JP2010010440A - 成膜方法 - Google Patents

成膜方法 Download PDFInfo

- Publication number

- JP2010010440A JP2010010440A JP2008168597A JP2008168597A JP2010010440A JP 2010010440 A JP2010010440 A JP 2010010440A JP 2008168597 A JP2008168597 A JP 2008168597A JP 2008168597 A JP2008168597 A JP 2008168597A JP 2010010440 A JP2010010440 A JP 2010010440A

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- main surface

- lattice constant

- thin film

- film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 64

- 230000015572 biosynthetic process Effects 0.000 title description 17

- 239000000758 substrate Substances 0.000 claims abstract description 448

- 239000010408 film Substances 0.000 claims abstract description 171

- 239000010409 thin film Substances 0.000 claims abstract description 141

- 239000000463 material Substances 0.000 claims abstract description 58

- 238000010438 heat treatment Methods 0.000 claims description 103

- 238000005452 bending Methods 0.000 claims description 36

- 239000002994 raw material Substances 0.000 claims description 8

- 150000001875 compounds Chemical class 0.000 claims description 7

- 150000002902 organometallic compounds Chemical class 0.000 claims description 4

- 239000013078 crystal Substances 0.000 abstract description 25

- 230000007704 transition Effects 0.000 abstract description 16

- 230000008859 change Effects 0.000 abstract description 6

- 229910002601 GaN Inorganic materials 0.000 description 84

- JMASRVWKEDWRBT-UHFFFAOYSA-N Gallium nitride Chemical compound [Ga]#N JMASRVWKEDWRBT-UHFFFAOYSA-N 0.000 description 81

- 229910052594 sapphire Inorganic materials 0.000 description 63

- 239000010980 sapphire Substances 0.000 description 63

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 47

- 239000007789 gas Substances 0.000 description 47

- 239000010410 layer Substances 0.000 description 45

- 239000004065 semiconductor Substances 0.000 description 32

- 229910052759 nickel Inorganic materials 0.000 description 22

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 22

- 238000011156 evaluation Methods 0.000 description 21

- 229910052814 silicon oxide Inorganic materials 0.000 description 20

- 229910000530 Gallium indium arsenide Inorganic materials 0.000 description 13

- JBRZTFJDHDCESZ-UHFFFAOYSA-N AsGa Chemical compound [As]#[Ga] JBRZTFJDHDCESZ-UHFFFAOYSA-N 0.000 description 11

- 229910001218 Gallium arsenide Inorganic materials 0.000 description 10

- 238000000151 deposition Methods 0.000 description 10

- 238000001947 vapour-phase growth Methods 0.000 description 9

- 238000010586 diagram Methods 0.000 description 8

- 229910052738 indium Inorganic materials 0.000 description 8

- 239000002356 single layer Substances 0.000 description 8

- 238000000560 X-ray reflectometry Methods 0.000 description 7

- 230000008021 deposition Effects 0.000 description 7

- 238000000927 vapour-phase epitaxy Methods 0.000 description 7

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 6

- XCZXGTMEAKBVPV-UHFFFAOYSA-N trimethylgallium Chemical compound C[Ga](C)C XCZXGTMEAKBVPV-UHFFFAOYSA-N 0.000 description 6

- 230000000694 effects Effects 0.000 description 5

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 150000004767 nitrides Chemical class 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 238000003384 imaging method Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 229910010271 silicon carbide Inorganic materials 0.000 description 4

- IBEFSUTVZWZJEL-UHFFFAOYSA-N trimethylindium Chemical compound C[In](C)C IBEFSUTVZWZJEL-UHFFFAOYSA-N 0.000 description 4

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 3

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- 150000004678 hydrides Chemical class 0.000 description 3

- NFFIWVVINABMKP-UHFFFAOYSA-N methylidynetantalum Chemical compound [Ta]#C NFFIWVVINABMKP-UHFFFAOYSA-N 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 239000002344 surface layer Substances 0.000 description 3

- 229910003468 tantalcarbide Inorganic materials 0.000 description 3

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 2

- 229910004298 SiO 2 Inorganic materials 0.000 description 2

- 239000000969 carrier Substances 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000011065 in-situ storage Methods 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 230000000644 propagated effect Effects 0.000 description 2

- 239000002296 pyrolytic carbon Substances 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- 230000003746 surface roughness Effects 0.000 description 2

- JLTRXTDYQLMHGR-UHFFFAOYSA-N trimethylaluminium Chemical compound C[Al](C)C JLTRXTDYQLMHGR-UHFFFAOYSA-N 0.000 description 2

- 238000007740 vapor deposition Methods 0.000 description 2

- PIGFYZPCRLYGLF-UHFFFAOYSA-N Aluminum nitride Chemical compound [Al]#N PIGFYZPCRLYGLF-UHFFFAOYSA-N 0.000 description 1

- 229910052582 BN Inorganic materials 0.000 description 1

- GYHNNYVSQQEPJS-UHFFFAOYSA-N Gallium Chemical compound [Ga] GYHNNYVSQQEPJS-UHFFFAOYSA-N 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- RNQKDQAVIXDKAG-UHFFFAOYSA-N aluminum gallium Chemical compound [Al].[Ga] RNQKDQAVIXDKAG-UHFFFAOYSA-N 0.000 description 1

- 150000001450 anions Chemical class 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 1

- 238000002109 crystal growth method Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 229910052733 gallium Inorganic materials 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 229910021478 group 5 element Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/20—Deposition of semiconductor materials on a substrate, e.g. epitaxial growth solid phase epitaxy

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/301—AIII BV compounds, where A is Al, Ga, In or Tl and B is N, P, As, Sb or Bi

- C23C16/303—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/10—Inorganic compounds or compositions

- C30B29/40—AIIIBV compounds wherein A is B, Al, Ga, In or Tl and B is N, P, As, Sb or Bi

- C30B29/403—AIII-nitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02367—Substrates

- H01L21/0237—Materials

- H01L21/0242—Crystalline insulating materials

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02436—Intermediate layers between substrates and deposited layers

- H01L21/02439—Materials

- H01L21/02455—Group 13/15 materials

- H01L21/02458—Nitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/02521—Materials

- H01L21/02538—Group 13/15 materials

- H01L21/0254—Nitrides

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02656—Special treatments

- H01L21/02658—Pretreatments

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Chemical Vapour Deposition (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Recrystallisation Techniques (AREA)

Abstract

【解決手段】成膜させたい薄膜を構成する材料の格子定数と、薄膜が成膜される基板の一方の主表面を構成する材料の格子定数とに応じて、主表面に沿った方向に対して基板を湾曲させる。そして、基板を湾曲させた状態で、その基板の一方の主表面上に薄膜を成膜させる。

【選択図】図9

Description

赤崎勇編書、「III族窒化物半導体」12章、培風館、1999年、p.230−235 赤崎勇編書、「III族窒化物半導体」8章、培風館、1999年、p.147−165

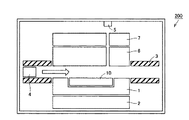

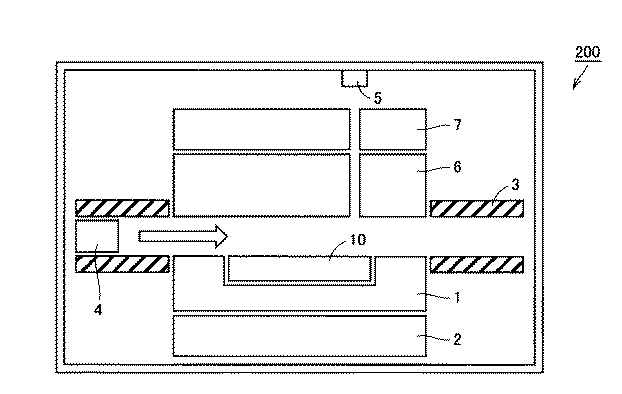

まず、本発明の成膜方法の原理について説明する。図2は、本発明の実施の形態における気相成長による成膜装置の内部の概要を示す概略断面図である。図2に示すように、本発明の実施の形態における気相成長による成膜装置200は基板10をセットするためのサセプタ1の上側に、加熱治具6を介して、サセプタ1の上側の主表面に対向するように配置された第1の加熱部材としてのヒータ7を備えている。また、図2に示すように、サセプタ1の下側にも、第2の加熱部材としてのヒータ2が配置されている。なお、ここで主表面とは、たとえば基板10やサセプタ1などの表面のうち最も面積の大きい、水平方向に沿った方向にセットされている表面をいう。また、ここでいう対向とは、たとえばサセプタ1の上側に、加熱治具6を介して配置されたヒータ7のように、両者間に別の部材が介在する場合も含むこととする。

Claims (10)

- 基板の一方の主表面上に薄膜を成膜させる成膜方法であり、

基板を準備する工程と、

前記主表面に沿った方向に対して前記基板を湾曲させる工程と、

前記基板を湾曲させた状態で、前記基板の一方の主表面上に薄膜を成膜させる工程とを備えている成膜方法。 - 前記基板を湾曲させる工程において前記基板を湾曲させた方向と、前記主表面に沿った方向に対して反対方向に、前記基板を湾曲させる工程と、

前記反対方向に前記基板を湾曲させた状態で、前記基板の一方の主表面上に薄膜を成膜させる工程とをさらに備えている、請求項1に記載の成膜方法。 - 前記基板を湾曲させる工程においては、

成膜させたい前記薄膜を構成する材料の格子定数である第1の格子定数と、前記薄膜が成膜される前記基板の一方の主表面を構成する材料の格子定数である第2の格子定数と、に応じて、前記主表面に沿った方向に対して前記基板を湾曲させる、請求項1または2に記載の成膜方法。 - 前記基板を湾曲させる工程においては、

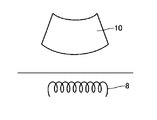

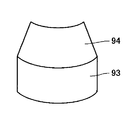

前記第1の格子定数が、前記第2の格子定数よりも大きければ、前記基板を、前記基板を湾曲させる工程を行なう前の形状よりも、前記一方の主表面側に凸向きの方向に湾曲させ、前記第1の格子定数が、前記第2の格子定数よりも小さければ、前記基板を、前記基板を湾曲させる工程を行なう前の形状よりも、前記一方の主表面側に凹向きの方向に湾曲させる、請求項1〜3のいずれか1項に記載の成膜方法。 - 前記基板を湾曲させる工程においては、

前記第1の格子定数が、前記第2の格子定数よりも大きければ、前記基板を、前記一方の主表面側に凸形状となるように湾曲させ、前記第1の格子定数が、前記第2の格子定数よりも小さければ、前記基板を、前記一方の主表面側に凹形状となるように湾曲させる、請求項1〜3のいずれか1項に記載の成膜方法。 - 前記基板を湾曲させる工程においては、前記基板の一方の主表面に対向するように配置された第1の加熱部材と、前記一方の主表面と反対側に位置する前記基板の他方の主表面に対向するように配置された第2の加熱部材との加熱温度を独立に制御して、前記基板を湾曲させる、請求項1〜5のいずれか1項に記載の成膜方法。

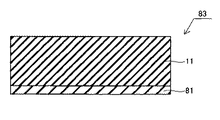

- 前記基板を準備する工程においては、互いに熱膨張係数の異なる材料からなる複数の層が積層した基板を準備する、請求項1〜6のいずれか1項に記載の成膜方法。

- 前記薄膜を成膜させる工程においては、加熱させた前記基板の一方の主表面上に、成膜させたい薄膜を構成する成分の原料ガスを供給する、請求項1〜7のいずれか1項に記載の成膜方法。

- 前記原料ガスは有機金属化合物の蒸気を含む、請求項8に記載の成膜方法。

- 前記原料ガスはIII族元素の化合物の蒸気を含む、請求項8または9に記載の成膜方法。

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008168597A JP5343419B2 (ja) | 2008-06-27 | 2008-06-27 | 成膜方法 |

| CN2009801245094A CN102077319B (zh) | 2008-06-27 | 2009-06-25 | 膜淀积方法 |

| KR1020117000250A KR20110022041A (ko) | 2008-06-27 | 2009-06-25 | 성막 방법 |

| EP09770224.5A EP2312616B1 (en) | 2008-06-27 | 2009-06-25 | Film deposition method |

| US13/000,835 US8404571B2 (en) | 2008-06-27 | 2009-06-25 | Film deposition method |

| PCT/JP2009/061633 WO2009157514A1 (ja) | 2008-06-27 | 2009-06-25 | 成膜方法 |

| TW098121674A TW201009898A (en) | 2008-06-27 | 2009-06-26 | Film deposition method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008168597A JP5343419B2 (ja) | 2008-06-27 | 2008-06-27 | 成膜方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010010440A true JP2010010440A (ja) | 2010-01-14 |

| JP5343419B2 JP5343419B2 (ja) | 2013-11-13 |

Family

ID=41444577

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008168597A Expired - Fee Related JP5343419B2 (ja) | 2008-06-27 | 2008-06-27 | 成膜方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8404571B2 (ja) |

| EP (1) | EP2312616B1 (ja) |

| JP (1) | JP5343419B2 (ja) |

| KR (1) | KR20110022041A (ja) |

| CN (1) | CN102077319B (ja) |

| TW (1) | TW201009898A (ja) |

| WO (1) | WO2009157514A1 (ja) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013131646A (ja) * | 2011-12-21 | 2013-07-04 | Sharp Corp | 結晶成長装置及び結晶成長方法 |

| JP2016160164A (ja) * | 2015-03-05 | 2016-09-05 | 日本電信電話株式会社 | 結晶成長方法 |

| US9910319B2 (en) | 2014-09-03 | 2018-03-06 | Samsung Display Co., Ltd. | Method of manufacturing curved liquid crystal display panel and apparatus for manufacturing curved liquid crystal display panel |

| WO2018135422A1 (ja) * | 2017-01-17 | 2018-07-26 | 国立大学法人名古屋大学 | 気相成長装置 |

| JP2022528476A (ja) * | 2019-04-12 | 2022-06-10 | エピルバック エービー | 成長中にウェハの平面性を提供する装置および方法 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI463194B (zh) * | 2012-03-30 | 2014-12-01 | Sintai Optical Shenzhen Co Ltd | Infrared cutoff filter structure |

| KR102711233B1 (ko) | 2018-08-03 | 2024-09-30 | 어플라이드 머티어리얼스, 인코포레이티드 | 램프헤드에서의 다중구역 램프 제어 및 개별 램프 제어 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05251427A (ja) * | 1992-03-05 | 1993-09-28 | Nippon Steel Corp | 薄膜の形成方法 |

| JP2003197535A (ja) * | 2001-12-21 | 2003-07-11 | Sumitomo Mitsubishi Silicon Corp | 気相成長装置および気相成長装置の温度検出方法ならびに温度制御方法 |

| JP2004349402A (ja) * | 2003-05-21 | 2004-12-09 | Sharp Corp | 半導体の結晶成長方法、結晶成長装置及びそれらを用いて形成された半導体基板 |

| JP2007214344A (ja) * | 2006-02-09 | 2007-08-23 | Sanyo Electric Co Ltd | 化合物半導体膜の形成方法 |

| JP2007273814A (ja) * | 2006-03-31 | 2007-10-18 | Furukawa Electric Co Ltd:The | シリコン基板及びその製造方法 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3808674A (en) * | 1972-08-10 | 1974-05-07 | Westinghouse Electric Corp | Epitaxial growth of thermically expandable films and particularly anisotropic ferro-electric films |

| US4830984A (en) * | 1987-08-19 | 1989-05-16 | Texas Instruments Incorporated | Method for heteroepitaxial growth using tensioning layer on rear substrate surface |

| DE68923890T2 (de) * | 1988-02-25 | 1996-02-22 | Japan Res Dev Corp | Strahlenoptische Elemente mit Graphit-Schichten. |

| US5044943A (en) * | 1990-08-16 | 1991-09-03 | Applied Materials, Inc. | Spoked susceptor support for enhanced thermal uniformity of susceptor in semiconductor wafer processing apparatus |

| JP3274190B2 (ja) * | 1992-09-26 | 2002-04-15 | 株式会社東芝 | 半導体エピタキシャル基板の製造方法 |

| DE69503285T2 (de) * | 1994-04-07 | 1998-11-05 | Sumitomo Electric Industries | Diamantwafer und Verfahren zur Herstellung eines Diamantwafers |

| US7198671B2 (en) * | 2001-07-11 | 2007-04-03 | Matsushita Electric Industrial Co., Ltd. | Layered substrates for epitaxial processing, and device |

| KR100698014B1 (ko) * | 2004-11-04 | 2007-03-23 | 한국전자통신연구원 | 발광 소자용 실리콘 질화막, 이를 이용한 발광 소자 및발광 소자용 실리콘 질화막의 제조방법 |

| US7262112B2 (en) * | 2005-06-27 | 2007-08-28 | The Regents Of The University Of California | Method for producing dislocation-free strained crystalline films |

| CN102084464A (zh) * | 2008-05-30 | 2011-06-01 | 奥塔装置公司 | 外延迁移堆栈和方法 |

-

2008

- 2008-06-27 JP JP2008168597A patent/JP5343419B2/ja not_active Expired - Fee Related

-

2009

- 2009-06-25 CN CN2009801245094A patent/CN102077319B/zh not_active Expired - Fee Related

- 2009-06-25 EP EP09770224.5A patent/EP2312616B1/en not_active Not-in-force

- 2009-06-25 KR KR1020117000250A patent/KR20110022041A/ko not_active Withdrawn

- 2009-06-25 WO PCT/JP2009/061633 patent/WO2009157514A1/ja not_active Ceased

- 2009-06-25 US US13/000,835 patent/US8404571B2/en not_active Expired - Fee Related

- 2009-06-26 TW TW098121674A patent/TW201009898A/zh unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05251427A (ja) * | 1992-03-05 | 1993-09-28 | Nippon Steel Corp | 薄膜の形成方法 |

| JP2003197535A (ja) * | 2001-12-21 | 2003-07-11 | Sumitomo Mitsubishi Silicon Corp | 気相成長装置および気相成長装置の温度検出方法ならびに温度制御方法 |

| JP2004349402A (ja) * | 2003-05-21 | 2004-12-09 | Sharp Corp | 半導体の結晶成長方法、結晶成長装置及びそれらを用いて形成された半導体基板 |

| JP2007214344A (ja) * | 2006-02-09 | 2007-08-23 | Sanyo Electric Co Ltd | 化合物半導体膜の形成方法 |

| JP2007273814A (ja) * | 2006-03-31 | 2007-10-18 | Furukawa Electric Co Ltd:The | シリコン基板及びその製造方法 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013131646A (ja) * | 2011-12-21 | 2013-07-04 | Sharp Corp | 結晶成長装置及び結晶成長方法 |

| US9910319B2 (en) | 2014-09-03 | 2018-03-06 | Samsung Display Co., Ltd. | Method of manufacturing curved liquid crystal display panel and apparatus for manufacturing curved liquid crystal display panel |

| JP2016160164A (ja) * | 2015-03-05 | 2016-09-05 | 日本電信電話株式会社 | 結晶成長方法 |

| WO2018135422A1 (ja) * | 2017-01-17 | 2018-07-26 | 国立大学法人名古屋大学 | 気相成長装置 |

| JP2018117005A (ja) * | 2017-01-17 | 2018-07-26 | 国立大学法人名古屋大学 | 気相成長装置 |

| JP2022528476A (ja) * | 2019-04-12 | 2022-06-10 | エピルバック エービー | 成長中にウェハの平面性を提供する装置および方法 |

| JP7581608B2 (ja) | 2019-04-12 | 2024-11-13 | ヴェエコ エスアイシー シーブイディ システムズ エービー | 成長中にウェハの平面性を提供する装置および方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102077319B (zh) | 2012-11-28 |

| US8404571B2 (en) | 2013-03-26 |

| TW201009898A (en) | 2010-03-01 |

| EP2312616A1 (en) | 2011-04-20 |

| EP2312616A4 (en) | 2011-09-07 |

| KR20110022041A (ko) | 2011-03-04 |

| JP5343419B2 (ja) | 2013-11-13 |

| US20110097880A1 (en) | 2011-04-28 |

| EP2312616B1 (en) | 2013-08-07 |

| WO2009157514A1 (ja) | 2009-12-30 |

| CN102077319A (zh) | 2011-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5343419B2 (ja) | 成膜方法 | |

| JP5274785B2 (ja) | AlGaN結晶層の形成方法 | |

| JP5697246B2 (ja) | エピタキシャル成長用サセプタ、これを用いたエピタキシャル成長装置およびこれを用いたエピタキシャル成長方法 | |

| US20060226414A1 (en) | Group III-V nitride-based semiconductor substrate and method of making same | |

| JP4769905B2 (ja) | p型AlGaN層の製造方法およびIII族窒化物半導体発光素子 | |

| KR101672213B1 (ko) | 반도체장치의 제조방법 | |

| JP2009071279A (ja) | 窒化ガリウム成長用基板及び窒化ガリウム基板の製造方法 | |

| JP4907476B2 (ja) | 窒化物半導体単結晶 | |

| JP4467615B2 (ja) | 窒化物半導体結晶の成長方法、成長装置、および、プログラム | |

| JP2005536883A (ja) | AlGaN単層またはAlGaN多層構造のMBE成長 | |

| US20030070610A1 (en) | Method and device for producing group III-N, group III-V-N and metal-nitrogen component structures on Si substrates | |

| KR101834802B1 (ko) | 반도체 소자 | |

| JP2009295685A (ja) | 成膜装置 | |

| JP2014003056A (ja) | 半導体積層構造およびこれを用いた半導体素子 | |

| JP2005353680A (ja) | エピタキシャル基板、半導体積層構造、およびエピタキシャル基板の製造方法 | |

| KR20090077471A (ko) | 질화갈륨 성장용 서셉터 및 질화갈륨 성장 방법 | |

| JP5015480B2 (ja) | 半導体単結晶基板の製造方法 | |

| JP2010123818A (ja) | 窒化物半導体多層構造体及びその製造方法 | |

| JP4578282B2 (ja) | アルミニウム系iii族窒化物結晶の製造方法 | |

| JP5898347B2 (ja) | 発光素子の製造方法 | |

| JP2012101977A (ja) | 窒化物半導体基板の製造方法及び窒化物半導体自立基板の製造方法 | |

| JP2011151422A (ja) | p型AlGaN層およびIII族窒化物半導体発光素子 | |

| JP2008044842A (ja) | Iii−v族窒化物系半導体基板 | |

| JP2004111865A (ja) | 半導体基板及びその製造方法 | |

| JP2007227494A (ja) | 発光素子形成用の積層構造体、発光素子、および発光素子の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101214 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130416 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130605 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130716 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130729 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |