JP2020523277A - ガラス基板の表面を処理する方法 - Google Patents

ガラス基板の表面を処理する方法 Download PDFInfo

- Publication number

- JP2020523277A JP2020523277A JP2019569357A JP2019569357A JP2020523277A JP 2020523277 A JP2020523277 A JP 2020523277A JP 2019569357 A JP2019569357 A JP 2019569357A JP 2019569357 A JP2019569357 A JP 2019569357A JP 2020523277 A JP2020523277 A JP 2020523277A

- Authority

- JP

- Japan

- Prior art keywords

- glass substrate

- glass

- gas

- major surface

- per minute

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 239000011521 glass Substances 0.000 title claims abstract description 84

- 239000000758 substrate Substances 0.000 title claims abstract description 46

- 238000000034 method Methods 0.000 claims abstract description 47

- 230000003746 surface roughness Effects 0.000 claims abstract description 16

- 239000007864 aqueous solution Substances 0.000 claims abstract description 11

- 238000004519 manufacturing process Methods 0.000 claims abstract description 5

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 claims description 36

- QPJSUIGXIBEQAC-UHFFFAOYSA-N n-(2,4-dichloro-5-propan-2-yloxyphenyl)acetamide Chemical compound CC(C)OC1=CC(NC(C)=O)=C(Cl)C=C1Cl QPJSUIGXIBEQAC-UHFFFAOYSA-N 0.000 claims description 30

- 239000007789 gas Substances 0.000 claims description 29

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 11

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 claims description 10

- 238000004140 cleaning Methods 0.000 claims description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 8

- 239000008367 deionised water Substances 0.000 claims description 6

- 229910021641 deionized water Inorganic materials 0.000 claims description 6

- 238000001035 drying Methods 0.000 claims description 6

- 229910052786 argon Inorganic materials 0.000 claims description 5

- 239000012159 carrier gas Substances 0.000 claims description 4

- 238000003286 fusion draw glass process Methods 0.000 claims description 4

- 229910052757 nitrogen Inorganic materials 0.000 claims description 4

- 238000005406 washing Methods 0.000 claims description 4

- 238000001039 wet etching Methods 0.000 description 9

- 238000004630 atomic force microscopy Methods 0.000 description 5

- 238000007786 electrostatic charging Methods 0.000 description 4

- 238000005530 etching Methods 0.000 description 4

- 239000000243 solution Substances 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 238000011282 treatment Methods 0.000 description 3

- 239000003513 alkali Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000001312 dry etching Methods 0.000 description 2

- 239000004973 liquid crystal related substance Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000001020 plasma etching Methods 0.000 description 2

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 235000006508 Nelumbo nucifera Nutrition 0.000 description 1

- 240000002853 Nelumbo nucifera Species 0.000 description 1

- 235000006510 Nelumbo pentapetala Nutrition 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000003929 acidic solution Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 229910000272 alkali metal oxide Inorganic materials 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 239000003599 detergent Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000010408 film Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- -1 for example Chemical class 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000007788 roughening Methods 0.000 description 1

- 238000003283 slot draw process Methods 0.000 description 1

- 238000010583 slow cooling Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 239000008399 tap water Substances 0.000 description 1

- 235000020679 tap water Nutrition 0.000 description 1

- 238000009997 thermal pre-treatment Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000003631 wet chemical etching Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C15/00—Surface treatment of glass, not in the form of fibres or filaments, by etching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/02—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by features of form at particular places, e.g. in edge regions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/10—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C23/00—Other surface treatment of glass not in the form of fibres or filaments

- C03C23/0075—Cleaning of glass

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C2204/00—Glasses, glazes or enamels with special properties

- C03C2204/08—Glass having a rough surface

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Surface Treatment Of Glass (AREA)

- Liquid Crystal (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201762520928P | 2017-06-16 | 2017-06-16 | |

| US62/520,928 | 2017-06-16 | ||

| PCT/US2018/037711 WO2018232213A1 (en) | 2017-06-16 | 2018-06-15 | Method of treating glass substrate surfaces |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2020523277A true JP2020523277A (ja) | 2020-08-06 |

| JP2020523277A5 JP2020523277A5 (enExample) | 2021-07-29 |

Family

ID=64660683

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019569357A Abandoned JP2020523277A (ja) | 2017-06-16 | 2018-06-15 | ガラス基板の表面を処理する方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20210147285A1 (enExample) |

| JP (1) | JP2020523277A (enExample) |

| KR (1) | KR20200019693A (enExample) |

| CN (1) | CN110831754A (enExample) |

| TW (1) | TW201904906A (enExample) |

| WO (1) | WO2018232213A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025027994A1 (ja) * | 2023-07-31 | 2025-02-06 | Agc株式会社 | 親水性ガラスを製造する方法および親水性ガラス |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021026232A (ja) * | 2019-08-08 | 2021-02-22 | 旭化成株式会社 | フレキシブル液晶表示装置 |

| KR102625137B1 (ko) * | 2020-09-21 | 2024-01-15 | (주) 엔피홀딩스 | 글라스의 표면 처리 방법 및 이를 위한 글라스 표면 처리 장치 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6066823A (ja) * | 1983-09-22 | 1985-04-17 | Semiconductor Energy Lab Co Ltd | 半導体エッチング方法 |

| IT1177081B (it) * | 1984-10-30 | 1987-08-26 | Vitreal Specchi Spa | Apparecchiatura per l'incisione in continuo all'acido su una faccia di lastre di vetro |

| TWI543948B (zh) * | 2009-05-07 | 2016-08-01 | 日本電氣硝子股份有限公司 | 玻璃基板及其製造方法 |

| TWI547455B (zh) * | 2011-04-15 | 2016-09-01 | Asahi Glass Co Ltd | Antireflective glass matrix |

| CN102898030B (zh) * | 2011-07-27 | 2015-04-22 | 比亚迪股份有限公司 | 一种触控板及其制作方法 |

| US9126858B2 (en) * | 2012-04-27 | 2015-09-08 | Avanstrate Inc. | Method for making glass substrate for display, glass substrate and display panel |

| US9561982B2 (en) * | 2013-04-30 | 2017-02-07 | Corning Incorporated | Method of cleaning glass substrates |

| WO2015045405A1 (ja) * | 2013-09-30 | 2015-04-02 | 日本板硝子株式会社 | ガラス板の製造方法 |

-

2018

- 2018-06-15 CN CN201880040340.3A patent/CN110831754A/zh active Pending

- 2018-06-15 WO PCT/US2018/037711 patent/WO2018232213A1/en not_active Ceased

- 2018-06-15 US US16/622,601 patent/US20210147285A1/en not_active Abandoned

- 2018-06-15 KR KR1020207001213A patent/KR20200019693A/ko not_active Withdrawn

- 2018-06-15 TW TW107120617A patent/TW201904906A/zh unknown

- 2018-06-15 JP JP2019569357A patent/JP2020523277A/ja not_active Abandoned

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025027994A1 (ja) * | 2023-07-31 | 2025-02-06 | Agc株式会社 | 親水性ガラスを製造する方法および親水性ガラス |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2018232213A1 (en) | 2018-12-20 |

| CN110831754A (zh) | 2020-02-21 |

| KR20200019693A (ko) | 2020-02-24 |

| US20210147285A1 (en) | 2021-05-20 |

| TW201904906A (zh) | 2019-02-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9561982B2 (en) | Method of cleaning glass substrates | |

| JP5687088B2 (ja) | ガラス基板の製造方法 | |

| JP2020523277A (ja) | ガラス基板の表面を処理する方法 | |

| TW200827315A (en) | Glass thinning method | |

| TW201817693A (zh) | 玻璃板及玻璃基板之製造方法 | |

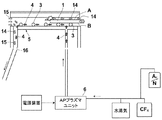

| JP6520928B2 (ja) | エッチング装置、エッチング方法、基板の製造方法、および基板 | |

| JP5066895B2 (ja) | ディスプレイ用ガラス基板およびその製造方法 | |

| JP6263534B2 (ja) | ガラス基板の製造方法、ガラス基板、および、ディスプレイ用パネル | |

| US6808645B2 (en) | Susceptor and surface processing method | |

| JP7415235B2 (ja) | Tft用ガラス基板 | |

| JP7070197B2 (ja) | Tft用ガラス基板 | |

| JP6870617B2 (ja) | ディスプレイ用ガラス基板およびその製造方法 | |

| KR20180096518A (ko) | 디스플레이용 유리 기판, 및 디스플레이용 유리 기판의 제조 방법 | |

| JP2014082407A (ja) | ウェットエッチング装置およびウェットエッチング方法 | |

| KR101543831B1 (ko) | 글래스 기판 및 글래스 기판의 제조 방법 | |

| JP2014009102A (ja) | ディスプレイ用ガラス基板の製造方法、および、ディスプレイ用ガラス基板の製造装置 | |

| JP2013075794A (ja) | ガラスカレットの除去方法 | |

| KR20240036521A (ko) | 석영 유리 지그의 제조 방법 및 석영 유리 지그 | |

| KR20080018320A (ko) | 기판 처리 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200619 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210615 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20210615 |

|

| A762 | Written abandonment of application |

Free format text: JAPANESE INTERMEDIATE CODE: A762 Effective date: 20220218 |