EP3199715B1 - Overflow for a basin, in particular rinsing basin - Google Patents

Overflow for a basin, in particular rinsing basin Download PDFInfo

- Publication number

- EP3199715B1 EP3199715B1 EP16197956.2A EP16197956A EP3199715B1 EP 3199715 B1 EP3199715 B1 EP 3199715B1 EP 16197956 A EP16197956 A EP 16197956A EP 3199715 B1 EP3199715 B1 EP 3199715B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- overflow

- sink

- sections

- section

- flow channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/24—Overflow devices for basins or baths

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/18—Sinks, whether or not connected to the waste-pipe

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/22—Outlet devices mounted in basins, baths, or sinks

- E03C1/23—Outlet devices mounted in basins, baths, or sinks with mechanical closure mechanisms

- E03C1/232—Outlet devices mounted in basins, baths, or sinks with mechanical closure mechanisms combined with overflow devices

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/24—Overflow devices for basins or baths

- E03C1/244—Separate devices to be placed on the outlet opening

Definitions

- the invention relates to an overflow for a sink according to the preamble of claim 1, with at least one inlet opening which is intended for mounting on a basin of the sink or on an overflow trough or a separate spout, and with an outlet opening which is intended for mounting on a Drain or ventilation valve of the basin or the sink is determined, wherein a flow channel for a fluid or water is arranged between the inlet opening and outlet opening and at least one section is provided in the flow channel in which the flow channel has an essentially circular cross section.

- the invention also relates to a sink with at least one overflow, which sink comprises an opening in a side wall of a sink or an opening in a horizontal surface of the sink, preferably in the area of an overflow trough or a separate spout, which opening is fluidically connected to the via an overflow Drain of the sink is connected, according to the preamble of claim 11.

- Such sinks or comparable trained sinks / bathtubs are from the EP 1 975 325 A2 , the US 2008/196161 A1 and the US 746 419 A known.

- the invention has for its object to provide an improved overflow in a simple and inexpensive manner so that overflowing water can be optimally and safely drained from the basin and / or the overflow trough or the separate spout.

- this solution should also be able to be implemented retrospectively (retrofittable) even in the case of already existing sinks and can be flexibly adapted to the geometry of the overflow or the sink.

- an overflow for a sink preferably a kitchen sink with at least one sink and an overflow trough or a separate spout, with at least one inlet opening which is intended for mounting on the basin or on the overflow trough or the separate spout, and with an outlet opening , which is intended for mounting on a drain or ventilation valve of the sink or basin, wherein a flow channel for a fluid is arranged between the inlet opening and the outlet opening and wherein at least one section (flow channel section) is provided in the flow channel in which the flow channel has an essentially circular cross-section, characterized in that several such sections with a circular cross-section are arranged in parallel in the flow channel, the sections being arranged next to one another, in the manner of a triangle, offset or arranged in a zigzag, in each case based on the position of their center elpoints.

- the overflow can, in particular, also have two or more inlet openings, one of which can be mounted or mounted on the basin and another on the overflow trough or the separate spout or another basin, if present.

- the implementation of several separate overflows according to the invention is possible, e.g. for every sink or for sink and overflow trough or spout.

- a sink according to the invention with at least one overflow which sink comprises an opening in a side wall of a sink or an opening in a horizontal surface of the sink, preferably in the area of an overflow trough or a separate spout, which opening has a Fluid overflow is connected to an outlet of the sink, characterized in that the sink has an overflow according to the invention or a further development thereof.

- a plurality of sections arranged in parallel are provided, in which the flow channel has an essentially circular cross section, even if the flow channel itself - which is the rule - Has a different cross-sectional geometry.

- the flow channel sections with a circular cross-section provide for eddy formation when liquid runs through the overflow, similar to an inverted bottle when it is set in motion about its longitudinal axis. As a result, there is less jammed air in the system and fluid drainage through the overflow is improved. This has a particularly advantageous effect, particularly in the case of overflow troughs and separate spouts, because with this arrangement, a dynamic pressure cannot really build up.

- the flow channel has a constant cross section in the sections, which can have a favorable effect on the vortex formation. This can apply to at least a large part of the sections mentioned.

- the flow channel in the sections viewed in the flow direction of the fluid, at least one for example, has a conical taper of its cross section. This can be the case, for example, in the area of the inlet opening.

- the flow channel in the sections can also have an expansion of its cross section, preferably in the region or in the direction of the outlet opening.

- the sections have a certain length L, which can be numerically linked to a diameter D of the section.

- L f ⁇ D.

- the overflow according to the invention provides that the sum of the cross sections of the sections is in the range of approximately 175 mm 2 , most preferably between approximately 150 mm 2 and approximately 200 mm 2nd

- At least one of the several sections mentioned can be arranged in the region of the inlet opening of the overflow, for example in the region of a so-called overflow head.

- the overflow head is the part of the overflow that is physically mounted on the or the sink in the area of an overflow opening of the sink or sink. The same applies to the inlet opening in the area of an overflow trough or a separate spout.

- one of the above-mentioned several sections is arranged in the region of the outlet opening of the overflow, that is to say more in the direction of the sink outlet.

- the circular flow channel sections can also be at any other point of the overflow or the overflow flow channel be arranged.

- another development of the overflow according to the invention provides that at least one of the plurality of sections mentioned is arranged in the region of an elbow of the flow channel, which elbow converts a first section of the flow channel, which is vertical when installed, into a second section of the flow channel, which is horizontal when installed.

- the at least one flow channel section can be arranged in the area of the first section (ie vertically) and / or in the area of the second section (ie horizontally).

- An advantageous retrofit element can be designed to be fitted into an existing overflow.

- An outer contour of the retrofit element can essentially correspond to an inner contour of the overflow in one area.

- the retrofit element can be used inside as an insert in an existing overflow. This can basically happen at any point of the overflow, e.g. also in the overflow head.

- the overflow head mentioned above if it includes the circular flow channel sections mentioned, can itself be regarded as a retrofit element because it can replace an existing overflow head of an existing overflow.

- the angled piece or angled part or to any other section of an existing overflow flow duct This can be retrofitted according to the invention by being replaced by a corresponding part which has the circular flow duct sections. Accordingly, the retrofit element then forms at least a partial section or segment of the overflow flow channel.

- a sink in particular a kitchen sink, is shown, which is designated overall by the reference numeral 1.

- the sink 1 comprises at least one sink basin 2, of which only a lower corner area is shown here, which comprises a basin wall 3 and a basin floor 4.

- a drain opening is provided at reference number 5, which communicates fluidically with a sink drain 6, which is known per se.

- a stopper or valve plug 7 is arranged, which in the exemplary embodiment shown closes the drain opening 5 in a fluid-tight manner, so that no water can flow out of the sink 2 through the drain opening 5.

- rinse water up to a schematically represented water level 9 is contained in the sink 2.

- the water level 9 lies at the level of an opening 10 in the basin wall 3, which opening 10 can also be referred to as an overflow opening.

- the opening 10 cannot be seen in FIG. 1 due to the type of representation chosen.

- the so-called overflow head 11 of a known overflow 12 is mounted on the outside of the basin wall 3, via which overflow 12 water 8 can flow from the sink 2 to the sink drain 6 when the water level 9 within the sink 2 has a certain level Level reached or exceeded.

- the overflow 12 comprises an inlet opening 13 in the area of the overflow head 11, which inlet opening 13 communicates with the already mentioned opening 10 in the basin wall 3 of the sink basin 2.

- a seal is regularly arranged around the inlet opening 13 in order to seal the overflow head 11 in a fluid-tight manner with respect to the basin wall 3. This seal is in Figure 1 not visible.

- overflow head 11 Figure 1 an angled overflow pipe 14, which defines at its end facing away from the overflow head 11 an outlet opening 15 through which the overflow 12 opens into the sink outlet 6.

- Inlet opening 13, overflow head 11, overflow pipe 14 and outlet opening 15 thus define a flow channel 14a from the opening 10 in the basin wall 3 of the sink basin 2 to the sink outlet 6, so that water 8 can flow out of the sink basin 2 through the overflow 12 when the water level 9 - as already stated - reaches or exceeds a certain level (a certain level).

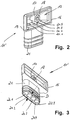

- Figure 2 shows an overall perspective view of an overflow head 11 'of an overflow according to the invention, which in Figure 2 is not shown further.

- Figure 2 shows an overall perspective view of an overflow head 11 'of an overflow according to the invention, which in Figure 2 is not shown further.

- the overflow head 11 'according to Figure 2 also includes the approximately rectangular inlet opening 13 already mentioned, which is surrounded by a correspondingly shaped sealing surface 16. Approximately in the center of the otherwise slightly funnel-shaped inlet opening 13, an approximately circular-cylindrical reinforced structure 17 is arranged centrally, which has a mounting hole 18 for fastening the overflow head 11 'in the region of the basin wall 3 (cf. Figure 1 ) trains. In a lower boundary surface 19 of the inlet opening 13 there are four openings or bores 20.1 to 20.4 arranged side by side in a row that extend parallel to each other through a connecting piece 21 of the overflow head 11 '. These openings or bores 20.1 to 20.4 each define a flow channel section of the overflow 12 (cf.

- FIG 1 Figure 1

- FIG. 3 Figure 1

- the connecting piece 21 of the overflow head 11 has externally projecting shapes which can be used to fasten a pushed-on pipe or hose (not shown) or for reinforcement purposes.

- Figure 3 shows the overflow head 11 'in a further perspective view obliquely from below, so that the formation and arrangement of the openings / bores or flow channel sections 20.1 to 20.4 can be easily recognized. As already stated, these lie next to one another on a line (based on their virtual centers; not shown) and each have approximately the same diameter D. However, the overflow according to the invention is in no way limited to the arrangement, number or size of the openings / bores 20.1 to 20.4 shown here.

- the openings / bores 20.1-20.4 can also have different diameters D, and there may be more or fewer than the four openings / bores 20.1-20.4 shown.

- these can be arranged next to one another, in the manner of a triangle, offset or arranged in a zigzag, or in the manner of a square or the like.

- only one such breakthrough can be present.

- the opening or, according to the invention the openings have or have an approximately circular diameter, although the connecting piece 21 of the overflow head 11 or its inlet opening 13 has a different geometry (oval or rectangular).

- the applicant has found that the presence of circular flow channel sections results in a significantly improved flow behavior of the overflowing water in the area of the overflow, comparable to the improved leakage of water from an overhead bottle when it simultaneously rotates around the bottle's longitudinal axis becomes.

- the openings / bores 20.1-20.4 can have a final widening in the area of the inlet opening 13 and / or in the area of a free (lower) end of the connecting piece 21, as in FIG Figure 3 is exemplified at 22.4 for the bore 20.4.

- Figure 4 shows further views of the overflow head 11 'according to the Figures 2 and 3 .

- the overflow head 11 ' is corresponding in a side view Figure 1 shown. This is not to be discussed further here. However, you can recognize those above by Figure 2 The aforementioned funnel-like tapering of the inlet opening 13 starting from the sealing surface 16 to the inside (left in Figure 4a ).

- Part 4b shows the overflow head 11 'in a view from the front.

- the reinforced structure 17 with the mounting hole 18 and the circumferential sealing surface 16 are clearly visible.

- Partial illustration 4c) illustrates the position of a section line BB, which is shown corresponding to the overflow head 11 'in the sectional view according to partial illustration 4d). Is clearly recognizable in Figure 4d ) the location and formation of the flow channel sections or breakthroughs / holes 20.1 - 20.4 with approximately the same diameter D, which can be identical for all four holes 20.1 - 20.4, which in Figure 4d is not recognizable due to the selected sectional representation.

- Reference symbol L denotes an axial length of the flow channel sections or openings / bores 20.1-20.4, which can also be identical for all four flow channel sections and essentially the entire axial length L of the connecting piece 21 from the inlet opening 13 to its free one End corresponds.

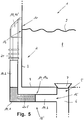

- Figure 5 schematically shows an alternative embodiment of the overflow (in Figure 5 designated by reference numeral 12 '), in which, as an alternative or in addition to the flow channel sections with a circular cross section formed in the area of the overflow head 11, 11', a (further) such flow channel section is provided in the area of the overflow pipe 14.

- the mentioned further flow channel section is special with reference numerals 20.5 designated and arranged in the area of an elbow 14.1, which connects a first pipe part 14.2, which is connected to the connecting piece 21 of the overflow head 11, 11 'in an extension thereof, with a second pipe part 14.3, which is connected to the sink outlet 6 and the outlet opening 15 of the overflow 12 'defined.

- the angle piece or angle part 14.1 is in Figure 5 shown hatched.

- the at least one flow channel section 20.5 could alternatively also be arranged in the region of the first pipe part 14.2 and / or the second pipe part 14.3.

- the proposed improvement in the area of a (sink) overflow can also be achieved by retrofitting an existing overflow in an existing sink, for example by retrofitting a corresponding pipe or angle part 14.1 - 14.3 or using it accordingly is used in an existing overflow.

- the diameter D of the openings / bores mentioned is in the range from 2 to 35 mm, with a corresponding plurality of openings having to be provided for smaller diameters D.

- the applicant has found that a minimum cross section summed over all openings or bores should be in the range from approximately 150 mm 2 to approximately 200 mm 2 , preferably approximately 175 mm 2 .

- the invention is not limited to use in the area of a sink, but can alternatively or additionally be used in the area of a so-called overflow trough or a separate spout.

- FIG. 6 shows a rinse 1 'with overflow trough 2'.

- This overflow trough 2 ' has an opening 10' (in the installed state) which is arranged horizontally, below which an overflow according to the invention (not shown here) is mounted or can be fitted, in order to make its advantages usable for such sinks 1 '.

- FIG. 7 shows a sink 1 "with a separate spout 2".

- This spout 2 " likewise has a horizontally arranged opening 10" (in the installed state), below which an overflow according to the invention (not shown here) is mounted or can be fitted, in order to make its advantages usable for such sinks 1 ".

- an overflow according to the invention in the sinks 1 ', 1 "can be carried out according to Figure 6 or 7 can also be provided in the area of the basin 2, as described above.

Description

Die Erfindung betrifft einen Überlauf für eine Spüle gemäß dem Oberbegriff des Anspruchs 1, mit wenigstens einer Einlauföffnung, die zur Montage an einem Becken der Spüle oder an einer Überlaufmulde bzw. einem separaten Ausguss bestimmt ist, und mit einer Auslauföffnung, die zur Montage an einem Ablauf oder Lüftungsventil des Beckens bzw. der Spüle bestimmt ist, wobei zwischen Einlauföffnung und Auslauföffnung ein Strömungskanal für ein Fluid bzw. Wasser angeordnet ist und wobei in dem Strömungskanal wenigstens ein Abschnitt vorgesehen ist, in dem der Strömungskanal einen im Wesentlichen kreisrunden Querschnitt aufweist.The invention relates to an overflow for a sink according to the preamble of

Die Erfindung betrifft auch eine Spüle mit wenigstens einem Überlauf, welche Spüle eine Öffnung in einer Seitenwand eines Spülenbeckens oder eine Öffnung in einer horizontalen Fläche der Spüle, vorzugsweise im Bereich einer Überlaufmulde oder eines separaten Ausgusses, umfasst, welche Öffnung über einen Überlauf fluidtechnisch mit dem Ablauf der Spüle verbunden ist, gemäß dem Oberbegriff des Anspruchs 11.The invention also relates to a sink with at least one overflow, which sink comprises an opening in a side wall of a sink or an opening in a horizontal surface of the sink, preferably in the area of an overflow trough or a separate spout, which opening is fluidically connected to the via an overflow Drain of the sink is connected, according to the preamble of claim 11.

Spülen bekannter Art, insbesondere Küchenspülen, weisen regelmäßig einen Überlauf auf, wie oben definiert, damit bei einem Verschluss des eigentlichen Spülenablaufs überschüssiges Wasser aus dem Spülenbecken oder einer Überlaufmulde ablaufen kann, wenn der Wasserstand ein bestimmtes Niveau erreicht hat bzw. wenn Wasser in die Überlaufmulde oder den Ausguss gelangt, z.B. von einer Abtropffläche der Spüle. Dadurch sollen Überschwemmungen und entsprechende Schäden vermieden werden.Sinks of a known type, in particular kitchen sinks, regularly have an overflow, as defined above, so that when the actual sink outlet is closed, excess water can drain out of the sink or an overflow trough if the water level has reached a certain level or if water flows into the overflow trough or the spout, e.g. from a sink drainer. This is to avoid flooding and damage.

Solche Spülen oder vergleichbar ausgebildete Waschbecken/Badewannen sind aus der

In der Vergangenheit hat es sich zuweilen als schwierig herausgestellt, eine ordnungsgemäße Funktion des Überlaufs zu gewährleisten, der regelmäßig in der Lage sein muss, eine relativ große Wassermenge von bis zu 12 l/min aus dem Spülenbecken abzuleiten. Beispielsweise wurden zu diesem Zweck aufwändige und entsprechend kostenträchtige Entlüftungen für den Überlauf vorgesehen, damit dieser seine Sicherheitsfunktion jederzeit uneingeschränkt erfüllen kann. Insbesondere bei der Entwässerung von Überlaufmulden oder separaten Ausgüssen hat sich gezeigt, dass der für eine ordnungsgemäße Funktion erforderliche Staudruck nur schwer zu erreichen ist.In the past, it has sometimes been difficult to ensure proper functioning of the overflow, which must be able to regularly dispense a relatively large amount of water of up to 12 l / min the sink sink. For this purpose, for example, complex and correspondingly costly vents have been provided for the overflow so that it can fulfill its safety function at any time without restrictions. Especially when draining overflow troughs or separate spouts, it has been shown that the back pressure required for proper functioning is difficult to achieve.

Der Erfindung liegt die Aufgabe zugrunde, in einfacher und kostengünstiger Weise einen verbesserten Überlauf zu schaffen, damit aus dem Becken und/oder der Überlaufmulde bzw. dem separaten Ausguss überlaufendes Wasser optimal und sicher abgeleitet werden kann. Vorzugsweise soll diese Lösung auch bei bereits bestehenden Spülen ohne großen baulichen Aufwand nachträglich realisierbar (nachrüstbar) und flexibel an die Geometrie des Überlaufs bzw. der Spüle anpassbar sein.The invention has for its object to provide an improved overflow in a simple and inexpensive manner so that overflowing water can be optimally and safely drained from the basin and / or the overflow trough or the separate spout. Preferably, this solution should also be able to be implemented retrospectively (retrofittable) even in the case of already existing sinks and can be flexibly adapted to the geometry of the overflow or the sink.

Die Aufgabe wird gelöst durch einen Überlauf mit den Merkmalen des Anspruchs 1 und durch eine Spüle mit den Merkmalen des Anspruchs 11. Vorteilhafte Weiterbildungen der jeweiligen Erfindungsgegenstände sind in den entsprechenden Unteransprüchen definiert.The object is achieved by an overflow with the features of

Erfindungsgemäß ist ein Überlauf für eine Spüle, vorzugsweise eine Küchenspüle mit wenigstens einem Spülenbecken und einer Überlaufmulde oder einem separaten Ausguss, mit wenigstens einer Einlauföffnung, die zur Montage an dem Becken oder an der Überlaufmulde bzw. dem separaten Ausguss bestimmt ist, und mit einer Auslauföffnung, die zur Montage an einem Ablauf oder Lüftungsventil der Spüle bzw. des Beckens bestimmt ist, wobei zwischen Einlauföffnung und Auslauföffnung ein Strömungskanal für ein Fluid angeordnet ist und wobei in dem Strömungskanal wenigstens ein Abschnitt (Strömungskanal-Abschnitt) vorgesehen ist, in dem der Strömungskanal einen im Wesentlichen kreisrunden Querschnitt aufweist, dadurch gekennzeichnet, dass in dem Strömungskanal mehrere solche Abschnitte mit kreisrundem Querschnitt parallel angeordnet sind, wobei die Abschnitte nebeneinander, nach Art eines Dreiecks, versetzt oder im Zick-Zack angeordnet sind, jeweils bezogen auf die Lage ihrer Mittelpunkte.According to the invention is an overflow for a sink, preferably a kitchen sink with at least one sink and an overflow trough or a separate spout, with at least one inlet opening which is intended for mounting on the basin or on the overflow trough or the separate spout, and with an outlet opening , which is intended for mounting on a drain or ventilation valve of the sink or basin, wherein a flow channel for a fluid is arranged between the inlet opening and the outlet opening and wherein at least one section (flow channel section) is provided in the flow channel in which the flow channel has an essentially circular cross-section, characterized in that several such sections with a circular cross-section are arranged in parallel in the flow channel, the sections being arranged next to one another, in the manner of a triangle, offset or arranged in a zigzag, in each case based on the position of their center elpoints.

Der Überlauf kann insbesondere auch zwei oder mehr Einlauföffnungen aufweisen, von denen eine an dem Becken und eine andere an der Überlaufmulde bzw. dem separaten Ausguss oder einem weiteren Becken -sofern vorhanden - montiert oder montierbar ist. Darüber hinaus ist auch die Realisierung mehrerer separater erfindungsgemäßer Überläufe möglich, z.B. für jedes Spülenbecken oder für Spülenbecken und Überlaufmulde bzw. Ausguss.The overflow can, in particular, also have two or more inlet openings, one of which can be mounted or mounted on the basin and another on the overflow trough or the separate spout or another basin, if present. In addition, the implementation of several separate overflows according to the invention is possible, e.g. for every sink or for sink and overflow trough or spout.

Gemäß einem anderen Aspekt der Erfindung ist eine erfindungsgemäße Spüle mit wenigstens einem Überlauf, welche Spüle eine Öffnung in einer Seitenwand eines Spülenbeckens oder eine Öffnung in einer horizontalen Fläche der Spüle, vorzugsweise im Bereich einer Überlaufmulde oder eines separaten Ausgusses, umfasst, welche Öffnung über einen Überlauf fluidtechnisch mit einem Ablauf der Spüle verbunden ist, dadurch gekennzeichnet, dass die Spüle einen erfindungsgemäßen Überlauf oder eine Weiterbildung hiervon aufweist.According to another aspect of the invention, a sink according to the invention with at least one overflow, which sink comprises an opening in a side wall of a sink or an opening in a horizontal surface of the sink, preferably in the area of an overflow trough or a separate spout, which opening has a Fluid overflow is connected to an outlet of the sink, characterized in that the sink has an overflow according to the invention or a further development thereof.

Erfindungsgemäß ist demnach vorgesehen, dass in dem zwischen der wenigstens einen Einlauföffnung und der Auslauföffnung des Überlaufs definierten Strömungskanal mehrere, parallel angeordnete Abschnitte vorgesehen sind, in denen der Strömungskanal einen im Wesentlichen kreisrunden Querschnitt aufweist, auch wenn der Strömungskanal an sich - was die Regel ist - eine hiervon abweichende Querschnittsgeometrie besitzt. Die genannten Strömungskanal-Abschnitte mit kreisrundem Querschnitt sorgen beim Ablaufen von Flüssigkeit durch den Überlauf für eine Wirbelbildung ähnlich wie bei einer umgedrehten Flasche, wenn diese um ihre Längsachse in Bewegung versetzt wird. Dadurch befindet sich weniger gestaute Luft im System, und das Ablaufen von Flüssigkeit durch den Überlauf wird verbessert. Dies wirkt sich vor allem bei Überlaufmulden und separaten Ausgüssen besonders vorteilhaft aus, weil sich bei dieser Anordnung ein Staudruck nicht wirklich aufbauen kann.According to the invention, it is therefore provided that in the flow channel defined between the at least one inlet opening and the outlet opening of the overflow, a plurality of sections arranged in parallel are provided, in which the flow channel has an essentially circular cross section, even if the flow channel itself - which is the rule - Has a different cross-sectional geometry. The flow channel sections with a circular cross-section provide for eddy formation when liquid runs through the overflow, similar to an inverted bottle when it is set in motion about its longitudinal axis. As a result, there is less jammed air in the system and fluid drainage through the overflow is improved. This has a particularly advantageous effect, particularly in the case of overflow troughs and separate spouts, because with this arrangement, a dynamic pressure cannot really build up.

In Weiterbildung des erfindungsgemäßen Überlaufs kann vorgesehen sein, dass der Strömungskanal in den Abschnitten einen konstanten Querschnitt aufweist, was sich günstig auf die Wirbelbildung auswirken kann. Dies kann zumindest für einen größten Teil der genannten Abschnitte gelten.In a further development of the overflow according to the invention it can be provided that the flow channel has a constant cross section in the sections, which can have a favorable effect on the vortex formation. This can apply to at least a large part of the sections mentioned.

Alternativ oder zusätzlich kann vorgesehen sein, dass der Strömungskanal in den Abschnitten, in Strömungsrichtung des Fluids gesehen, wenigstens eine beispielsweise konische Verjüngung seines Querschnitts aufweist. Dies kann beispielsweise im Bereich der Einlauföffnung der Fall sein. Weiterhin kann der Strömungskanal in den Abschnitten auch eine Erweiterung seines Querschnitts aufweisen, vorzugsweise im Bereich oder in Richtung der Auslauföffnung.Alternatively or additionally, it can be provided that the flow channel in the sections, viewed in the flow direction of the fluid, at least one for example, has a conical taper of its cross section. This can be the case, for example, in the area of the inlet opening. Furthermore, the flow channel in the sections can also have an expansion of its cross section, preferably in the region or in the direction of the outlet opening.

Um die angesprochene Wirbelbildung weiter zu optimieren, zeichnet sich eine andere Weiterbildung des erfindungsgemäßen Überlaufs dadurch aus, dass die Abschnitte eine bestimmte Länge L aufweisen, die zahlenmäßig mit einem Durchmesser D des Abschnitts verknüpft sein kann. Dabei kann gelten: L = f · D. Der Faktor f kann zwischen etwa 2 und etwa 5 liegen, und er kann seinerseits von dem Durchmesser D abhängen, f = f(D).In order to further optimize the vortex formation mentioned, another development of the overflow according to the invention is characterized in that the sections have a certain length L, which can be numerically linked to a diameter D of the section. The following can apply: L = f · D. The factor f can be between approximately 2 and approximately 5, and in turn can depend on the diameter D, f = f (D).

Um einen hinreichenden Überlauf von bis zu 12 l/min zu ermöglichen, sieht eine andere Weiterbildung des erfindungsgemäßen Überlaufs vor, dass eine Summe der Querschnitte der Abschnitte im Bereich von etwa 175 mm2 liegt, höchst vorzugsweise zwischen etwa 150 mm2 und etwa 200 mm2.In order to enable a sufficient overflow of up to 12 l / min, another development of the overflow according to the invention provides that the sum of the cross sections of the sections is in the range of approximately 175 mm 2 , most preferably between approximately 150 mm 2 and approximately 200 mm 2nd

Weiterhin kann vorteilhaft sein, wenn die mehreren Abschnitte zueinander im Wesentlichen identisch ausgebildet sind, ohne dass die Erfindung jedoch hierauf beschränkt wäre.It can also be advantageous if the plurality of sections are essentially identical to one another, but without the invention being restricted to this.

Wenigstens einer der genannten mehreren Abschnitte kann im Bereich der Einlauföffnung des Überlaufs angeordnet sein, beispielsweise im Bereich eines sogenannten Überlaufkopfes. Bei dem Überlaufkopf handelt es sich um denjenigen Teil des Überlaufs, der unmittelbar im Bereich einer Überlauföffnung der Spüle bzw. des Spülenbeckens an dieser bzw. an diesem physikalisch montiert wird. Entsprechendes gilt für die Einlauföffnung im Bereich einer Überlaufmulde oder eines separaten Ausgusses.At least one of the several sections mentioned can be arranged in the region of the inlet opening of the overflow, for example in the region of a so-called overflow head. The overflow head is the part of the overflow that is physically mounted on the or the sink in the area of an overflow opening of the sink or sink. The same applies to the inlet opening in the area of an overflow trough or a separate spout.

Alternativ oder zusätzlich kann jedoch vorgesehen sein, dass einer der genannten mehreren Abschnitte im Bereich der Auslauföffnung des Überlaufs, also eher in Richtung Spülen-Ablauf, angeordnet ist.Alternatively or additionally, however, it can be provided that one of the above-mentioned several sections is arranged in the region of the outlet opening of the overflow, that is to say more in the direction of the sink outlet.

Grundsätzlich können die kreisrunden Strömungskanal-Abschnitte jedoch auch an einer beliebig anderen Stelle des Überlaufs bzw. des Überlauf-Strömungskanals angeordnet sein. Entsprechend sieht eine andere Weiterbildung des erfindungsgemäßen Überlaufs vor, dass wenigstens einer der genannten mehreren Abschnitte im Bereich eines Winkelstücks des Strömungskanals angeordnet ist, welches Winkelstück einen ersten, bei Montage vertikalen Abschnitt des Strömungskanals in einen zweiten, bei Montage horizontalen Abschnitt des Strömungskanals überführt. Dabei kann der wenigstens eine Strömungskanal-Abschnitt im Bereich des ersten Abschnitts (also vertikal) und/oder im Bereich des zweiten Abschnitts (also horizontal) angeordnet sein.In principle, however, the circular flow channel sections can also be at any other point of the overflow or the overflow flow channel be arranged. Accordingly, another development of the overflow according to the invention provides that at least one of the plurality of sections mentioned is arranged in the region of an elbow of the flow channel, which elbow converts a first section of the flow channel, which is vertical when installed, into a second section of the flow channel, which is horizontal when installed. The at least one flow channel section can be arranged in the area of the first section (ie vertically) and / or in the area of the second section (ie horizontally).

Ein vorteilhaftes Nachrüstelement kann dazu ausgebildet sein, in einen bestehenden Überlauf eingepasst zu werden. Dabei kann eine Außenkontur des Nachrüstelements im Wesentlichen einer Innenkontur des Überlaufs in einem Bereich entsprechen. Auf diese Weise lässt sich das Nachrüstelement innen, als eine Art Einsatz, in einen bestehenden Überlauf einsetzen. Dies kann grundsätzlich an einer beliebigen Stelle des Überlaufs geschehen, also z.B. auch im Überlaufkopf. Allerdings lässt sich der weiter oben angesprochene Überlaufkopf, wenn dieser die genannten kreisrunden Strömungskanal-Abschnitte umfasst, selbst bereits als ein Nachrüstelement auffassen, weil er einen bestehenden Überlaufkopf eines bestehenden Überlaufs ersetzen kann. Gleiches gilt für das angesprochene Winkelstück oder Winkelteil oder auch für einen beliebigen anderen Abschnitt eines bestehenden Überlauf-Strömungskanals: Dieser kann erfindungsgemäß nachgerüstet werden, indem er gegen ein entsprechendes Teil ausgetauscht wird, welches die kreisrunden Strömungskanal-Abschnitte aufweist. Entsprechend bildet das Nachrüstelement dann wenigstens einen TeilAbschnitt oder Segment des Überlauf-Strömungskanals.An advantageous retrofit element can be designed to be fitted into an existing overflow. An outer contour of the retrofit element can essentially correspond to an inner contour of the overflow in one area. In this way, the retrofit element can be used inside as an insert in an existing overflow. This can basically happen at any point of the overflow, e.g. also in the overflow head. However, the overflow head mentioned above, if it includes the circular flow channel sections mentioned, can itself be regarded as a retrofit element because it can replace an existing overflow head of an existing overflow. The same applies to the angled piece or angled part or to any other section of an existing overflow flow duct: This can be retrofitted according to the invention by being replaced by a corresponding part which has the circular flow duct sections. Accordingly, the retrofit element then forms at least a partial section or segment of the overflow flow channel.

Auf diese Weise lassen sich quasi alle bestehenden Überläufe in einfacher und kostengünstiger Weise im Sinne der vorliegenden Erfindung strömungsoptimiert nachrüsten.In this way, virtually all existing overflows can be retrofitted in a flow-optimized manner in a simple and cost-effective manner within the meaning of the present invention.

Die nachfolgenden Zeichnungen zeigen einige Ausführungsbeispiele für einen Überlauf und Spüle gemäß der Präambel der Ansprüche 1 und 11.

Figur 1- zeigt schematisch, teilweise im Schnitt, eine Spüle mit einem Überlauf;

Figur 2- zeigt den Überlaufkopf eines Überlaufs in perspektivischer Darstellung.

Figur 3- zeigt den Überlaufkopf aus

Figur 2 Figur 4- zeigt verschiedene weitere Ansichten des Überlaufkopfs aus

Figur 2 und 3 Figur 5- zeigt schematisch eine alternative Ausgestaltung der Spüle aus

Figur 1, teilweise im Schnitt; Figur 6- zeigt eine alternative Spülenform mit Überlaufmulde; und

Figur 7- zeigt eine weitere alternative Spülenform mit separatem Ausguss.

- Figure 1

- shows schematically, partly in section, a sink with an overflow;

- Figure 2

- shows the overflow head of an overflow in a perspective view.

- Figure 3

- shows the overflow head

Figure 2 in a different perspective view. - Figure 4

- shows various other views of the overflow head

Figures 2 and 3 ; - Figure 5

- shows schematically an alternative embodiment of the sink from Figure 1, partly in section;

- Figure 6

- shows an alternative sink shape with overflow trough; and

- Figure 7

- shows another alternative sink shape with separate spout.

In

Im Bereich der Öffnung 10 ist außen an der Beckenwand 3 der sogenannte Überlaufkopf 11 eines an sich bekannten Überlaufs 12 montiert, über welchen Überlauf 12 Wasser 8 aus dem Spülenbecken 2 zum Spülenablauf 6 fließen kann, wenn der Wasserspiegel 9 innerhalb des Spülenbeckens 2 einen gewissen Pegelstand erreicht bzw. überschreitet. Der Überlauf 12 umfasst, neben dem bereits erwähnten Überlaufkopf 11, eine Einlauföffnung 13 im Bereich des Überlaufkopfes 11, welche Einlauföffnung 13 mit der bereits erwähnten Öffnung 10 in der Beckenwand 3 des Spülenbeckens 2 kommuniziert. Um die Einlauföffnung 13 herum ist regelmäßig eine Dichtung angeordnet, um den Überlaufkopf 11 fluiddicht gegenüber der Beckenwand 3 abzudichten. Diese Dichtung ist in

Die bislang anhand von

Der Überlaufkopf 11' gemäß

Beispielsweise können die Durchbrüche/Bohrungen 20.1 - 20.4 auch unterschiedliche Durchmesser D aufweisen, und es können mehr oder weniger als die vier dargestellten Durchbrüche/Bohrungen 20.1 - 20.4 vorhanden sein. Außerdem können diese erfindungsgemäß nebeneinander, nach Art eines Dreiecks, versetzt oder im Zick-Zack angeordnet sein, oder nach Art eines Quadrats oder dergleichen. Alternativ kann abweichend von der Erfindung nur ein einziger derartiger Durchbruch vorhanden sein. Wesentlich ist in jedem Fall, dass der Durchbruch oder erfindungsgemäß die Durchbrüche einen in etwa kreisrunden Durchmesser aufweist bzw. aufweisen, obwohl der Anschlussstutzen 21 des Überlaufkopfes 11 bzw. dessen Einlauföffnung 13 eine hiervon abweichende Geometrie (oval bzw. rechteckig) aufweist. Die Anmelderin hat herausgefunden, dass durch das Vorhandensein von kreisrunden Strömungskanal-Abschnitten ein deutlich verbessertes Fließverhalten des überlaufenden Wassers im Bereich des Überlaufs auftritt, vergleichbar mit dem verbesserten Auslaufen von Wasser aus einer über Kopf gehaltenen Flasche, wenn diese zugleich in Rotation um die Flaschenlängsachse versetzt wird.For example, the openings / bores 20.1-20.4 can also have different diameters D, and there may be more or fewer than the four openings / bores 20.1-20.4 shown. In addition, according to the invention, these can be arranged next to one another, in the manner of a triangle, offset or arranged in a zigzag, or in the manner of a square or the like. Alternatively, in contrast to the invention, only one such breakthrough can be present. It is essential in any case that the opening or, according to the invention, the openings have or have an approximately circular diameter, although the connecting

Die Durchbrüche/Bohrungen 20.1 - 20.4 können im Bereich der Einlauföffnung 13 und/oder im Bereich eines freien (unteren) Endes des Anschlussstutzens 21 eine endständige Aufweitung aufweisen, wie in

In Teilabbildung 4a) ist der Überlaufkopf 11' in einer seitlichen Ansicht entsprechend

In Teilabbildung 4b) ist der der Überlaufkopf 11' in einer Ansicht von vorne gezeigt. Gut erkennbar ist die verstärkte Struktur 17 mit Montagebohrung 18 sowie die umlaufende Dichtfläche 16.Part 4b) shows the overflow head 11 'in a view from the front. The reinforced

Teilabbildung 4c) verdeutlicht die Lage einer Schnittlinie B-B, welcher entsprechend der Überlaufkopf 11' in der Schnittansicht gemäß Teilabbildung 4d) dargestellt ist. Gut erkennbar ist in

Wie der Fachmann erkennt, könnte der wenigstens eine Strömungskanal-Abschnitt 20.5 alternativ auch im Bereich des ersten Rohrteils 14.2 und/oder des zweiten Rohrteils 14.3 angeordnet sein. In allen diesen Fällen lässt sich die vorliegend vorgeschlagene Verbesserung im Bereich eines (Spülen-)Überlaufs auch durch entsprechende Nachrüstung eines bereits bestehenden Überlaufs bei einer bereits bestehenden Spüle realisieren, indem beispielsweise ein entsprechendes Rohr- oder Winkelteil 14.1 - 14.3 nachträglich eingebaut oder ein entsprechender Einsatz bei einem bestehenden Überlauf eingesetzt wird. Gleiches gilt auch hinsichtlich des Überlaufkopfes 11', der einen bestehenden, vorbekannten Überlaufkopf 11 ersetzen kann.As the person skilled in the art recognizes, the at least one flow channel section 20.5 could alternatively also be arranged in the region of the first pipe part 14.2 and / or the second pipe part 14.3. In all of these cases, the proposed improvement in the area of a (sink) overflow can also be achieved by retrofitting an existing overflow in an existing sink, for example by retrofitting a corresponding pipe or angle part 14.1 - 14.3 or using it accordingly is used in an existing overflow. The same applies to the overflow head 11 ', which can replace an existing, known overflow head 11.

Ohne Beschränkung hat es sich als besonders günstig erwiesen, wenn der genannte Durchmesser D der Durchbrüche/Bohrungen im Bereich von 2 bis 35 mm liegt, wobei bei kleineren Durchmessern D eine entsprechende Mehrzahl an Durchbrüchen vorzusehen sein wird. Die Anmelderin hat herausgefunden, dass ein über alle Durchbrüche bzw. Bohrungen summierter Mindestquerschnitt im Bereich von etwa 150 mm2 bis etwa 200 mm2, vorzugsweise etwa 175 mm2, liegen sollte. Eine bevorzugte Länge L der Durchbrüche/Bohrungen beträgt etwa 5 bis 150 mm und kann vom gewählten Durchmesser D abhängig sein: L = f · D, wobei f = f(D) einen Wert zwischen etwa 2 und etwa 5 annehmen kann.Without limitation, it has proven to be particularly advantageous if the diameter D of the openings / bores mentioned is in the range from 2 to 35 mm, with a corresponding plurality of openings having to be provided for smaller diameters D. The applicant has found that a minimum cross section summed over all openings or bores should be in the range from approximately 150 mm 2 to approximately 200 mm 2 , preferably approximately 175 mm 2 . A preferred length L of the openings / bores is approximately 5 to 150 mm and can depend on the selected diameter D: L = f · D, where f = f (D) can have a value between approximately 2 and approximately 5.

Die Erfindung ist nicht auf die Anwendung im Bereich eines Spülenbeckens beschränkt, sondern sie kann alternativ oder zusätzlich im Bereich einer sog. Überlaufmulde bzw. eines separaten Ausgusses Verwendung finden.The invention is not limited to use in the area of a sink, but can alternatively or additionally be used in the area of a so-called overflow trough or a separate spout.

Selbstverständlich kann ein erfindungsgemäßer Überlauf bei den Spülen 1', 1" gemäß

Claims (11)

- Overflow (12, 12') for a sink (1, 1', 1"), having at least one inlet opening (13) which is intended for mounting on a basin (2) or an overflow tray (2') or a separate drain outlet (2") of the sink (1, 1', 1"), and having an outlet opening (15) which is intended for mounting at an outlet (6) or venting valve of the sink (1, 1', 1"), wherein between the inlet opening (13) and the outlet opening (15) there is arranged a flow channel (14a) for a fluid (8), there being provided in the flow channel (14a) at least one section (20.1-20.4; 20.5) in which the flow channel (14a) has a substantially circular cross-section,

characterised in that

a plurality of such sections of circular cross-section (20.1-20.4) are arranged in parallel in the flow channel (14a), the sections (20.1-20.4) being arranged one next to the other, triangle-like, offset or in a zig-zag, in each case in relation to the position of their centre points. - Overflow (12, 12') according to claim 1, characterised in that the flow channel (14a) has, in the sections, a constant cross-section.

- Overflow (12, 12') according to claim 1, characterised in that the flow channel (14a) has, in the sections, at least one tapering of its cross-section in the direction of flow of the fluid (8).

- Overflow (12, 12') according to any one of claims 1 to 3, characterised in that the sections have a length L, for which the following applies:

L ≥ f x D, 2 ≤ f ≤ 5, if D denotes a diameter of the section, f denotes a factor, and wherein preferably 2 mm ≤ D ≤ 35 mm. - Overflow (12, 12') according to claim 4, characterised in that a sum of the cross-sections of the sections (20.1-20.4) is at least approximately 175 mm2.

- Overflow (12, 12') according to any one of claims 1 to 5, characterised in that the sections (20.1-20.4) are arranged in the region of the inlet opening (13).

- Overflow (12, 12') according to any one of claims 1 to 6, characterised in that the sections (20.1-20.4) are arranged in the region of an overflow head (11') of the overflow.

- Overflow (12, 12') according to any one of claims 1 to 5, characterised in that the sections are arranged in the region of the outlet opening (15).

- Overflow (12, 12') according to any one of claims 1 to 5 or claim 8, characterised in that the sections are arranged in the region of an angle piece (14.1) of the flow channel (14a), which angle piece (14.1) provides a transition from a first section (14.2) of the flow channel (14a), which first section is vertical when mounted, to a second section (14.3) of the flow channel (14a), which second section is horizontal when mounted.

- Overflow (12, 12') according to claim 9, characterised in that the sections are arranged in the region of the second section (14.3).

- Sink (1, 1', 1") having at least one overflow (12, 12') which comprises an opening (10) in a side wall (3) of a basin (2) or an opening in a horizontal surface of the sink, preferably in the region of an overflow tray (2') or a separate drain outlet (2"), which opening (10) is in fluidic communication with an outlet of the sink (1) via the overflow (12, 12'),

characterised in that

the overflow (12, 12') is constructed in accordance with any one of claims 1 to 10.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016100338.7A DE102016100338A1 (en) | 2016-01-11 | 2016-01-11 | Overflow for a pool, especially sinks |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3199715A2 EP3199715A2 (en) | 2017-08-02 |

| EP3199715A3 EP3199715A3 (en) | 2017-10-18 |

| EP3199715B1 true EP3199715B1 (en) | 2020-03-25 |

Family

ID=57286283

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16197956.2A Active EP3199715B1 (en) | 2016-01-11 | 2016-11-09 | Overflow for a basin, in particular rinsing basin |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3199715B1 (en) |

| CN (1) | CN106958274B (en) |

| CH (1) | CH711775B1 (en) |

| DE (1) | DE102016100338A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6490168B1 (en) * | 2017-09-12 | 2019-03-27 | 吉本産業株式会社 | Basin |

| CN111677060A (en) * | 2020-07-07 | 2020-09-18 | 临海市朵纳卫浴有限公司 | Water tank for splicing rock plate table top |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US746419A (en) * | 1902-10-13 | 1903-12-08 | James J Wade | Basin or bath fitting. |

| DE1961497U (en) * | 1967-01-07 | 1967-06-01 | Franz Scheffer Fa | ON-SITE ADAPTABLE DRAIN FITTING. |

| BE795796A (en) * | 1972-03-27 | 1973-06-18 | Gebert & Cie | DISCHARGE DEVICE FOR TUBS |

| DE9202872U1 (en) * | 1992-03-05 | 1992-05-21 | Fa. Franz Viegener Ii, 5952 Attendorn, De | |

| CN2312256Y (en) * | 1997-11-03 | 1999-03-31 | 和宏实业有限公司 | Water overflow means for washbasin |

| US6249920B1 (en) * | 1998-05-07 | 2001-06-26 | Mcguire Manufacturing Co., Inc. | Grid drain |

| US20080196161A1 (en) * | 2004-10-22 | 2008-08-21 | Wcm Industries, Inc. | Flexible Bathtub Waste Pipe Assembly for Bathtubs and the Like |

| DE102007014839A1 (en) * | 2007-03-28 | 2008-10-02 | Niro-Plan Ag | kitchen sink |

| JP5756937B2 (en) * | 2009-09-30 | 2015-07-29 | 丸一株式会社 | Remote-controlled drain plug device |

| CN101824844A (en) * | 2010-04-01 | 2010-09-08 | 宁波搏盛阀门管件有限公司 | Sink and sink overflow device |

| CN202018306U (en) * | 2011-03-29 | 2011-10-26 | 温州市捷达石化仪表有限公司 | Porous balance flow meter |

-

2016

- 2016-01-11 DE DE102016100338.7A patent/DE102016100338A1/en not_active Withdrawn

- 2016-01-15 CH CH00058/16A patent/CH711775B1/en not_active IP Right Cessation

- 2016-11-09 EP EP16197956.2A patent/EP3199715B1/en active Active

- 2016-12-09 CN CN201611129358.XA patent/CN106958274B/en not_active Expired - Fee Related

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102016100338A1 (en) | 2017-07-13 |

| CH711775B1 (en) | 2017-05-15 |

| CN106958274B (en) | 2020-12-04 |

| CN106958274A (en) | 2017-07-18 |

| EP3199715A3 (en) | 2017-10-18 |

| EP3199715A2 (en) | 2017-08-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2508686B1 (en) | Retention assembly for precipitation and waste water | |

| EP3199715B1 (en) | Overflow for a basin, in particular rinsing basin | |

| DE202014007392U1 (en) | Water outlet with multiple siphon trap | |

| EP1812167B1 (en) | Jet outlet element for sanitary fittings | |

| EP2157249B1 (en) | Drainage fitting with odour trap | |

| EP2157247B1 (en) | Drain outlet | |

| EP3222357B2 (en) | Sludge separator | |

| DE202018103156U1 (en) | Wasserauslassvorrichtung | |

| EP2871294B1 (en) | Inlet valve for a cistern | |

| DE10360310A1 (en) | draining device | |

| DE2159963B2 (en) | Cavitation-reducing throttle device | |

| EP3469158B1 (en) | Discharge valve | |

| EP1484453B1 (en) | Overflow and outlet device for sanitary apparatus | |

| DE3822555C2 (en) | ||

| DE102016101528A1 (en) | Scum deduction | |

| DE202021106357U1 (en) | Flush toilet | |

| EP3138969B1 (en) | Drain valve with flow current choke element | |

| DE102019125686A1 (en) | Drainage unit for draining surface water | |

| EP2995731A1 (en) | Water outlet with multiple siphon odour trap | |

| EP3421676B1 (en) | Odour seal element for installation in a drain, in particular the drain of a waterless urinal | |

| EP3485101B1 (en) | Drain sieve for a washbasin | |

| DE102017012291B3 (en) | Backflow preventer and safety fitting | |

| DE2822299A1 (en) | Flow regulator for fluid - has flexible walled chamber filled with low density fluid and acting as throttle valve | |

| DE102021117601A1 (en) | Washbasin for rooms with increased hygiene requirements and washbasin | |

| DE102014012288A1 (en) | Rainwater filter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E03C 1/232 20060101ALI20170914BHEP Ipc: E03C 1/18 20060101AFI20170914BHEP Ipc: E03C 1/24 20060101ALI20170914BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180418 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190712 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTC | Intention to grant announced (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAL | Information related to payment of fee for publishing/printing deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| INTG | Intention to grant announced |

Effective date: 20200103 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTC | Intention to grant announced (deleted) | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| INTG | Intention to grant announced |

Effective date: 20200207 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016009253 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1248706 Country of ref document: AT Kind code of ref document: T Effective date: 20200415 Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: VALIPAT S.A. C/O BOVARD SA NEUCHATEL, CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200625 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200625 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200325 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200725 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200818 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502016009253 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| 26N | No opposition filed |

Effective date: 20210112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502016009253 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20201109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201109 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210601 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200325 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1248706 Country of ref document: AT Kind code of ref document: T Effective date: 20211109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211109 |