JP4479552B2 - ホースおよびその製法 - Google Patents

ホースおよびその製法 Download PDFInfo

- Publication number

- JP4479552B2 JP4479552B2 JP2005082225A JP2005082225A JP4479552B2 JP 4479552 B2 JP4479552 B2 JP 4479552B2 JP 2005082225 A JP2005082225 A JP 2005082225A JP 2005082225 A JP2005082225 A JP 2005082225A JP 4479552 B2 JP4479552 B2 JP 4479552B2

- Authority

- JP

- Japan

- Prior art keywords

- resin layer

- film

- chromium

- metal

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 14

- 239000010410 layer Substances 0.000 claims description 249

- 239000010408 film Substances 0.000 claims description 178

- 229910052751 metal Inorganic materials 0.000 claims description 155

- 239000002184 metal Substances 0.000 claims description 155

- 229920005989 resin Polymers 0.000 claims description 149

- 239000011347 resin Substances 0.000 claims description 149

- 238000007747 plating Methods 0.000 claims description 100

- 239000011651 chromium Substances 0.000 claims description 67

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims description 66

- 229910052804 chromium Inorganic materials 0.000 claims description 66

- 230000002093 peripheral effect Effects 0.000 claims description 64

- 238000000034 method Methods 0.000 claims description 24

- 238000005240 physical vapour deposition Methods 0.000 claims description 17

- 238000004544 sputter deposition Methods 0.000 claims description 13

- 239000002356 single layer Substances 0.000 claims description 6

- 238000007733 ion plating Methods 0.000 claims description 3

- 238000007740 vapor deposition Methods 0.000 claims description 3

- 239000010409 thin film Substances 0.000 claims description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 24

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 22

- 239000000446 fuel Substances 0.000 description 19

- 239000000853 adhesive Substances 0.000 description 18

- 230000001070 adhesive effect Effects 0.000 description 18

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 16

- 229910000423 chromium oxide Inorganic materials 0.000 description 16

- 230000015572 biosynthetic process Effects 0.000 description 13

- 229910052759 nickel Inorganic materials 0.000 description 12

- 229910052763 palladium Inorganic materials 0.000 description 11

- 239000000454 talc Substances 0.000 description 11

- 229910052623 talc Inorganic materials 0.000 description 11

- 230000000052 comparative effect Effects 0.000 description 10

- 238000005530 etching Methods 0.000 description 10

- 239000000463 material Substances 0.000 description 9

- 230000035699 permeability Effects 0.000 description 9

- 239000004734 Polyphenylene sulfide Substances 0.000 description 7

- 238000009713 electroplating Methods 0.000 description 7

- 229920000069 polyphenylene sulfide Polymers 0.000 description 7

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 6

- 239000011229 interlayer Substances 0.000 description 6

- 239000003502 gasoline Substances 0.000 description 5

- 238000007772 electroless plating Methods 0.000 description 4

- 238000001125 extrusion Methods 0.000 description 4

- 238000001755 magnetron sputter deposition Methods 0.000 description 4

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 229920006122 polyamide resin Polymers 0.000 description 4

- 229910001220 stainless steel Inorganic materials 0.000 description 4

- 229920000299 Nylon 12 Polymers 0.000 description 3

- 239000004721 Polyphenylene oxide Substances 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 239000011261 inert gas Substances 0.000 description 3

- 239000007769 metal material Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229920000570 polyether Polymers 0.000 description 3

- -1 polyethylene terephthalate Polymers 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- LCGLNKUTAGEVQW-UHFFFAOYSA-N Dimethyl ether Chemical compound COC LCGLNKUTAGEVQW-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910017052 cobalt Inorganic materials 0.000 description 2

- 239000010941 cobalt Substances 0.000 description 2

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 239000003915 liquefied petroleum gas Substances 0.000 description 2

- 229910044991 metal oxide Inorganic materials 0.000 description 2

- 150000004706 metal oxides Chemical class 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 229910052697 platinum Inorganic materials 0.000 description 2

- 229920006111 poly(hexamethylene terephthalamide) Polymers 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920001707 polybutylene terephthalate Polymers 0.000 description 2

- 229920001225 polyester resin Polymers 0.000 description 2

- 239000004645 polyester resin Substances 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229910052709 silver Inorganic materials 0.000 description 2

- 239000004332 silver Substances 0.000 description 2

- 229910052718 tin Inorganic materials 0.000 description 2

- 239000011135 tin Substances 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- 239000011701 zinc Substances 0.000 description 2

- 239000004953 Aliphatic polyamide Substances 0.000 description 1

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 229910000990 Ni alloy Inorganic materials 0.000 description 1

- 229910021586 Nickel(II) chloride Inorganic materials 0.000 description 1

- 229910018487 Ni—Cr Inorganic materials 0.000 description 1

- 229920000571 Nylon 11 Polymers 0.000 description 1

- 229920002292 Nylon 6 Polymers 0.000 description 1

- 229920000305 Nylon 6,10 Polymers 0.000 description 1

- 229920002302 Nylon 6,6 Polymers 0.000 description 1

- 229920000572 Nylon 6/12 Polymers 0.000 description 1

- 229920012310 Polyamide 9T (PA9T) Polymers 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 229920006121 Polyxylylene adipamide Polymers 0.000 description 1

- BUGBHKTXTAQXES-UHFFFAOYSA-N Selenium Chemical compound [Se] BUGBHKTXTAQXES-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 229920013629 Torelina Polymers 0.000 description 1

- 239000004742 Torelina™ Substances 0.000 description 1

- 229920003231 aliphatic polyamide Polymers 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 1

- 239000004327 boric acid Substances 0.000 description 1

- 239000001110 calcium chloride Substances 0.000 description 1

- 229910001628 calcium chloride Inorganic materials 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 150000001844 chromium Chemical class 0.000 description 1

- OLFCLHDBKGQITG-UHFFFAOYSA-N chromium(3+) nickel(2+) oxygen(2-) Chemical compound [Ni+2].[O-2].[Cr+3] OLFCLHDBKGQITG-UHFFFAOYSA-N 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 125000004435 hydrogen atom Chemical class [H]* 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000003345 natural gas Substances 0.000 description 1

- QMMRZOWCJAIUJA-UHFFFAOYSA-L nickel dichloride Chemical compound Cl[Ni]Cl QMMRZOWCJAIUJA-UHFFFAOYSA-L 0.000 description 1

- LGQLOGILCSXPEA-UHFFFAOYSA-L nickel sulfate Chemical compound [Ni+2].[O-]S([O-])(=O)=O LGQLOGILCSXPEA-UHFFFAOYSA-L 0.000 description 1

- 229910000363 nickel(II) sulfate Inorganic materials 0.000 description 1

- 229910000623 nickel–chromium alloy Inorganic materials 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920000412 polyarylene Polymers 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000009719 polyimide resin Substances 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 229910052711 selenium Inorganic materials 0.000 description 1

- 239000011669 selenium Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 229910052727 yttrium Inorganic materials 0.000 description 1

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 1

- 229910052845 zircon Inorganic materials 0.000 description 1

- GFQYVLUOOAAOGM-UHFFFAOYSA-N zirconium(iv) silicate Chemical compound [Zr+4].[O-][Si]([O-])([O-])[O-] GFQYVLUOOAAOGM-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L11/00—Hoses, i.e. flexible pipes

- F16L11/04—Hoses, i.e. flexible pipes made of rubber or flexible plastics

- F16L11/045—Hoses, i.e. flexible pipes made of rubber or flexible plastics with four or more layers without reinforcement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L9/00—Rigid pipes

- F16L9/14—Compound tubes, i.e. made of materials not wholly covered by any one of the preceding groups

- F16L9/147—Compound tubes, i.e. made of materials not wholly covered by any one of the preceding groups comprising only layers of metal and plastics with or without reinforcement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L11/00—Hoses, i.e. flexible pipes

- F16L11/04—Hoses, i.e. flexible pipes made of rubber or flexible plastics

- F16L2011/047—Hoses, i.e. flexible pipes made of rubber or flexible plastics with a diffusion barrier layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/4998—Combined manufacture including applying or shaping of fluent material

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Laminated Bodies (AREA)

- Physical Vapour Deposition (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Description

東レ社製、トレリナA670X01

PA12(エムス社製、グリルアミドL25AH、末端アミノ基濃度:60μ当量/g)

硫酸ニッケル :250g/リットル

塩化ニッケル : 45g/リットル

ほう酸 : 40g/リットル

ピット防止剤(奥野製薬工業社製、アクナH) : 2ml/リットル

一次光沢剤(奥野製薬工業社製、Mu−2) : 5ml/リットル

pH:4.2

温度:50℃

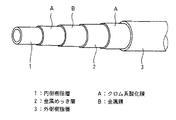

まず、上記PPS樹脂を用いて、内側樹脂層を押出成形した。ついで、この内側樹脂層の外周面に、DCマグネトロンスパッタリング装置を用いて、後記の表2に示す条件にて、スパッタリングにより、クロム系酸化膜を形成し、つづいて、後記の表2に示す条件にて、スパッタリングにより、金属膜を形成した。その後、それを、窒素ガス雰囲気下で、上記DCマグネトロンスパッタリング装置から取り出し、すぐに、上記ワット浴に浸けた。そして、上記金属膜の外周面に、上記ワット浴にて、電流密度1A/dm2 で5分間、電解めっきを行い、ニッケルめっき層(金属めっき層)を形成した。つぎに、それを上記ワット浴から取り出し、ニッケルめっき層の外周面を乾燥させた後、そのニッケルめっき層の外周面に、DCマグネトロンスパッタリング装置を用いて、後記の表2に示す条件にて、スパッタリングにより、クロム系酸化膜を形成した。そして、このクロム系酸化膜の外周面に、外側樹脂層を押出成形した。このとき、内側樹脂層から外側樹脂層までの全体の厚みが1.5mmになるようにした。このようにして、図1に示す6層構造の燃料輸送用ホース(内径33mm、外径36mm)を作製した。

まず、上記PPS樹脂を用いて、内側樹脂層を押出成形した。ついで、この内側樹脂層を上記ワット浴に浸け、この内側樹脂層の外周面に直接、上記実施例と同様にして電解めっきを行ったが、ニッケルめっき層(金属めっき層)は形成されなかった。そこで、上記内側樹脂層をアルカリニッケル液(奥野製薬工業社製、TMP−化学ニッケル)に浸け、40℃で5分間、無電解ニッケルめっきを行ったが、ニッケルめっき層(金属めっき層)は形成されなかった。そして、この内側樹脂層のみからなる燃料輸送用ホース(内径33mm、外径33.2mm)を比較例1とした。

まず、上記PPS樹脂を用いて、内側樹脂層を押出成形した。ついで、この内側樹脂層の外周面に、DCマグネトロンスパッタリング装置を用いて、後記の表2に示す条件にて、スパッタリングにより、Ni−Cr金属膜のみを形成した。それ以降は、上記実施例と同様にして、ニッケルめっき層(金属めっき層),クロム系酸化膜,外側樹脂層を順に形成した。このようにして、5層構造の燃料輸送用ホース(内径33mm、外径36mm)を作製した。

まず、上記PPS樹脂を用いて、内側樹脂層を押出成形した。ついで、この内側樹脂層の外周面に直接、上記実施例と同様にして外側樹脂層を押出成形した。このようにして、2層構造の燃料輸送用ホース(内径33mm、外径36mm)を作製した。

上記各燃料輸送用ホースを長手方向に切り開いた後、直径56mmの円盤状に打ち抜き、各サンプルを作製した。そして、差圧式・蒸気透過率測定装置(GTRテック社製、GTR−30XATG)を用いて,上記サンプルにおける、市販レギュラーガソリンと、エタノールとを90:10(体積割合)で混合したアルコール添加ガソリンの透過係数を、40℃で2週間測定した。なお、表中の透過係数は、2週間後の数値を示す。

各燃料輸送用ホースを10mm幅で短冊状に切断して、サンプルを作製した。そして、各サンプルの先端部の各層を剥離し、その剥離した内側樹脂層と金属めっき層の各層の先端部を引張試験機(オリエンテック社製)の各チャックに挟み、引張速度50mm/分の条件で、内側樹脂層/金属めっき層間の180度剥離強度(N/cm)を測定した。同様にして、金属めっき層/外側樹脂層間(比較例3は、内側樹脂層/外側樹脂層間)の180度剥離強度(N/cm)を測定した。なお、剥離強度が20N/cm以上であれば、層間接着性が良好であると考えられる。

2 金属めっき層

3 外側樹脂層

A クロム系酸化膜

B 金属膜

Claims (3)

- 管状の内側樹脂層と、この内側樹脂層の外周に形成された金属めっき層と、この金属めっき層の外周に形成された外側樹脂層とを備えたホースであって、上記内側樹脂層と金属めっき層との間に、クロム系酸化膜と金属膜とを備えた多層膜が形成され、その多層膜のうちのクロム系酸化膜が上記内側樹脂層の外周面上に位置決めされ、上記多層膜のうちの金属膜の外周面上に上記金属めっき層が位置決めされ、かつ、上記金属めっき層と外側樹脂層との間に、クロム系酸化膜を備えた単層膜もしくは多層膜が形成され、その多層膜のうちのクロム系酸化膜の外周面上に上記外側樹脂層が位置決めされていることを特徴とするホース。

- 上記請求項1記載のホースの製法であって、内側樹脂層の外周面に、スパッタリング,イオンプレーティングおよび真空蒸着からなる群から選ばれた少なくとも一つの物理蒸着法により、クロム系酸化膜を形成する工程と、このクロム系酸化膜の外周に、上記物理蒸着法により、金属膜を形成する工程と、この金属膜の外周面に金属めっき層を形成した後、この金属めっき層の外周面に、上記物理蒸着法により、クロム系酸化薄膜を備えた単層膜もしくは多層膜を形成する工程と、その多層膜のうちのクロム系酸化膜の外周面に外側樹脂層を形成する工程とを備えていることを特徴とするホースの製法。

- 請求項2記載のホースの製法において、上記内側樹脂層の外周に上記金属膜を形成した後から、その金属膜の外周面に金属めっき層を形成する工程に移るまでが、不活性ガスの雰囲気下で行われるホースの製法。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005082225A JP4479552B2 (ja) | 2005-03-22 | 2005-03-22 | ホースおよびその製法 |

| US11/385,753 US7434599B2 (en) | 2005-03-22 | 2006-03-22 | Hose and method of producing the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005082225A JP4479552B2 (ja) | 2005-03-22 | 2005-03-22 | ホースおよびその製法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006266318A JP2006266318A (ja) | 2006-10-05 |

| JP4479552B2 true JP4479552B2 (ja) | 2010-06-09 |

Family

ID=37033988

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005082225A Expired - Fee Related JP4479552B2 (ja) | 2005-03-22 | 2005-03-22 | ホースおよびその製法 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US7434599B2 (ja) |

| JP (1) | JP4479552B2 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006118669A (ja) * | 2004-10-25 | 2006-05-11 | Sanoh Industrial Co Ltd | 樹脂チューブ |

| JP4544125B2 (ja) * | 2005-10-17 | 2010-09-15 | 東海ゴム工業株式会社 | 低透過樹脂ホースおよびその製法 |

| JP4544129B2 (ja) * | 2005-10-25 | 2010-09-15 | 東海ゴム工業株式会社 | 低透過樹脂ホースおよびその製法 |

| JP4896703B2 (ja) * | 2006-12-26 | 2012-03-14 | 東海ゴム工業株式会社 | ニッケル電気めっき膜およびその製法 |

| DE102010009796A1 (de) * | 2010-03-01 | 2011-09-01 | Rehau Ag + Co. | Verwendung eines Rohres zum Transport von reinem Wasserstoff |

| WO2011155450A1 (ja) * | 2010-06-09 | 2011-12-15 | 三桜工業株式会社 | 自動車配管用金属管およびその表面処理方法 |

| JP2013538154A (ja) * | 2010-09-03 | 2013-10-10 | アエラズール エス.エー. | 航空機用熱可塑性プラスチックホース |

| US9746108B2 (en) * | 2014-03-04 | 2017-08-29 | W.E. Hall Company, Inc. | Composite underground pipe structure |

| JP6467195B2 (ja) | 2014-11-10 | 2019-02-06 | 三桜工業株式会社 | 車輌配管用被覆金属管 |

| US20180274700A1 (en) * | 2015-09-28 | 2018-09-27 | Bridgestone Corporation | Resin material for hose, hose tube and hose |

| US12498076B2 (en) * | 2022-06-23 | 2025-12-16 | Dynaflex Products | Method of plating an automotive exhaust pipe |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS581076A (ja) * | 1981-06-26 | 1983-01-06 | Nisshin Steel Co Ltd | Lng又はlpgタンク用高ニッケル―鉄合金鋼板の表面処理方法 |

| US4467002A (en) * | 1981-12-15 | 1984-08-21 | Raychem Limited | Dimensionally-recoverable article |

| US4606953A (en) * | 1983-06-23 | 1986-08-19 | Nippon Steel Corporation | Polypropylene coated steel pipe |

| US4916031A (en) * | 1985-11-20 | 1990-04-10 | Toyo Seikan Kaisha, Ltd. | Surface-treated steel plate and bonded structure of metal material |

| US5271977A (en) * | 1989-02-10 | 1993-12-21 | Bridgestone Corporation | Low permeable rubber hose |

| JPH04131581A (ja) * | 1990-09-25 | 1992-05-06 | Bridgestone Corp | 低透過性ゴムホース |

| JPH08269723A (ja) | 1995-03-27 | 1996-10-15 | Toyoda Gosei Co Ltd | めっき層を有する樹脂成形品及びその製造方法 |

| GB2311114B (en) * | 1996-03-15 | 1999-04-28 | T & N Technology Ltd | Convoluted flexible protective sleeves |

| US6546963B2 (en) * | 2000-12-08 | 2003-04-15 | Halter Marine, Inc. | Fire resistant piping system |

| US7033679B2 (en) * | 2001-01-25 | 2006-04-25 | Kyocera Optec Co., Ltd. | Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member, thin film forming apparatus and thin film forming method for producing metal film and metal oxide film |

-

2005

- 2005-03-22 JP JP2005082225A patent/JP4479552B2/ja not_active Expired - Fee Related

-

2006

- 2006-03-22 US US11/385,753 patent/US7434599B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US7434599B2 (en) | 2008-10-14 |

| JP2006266318A (ja) | 2006-10-05 |

| US20060213569A1 (en) | 2006-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4479552B2 (ja) | ホースおよびその製法 | |

| US6652939B2 (en) | Low permeation nylon tube with aluminum barrier layer | |

| KR920009633B1 (ko) | 다층피막을 가진 내열성 및 내식성 강관 | |

| US6591871B2 (en) | Low permeation polybutylene terephthalate and polybutylene naphthalate fuel and vapor tubes | |

| JP4383487B2 (ja) | 金属張積層体及び金属張積層体の製造方法 | |

| AU2002341655A1 (en) | Low permeation nylon tube with aluminium barrier layer | |

| KR20130085055A (ko) | 액정 폴리머 구리 피복 적층판 및 당해 적층판에 사용하는 구리박 | |

| CN100503889C (zh) | 具有对树脂层的接合性优异的金属层和树脂层的非六价铬系的耐腐蚀包膜 | |

| JP5773515B2 (ja) | スチール製の燃料圧送配管 | |

| US6974614B2 (en) | Low permeation high density polyethylene tube with aluminum barrier layer | |

| US20030077411A1 (en) | Process for making a fluid-impermeable layer, and an impermeable hose | |

| TW201325891A (zh) | 附樹脂薄膜的金屬製外部材料及其製造方法 | |

| CN101146679B (zh) | 多层结构体 | |

| WO2004009871A1 (ja) | 多層めっき自動車燃料配管部品 | |

| JP2010141227A (ja) | プリント配線板用圧延銅箔 | |

| EP2082871A1 (en) | Resin pipe | |

| JP5639948B2 (ja) | 車両用配管の表面処理構造 | |

| JP4562510B2 (ja) | 多層樹脂チューブ | |

| CN113481473B (zh) | 一种钛合金轴承座及其制备方法和航空部件 | |

| KR20110024527A (ko) | 전해 동박 및 그 제조 방법 | |

| US20050224135A1 (en) | Fuel filler pipe for automobile | |

| JP5300119B2 (ja) | シームレス缶用表面処理鋼板、樹脂被覆鋼板及びシームレス缶 | |

| JP4923855B2 (ja) | 表面処理金属板およびその製造方法、ならびに樹脂被覆金属板、金属缶および缶蓋 | |

| CN101428718B (zh) | 缠绕连接处理用金合金丝的卷筒 | |

| JP2010053389A (ja) | めっき処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070913 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100129 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100223 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100308 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130326 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130326 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140326 Year of fee payment: 4 |

|

| LAPS | Cancellation because of no payment of annual fees |