高稳定错位四气楔密封结构 |

| US9574453B2 (en) * | 2014-01-02 | 2017-02-21 | General Electric Company | Steam turbine and methods of assembling the same |

| US9359908B2 (en) | 2014-07-08 | 2016-06-07 | General Electric Company | Film riding seal assembly for turbomachinery |

| US10161259B2 (en) | 2014-10-28 | 2018-12-25 | General Electric Company | Flexible film-riding seal |

| GB201715169D0 (en) | 2017-09-20 | 2017-11-01 | Rolls Royce Plc | Seal for a gas turbine |

| US20190195072A1 (en) * | 2017-12-22 | 2019-06-27 | Rolls-Royce North American Technologies Inc. | Turbine rotor disc having multiple rims |

| CN108331783A (zh) * | 2018-02-24 | 2018-07-27 | 西安交通大学 | 一种正交各向异性旋转密封结构 |

| JP6846374B2 (ja) * | 2018-03-08 | 2021-03-24 | 三菱重工業株式会社 | 動翼側シール装置、静翼側シール装置及び回転機械 |

| CN110439631B (zh) * | 2019-08-21 | 2024-05-28 | 沈阳航空航天大学 | 一种可主动间隙控制的迷宫密封结构 |

| CN115021459A (zh) * | 2022-05-30 | 2022-09-06 | 江苏中工高端装备研究院有限公司 | 一种用于环形永磁同步电机的高可靠防尘密封结构 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR852718A (fr) * | 1938-10-21 | 1940-03-01 | Automobiles Soc Nouv | Perfectionnements apportés aux moteurs à huile lourde ou autre combustible |

| JPS56148152U (ja) * | 1980-04-07 | 1981-11-07 | ||

| IT1152732B (it) * | 1982-10-19 | 1987-01-07 | Nuovo Pignone Spa | Tenuta a labirinto perfezionata |

| JPS633570U (ja) * | 1986-06-26 | 1988-01-11 | ||

| JPS63293365A (ja) * | 1987-05-27 | 1988-11-30 | Hitachi Plant Eng & Constr Co Ltd | ラビリンスパツキン加工装置 |

| JPH05195707A (ja) * | 1992-01-17 | 1993-08-03 | Mitsubishi Heavy Ind Ltd | タービンロータの軸封装置 |

| JP3492101B2 (ja) | 1996-08-16 | 2004-02-03 | 三菱重工業株式会社 | 流体機械のスワール防止装置 |

| US7004475B2 (en) * | 2003-09-26 | 2006-02-28 | Siemens Westinghouse Power Corporation | Flow dam design for labyrinth seals to promote rotor stability |

| JP2005214144A (ja) * | 2004-01-30 | 2005-08-11 | Toshiba Corp | 流体機械の旋回流防止装置 |

| FR2893357B1 (fr) | 2005-11-15 | 2011-05-06 | Snecma | Lechette annulaire destinee a un labyrinthe d'etancheite et son procede de fabrication |

| FR2930593B1 (fr) * | 2008-04-23 | 2013-05-31 | Snecma | Piece thermomecanique de revolution autour d'un axe longitudinal, comprenant au moins une couronne abradable destinee a un labyrinthe d'etancheite |

-

2008

- 2008-06-30 JP JP2008169773A patent/JP4696147B2/ja not_active Expired - Fee Related

-

2009

- 2009-06-25 US US12/491,391 patent/US8388311B2/en not_active Expired - Fee Related

- 2009-06-30 EP EP09164093A patent/EP2141363B1/en not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| US20100166544A1 (en) | 2010-07-01 |

| US8388311B2 (en) | 2013-03-05 |

| EP2141363A3 (en) | 2010-11-03 |

| EP2141363A2 (en) | 2010-01-06 |

| EP2141363B1 (en) | 2012-08-01 |

| JP2010007611A (ja) | 2010-01-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4696147B2 (ja) | ターボ機械 | |

| JP6198200B2 (ja) | 回転機械 | |

| US10281046B2 (en) | Fluid machine having a labyrinth seal | |

| JP5524427B2 (ja) | 過給機のスラスト軸受装置 | |

| JP5922796B2 (ja) | シール装置、および、回転機械 | |

| JP2012087929A (ja) | ラビリンスシールシステム | |

| KR102020138B1 (ko) | 라비린스 시일 | |

| JP5972374B2 (ja) | 軸流流体機械 | |

| WO2015115558A1 (ja) | シール構造、及び回転機械 | |

| JP5643245B2 (ja) | ターボ機械 | |

| JP2016089768A (ja) | シール装置及びターボ機械 | |

| JP6426993B2 (ja) | ティルティングパッド型ジャーナル軸受 | |

| CN108368745B (zh) | 密封结构及涡轮 | |

| JPWO2014091599A1 (ja) | 回転流体機械 | |

| JP2011247158A (ja) | シール構造、これを備えたタービン機械およびこれを備えた発電プラント | |

| RU2011112993A (ru) | Ротор и уплотнительное устройство для ротационной машины | |

| JPWO2016030952A1 (ja) | シール機構、回転機械 | |

| JP2017227259A (ja) | ラビリンスシール | |

| JP2019157662A (ja) | 動翼側シール装置、静翼側シール装置及び回転機械 | |

| EP3056667A2 (en) | Turbine bucket for control of wheelspace purge air | |

| JP6204757B2 (ja) | 流体機械 | |

| JP2017155625A5 (ja) | ||

| JP2011163421A (ja) | ターボ機械用ラビリンスシール装置 | |

| CN105318011B (zh) | 一种可以适应转子振动的低泄漏f型交错齿迷宫密封 | |

| JP5694128B2 (ja) | 蒸気タービン |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100311 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100609 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100615 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100809 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110201 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110228 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140304 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |