JP2007088401A - 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 - Google Patents

基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 Download PDFInfo

- Publication number

- JP2007088401A JP2007088401A JP2005349556A JP2005349556A JP2007088401A JP 2007088401 A JP2007088401 A JP 2007088401A JP 2005349556 A JP2005349556 A JP 2005349556A JP 2005349556 A JP2005349556 A JP 2005349556A JP 2007088401 A JP2007088401 A JP 2007088401A

- Authority

- JP

- Japan

- Prior art keywords

- processing

- substrate

- film

- measurement

- chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000012545 processing Methods 0.000 title claims abstract description 660

- 239000000758 substrate Substances 0.000 title claims abstract description 256

- 238000003672 processing method Methods 0.000 title claims description 20

- 238000000034 method Methods 0.000 claims abstract description 462

- 230000008569 process Effects 0.000 claims abstract description 430

- 238000005259 measurement Methods 0.000 claims abstract description 244

- 238000012546 transfer Methods 0.000 claims abstract description 181

- 239000007789 gas Substances 0.000 claims description 89

- 239000002245 particle Substances 0.000 claims description 62

- 230000015572 biosynthetic process Effects 0.000 claims description 58

- 230000007246 mechanism Effects 0.000 claims description 31

- 238000006243 chemical reaction Methods 0.000 claims description 29

- 238000010438 heat treatment Methods 0.000 claims description 26

- 230000004888 barrier function Effects 0.000 claims description 21

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical group [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims description 12

- 238000009832 plasma treatment Methods 0.000 claims description 12

- 229910052710 silicon Inorganic materials 0.000 claims description 12

- 239000010703 silicon Substances 0.000 claims description 12

- 239000001301 oxygen Substances 0.000 claims description 4

- 229910052760 oxygen Inorganic materials 0.000 claims description 4

- 235000012431 wafers Nutrition 0.000 abstract description 250

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 abstract description 38

- 238000007669 thermal treatment Methods 0.000 abstract 1

- 239000010408 film Substances 0.000 description 507

- 238000000151 deposition Methods 0.000 description 38

- 239000010410 layer Substances 0.000 description 38

- 230000008021 deposition Effects 0.000 description 32

- 239000000047 product Substances 0.000 description 32

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 18

- 238000004140 cleaning Methods 0.000 description 16

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 15

- 230000006378 damage Effects 0.000 description 15

- 239000004065 semiconductor Substances 0.000 description 15

- 238000005137 deposition process Methods 0.000 description 13

- 238000011156 evaluation Methods 0.000 description 13

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 description 10

- 229910004298 SiO 2 Inorganic materials 0.000 description 10

- 238000013500 data storage Methods 0.000 description 10

- 238000010586 diagram Methods 0.000 description 10

- 230000006870 function Effects 0.000 description 9

- 238000011068 loading method Methods 0.000 description 8

- 230000003287 optical effect Effects 0.000 description 8

- 238000003860 storage Methods 0.000 description 8

- 239000010409 thin film Substances 0.000 description 8

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 7

- 238000005108 dry cleaning Methods 0.000 description 7

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 6

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 6

- 229910008484 TiSi Inorganic materials 0.000 description 6

- 238000005268 plasma chemical vapour deposition Methods 0.000 description 6

- 230000007723 transport mechanism Effects 0.000 description 6

- 229910000040 hydrogen fluoride Inorganic materials 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 230000003647 oxidation Effects 0.000 description 5

- 238000007254 oxidation reaction Methods 0.000 description 5

- 238000009792 diffusion process Methods 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000003909 pattern recognition Methods 0.000 description 4

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 4

- 229910052721 tungsten Inorganic materials 0.000 description 4

- 239000010937 tungsten Substances 0.000 description 4

- 229910004129 HfSiO Inorganic materials 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- 229910052786 argon Inorganic materials 0.000 description 3

- 238000005229 chemical vapour deposition Methods 0.000 description 3

- 239000013078 crystal Substances 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 238000011049 filling Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 229910021420 polycrystalline silicon Inorganic materials 0.000 description 3

- 229910052814 silicon oxide Inorganic materials 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 239000002344 surface layer Substances 0.000 description 3

- 230000007704 transition Effects 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 238000000231 atomic layer deposition Methods 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000003384 imaging method Methods 0.000 description 2

- 238000009616 inductively coupled plasma Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 230000001788 irregular Effects 0.000 description 2

- 229920005591 polysilicon Polymers 0.000 description 2

- 239000012495 reaction gas Substances 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000009751 slip forming Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910021193 La 2 O 3 Inorganic materials 0.000 description 1

- 230000005856 abnormality Effects 0.000 description 1

- 230000001464 adherent effect Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000000572 ellipsometry Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 238000005429 filling process Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000005416 organic matter Substances 0.000 description 1

- 230000010287 polarization Effects 0.000 description 1

- 238000007781 pre-processing Methods 0.000 description 1

- ADTDNFFHPRZSOT-PVFUSPOPSA-N ram-330 Chemical compound C([C@H]1N(CC2)C)C3=CC=C(OC)C(OC)=C3[C@]32[C@@]1(O)CC[C@@H](OC(=O)OCC)C3 ADTDNFFHPRZSOT-PVFUSPOPSA-N 0.000 description 1

- 229910001404 rare earth metal oxide Inorganic materials 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- 230000003595 spectral effect Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 238000000427 thin-film deposition Methods 0.000 description 1

- 229910000314 transition metal oxide Inorganic materials 0.000 description 1

- 230000005641 tunneling Effects 0.000 description 1

- 238000001039 wet etching Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/54—Apparatus specially adapted for continuous coating

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02043—Cleaning before device manufacture, i.e. Begin-Of-Line process

- H01L21/02046—Dry cleaning only

- H01L21/02049—Dry cleaning only with gaseous HF

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02057—Cleaning during device manufacture

- H01L21/0206—Cleaning during device manufacture during, before or after processing of insulating layers

- H01L21/02063—Cleaning during device manufacture during, before or after processing of insulating layers the processing being the formation of vias or contact holes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

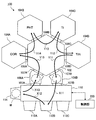

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67155—Apparatus for manufacturing or treating in a plurality of work-stations

- H01L21/67184—Apparatus for manufacturing or treating in a plurality of work-stations characterized by the presence of more than one transfer chamber

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67739—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations into and out of processing chamber

- H01L21/67745—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations into and out of processing chamber characterized by movements or sequence of movements of transfer devices

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Materials Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Drying Of Semiconductors (AREA)

- Formation Of Insulating Films (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005349556A JP2007088401A (ja) | 2005-08-25 | 2005-12-02 | 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 |

| PCT/JP2006/316747 WO2007023951A1 (ja) | 2005-08-25 | 2006-08-25 | 基板処理装置及び基板処理方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005244797 | 2005-08-25 | ||

| JP2005349556A JP2007088401A (ja) | 2005-08-25 | 2005-12-02 | 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007088401A true JP2007088401A (ja) | 2007-04-05 |

| JP2007088401A5 JP2007088401A5 (enExample) | 2008-12-25 |

Family

ID=37771689

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005349556A Pending JP2007088401A (ja) | 2005-08-25 | 2005-12-02 | 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2007088401A (enExample) |

| WO (1) | WO2007023951A1 (enExample) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009158774A (ja) * | 2007-12-27 | 2009-07-16 | Tokyo Electron Ltd | 基板処理方法、基板処理装置及び記憶媒体 |

| JP2020172706A (ja) * | 2020-07-03 | 2020-10-22 | デクセリアルズ株式会社 | 光学膜の製造方法 |

| KR20200124314A (ko) * | 2018-03-20 | 2020-11-02 | 도쿄엘렉트론가부시키가이샤 | 계측 통합형 기판 프로세싱 툴 및 그 이용 방법 |

| JP2021144022A (ja) * | 2020-03-10 | 2021-09-24 | 東京エレクトロン株式会社 | 膜厚測定装置および膜厚測定方法、ならびに成膜システムおよび成膜方法 |

| CN114446767A (zh) * | 2020-11-06 | 2022-05-06 | 应用材料公司 | 增强材料结构的处置 |

| JP2022097945A (ja) * | 2020-12-21 | 2022-07-01 | 株式会社アルバック | 基板処理装置及び基板処理方法 |

| JP2022549489A (ja) * | 2019-09-25 | 2022-11-25 | ベネク・オサケユフティオ | 半導体基板の表面を処理するための方法及び装置 |

| JP2023018500A (ja) * | 2021-07-27 | 2023-02-08 | 東京エレクトロン株式会社 | 窒化チタン膜を形成する方法、及び窒化チタン膜を形成する装置 |

| WO2025053542A1 (ko) * | 2023-09-04 | 2025-03-13 | 한화정밀기계 주식회사 | 기판 처리 장치 및 방법 |

| KR20250044562A (ko) * | 2023-09-22 | 2025-04-01 | 삼성디스플레이 주식회사 | 표시 장치의 제조장치 및 표시 장치의 제조방법 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001305072A (ja) * | 2000-04-25 | 2001-10-31 | Advantest Corp | 基板の欠陥検出方法及び装置 |

| JP2001338964A (ja) * | 2000-05-26 | 2001-12-07 | Hitachi Ltd | 試料処理装置および処理方法 |

| JP2003098112A (ja) * | 2001-09-25 | 2003-04-03 | Hitachi Ltd | 薄膜デバイスの表面画像の検出・出力方法及びその装置並びにそれを用いた薄膜デバイスの製造方法及びその製造装置 |

| JP2003297822A (ja) * | 2002-03-29 | 2003-10-17 | Tokyo Electron Ltd | 絶縁膜の形成方法 |

| JP2004071796A (ja) * | 2002-08-06 | 2004-03-04 | Hitachi Kokusai Electric Inc | 縦型半導体製造装置 |

| JP2004119635A (ja) * | 2002-09-25 | 2004-04-15 | Tokyo Electron Ltd | 被処理体の搬送方法 |

| JP2004363316A (ja) * | 2003-06-04 | 2004-12-24 | Tokyo Electron Ltd | プラズマ処理方法 |

| JP2005039185A (ja) * | 2003-06-24 | 2005-02-10 | Tokyo Electron Ltd | 被処理体処理装置、その被処理体処理方法、圧力制御方法、被処理体搬送方法、及び搬送装置 |

-

2005

- 2005-12-02 JP JP2005349556A patent/JP2007088401A/ja active Pending

-

2006

- 2006-08-25 WO PCT/JP2006/316747 patent/WO2007023951A1/ja not_active Ceased

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001305072A (ja) * | 2000-04-25 | 2001-10-31 | Advantest Corp | 基板の欠陥検出方法及び装置 |

| JP2001338964A (ja) * | 2000-05-26 | 2001-12-07 | Hitachi Ltd | 試料処理装置および処理方法 |

| JP2003098112A (ja) * | 2001-09-25 | 2003-04-03 | Hitachi Ltd | 薄膜デバイスの表面画像の検出・出力方法及びその装置並びにそれを用いた薄膜デバイスの製造方法及びその製造装置 |

| JP2003297822A (ja) * | 2002-03-29 | 2003-10-17 | Tokyo Electron Ltd | 絶縁膜の形成方法 |

| JP2004071796A (ja) * | 2002-08-06 | 2004-03-04 | Hitachi Kokusai Electric Inc | 縦型半導体製造装置 |

| JP2004119635A (ja) * | 2002-09-25 | 2004-04-15 | Tokyo Electron Ltd | 被処理体の搬送方法 |

| JP2004363316A (ja) * | 2003-06-04 | 2004-12-24 | Tokyo Electron Ltd | プラズマ処理方法 |

| JP2005039185A (ja) * | 2003-06-24 | 2005-02-10 | Tokyo Electron Ltd | 被処理体処理装置、その被処理体処理方法、圧力制御方法、被処理体搬送方法、及び搬送装置 |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101553075B1 (ko) | 2007-12-27 | 2015-09-14 | 도쿄엘렉트론가부시키가이샤 | 기판 처리 방법, 기판 처리 장치 및 기억 매체 |

| JP2009158774A (ja) * | 2007-12-27 | 2009-07-16 | Tokyo Electron Ltd | 基板処理方法、基板処理装置及び記憶媒体 |

| KR20200124314A (ko) * | 2018-03-20 | 2020-11-02 | 도쿄엘렉트론가부시키가이샤 | 계측 통합형 기판 프로세싱 툴 및 그 이용 방법 |

| KR102655137B1 (ko) | 2018-03-20 | 2024-04-04 | 도쿄엘렉트론가부시키가이샤 | 계측 통합형 기판 프로세싱 툴 및 그 이용 방법 |

| JP7395721B2 (ja) | 2019-09-25 | 2023-12-11 | ベネク・オサケユフティオ | 半導体基板の表面を処理するための方法及び装置 |

| US12421596B2 (en) | 2019-09-25 | 2025-09-23 | Beneq Oy | Method and apparatus for processing surface of a semiconductor substrate |

| JP2022549489A (ja) * | 2019-09-25 | 2022-11-25 | ベネク・オサケユフティオ | 半導体基板の表面を処理するための方法及び装置 |

| JP2021144022A (ja) * | 2020-03-10 | 2021-09-24 | 東京エレクトロン株式会社 | 膜厚測定装置および膜厚測定方法、ならびに成膜システムおよび成膜方法 |

| JP2020172706A (ja) * | 2020-07-03 | 2020-10-22 | デクセリアルズ株式会社 | 光学膜の製造方法 |

| JP7146853B2 (ja) | 2020-07-03 | 2022-10-04 | デクセリアルズ株式会社 | 光学膜の製造方法 |

| JP7604570B2 (ja) | 2020-11-06 | 2024-12-23 | アプライド マテリアルズ インコーポレイテッド | 材料構造を改良するための処理 |

| JP7313414B2 (ja) | 2020-11-06 | 2023-07-24 | アプライド マテリアルズ インコーポレイテッド | 材料構造を改良するための処理 |

| JP2023164786A (ja) * | 2020-11-06 | 2023-11-14 | アプライド マテリアルズ インコーポレイテッド | 材料構造を改良するための処理 |

| JP2022077990A (ja) * | 2020-11-06 | 2022-05-24 | アプライド マテリアルズ インコーポレイテッド | 材料構造を改良するための処理 |

| CN114446767A (zh) * | 2020-11-06 | 2022-05-06 | 应用材料公司 | 增强材料结构的处置 |

| JP2022097945A (ja) * | 2020-12-21 | 2022-07-01 | 株式会社アルバック | 基板処理装置及び基板処理方法 |

| JP2023018500A (ja) * | 2021-07-27 | 2023-02-08 | 東京エレクトロン株式会社 | 窒化チタン膜を形成する方法、及び窒化チタン膜を形成する装置 |

| JP7683383B2 (ja) | 2021-07-27 | 2025-05-27 | 東京エレクトロン株式会社 | 窒化チタン膜を形成する方法、及び窒化チタン膜を形成する装置 |

| WO2025053542A1 (ko) * | 2023-09-04 | 2025-03-13 | 한화정밀기계 주식회사 | 기판 처리 장치 및 방법 |

| KR20250044562A (ko) * | 2023-09-22 | 2025-04-01 | 삼성디스플레이 주식회사 | 표시 장치의 제조장치 및 표시 장치의 제조방법 |

| KR102798048B1 (ko) | 2023-09-22 | 2025-04-24 | 삼성디스플레이 주식회사 | 표시 장치의 제조장치 및 표시 장치의 제조방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007023951A1 (ja) | 2007-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10861744B2 (en) | Platform and method of operating for integrated end-to-end CMP-less interconnect process | |

| US7585686B2 (en) | Method and apparatus for processing a wafer | |

| US7159599B2 (en) | Method and apparatus for processing a wafer | |

| TWI464790B (zh) | Film forming method and substrate processing device | |

| US20070134821A1 (en) | Cluster tool for advanced front-end processing | |

| KR100456105B1 (ko) | 반도체 제조방법, 기판 처리방법 및 반도체 제조장치 | |

| US20070196011A1 (en) | Integrated vacuum metrology for cluster tool | |

| US20050257890A1 (en) | Method of cleaning an interior of a remote plasma generating tube and appartus and method for processing a substrate using the same | |

| US20210111067A1 (en) | Gap fill deposition process | |

| JP2009543355A (ja) | 進歩型フロントエンド処理のためのクラスターツール | |

| US11127597B2 (en) | Etching method | |

| US7510972B2 (en) | Method of processing substrate, post-chemical mechanical polishing cleaning method, and method of and program for manufacturing electronic device | |

| US20060196527A1 (en) | Method of surface processing substrate, method of cleaning substrate, and programs for implementing the methods | |

| JP5046506B2 (ja) | 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 | |

| KR101678266B1 (ko) | 반도체 장치의 제조 방법 및 제조 장치 | |

| JP2007088401A (ja) | 基板処理装置,基板処理方法,プログラム,プログラムを記録した記録媒体 | |

| JP2007056336A (ja) | 基板処理装置,基板処理装置の基板搬送方法,プログラム,プログラムを記録した記録媒体 | |

| US12020992B2 (en) | Methods and apparatus for processing a substrate | |

| JP2008192835A (ja) | 成膜方法,基板処理装置,および半導体装置 | |

| JP4895256B2 (ja) | 基板の表面処理方法 | |

| TWI385722B (zh) | Substrate processing method, cleaning method after chemical mechanical polishing, the method and program for producing electronic device | |

| US20070031596A1 (en) | Method for reducing particle contamination in a low pressure CVD apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081111 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081111 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100914 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110329 |