JP3761741B2 - 黄銅とこの黄銅製品 - Google Patents

黄銅とこの黄銅製品 Download PDFInfo

- Publication number

- JP3761741B2 JP3761741B2 JP12701999A JP12701999A JP3761741B2 JP 3761741 B2 JP3761741 B2 JP 3761741B2 JP 12701999 A JP12701999 A JP 12701999A JP 12701999 A JP12701999 A JP 12701999A JP 3761741 B2 JP3761741 B2 JP 3761741B2

- Authority

- JP

- Japan

- Prior art keywords

- brass

- cutting

- hot

- present

- parts

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229910001369 Brass Inorganic materials 0.000 title claims description 72

- 239000010951 brass Substances 0.000 title claims description 72

- 238000005520 cutting process Methods 0.000 claims description 43

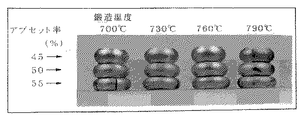

- 238000005242 forging Methods 0.000 claims description 24

- 229910052711 selenium Inorganic materials 0.000 claims description 14

- 229910052742 iron Inorganic materials 0.000 claims description 4

- 239000012535 impurity Substances 0.000 claims description 3

- 239000000463 material Substances 0.000 description 30

- 239000010949 copper Substances 0.000 description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 19

- 239000000956 alloy Substances 0.000 description 18

- 229910045601 alloy Inorganic materials 0.000 description 16

- 229910052797 bismuth Inorganic materials 0.000 description 14

- 229910052802 copper Inorganic materials 0.000 description 14

- 239000000047 product Substances 0.000 description 12

- 238000002386 leaching Methods 0.000 description 11

- 238000012360 testing method Methods 0.000 description 11

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 8

- 238000005260 corrosion Methods 0.000 description 8

- 230000007797 corrosion Effects 0.000 description 8

- 238000010828 elution Methods 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 8

- 238000002844 melting Methods 0.000 description 8

- 230000008018 melting Effects 0.000 description 8

- 238000000034 method Methods 0.000 description 8

- 238000011156 evaluation Methods 0.000 description 6

- 239000000203 mixture Substances 0.000 description 6

- 239000000523 sample Substances 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 239000013078 crystal Substances 0.000 description 5

- 229910052745 lead Inorganic materials 0.000 description 5

- 229910000881 Cu alloy Inorganic materials 0.000 description 4

- 238000001816 cooling Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 229910000906 Bronze Inorganic materials 0.000 description 3

- 230000002411 adverse Effects 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical group [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 3

- 230000007613 environmental effect Effects 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- 238000005096 rolling process Methods 0.000 description 3

- 239000012488 sample solution Substances 0.000 description 3

- 239000000243 solution Substances 0.000 description 3

- 238000010998 test method Methods 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- 239000010974 bronze Substances 0.000 description 2

- ORTQZVOHEJQUHG-UHFFFAOYSA-L copper(II) chloride Chemical compound Cl[Cu]Cl ORTQZVOHEJQUHG-UHFFFAOYSA-L 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 229910000765 intermetallic Inorganic materials 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

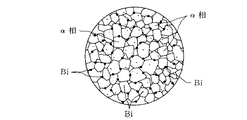

- 238000001000 micrograph Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 238000011056 performance test Methods 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- 229910017518 Cu Zn Inorganic materials 0.000 description 1

- 229910017755 Cu-Sn Inorganic materials 0.000 description 1

- 229910017752 Cu-Zn Inorganic materials 0.000 description 1

- 229910017927 Cu—Sn Inorganic materials 0.000 description 1

- 229910017943 Cu—Zn Inorganic materials 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 238000012790 confirmation Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009749 continuous casting Methods 0.000 description 1

- TVZPLCNGKSPOJA-UHFFFAOYSA-N copper zinc Chemical group [Cu].[Zn] TVZPLCNGKSPOJA-UHFFFAOYSA-N 0.000 description 1

- 229960003280 cupric chloride Drugs 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000004993 emission spectroscopy Methods 0.000 description 1

- 239000013067 intermediate product Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 210000002445 nipple Anatomy 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000005204 segregation Methods 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C9/00—Alloys based on copper

- C22C9/04—Alloys based on copper with zinc as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/08—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of copper or alloys based thereon

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Forging (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP12701999A JP3761741B2 (ja) | 1999-05-07 | 1999-05-07 | 黄銅とこの黄銅製品 |

| GB0022003A GB2366571B (en) | 1999-05-07 | 2000-09-07 | Copper-based alloy, method for production of the alloy, and products using the alloy |

| US09/657,227 US6599378B1 (en) | 1999-05-07 | 2000-09-07 | Copper-based alloy, method for production of the alloy, and products using the alloy |

| CNB001306618A CN1236085C (zh) | 1999-05-07 | 2000-10-10 | 铜基合金 |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP12701999A JP3761741B2 (ja) | 1999-05-07 | 1999-05-07 | 黄銅とこの黄銅製品 |

| GB0022003A GB2366571B (en) | 1999-05-07 | 2000-09-07 | Copper-based alloy, method for production of the alloy, and products using the alloy |

| US09/657,227 US6599378B1 (en) | 1999-05-07 | 2000-09-07 | Copper-based alloy, method for production of the alloy, and products using the alloy |

| CNB001306618A CN1236085C (zh) | 1999-05-07 | 2000-10-10 | 铜基合金 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2000319736A JP2000319736A (ja) | 2000-11-21 |

| JP2000319736A5 JP2000319736A5 (enExample) | 2004-09-16 |

| JP3761741B2 true JP3761741B2 (ja) | 2006-03-29 |

Family

ID=29219747

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP12701999A Expired - Lifetime JP3761741B2 (ja) | 1999-05-07 | 1999-05-07 | 黄銅とこの黄銅製品 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6599378B1 (enExample) |

| JP (1) | JP3761741B2 (enExample) |

| CN (1) | CN1236085C (enExample) |

| GB (1) | GB2366571B (enExample) |

Families Citing this family (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1598436A4 (en) * | 2002-12-27 | 2007-08-22 | Sumitomo Light Metal Ind | METAL MATERIAL AND MANUFACTURING METHOD THEREFOR |

| JP4225540B2 (ja) * | 2003-05-19 | 2009-02-18 | 前澤工業株式会社 | 水道用仕切弁及びその弁類 |

| ATE353981T1 (de) * | 2003-08-18 | 2007-03-15 | Dowa Holdings Co Ltd | Kupferlegierung, die exzellente korrosionsbeständigkeit und entzinkungsbeständigkeit aufweist, und eine methode zu deren herstellung |

| JP4390581B2 (ja) * | 2004-02-16 | 2009-12-24 | サンエツ金属株式会社 | ワイヤ放電加工用電極線 |

| CN100424207C (zh) * | 2004-03-29 | 2008-10-08 | 三越金属株式会社 | 黄铜 |

| JP4522736B2 (ja) * | 2004-03-30 | 2010-08-11 | 株式会社キッツ | 金型鋳造用銅基合金とこの合金を用いた鋳塊・製品 |

| JP4620963B2 (ja) * | 2004-03-31 | 2011-01-26 | Dowaホールディングス株式会社 | 黄銅およびその製造方法ならびにこれを用いた部品 |

| US8057850B2 (en) * | 2006-11-09 | 2011-11-15 | Alliance For Sustainable Energy, Llc | Formation of copper-indium-selenide and/or copper-indium-gallium-selenide films from indium selenide and copper selenide precursors |

| EP2101931B1 (en) * | 2006-11-09 | 2015-05-13 | Alliance for Sustainable Energy, LLC | Precursors for formation of copper selenide, indium selenide, copper indium diselenide, and/or copper indium gallium diselenide films |

| JP4575910B2 (ja) * | 2006-11-24 | 2010-11-04 | 日立アプライアンス株式会社 | 軸受 |

| JP4395159B2 (ja) * | 2006-11-24 | 2010-01-06 | 日立アプライアンス株式会社 | 冷凍装置 |

| AU2007340472B2 (en) * | 2006-12-28 | 2011-04-21 | Kitz Corporation | Leadless brass alloy excellent in stress corrosion cracking resistance |

| JP5111922B2 (ja) * | 2007-03-30 | 2013-01-09 | 株式会社コベルコ マテリアル銅管 | 熱交換器用銅合金管 |

| KR20100016295A (ko) * | 2007-04-09 | 2010-02-12 | 유에스브이 리미티드 | 클로피도그렐 바이설페이트의 안정한 약학적 조성물 및 그의 제조 방법 |

| CN101469384B (zh) * | 2007-12-28 | 2011-11-16 | 比亚迪股份有限公司 | 一种黄铜合金材料及其制备方法 |

| CN101307419B (zh) * | 2008-05-29 | 2010-06-23 | 燕山大学 | 一种铝青铜合金晶粒细化的方法 |

| US8273192B2 (en) * | 2008-06-11 | 2012-09-25 | Xiamen Lota International Co., Ltd. | Lead-free, bismuth-free free-cutting phosphorous brass alloy |

| CN101285138B (zh) * | 2008-06-11 | 2010-09-08 | 路达(厦门)工业有限公司 | 无铅易切削磷黄铜合金及其制造方法 |

| CN101440444B (zh) * | 2008-12-02 | 2010-05-12 | 路达(厦门)工业有限公司 | 无铅易切削高锌硅黄铜合金及其制造方法 |

| US8518192B2 (en) | 2009-03-03 | 2013-08-27 | QuesTek Innovations, LLC | Lead-free, high-strength, high-lubricity copper alloys |

| US8349097B2 (en) * | 2009-09-17 | 2013-01-08 | Modern Islands Co., Ltd. | Dezincification-resistant copper alloy and method for producing product comprising the same |

| US20110064602A1 (en) * | 2009-09-17 | 2011-03-17 | Modern Islands Co., Ltd. | Dezincification-resistant copper alloy |

| US20110081271A1 (en) * | 2009-10-07 | 2011-04-07 | Modern Islands Co., Ltd. | Low-lead copper alloy |

| US20110081272A1 (en) * | 2009-10-07 | 2011-04-07 | Modern Islands Co., Ltd. | Low-lead copper alloy |

| WO2011146115A1 (en) | 2010-05-21 | 2011-11-24 | Heliovolt Corporation | Liquid precursor for deposition of copper selenide and method of preparing the same |

| US9142408B2 (en) | 2010-08-16 | 2015-09-22 | Alliance For Sustainable Energy, Llc | Liquid precursor for deposition of indium selenide and method of preparing the same |

| US8465003B2 (en) | 2011-08-26 | 2013-06-18 | Brasscraft Manufacturing Company | Plumbing fixture made of bismuth brass alloy |

| US8211250B1 (en) | 2011-08-26 | 2012-07-03 | Brasscraft Manufacturing Company | Method of processing a bismuth brass article |

| US8721765B2 (en) * | 2011-11-14 | 2014-05-13 | Mueller Industries, Inc. | Lead free dezincification alloy and method of making same |

| US9105797B2 (en) | 2012-05-31 | 2015-08-11 | Alliance For Sustainable Energy, Llc | Liquid precursor inks for deposition of In—Se, Ga—Se and In—Ga—Se |

| EP2883971B1 (en) * | 2012-08-09 | 2018-10-03 | YKK Corporation | Fastening copper alloy |

| DE102013003817A1 (de) * | 2013-03-07 | 2014-09-11 | Grohe Ag | Kupfer-Zink-Legierung für eine Sanitärarmatur sowie Verfahren zu deren Herstellung |

| JP6420566B2 (ja) * | 2014-04-30 | 2018-11-07 | 株式会社キッツ | 低鉛黄銅製接液部材の製造方法 |

| CN104404291B (zh) * | 2014-11-14 | 2017-03-08 | 宁波杭桥铜业有限公司 | 一种无铅铋黄铜及其制作工艺 |

| CN104831116B (zh) * | 2015-05-16 | 2017-08-25 | 四川鑫炬矿业资源开发股份有限公司 | 一种环保易切削抗热裂硒铋黄铜材料及其制备工艺 |

| KR102215220B1 (ko) * | 2016-03-25 | 2021-02-16 | 엔지케이 인슐레이터 엘티디 | 구리 합금 및 그 제조 방법 |

| CN106636729A (zh) * | 2016-10-05 | 2017-05-10 | 宁波兴业盛泰集团有限公司 | 一种动力电池连接器用多元铜合金板带材及其制备方法 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52155373A (en) * | 1976-05-28 | 1977-12-23 | Tokyo Shibaura Electric Co | Vacuum breaker |

| US5167726A (en) * | 1990-05-15 | 1992-12-01 | At&T Bell Laboratories | Machinable lead-free wrought copper-containing alloys |

| US5288458A (en) * | 1991-03-01 | 1994-02-22 | Olin Corporation | Machinable copper alloys having reduced lead content |

| US5637160A (en) * | 1991-03-01 | 1997-06-10 | Olin Corporation | Corrosion-resistant bismuth brass |

| US5630984A (en) * | 1992-06-02 | 1997-05-20 | Ideal-Standard Gmbh | Brass alloy |

| AU5005793A (en) * | 1992-08-14 | 1994-03-15 | Thomas D. Nielsen | Lead-free copper base alloys |

| US5330712A (en) * | 1993-04-22 | 1994-07-19 | Federalloy, Inc. | Copper-bismuth alloys |

| US5360591A (en) * | 1993-05-17 | 1994-11-01 | Kohler Co. | Reduced lead bismuth yellow brass |

| JP3335002B2 (ja) * | 1994-05-12 | 2002-10-15 | 中越合金鋳工株式会社 | 熱間加工性に優れた無鉛快削黄銅合金 |

| JP3085627B2 (ja) * | 1994-05-25 | 2000-09-11 | 中越合金鋳工株式会社 | シンクロナイザーリング |

| JP2889829B2 (ja) | 1994-10-20 | 1999-05-10 | 株式会社タブチ | 無鉛快削青銅合金 |

| US5653827A (en) * | 1995-06-06 | 1997-08-05 | Starline Mfg. Co., Inc. | Brass alloys |

| US5614038A (en) | 1995-06-21 | 1997-03-25 | Asarco Incorporated | Method for making machinable lead-free copper alloys with additive |

| JP3956322B2 (ja) * | 1996-05-30 | 2007-08-08 | 中越合金鋳工株式会社 | ワンウェイクラッチ用エンドベアリング及びその他の摺動部品 |

| JP2000169919A (ja) * | 1998-12-04 | 2000-06-20 | Sanbo Copper Alloy Co Ltd | 無鉛銅基合金材 |

-

1999

- 1999-05-07 JP JP12701999A patent/JP3761741B2/ja not_active Expired - Lifetime

-

2000

- 2000-09-07 US US09/657,227 patent/US6599378B1/en not_active Expired - Lifetime

- 2000-09-07 GB GB0022003A patent/GB2366571B/en not_active Expired - Fee Related

- 2000-10-10 CN CNB001306618A patent/CN1236085C/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN1346897A (zh) | 2002-05-01 |

| GB2366571B (en) | 2004-10-06 |

| GB0022003D0 (en) | 2000-10-25 |

| JP2000319736A (ja) | 2000-11-21 |

| GB2366571A (en) | 2002-03-13 |

| CN1236085C (zh) | 2006-01-11 |

| US6599378B1 (en) | 2003-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3761741B2 (ja) | 黄銅とこの黄銅製品 | |

| JP6266737B2 (ja) | 耐応力腐食割れ性に優れた黄銅合金と加工部品及び接液部品 | |

| CN110337499B (zh) | 高强度易切削性铜合金及高强度易切削性铜合金的制造方法 | |

| US6974509B2 (en) | Brass | |

| US20080145265A1 (en) | Copper-based alloy | |

| CN106460135A (zh) | 使用黄铜的热锻件的制造方法和热锻件、以及使用该热锻件成形的阀门、水龙头等浸湿制品 | |

| WO1998045490A1 (fr) | Alliage cuivreux de bonne tenue a la fissuration par corrosion sous contrainte, resistant a la corrosion, se pretant au travail a chaud, et procede de production | |

| WO2019035224A1 (ja) | 快削性銅合金、及び、快削性銅合金の製造方法 | |

| EP1921173A1 (en) | Bronze low-lead alloy | |

| JP2005325413A (ja) | 無鉛白色銅合金とこの合金を用いた鋳塊・製品 | |

| JP3375883B2 (ja) | 黄銅製鍛造弁・栓類と弁・栓類の黄銅製鍛造部品 | |

| JP6448168B1 (ja) | 快削性銅合金、及び、快削性銅合金の製造方法 | |

| CN119776696A (zh) | 锻造无铅铜合金及其制造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20040922 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20050617 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20050912 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20051011 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051206 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060110 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060111 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20090120 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110120 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110120 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110120 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120120 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120120 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130120 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130120 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130120 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140120 Year of fee payment: 8 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |