JP4616576B2 - チャック装置 - Google Patents

チャック装置 Download PDFInfo

- Publication number

- JP4616576B2 JP4616576B2 JP2004123777A JP2004123777A JP4616576B2 JP 4616576 B2 JP4616576 B2 JP 4616576B2 JP 2004123777 A JP2004123777 A JP 2004123777A JP 2004123777 A JP2004123777 A JP 2004123777A JP 4616576 B2 JP4616576 B2 JP 4616576B2

- Authority

- JP

- Japan

- Prior art keywords

- ratchet teeth

- spring member

- chuck device

- holding

- retainer spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 210000000078 claw Anatomy 0.000 claims description 19

- 229910000831 Steel Inorganic materials 0.000 claims description 11

- 239000010959 steel Substances 0.000 claims description 11

- 239000011248 coating agent Substances 0.000 claims description 8

- 238000000576 coating method Methods 0.000 claims description 8

- 230000002093 peripheral effect Effects 0.000 claims description 8

- 229910052782 aluminium Inorganic materials 0.000 claims description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims description 4

- 229920003002 synthetic resin Polymers 0.000 claims description 4

- 239000000057 synthetic resin Substances 0.000 claims description 4

- 229910000838 Al alloy Inorganic materials 0.000 claims description 3

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 claims description 3

- 229910045601 alloy Inorganic materials 0.000 claims description 3

- 239000000956 alloy Substances 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 claims description 3

- 229920005989 resin Polymers 0.000 claims description 3

- 239000011347 resin Substances 0.000 claims description 3

- 230000000717 retained effect Effects 0.000 claims description 3

- 239000010935 stainless steel Substances 0.000 claims description 3

- 229910001220 stainless steel Inorganic materials 0.000 claims description 3

- 239000012209 synthetic fiber Substances 0.000 claims description 2

- 229920002994 synthetic fiber Polymers 0.000 claims description 2

- 229910001234 light alloy Inorganic materials 0.000 description 5

- 238000003825 pressing Methods 0.000 description 5

- 230000002265 prevention Effects 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 125000004122 cyclic group Chemical group 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 238000009751 slip forming Methods 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B31/00—Chucks; Expansion mandrels; Adaptations thereof for remote control

- B23B31/02—Chucks

- B23B31/10—Chucks characterised by the retaining or gripping devices or their immediate operating means

- B23B31/12—Chucks with simultaneously-acting jaws, whether or not also individually adjustable

- B23B31/1207—Chucks with simultaneously-acting jaws, whether or not also individually adjustable moving obliquely to the axis of the chuck in a plane containing this axis

- B23B31/1238—Jaws movement actuated by a nut with conical screw-thread

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B31/00—Chucks; Expansion mandrels; Adaptations thereof for remote control

- B23B31/02—Chucks

- B23B31/10—Chucks characterised by the retaining or gripping devices or their immediate operating means

- B23B31/12—Chucks with simultaneously-acting jaws, whether or not also individually adjustable

- B23B31/1207—Chucks with simultaneously-acting jaws, whether or not also individually adjustable moving obliquely to the axis of the chuck in a plane containing this axis

- B23B31/123—Chucks with simultaneously-acting jaws, whether or not also individually adjustable moving obliquely to the axis of the chuck in a plane containing this axis with locking arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2222/00—Materials of tools or workpieces composed of metals, alloys or metal matrices

- B23B2222/04—Aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2222/00—Materials of tools or workpieces composed of metals, alloys or metal matrices

- B23B2222/80—Stainless steel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2222/00—Materials of tools or workpieces composed of metals, alloys or metal matrices

- B23B2222/88—Titanium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2226/00—Materials of tools or workpieces not comprising a metal

- B23B2226/27—Composites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2228/00—Properties of materials of tools or workpieces, materials of tools or workpieces applied in a specific manner

- B23B2228/10—Coatings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S279/00—Chucks or sockets

- Y10S279/902—Keyless type socket

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T279/00—Chucks or sockets

- Y10T279/17—Socket type

- Y10T279/17615—Obliquely guided reciprocating jaws

- Y10T279/17623—Threaded sleeve and jaw

- Y10T279/17632—Conical sleeve

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T279/00—Chucks or sockets

- Y10T279/32—Means to prevent jaw loosening

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Gripping On Spindles (AREA)

- Springs (AREA)

Description

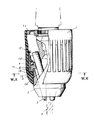

2 本体

2a 孔

3 爪

4 工具

5 ラチェット歯

7 係止バネ体

13 硬質部材

13a 傾斜縁

13b 直交縁

14 凹状固定部

17 回動体

30 係止バネ体

31 係止バネ体

Claims (11)

- 回動筒を回動させることにより本体の先端に設けられた孔に挿入される複数の爪を拡縮摺動させ、前記爪により工具を挟持するチャック装置であって、前記本体には環状のラチェット歯が設けられ、また前記回動筒の内方にして前記本体には前記爪と螺合し該回動筒と共に回動する環状の回動体が被嵌され、また前記ラチェット歯の外方には該ラチェット歯と係止する着脱自在な係止バネ体が配設され、この係止バネ体は前記回動体の回動に伴い前記ラチェット歯の周囲を回動する状態で設けられ、この係止バネ体は前記回動体に凹凸嵌合手段により取り付けられ、更に前記ラチェット歯と前記係止バネ体が係止した状態及びこの係止が解除した状態を保持する保持部が設けられ、前記ラチェット歯は、前記本体とは別体にして該本体の周面に形成した凹状固定部に巻き付け固定された帯状で該本体より高硬度の硬質部材に形成されていることを特徴とするチャック装置。

- 請求項1記載のチャック装置において、前記硬質部材は、前記凹状固定部に巻き付けた状態で該凹状固定部をかしめて固定されているものであることを特徴とするチャック装置。

- 請求項1,2いずれか1項に記載のチャック装置において、前記硬質部材は、両端縁が傾斜縁若しくは側縁に対して直交する直交縁に形成されていることを特徴とするチャック装置。

- 請求項1〜3いずれか1項に記載のチャック装置において、前記硬質部材として、鋼若しくはステンレスが採用されていることを特徴とするチャック装置。

- 請求項1〜4いずれか1項に記載のチャック装置において、前記本体は、軽量部材で形成されていることを特徴とするチャック装置。

- 請求項5記載のチャック装置において、前記軽量部材として、非鉄金属若しくはこれらの合金,合成樹脂または繊維強化樹脂が採用されていることを特徴とするチャック装置。

- 請求項1〜6いずれか1項に記載のチャック装置において、前記保持部は、前記係止バネ体を所定の位置に保持することで、前記ラチェット歯と前記係止バネ体が係止した状態及びこの係止が解除した状態を保持するように構成したものであることを特徴とするチャック装置。

- 回動筒を回動させることにより本体に設けられた孔に挿入される複数の爪を拡縮摺動させ、前記爪により工具を挟持するチャック装置であって、前記本体には環状のラチェット歯が設けられ、また前記回動筒の内方にして前記本体には前記爪と螺合し前記回動筒と共に回動する環状の回動体が被嵌され、また前記ラチェット歯の外方には該ラチェット歯と係止する着脱自在な係止バネ体が配設され、この係止バネ体は二つのバネ体から成り、一方の係止バネ体は前記ラチェット歯との係止作用を担うように構成され、また、他方の係止バネ体は前記回動筒の位置を保持することで前記一方の係止バネ体の位置を保持する作用を担うように構成され、これらの係止バネ体は前記回動体の回動に伴い前記ラチェット歯の周囲を回動する状態で設けられ、これらの係止バネ体は前記回動体に凹凸嵌合手段により取り付けられ、さらに前記ラチェット歯と前記一方の係止バネ体が係止した状態及びこの係止が解除した状態を保持する保持部が設けられ、この保持部は前記本体と前記回動筒との間に配されると共に前記他方の係止バネ体と前記回動筒の内面とで構成され、前記本体はアルミ若しくはアルミ合金製等の軽量部材で構成され、前記環状のラチェット歯は、前記本体とは別体にして該本体の周面に形成した凹状固定部に巻き付け固定された帯状で該本体より高硬度の硬質部材に形成されていることを特徴とするチャック装置。

- 請求項8記載のチャック装置において、前記硬質部材は、前記凹状固定部に巻き付けた状態で該凹状固定部をかしめて固定されているものであることを特徴とするチャック装置。

- 請求項8,9いずれか1項に記載のチャック装置において、前記他方の係止バネ体と前記回動筒との凹凸嵌合により、前記ラチェット歯と前記一方の係止バネ体が係止した状態及びこの係止が解除した状態が保持されるように構成されていることを特徴とするチャック装置。

- 請求項1〜10いずれか1項に記載のチャック装置において、前記ラチェット歯に、硬質にして摩擦係数が可及的に小さいコーティングが施されていることを特徴とするチャック装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004123777A JP4616576B2 (ja) | 2004-04-20 | 2004-04-20 | チャック装置 |

| US11/105,506 US7497444B2 (en) | 2004-04-20 | 2005-04-14 | Chuck device |

| CNB2005100660869A CN100491032C (zh) | 2004-04-20 | 2005-04-20 | 卡紧装置 |

| DE200510018310 DE102005018310B4 (de) | 2004-04-20 | 2005-04-20 | Spannfutter |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004123777A JP4616576B2 (ja) | 2004-04-20 | 2004-04-20 | チャック装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005305574A JP2005305574A (ja) | 2005-11-04 |

| JP2005305574A5 JP2005305574A5 (ja) | 2007-06-14 |

| JP4616576B2 true JP4616576B2 (ja) | 2011-01-19 |

Family

ID=35095500

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004123777A Expired - Lifetime JP4616576B2 (ja) | 2004-04-20 | 2004-04-20 | チャック装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7497444B2 (ja) |

| JP (1) | JP4616576B2 (ja) |

| CN (1) | CN100491032C (ja) |

| DE (1) | DE102005018310B4 (ja) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2715890Y (zh) * | 2004-08-03 | 2005-08-10 | 山东威达机械股份有限公司 | 带响自锁式钻夹头 |

| US7708288B2 (en) * | 2005-05-18 | 2010-05-04 | Jacobs Chuck Manufacturing Company | Locking chuck |

| US7527273B2 (en) * | 2005-09-02 | 2009-05-05 | Jacobs Chuck Manufacturing Company | Locking chuck |

| CN100578036C (zh) * | 2005-09-28 | 2010-01-06 | 山东威达机械股份有限公司 | 单向离合装置及采用该装置的柄类工具夹持结构 |

| US20080033473A1 (en) * | 2006-08-03 | 2008-02-07 | Daniel Refai | Blunt Dissection and Tissue Elevation Instrument |

| DE102006050916A1 (de) * | 2006-10-28 | 2008-04-30 | Röhm Gmbh | Nachspannendes Bohrfutter |

| DE102007006329A1 (de) * | 2006-12-08 | 2008-06-19 | Robert Bosch Gmbh | Aufsatz für eine Handwerkzeugmaschine |

| CN100999025A (zh) * | 2006-12-30 | 2007-07-18 | 李新平 | 自锁式手紧钻夹头 |

| US8459659B2 (en) * | 2007-12-19 | 2013-06-11 | Illinois Tool Works Inc. | Hybrid lathe chuck |

| DE202009005187U1 (de) * | 2008-11-24 | 2009-10-29 | Zhejiang Sanou Machinery Co. Ltd., Taizhou | Schlüsselloses Bohrfutter mit Selbstverriegelung |

| JP5378056B2 (ja) * | 2009-04-30 | 2013-12-25 | ユキワ精工株式会社 | チャック装置 |

| DE102009057200A1 (de) * | 2009-11-26 | 2011-06-01 | C. & E. Fein Gmbh | Vorsatz für eine Werkzeugmaschine |

| DE202012102742U1 (de) | 2012-07-23 | 2013-04-25 | Röhm Gmbh | Bohrfutter |

| US10556276B2 (en) * | 2013-03-14 | 2020-02-11 | Apex Brands, Inc. | Locking chuck |

| US10603722B2 (en) | 2014-10-10 | 2020-03-31 | Apex Brands, Inc. | Locking chuck |

| US11123806B2 (en) * | 2016-10-14 | 2021-09-21 | Apex Brands, Inc. | Chuck with slip protection |

| JP6787571B2 (ja) | 2016-12-06 | 2020-11-18 | ユキワ精工株式会社 | チャック装置 |

| US11511354B2 (en) * | 2017-07-28 | 2022-11-29 | Apex Brands, Inc. | Locking chuck with anti-vibration feature |

| CN112566537B (zh) | 2018-08-17 | 2024-09-27 | 富士胶片株式会社 | 内窥镜系统 |

| WO2020036224A1 (ja) | 2018-08-17 | 2020-02-20 | 富士フイルム株式会社 | 内視鏡システム |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5748408A (en) * | 1980-07-04 | 1982-03-19 | Amyot Ets Sa | Chuck for fitting tool to machine tool |

| JPS6299007A (ja) * | 1985-10-25 | 1987-05-08 | Matsushita Electric Works Ltd | 締め付け具 |

| JPS63139603A (ja) * | 1986-11-21 | 1988-06-11 | ギュンタ ホルスト ロェーム | ドリルチャック |

| JPH02172606A (ja) * | 1988-12-23 | 1990-07-04 | Matsushita Electric Works Ltd | 締め付け具 |

| JP2003225813A (ja) * | 2002-01-31 | 2003-08-12 | Yukiwa Seiko Inc | チャック装置 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0283105A (ja) * | 1988-03-28 | 1990-03-23 | Matsushita Electric Works Ltd | 締め付け具 |

| US5232230A (en) * | 1992-09-28 | 1993-08-03 | Lin Pi Chu | Chuck assembly for a drilling apparatus |

| US5957469A (en) * | 1996-09-25 | 1999-09-28 | Power Tool Holders, Inc. | Spring chuck |

| DE19800998C2 (de) * | 1998-01-14 | 2001-05-17 | Roehm Gmbh | Bohrfutter mit einem Futterkörper aus Kunststoff |

| DE29823512U1 (de) * | 1998-01-14 | 1999-08-26 | Röhm GmbH, 89567 Sontheim | Bohrfutter |

| CN1220569C (zh) * | 2001-06-10 | 2005-09-28 | 山东威达机械股份有限公司 | 自紧钻夹头 |

| US6824141B1 (en) * | 2001-08-30 | 2004-11-30 | Yukiwa Seiko Kabushiki Kaisha | Chuck device |

| JP2003071618A (ja) | 2001-08-30 | 2003-03-12 | Yukiwa Seiko Inc | チャック装置 |

| JP4015857B2 (ja) * | 2002-01-18 | 2007-11-28 | ユキワ精工株式会社 | チャック装置 |

| CN2582790Y (zh) * | 2002-11-25 | 2003-10-29 | 山东威达机械股份有限公司 | 自锁钻夹头 |

| CN2633481Y (zh) * | 2003-07-17 | 2004-08-18 | 山东威达机械股份有限公司 | 锁紧式钻夹头 |

| US20050087937A1 (en) * | 2003-10-22 | 2005-04-28 | Wenhua Zhou | Lock type manually tightened chuck |

| US7360770B2 (en) * | 2004-08-17 | 2008-04-22 | Black & Decker Inc. | Keyless chuck with automatic and manual locking |

| US7472913B2 (en) * | 2005-06-09 | 2009-01-06 | Jacobs Chuck Manufacturing Company | Drill chuck |

| US7527273B2 (en) * | 2005-09-02 | 2009-05-05 | Jacobs Chuck Manufacturing Company | Locking chuck |

| FR2897789B1 (fr) * | 2006-02-27 | 2008-05-09 | Amyot Sa Sa Ets | Mandrin porte-outil pour l'equipement d'une machine tourante muni de moyens de verrouillage radial et axial sequences |

| US7896356B2 (en) * | 2006-04-10 | 2011-03-01 | Shandong Weida Machinery Co., Ltd. | Drill chuck with two-stage gripping |

-

2004

- 2004-04-20 JP JP2004123777A patent/JP4616576B2/ja not_active Expired - Lifetime

-

2005

- 2005-04-14 US US11/105,506 patent/US7497444B2/en active Active

- 2005-04-20 CN CNB2005100660869A patent/CN100491032C/zh active Active

- 2005-04-20 DE DE200510018310 patent/DE102005018310B4/de active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5748408A (en) * | 1980-07-04 | 1982-03-19 | Amyot Ets Sa | Chuck for fitting tool to machine tool |

| JPS6299007A (ja) * | 1985-10-25 | 1987-05-08 | Matsushita Electric Works Ltd | 締め付け具 |

| JPS63139603A (ja) * | 1986-11-21 | 1988-06-11 | ギュンタ ホルスト ロェーム | ドリルチャック |

| JPH02172606A (ja) * | 1988-12-23 | 1990-07-04 | Matsushita Electric Works Ltd | 締め付け具 |

| JP2003225813A (ja) * | 2002-01-31 | 2003-08-12 | Yukiwa Seiko Inc | チャック装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN100491032C (zh) | 2009-05-27 |

| US20050230926A1 (en) | 2005-10-20 |

| JP2005305574A (ja) | 2005-11-04 |

| DE102005018310A1 (de) | 2005-11-10 |

| DE102005018310B4 (de) | 2015-05-13 |

| CN1693019A (zh) | 2005-11-09 |

| US7497444B2 (en) | 2009-03-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4616576B2 (ja) | チャック装置 | |

| JP4053301B2 (ja) | チャック装置 | |

| JP4015857B2 (ja) | チャック装置 | |

| US7837200B2 (en) | Chuck | |

| US7527273B2 (en) | Locking chuck | |

| JP5378056B2 (ja) | チャック装置 | |

| US7360770B2 (en) | Keyless chuck with automatic and manual locking | |

| US7178216B2 (en) | Keyless chuck and associated method | |

| US20060027979A1 (en) | Lockable chuck | |

| JP2010260122A5 (ja) | ||

| JP2003071618A (ja) | チャック装置 | |

| US20030071425A1 (en) | Anti-slip type electric drill chuck | |

| US20130025894A1 (en) | Tool having torque-controlled spindle lock assembly | |

| US11511354B2 (en) | Locking chuck with anti-vibration feature | |

| WO2018105161A1 (ja) | チャック装置 | |

| JP4090631B2 (ja) | レンチ | |

| JPH02172605A (ja) | 締め付け具 | |

| TWI798239B (zh) | 軸承座圈和密封件傳動工具及安裝軸承座圈的方法 | |

| JP2711948B2 (ja) | 軸等の固定構造 | |

| JP7096119B2 (ja) | 歯科用トルクレンチ | |

| MXPA97009654A (en) | Keyless mandrel actuated through pala |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070419 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070419 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090827 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100517 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100716 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100927 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101022 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4616576 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131029 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |