JP2011167629A - 水素ガスの分離方法、および水素ガス分離装置 - Google Patents

水素ガスの分離方法、および水素ガス分離装置 Download PDFInfo

- Publication number

- JP2011167629A JP2011167629A JP2010033552A JP2010033552A JP2011167629A JP 2011167629 A JP2011167629 A JP 2011167629A JP 2010033552 A JP2010033552 A JP 2010033552A JP 2010033552 A JP2010033552 A JP 2010033552A JP 2011167629 A JP2011167629 A JP 2011167629A

- Authority

- JP

- Japan

- Prior art keywords

- tsa

- gas

- adsorption

- adsorbent

- adsorption tower

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 title claims abstract description 182

- 238000000034 method Methods 0.000 title claims abstract description 164

- 238000001179 sorption measurement Methods 0.000 claims abstract description 369

- 239000007789 gas Substances 0.000 claims abstract description 270

- 239000003463 adsorbent Substances 0.000 claims abstract description 138

- 239000001257 hydrogen Substances 0.000 claims abstract description 105

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 105

- 238000000926 separation method Methods 0.000 claims abstract description 93

- 230000008569 process Effects 0.000 claims abstract description 74

- 239000012535 impurity Substances 0.000 claims abstract description 51

- 238000003795 desorption Methods 0.000 claims abstract description 29

- 230000008929 regeneration Effects 0.000 claims abstract description 19

- 238000011069 regeneration method Methods 0.000 claims abstract description 19

- 239000003507 refrigerant Substances 0.000 claims description 66

- 229910021536 Zeolite Inorganic materials 0.000 claims description 27

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 claims description 27

- 239000010457 zeolite Substances 0.000 claims description 27

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 21

- 239000007788 liquid Substances 0.000 claims description 21

- 238000010438 heat treatment Methods 0.000 claims description 13

- 150000002431 hydrogen Chemical class 0.000 claims description 13

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 12

- 150000002500 ions Chemical class 0.000 claims description 12

- 238000003860 storage Methods 0.000 claims description 12

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims description 9

- 229910052791 calcium Inorganic materials 0.000 claims description 8

- 238000000629 steam reforming Methods 0.000 claims description 8

- 229910002804 graphite Inorganic materials 0.000 claims description 6

- 239000010439 graphite Substances 0.000 claims description 6

- 229910052744 lithium Inorganic materials 0.000 claims description 6

- 239000002994 raw material Substances 0.000 claims description 6

- 239000000377 silicon dioxide Substances 0.000 claims description 6

- 239000004215 Carbon black (E152) Substances 0.000 claims description 5

- 229930195733 hydrocarbon Natural products 0.000 claims description 5

- 150000002430 hydrocarbons Chemical class 0.000 claims description 5

- 229910052680 mordenite Inorganic materials 0.000 claims description 5

- 229920005990 polystyrene resin Polymers 0.000 claims description 5

- 230000001172 regenerating effect Effects 0.000 claims description 2

- 238000011084 recovery Methods 0.000 abstract description 12

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 34

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 34

- 229910002091 carbon monoxide Inorganic materials 0.000 description 33

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 20

- 239000000446 fuel Substances 0.000 description 16

- 238000001816 cooling Methods 0.000 description 14

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 12

- 229910002092 carbon dioxide Inorganic materials 0.000 description 10

- 239000001569 carbon dioxide Substances 0.000 description 10

- 239000002808 molecular sieve Substances 0.000 description 10

- URGAHOPLAPQHLN-UHFFFAOYSA-N sodium aluminosilicate Chemical compound [Na+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O URGAHOPLAPQHLN-UHFFFAOYSA-N 0.000 description 10

- 239000012267 brine Substances 0.000 description 9

- HPALAKNZSZLMCH-UHFFFAOYSA-M sodium;chloride;hydrate Chemical compound O.[Na+].[Cl-] HPALAKNZSZLMCH-UHFFFAOYSA-M 0.000 description 9

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 6

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 6

- 239000007864 aqueous solution Substances 0.000 description 6

- 239000003054 catalyst Substances 0.000 description 6

- 238000004140 cleaning Methods 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000011575 calcium Substances 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 5

- 239000003345 natural gas Substances 0.000 description 5

- LCGLNKUTAGEVQW-UHFFFAOYSA-N Dimethyl ether Chemical compound COC LCGLNKUTAGEVQW-UHFFFAOYSA-N 0.000 description 4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 230000003647 oxidation Effects 0.000 description 4

- 238000007254 oxidation reaction Methods 0.000 description 4

- 238000004904 shortening Methods 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 3

- 238000002407 reforming Methods 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000001110 calcium chloride Substances 0.000 description 2

- 229910001628 calcium chloride Inorganic materials 0.000 description 2

- 230000006837 decompression Effects 0.000 description 2

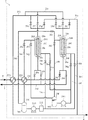

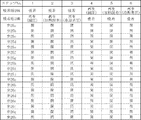

- 238000010586 diagram Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 239000003502 gasoline Substances 0.000 description 2

- 239000003350 kerosene Substances 0.000 description 2

- 239000003915 liquefied petroleum gas Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 231100000572 poisoning Toxicity 0.000 description 2

- 230000000607 poisoning effect Effects 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 238000010926 purge Methods 0.000 description 2

- 238000011946 reduction process Methods 0.000 description 2

- 238000006057 reforming reaction Methods 0.000 description 2

- 230000001629 suppression Effects 0.000 description 2

- 230000009466 transformation Effects 0.000 description 2

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical group [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 239000010779 crude oil Substances 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000012013 faujasite Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000002803 fossil fuel Substances 0.000 description 1

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 1

- 238000005342 ion exchange Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 229910001416 lithium ion Inorganic materials 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 239000005518 polymer electrolyte Substances 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

- -1 water vapor (H 2 O) Chemical class 0.000 description 1

Images

Landscapes

- Separation Of Gases By Adsorption (AREA)

- Hydrogen, Water And Hydrids (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010033552A JP2011167629A (ja) | 2010-02-18 | 2010-02-18 | 水素ガスの分離方法、および水素ガス分離装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010033552A JP2011167629A (ja) | 2010-02-18 | 2010-02-18 | 水素ガスの分離方法、および水素ガス分離装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011167629A true JP2011167629A (ja) | 2011-09-01 |

| JP2011167629A5 JP2011167629A5 (enExample) | 2013-02-14 |

Family

ID=44682311

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010033552A Pending JP2011167629A (ja) | 2010-02-18 | 2010-02-18 | 水素ガスの分離方法、および水素ガス分離装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2011167629A (enExample) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014156467A1 (ja) * | 2013-03-28 | 2014-10-02 | 住友精化株式会社 | 水素ガスの精製方法及び精製装置 |

| JP2017032016A (ja) * | 2015-07-30 | 2017-02-09 | 株式会社神戸製鋼所 | 水素ガス供給方法及び水素ステーション |

| JP2017080665A (ja) * | 2015-10-27 | 2017-05-18 | 大陽日酸株式会社 | 吸着剤、吸着剤の製造方法、一酸化炭素除去装置、および一酸化炭素除去方法 |

| KR20200036896A (ko) * | 2017-08-03 | 2020-04-07 | 레르 리키드 쏘시에떼 아노님 뿌르 레뜌드 에렉스뿔라따시옹 데 프로세데 조르즈 클로드 | 기체 수소 스트림의 연속 제조 방법 |

| WO2020196530A1 (ja) | 2019-03-28 | 2020-10-01 | Jxtgエネルギー株式会社 | 水素ガス供給装置および水素ガス供給方法 |

| WO2020196491A1 (ja) | 2019-03-27 | 2020-10-01 | Jxtgエネルギー株式会社 | 水素ガス供給装置および水素ガス供給方法 |

| CN113045011A (zh) * | 2021-03-15 | 2021-06-29 | 扬州工业职业技术学院 | 一种流化床吸附装置及其水处理工艺 |

| JPWO2023095683A1 (enExample) * | 2021-11-24 | 2023-06-01 | ||

| CN120860765A (zh) * | 2025-09-29 | 2025-10-31 | 振华新材料(东营)有限公司 | 一种变温吸附工业氢气提纯装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07138007A (ja) * | 1993-11-17 | 1995-05-30 | Nippon Sanso Kk | アルゴンガスの精製方法及び装置 |

| JPH1192113A (ja) * | 1997-09-17 | 1999-04-06 | Ishikawajima Harima Heavy Ind Co Ltd | オゾン吸脱着装置 |

| JP2002274811A (ja) * | 2001-03-16 | 2002-09-25 | Air Water Inc | 水素製造方法およびそれに用いる装置 |

| WO2006132040A1 (ja) * | 2005-06-07 | 2006-12-14 | Kabushiki Kaisha Kobe Seiko Sho | 高純度水素製造方法 |

-

2010

- 2010-02-18 JP JP2010033552A patent/JP2011167629A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07138007A (ja) * | 1993-11-17 | 1995-05-30 | Nippon Sanso Kk | アルゴンガスの精製方法及び装置 |

| JPH1192113A (ja) * | 1997-09-17 | 1999-04-06 | Ishikawajima Harima Heavy Ind Co Ltd | オゾン吸脱着装置 |

| JP2002274811A (ja) * | 2001-03-16 | 2002-09-25 | Air Water Inc | 水素製造方法およびそれに用いる装置 |

| WO2006132040A1 (ja) * | 2005-06-07 | 2006-12-14 | Kabushiki Kaisha Kobe Seiko Sho | 高純度水素製造方法 |

Cited By (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014156467A1 (ja) * | 2013-03-28 | 2014-10-02 | 住友精化株式会社 | 水素ガスの精製方法及び精製装置 |

| JP2017032016A (ja) * | 2015-07-30 | 2017-02-09 | 株式会社神戸製鋼所 | 水素ガス供給方法及び水素ステーション |

| JP2017080665A (ja) * | 2015-10-27 | 2017-05-18 | 大陽日酸株式会社 | 吸着剤、吸着剤の製造方法、一酸化炭素除去装置、および一酸化炭素除去方法 |

| KR102624566B1 (ko) * | 2017-08-03 | 2024-01-11 | 레르 리키드 쏘시에떼 아노님 뿌르 레드 에렉스뿔라따시옹 데 프로세데 조르즈 클로드 | 기체 수소 스트림의 연속 제조 방법 |

| KR20200036896A (ko) * | 2017-08-03 | 2020-04-07 | 레르 리키드 쏘시에떼 아노님 뿌르 레뜌드 에렉스뿔라따시옹 데 프로세데 조르즈 클로드 | 기체 수소 스트림의 연속 제조 방법 |

| JP2020529956A (ja) * | 2017-08-03 | 2020-10-15 | レール・リキード−ソシエテ・アノニム・プール・レテュード・エ・レクスプロワタシオン・デ・プロセデ・ジョルジュ・クロード | ガス状水素流の連続生産方法 |

| US11491437B2 (en) | 2017-08-03 | 2022-11-08 | L'Air Liquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Method for the continuous production of a gaseous hydrogen stream |

| JP7245818B2 (ja) | 2017-08-03 | 2023-03-24 | レール・リキード-ソシエテ・アノニム・プール・レテュード・エ・レクスプロワタシオン・デ・プロセデ・ジョルジュ・クロード | ガス状水素流の連続生産方法 |

| EP3661624B1 (fr) * | 2017-08-03 | 2024-09-18 | L'Air Liquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Procédé de production continue d'un flux gazeux d'hydrogène |

| WO2020196491A1 (ja) | 2019-03-27 | 2020-10-01 | Jxtgエネルギー株式会社 | 水素ガス供給装置および水素ガス供給方法 |

| US12233377B2 (en) | 2019-03-27 | 2025-02-25 | Eneos Corporation | Hydrogen gas supply apparatus and hydrogen gas supply method |

| WO2020196530A1 (ja) | 2019-03-28 | 2020-10-01 | Jxtgエネルギー株式会社 | 水素ガス供給装置および水素ガス供給方法 |

| CN113045011B (zh) * | 2021-03-15 | 2021-10-29 | 扬州工业职业技术学院 | 一种流化床吸附装置及其水处理工艺 |

| CN113045011A (zh) * | 2021-03-15 | 2021-06-29 | 扬州工业职业技术学院 | 一种流化床吸附装置及其水处理工艺 |

| WO2023095683A1 (ja) * | 2021-11-24 | 2023-06-01 | 株式会社Ihi | 二酸化炭素回収システム及び二酸化炭素回収方法 |

| GB2626881A (en) * | 2021-11-24 | 2024-08-07 | Ihi Corp | Carbon dioxide recovering system and carbon dioxide recovering method |

| JPWO2023095683A1 (enExample) * | 2021-11-24 | 2023-06-01 | ||

| JP7694700B2 (ja) | 2021-11-24 | 2025-06-18 | 株式会社Ihi | 二酸化炭素回収システム及び二酸化炭素回収方法 |

| CN120860765A (zh) * | 2025-09-29 | 2025-10-31 | 振华新材料(东营)有限公司 | 一种变温吸附工业氢气提纯装置 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI521056B (zh) | Methane recovery method and methane recovery unit | |

| JP2011167629A (ja) | 水素ガスの分離方法、および水素ガス分離装置 | |

| US7892328B2 (en) | PSA apparatus for producing high-purity hydrogen gas | |

| KR20240023427A (ko) | 그린 수소를 위한 암모니아 분해 | |

| JP6305868B2 (ja) | 水素ガスの精製方法及びその精製装置 | |

| CN102083512A (zh) | 二氧化碳回收 | |

| JP2014514136A (ja) | 圧力−温度スイング吸着法 | |

| CN103159192B (zh) | 氦气的纯化方法和纯化装置 | |

| JP2010042381A (ja) | キセノン吸着剤、キセノン濃縮方法、キセノン濃縮装置および空気液化分離装置 | |

| JP6571588B2 (ja) | 水素ガス製造方法及び水素ガス製造装置 | |

| JP5748272B2 (ja) | ヘリウムガスの精製方法および精製装置 | |

| JP5729765B2 (ja) | ヘリウムガスの精製方法および精製装置 | |

| JP5683390B2 (ja) | ヘリウムガスの精製方法および精製装置 | |

| JP5896467B2 (ja) | アルゴンガスの精製方法および精製装置 | |

| JP2017226562A (ja) | 水素ガス製造方法及び水素ガス製造装置 | |

| US8372375B2 (en) | Method of producing high-purity hydrogen | |

| CN103224225B (zh) | 氩气的纯化方法及纯化装置 | |

| JP2011195434A (ja) | アルゴンガスの精製方法および精製装置 | |

| JP6640660B2 (ja) | 水素ガス製造方法及び水素ガス製造装置 | |

| JP3985006B2 (ja) | 高純度水素製造方法 | |

| JP3947752B2 (ja) | 高純度水素製造方法 | |

| JP2017197407A (ja) | 水素ガス製造方法及び水素ガス製造装置 | |

| JP6585545B2 (ja) | 水素ガス製造方法及び水素ガス製造装置 | |

| JP2012082080A (ja) | アルゴン精製方法、およびアルゴン精製装置 | |

| CN102807199B (zh) | 氩气的提纯方法及提纯装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121220 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20121220 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130516 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130625 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130823 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140520 |