JP2008212921A - 塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 - Google Patents

塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 Download PDFInfo

- Publication number

- JP2008212921A JP2008212921A JP2008010230A JP2008010230A JP2008212921A JP 2008212921 A JP2008212921 A JP 2008212921A JP 2008010230 A JP2008010230 A JP 2008010230A JP 2008010230 A JP2008010230 A JP 2008010230A JP 2008212921 A JP2008212921 A JP 2008212921A

- Authority

- JP

- Japan

- Prior art keywords

- coating

- substrate

- height

- profile

- base material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000576 coating method Methods 0.000 title claims abstract description 280

- 239000011248 coating agent Substances 0.000 title claims abstract description 257

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 27

- 239000000758 substrate Substances 0.000 claims abstract description 298

- 239000007788 liquid Substances 0.000 claims abstract description 68

- 238000001514 detection method Methods 0.000 claims abstract description 14

- 239000000463 material Substances 0.000 claims description 74

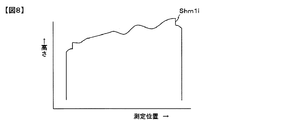

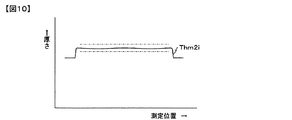

- 238000005259 measurement Methods 0.000 claims description 60

- 230000005856 abnormality Effects 0.000 claims description 53

- 238000000034 method Methods 0.000 claims description 29

- 238000012545 processing Methods 0.000 claims description 25

- 230000008569 process Effects 0.000 claims description 13

- 230000002159 abnormal effect Effects 0.000 claims description 11

- 230000008859 change Effects 0.000 claims description 7

- 230000002401 inhibitory effect Effects 0.000 abstract 1

- 238000013024 troubleshooting Methods 0.000 abstract 1

- 239000011521 glass Substances 0.000 description 52

- 238000005192 partition Methods 0.000 description 14

- 239000000126 substance Substances 0.000 description 11

- 239000011324 bead Substances 0.000 description 6

- 230000002950 deficient Effects 0.000 description 6

- 238000007607 die coating method Methods 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 239000000428 dust Substances 0.000 description 4

- 230000007547 defect Effects 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 238000013480 data collection Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000010304 firing Methods 0.000 description 2

- 239000004973 liquid crystal related substance Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 229910052709 silver Inorganic materials 0.000 description 2

- 239000004332 silver Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 239000006089 photosensitive glass Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000005488 sandblasting Methods 0.000 description 1

- 238000006748 scratching Methods 0.000 description 1

- 230000002393 scratching effect Effects 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

Images

Landscapes

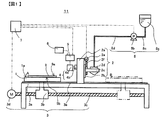

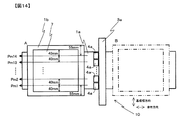

- Coating Apparatus (AREA)

- Manufacture Of Electron Tubes, Discharge Lamp Vessels, Lead-In Wires, And The Like (AREA)

- Gas-Filled Discharge Tubes (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008010230A JP2008212921A (ja) | 2007-02-08 | 2008-01-21 | 塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007028804 | 2007-02-08 | ||

| JP2008010230A JP2008212921A (ja) | 2007-02-08 | 2008-01-21 | 塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008212921A true JP2008212921A (ja) | 2008-09-18 |

| JP2008212921A5 JP2008212921A5 (enExample) | 2011-03-03 |

Family

ID=39833597

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008010230A Withdrawn JP2008212921A (ja) | 2007-02-08 | 2008-01-21 | 塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2008212921A (enExample) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102192915A (zh) * | 2010-03-12 | 2011-09-21 | 东京毅力科创株式会社 | 背面异物检测方法、背面异物检测装置以及涂布装置 |

| JP2014139964A (ja) * | 2013-01-21 | 2014-07-31 | Disco Abrasive Syst Ltd | ウェーハの加工方法 |

| CN104353585A (zh) * | 2014-12-02 | 2015-02-18 | 天津航空机电有限公司 | 一种航空断路器接线片专用胶体的涂胶装置与方法 |

| KR101740383B1 (ko) * | 2014-11-26 | 2017-06-09 | (주)서우케이엔제이 | 도포판에의 피막액 균일 도포장치 |

| CN108372081A (zh) * | 2017-01-31 | 2018-08-07 | 阿尔法设计株式会社 | 涂布装置、涂布方法、程序 |

| CN118051069A (zh) * | 2024-03-29 | 2024-05-17 | 广州泽亨实业有限公司 | 一种涂层厚度自动控制方法和系统 |

-

2008

- 2008-01-21 JP JP2008010230A patent/JP2008212921A/ja not_active Withdrawn

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102192915A (zh) * | 2010-03-12 | 2011-09-21 | 东京毅力科创株式会社 | 背面异物检测方法、背面异物检测装置以及涂布装置 |

| JP2011192697A (ja) * | 2010-03-12 | 2011-09-29 | Tokyo Electron Ltd | 裏面異物検出方法及び裏面異物検出装置及び塗布装置 |

| KR101738690B1 (ko) | 2010-03-12 | 2017-05-22 | 도쿄엘렉트론가부시키가이샤 | 이면 이물 검출방법 및 이면 이물 검출장치 및 도포장치 |

| JP2014139964A (ja) * | 2013-01-21 | 2014-07-31 | Disco Abrasive Syst Ltd | ウェーハの加工方法 |

| TWI602229B (zh) * | 2013-01-21 | 2017-10-11 | Disco Corp | Wafer processing methods |

| KR101740383B1 (ko) * | 2014-11-26 | 2017-06-09 | (주)서우케이엔제이 | 도포판에의 피막액 균일 도포장치 |

| CN104353585A (zh) * | 2014-12-02 | 2015-02-18 | 天津航空机电有限公司 | 一种航空断路器接线片专用胶体的涂胶装置与方法 |

| CN108372081A (zh) * | 2017-01-31 | 2018-08-07 | 阿尔法设计株式会社 | 涂布装置、涂布方法、程序 |

| JP2018122227A (ja) * | 2017-01-31 | 2018-08-09 | アルファーデザイン株式会社 | 塗布装置、塗布方法、プログラム |

| CN118051069A (zh) * | 2024-03-29 | 2024-05-17 | 广州泽亨实业有限公司 | 一种涂层厚度自动控制方法和系统 |

| CN118051069B (zh) * | 2024-03-29 | 2024-07-16 | 广州泽亨实业有限公司 | 一种涂层厚度自动控制方法和系统 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4325084B2 (ja) | 塗布方法およびそれを用いたカラーフィルタの製造方法 | |

| JP2008212921A (ja) | 塗布方法、プラズマディスプレイ用部材の製造方法および塗布装置 | |

| JP2009175708A (ja) | 液晶滴下装置 | |

| JP7097666B2 (ja) | フィルムの製造方法および真空成膜装置 | |

| JP4841459B2 (ja) | ペーストパターン検査方法 | |

| JPH11165111A (ja) | 塗布膜形成方法および塗布装置 | |

| JP4010188B2 (ja) | 塗膜の厚さ測定方法および測定装置と塗膜形成部材の製造方法 | |

| JP4105613B2 (ja) | 基板処理装置 | |

| JP5953759B2 (ja) | 間隙測定方法および間隙装置ならびに塗布方法および塗布装置。 | |

| JP2009101345A (ja) | 塗布方法および塗布装置、並びにプラズマディスプレイ用部材の製造方法およびその製造装置。 | |

| US20050239365A1 (en) | Method and apparatus for repairing plasma display electrode | |

| JP2011082230A (ja) | 基板塗布装置 | |

| JP2010042393A (ja) | 基板のリペア区間設定方法(methodfordesignatingrepairsectiononsubstrate) | |

| JP2008023471A (ja) | ペースト塗布機及びペースト塗布方法 | |

| JP6333065B2 (ja) | 塗布装置 | |

| KR100804771B1 (ko) | 실런트 도포 상태에 근거한 액정 적하량 결정 방법 | |

| JPWO2006013915A1 (ja) | ディスプレイパネルの検査方法、検査装置および製造方法 | |

| KR101089747B1 (ko) | 도포 장치의 제어 방법 | |

| JP4952320B2 (ja) | 塗液の塗布装置 | |

| JP2006071625A (ja) | ディスプレイパネルの検査方法、検査装置および製造方法 | |

| JP2010058097A (ja) | 塗布方法および塗布装置、並びにプラズマディスプレイ用部材の製造方法およびその製造装置。 | |

| JP2011255260A (ja) | 塗布方法および塗布装置ならびにプラズマディスプレイ用部材の製造方法およびプラズマディスプレイ用部材の製造装置 | |

| JP5866094B2 (ja) | ペースト塗布装置及びペースト塗布方法 | |

| JP2004081983A (ja) | 基板処理装置 | |

| JP2004303549A (ja) | プラズマディスプレイ用基板の製造方法および製造装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20100319 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20100827 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100906 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110113 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110113 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20120111 |