JP2016108398A - 部材 - Google Patents

部材 Download PDFInfo

- Publication number

- JP2016108398A JP2016108398A JP2014245346A JP2014245346A JP2016108398A JP 2016108398 A JP2016108398 A JP 2016108398A JP 2014245346 A JP2014245346 A JP 2014245346A JP 2014245346 A JP2014245346 A JP 2014245346A JP 2016108398 A JP2016108398 A JP 2016108398A

- Authority

- JP

- Japan

- Prior art keywords

- metal

- carbon fiber

- composite member

- heat

- fiber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F21/00—Constructions of heat-exchange apparatus characterised by the selection of particular materials

- F28F21/06—Constructions of heat-exchange apparatus characterised by the selection of particular materials of plastics material

- F28F21/067—Details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/12—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by the relative arrangement of fibres or filaments of different layers, e.g. the fibres or filaments being parallel or perpendicular to each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C1/00—Fuselages; Constructional features common to fuselages, wings, stabilising surfaces or the like

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/0405—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres

- C08J5/042—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres with carbon fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/047—Reinforcing macromolecular compounds with loose or coherent fibrous material with mixed fibrous material

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/06—Reinforcing macromolecular compounds with loose or coherent fibrous material using pretreated fibrous materials

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K5/00—Heat-transfer, heat-exchange or heat-storage materials, e.g. refrigerants; Materials for the production of heat or cold by chemical reactions other than by combustion

- C09K5/08—Materials not undergoing a change of physical state when used

- C09K5/14—Solid materials, e.g. powdery or granular

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/106—Carbon fibres, e.g. graphite fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/18—Aircraft

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C1/00—Fuselages; Constructional features common to fuselages, wings, stabilising surfaces or the like

- B64C1/40—Sound or heat insulation, e.g. using insulation blankets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C1/00—Fuselages; Constructional features common to fuselages, wings, stabilising surfaces or the like

- B64C2001/0054—Fuselage structures substantially made from particular materials

- B64C2001/0072—Fuselage structures substantially made from particular materials from composite materials

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2363/00—Characterised by the use of epoxy resins; Derivatives of epoxy resins

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F2013/001—Particular heat conductive materials, e.g. superconductive elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2255/00—Heat exchanger elements made of materials having special features or resulting from particular manufacturing processes

- F28F2255/06—Heat exchanger elements made of materials having special features or resulting from particular manufacturing processes composite, e.g. polymers with fillers or fibres

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T50/00—Aeronautics or air transport

- Y02T50/40—Weight reduction

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Polymers & Plastics (AREA)

- Medicinal Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Aviation & Aerospace Engineering (AREA)

- Inorganic Chemistry (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Moulding By Coating Moulds (AREA)

- Laminated Bodies (AREA)

- Reinforced Plastic Materials (AREA)

Abstract

Description

第1実施形態について説明する。図1は、本実施形態に係る航空機1の一例を示す図である。図1に示すように、航空機1は、胴体2と、主翼3と、水平尾翼4と、垂直尾翼5と、エンジン6と、燃料タンク7と、コックピット8と、電子機器9と、バッテリ10と、を備えている。

第2実施形態について説明する。以下の説明において、上述の実施形態と同一又は同等の構成部分については同一の符号を付し、その説明を簡略又は省略する。

第3実施形態について説明する。以下の説明において、上述の実施形態と同一又は同等の構成部分については同一の符号を付し、その説明を簡略又は省略する。

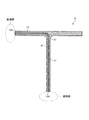

2 胴体

3 主翼

4 水平尾翼

5 垂直尾翼

6 エンジン

7 燃料タンク

8 コックピット

9 電子機器

10 バッテリ

11 複合部材

12 金属コート炭素繊維

12A 一端部

12B 他端部

13 プラスチック

14 金属コート炭素繊維強化プラスチック

15 炭素繊維

16 金属

17 プリプレグシート

20 部材

21 複合部材

29 リブライン

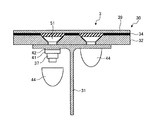

30 外板

31 シアタイ

32 炭素繊維強化プラスチック層

34 ガラス繊維強化プラスチック層

37 カラー

39 銅ペイント層

41 ワッシャ

42 スペーサ

44 キャップ

51 ファスナ

Claims (5)

- 金属コート炭素繊維及びピッチ系炭素繊維の一方又は両方を含む熱伝導性炭素繊維で強化されたプラスチックを有する第1複合部材を備え、

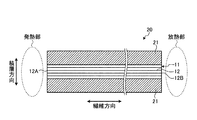

繊維方向に関して前記熱伝導性炭素繊維の一端部が発熱部に配置され、前記熱伝導性炭素繊維の他端部が放熱部に配置される部材。 - 金属コート炭素繊維及びピッチ系炭素繊維の一方又は両方を含む熱伝導性炭素繊維で強化されたプラスチックを有する第1複合部材を備え、

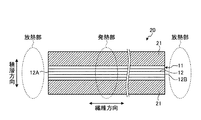

繊維方向に関して前記熱伝導性炭素繊維の中央部が発熱部に配置され、前記熱伝導性炭素繊維の一端部及び他端部が放熱部に配置される部材。 - 前記第1複合部材は、前記繊維方向と交差する並列方向に配置された複数の前記熱伝導性炭素繊維を含むプリプレグシートを前記繊維方向及び前記並列方向と交差する積層方向に複数積層した積層体を含み、

前記繊維方向に関する熱伝導率は、前記並列方向に関する熱伝導率及び前記積層方向に関する熱伝導率よりも大きい請求項1又は請求項2に記載の部材。 - 前記第1複合部材は板状部材であり、

前記第1複合部材の表面及び裏面の一方又は両方に配置され、炭素繊維で強化されたプラスチックを含む第2複合部材を備え、

前記熱伝導性炭素繊維の一端部及び他端部のそれぞれは露出する請求項1から請求項3のいずれか一項に記載の部材。 - 前記発熱部は、前記航空機の電子機器を含み、前記放熱部は、前記航空機の燃料タンクを含む請求項1から請求項4のいずれか一項に記載の部材。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014245346A JP6550230B2 (ja) | 2014-12-03 | 2014-12-03 | 部材 |

| US15/531,606 US20180281983A1 (en) | 2014-12-03 | 2015-10-23 | Member |

| EP15864708.1A EP3214112B1 (en) | 2014-12-03 | 2015-10-23 | Heat passage member |

| PCT/JP2015/080002 WO2016088470A1 (ja) | 2014-12-03 | 2015-10-23 | 部材 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014245346A JP6550230B2 (ja) | 2014-12-03 | 2014-12-03 | 部材 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016108398A true JP2016108398A (ja) | 2016-06-20 |

| JP2016108398A5 JP2016108398A5 (ja) | 2017-11-30 |

| JP6550230B2 JP6550230B2 (ja) | 2019-07-24 |

Family

ID=56091426

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014245346A Active JP6550230B2 (ja) | 2014-12-03 | 2014-12-03 | 部材 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20180281983A1 (ja) |

| EP (1) | EP3214112B1 (ja) |

| JP (1) | JP6550230B2 (ja) |

| WO (1) | WO2016088470A1 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020062768A (ja) * | 2018-10-15 | 2020-04-23 | 有限会社ヒロセ金型 | 炭素繊維強化樹脂成形品の製造方法、及び炭素繊維強化樹脂成形品 |

| JP2021017647A (ja) * | 2019-07-18 | 2021-02-15 | ハミルトン・サンドストランド・コーポレイションHamilton Sundstrand Corporation | 構成要素を形成する方法、プレート及びフレーム熱交換器を形成する方法および熱交換プレート |

| WO2021201165A1 (ja) * | 2020-04-03 | 2021-10-07 | 日本製鉄株式会社 | 蓄電デバイス構造体及び蓄電デバイス構造体の放熱方法 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10723437B2 (en) * | 2017-05-30 | 2020-07-28 | The Boeing Company | System for structurally integrated thermal management for thin wing aircraft control surface actuators |

| EA202191198A1 (ru) | 2018-11-01 | 2021-09-14 | Этомос Ньюклиар Энд Спейс Корпорейшн | Система ребер радиатора, выполненных из углеродного волокна |

| CN114474557B (zh) * | 2021-12-31 | 2023-11-10 | 富联裕展科技(深圳)有限公司 | 金属塑胶结合件及其形成方法、电子产品壳体 |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001073255A (ja) * | 1999-08-31 | 2001-03-21 | Fujikura Rubber Ltd | 放熱シート |

| US20030116678A1 (en) * | 2001-12-21 | 2003-06-26 | Gardner Slade H. | Aircraft structures having improved through-thickness thermal conductivity |

| JP2004528717A (ja) * | 2001-04-30 | 2004-09-16 | サーモ コムポジット、エルエルシー | 熱管理材料、デバイスおよび方法 |

| JP2005213459A (ja) * | 2004-01-30 | 2005-08-11 | Nippon Steel Corp | 高熱伝導材料 |

| JP2006513390A (ja) * | 2002-12-19 | 2006-04-20 | スリーエム イノベイティブ プロパティズ カンパニー | 可撓性吸熱器 |

| WO2006112487A1 (ja) * | 2005-04-18 | 2006-10-26 | Teijin Limited | ピッチ系炭素繊維、マットおよびそれらを含む樹脂成形体 |

| JP2008138968A (ja) * | 2006-12-04 | 2008-06-19 | Honda Motor Co Ltd | 熱交換器の製造方法及び熱交換器 |

| JP2010229238A (ja) * | 2009-03-26 | 2010-10-14 | Mitsubishi Plastics Inc | 炭素繊維強化樹脂シート及びそのロール巻回体 |

| JP2011046967A (ja) * | 2010-12-07 | 2011-03-10 | Mitsubishi Engineering Plastics Corp | 熱伝導性ポリカーボネート系樹脂組成物および成形体 |

| JP2011100959A (ja) * | 2009-10-05 | 2011-05-19 | Sumitomo Electric Ind Ltd | フレキシブル基板、フレキシブル基板モジュール及びそれらの製造方法 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5352893B2 (ja) * | 2008-04-14 | 2013-11-27 | 東洋炭素株式会社 | 炭素繊維炭素複合成形体及び炭素繊維強化炭素複合体材料並びにその製造方法 |

-

2014

- 2014-12-03 JP JP2014245346A patent/JP6550230B2/ja active Active

-

2015

- 2015-10-23 EP EP15864708.1A patent/EP3214112B1/en active Active

- 2015-10-23 US US15/531,606 patent/US20180281983A1/en not_active Abandoned

- 2015-10-23 WO PCT/JP2015/080002 patent/WO2016088470A1/ja not_active Ceased

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001073255A (ja) * | 1999-08-31 | 2001-03-21 | Fujikura Rubber Ltd | 放熱シート |

| JP2004528717A (ja) * | 2001-04-30 | 2004-09-16 | サーモ コムポジット、エルエルシー | 熱管理材料、デバイスおよび方法 |

| US20030116678A1 (en) * | 2001-12-21 | 2003-06-26 | Gardner Slade H. | Aircraft structures having improved through-thickness thermal conductivity |

| JP2006513390A (ja) * | 2002-12-19 | 2006-04-20 | スリーエム イノベイティブ プロパティズ カンパニー | 可撓性吸熱器 |

| JP2005213459A (ja) * | 2004-01-30 | 2005-08-11 | Nippon Steel Corp | 高熱伝導材料 |

| WO2006112487A1 (ja) * | 2005-04-18 | 2006-10-26 | Teijin Limited | ピッチ系炭素繊維、マットおよびそれらを含む樹脂成形体 |

| JP2008138968A (ja) * | 2006-12-04 | 2008-06-19 | Honda Motor Co Ltd | 熱交換器の製造方法及び熱交換器 |

| JP2010229238A (ja) * | 2009-03-26 | 2010-10-14 | Mitsubishi Plastics Inc | 炭素繊維強化樹脂シート及びそのロール巻回体 |

| JP2011100959A (ja) * | 2009-10-05 | 2011-05-19 | Sumitomo Electric Ind Ltd | フレキシブル基板、フレキシブル基板モジュール及びそれらの製造方法 |

| JP2011046967A (ja) * | 2010-12-07 | 2011-03-10 | Mitsubishi Engineering Plastics Corp | 熱伝導性ポリカーボネート系樹脂組成物および成形体 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020062768A (ja) * | 2018-10-15 | 2020-04-23 | 有限会社ヒロセ金型 | 炭素繊維強化樹脂成形品の製造方法、及び炭素繊維強化樹脂成形品 |

| JP7149577B2 (ja) | 2018-10-15 | 2022-10-07 | 有限会社ヒロセ金型 | 炭素繊維強化樹脂成形品の製造方法、及び炭素繊維強化樹脂成形品 |

| JP2021017647A (ja) * | 2019-07-18 | 2021-02-15 | ハミルトン・サンドストランド・コーポレイションHamilton Sundstrand Corporation | 構成要素を形成する方法、プレート及びフレーム熱交換器を形成する方法および熱交換プレート |

| JP7319904B2 (ja) | 2019-07-18 | 2023-08-02 | ハミルトン・サンドストランド・コーポレイション | 構成要素を形成する方法、プレート及びフレーム熱交換器を形成する方法および熱交換プレート |

| WO2021201165A1 (ja) * | 2020-04-03 | 2021-10-07 | 日本製鉄株式会社 | 蓄電デバイス構造体及び蓄電デバイス構造体の放熱方法 |

| JPWO2021201165A1 (ja) * | 2020-04-03 | 2021-10-07 | ||

| JP7430248B2 (ja) | 2020-04-03 | 2024-02-09 | 日本製鉄株式会社 | 蓄電デバイス構造体及び蓄電デバイス構造体の放熱方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20180281983A1 (en) | 2018-10-04 |

| JP6550230B2 (ja) | 2019-07-24 |

| EP3214112B1 (en) | 2021-04-14 |

| EP3214112A1 (en) | 2017-09-06 |

| WO2016088470A1 (ja) | 2016-06-09 |

| EP3214112A4 (en) | 2017-11-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6550230B2 (ja) | 部材 | |

| CN103338929B (zh) | 包含粘弹性夹层的多功能复合材料 | |

| EP3339013B1 (en) | Heated floor panels with thermally conductive and electrically insulating fabric | |

| JP6571000B2 (ja) | 熱伝導性複合材及びその製造方法 | |

| US11338933B2 (en) | Acoustic honeycomb panel with integrated electrical heater | |

| US9776386B2 (en) | Manufacturing method of partially cured composite components | |

| US10807326B2 (en) | Method of making complex carbon nanotube sheets | |

| JP6238168B2 (ja) | 複合材構造 | |

| JP2016108398A5 (ja) | ||

| EP3339178B1 (en) | Electrically conductive resin matrix for cnt heater | |

| CN206602672U (zh) | 飞机电防冰除冰电加热结构 | |

| US9974209B1 (en) | Heat sink and method | |

| JP6719867B2 (ja) | 複雑繊維強化複合構造体を硬化させるためのシステム及び方法 | |

| JP2013028166A (ja) | 熱防御複合材の製造方法 | |

| US6612523B2 (en) | Aircraft structures having improved through-thickness thermal conductivity | |

| CN110654526A (zh) | 一种高温高热部位均温化方法及均温化结构 | |

| CN202944564U (zh) | 一种用于腹鳍与控制舱体的连接结构 | |

| EP3135475B1 (en) | Composite material structure | |

| JP2010023240A (ja) | 熱防御複合材の製造方法 | |

| JP6547982B2 (ja) | チョップドテープ繊維強化熱可塑性樹脂シート材及びその製造方法 | |

| JP2015030108A (ja) | 炭素繊維プリフォームの製造装置および炭素繊維プリフォームの製造方法 | |

| KR102827548B1 (ko) | 기계적 체결과 전기적 연결이 동시에 가능한 단일 체결 구조를 가지는 구조용 배터리 및 이의 제조방법 | |

| US9072184B2 (en) | Carbon fiber spacecraft panel with integral metallic foil power return | |

| EP3152045B1 (en) | Method for making a composite structure utilizing thermal properties of forming elements | |

| CN205906198U (zh) | 一种飞机夹芯复合材料球面框结构 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171016 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20171016 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20181204 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190115 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190604 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190701 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6550230 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |