EP3111153B1 - Tube d'échangeur de chaleur métallique - Google Patents

Tube d'échangeur de chaleur métallique Download PDFInfo

- Publication number

- EP3111153B1 EP3111153B1 EP15704718.4A EP15704718A EP3111153B1 EP 3111153 B1 EP3111153 B1 EP 3111153B1 EP 15704718 A EP15704718 A EP 15704718A EP 3111153 B1 EP3111153 B1 EP 3111153B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- channel

- heat exchanger

- additional structures

- ribs

- exchanger pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002184 metal Substances 0.000 title claims 2

- 239000000463 material Substances 0.000 claims description 15

- 239000012530 fluid Substances 0.000 claims description 12

- 239000007788 liquid Substances 0.000 description 21

- 238000001704 evaporation Methods 0.000 description 15

- 230000008020 evaporation Effects 0.000 description 15

- 238000000034 method Methods 0.000 description 13

- 239000011148 porous material Substances 0.000 description 11

- 230000008569 process Effects 0.000 description 10

- 238000012546 transfer Methods 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 7

- 230000011218 segmentation Effects 0.000 description 5

- 230000002349 favourable effect Effects 0.000 description 3

- 230000006911 nucleation Effects 0.000 description 3

- 238000010899 nucleation Methods 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003507 refrigerant Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 101100334009 Caenorhabditis elegans rib-2 gene Proteins 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 239000012267 brine Substances 0.000 description 1

- 230000005587 bubbling Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 238000005057 refrigeration Methods 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- HPALAKNZSZLMCH-UHFFFAOYSA-M sodium;chloride;hydrate Chemical compound O.[Na+].[Cl-] HPALAKNZSZLMCH-UHFFFAOYSA-M 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/34—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely

- F28F1/36—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely the means being helically wound fins or wire spirals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D21/0017—Flooded core heat exchangers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/42—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element

- F28F1/422—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element with outside means integral with the tubular element and inside means integral with the tubular element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/06—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by affecting the pattern of flow of the heat-exchange media

- F28F13/08—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by affecting the pattern of flow of the heat-exchange media by varying the cross-section of the flow channels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/18—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by applying coatings, e.g. radiation-absorbing, radiation-reflecting; by surface treatment, e.g. polishing

- F28F13/185—Heat-exchange surfaces provided with microstructures or with porous coatings

- F28F13/187—Heat-exchange surfaces provided with microstructures or with porous coatings especially adapted for evaporator surfaces or condenser surfaces, e.g. with nucleation sites

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F21/00—Constructions of heat-exchange apparatus characterised by the selection of particular materials

- F28F21/08—Constructions of heat-exchange apparatus characterised by the selection of particular materials of metal

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2339/00—Details of evaporators; Details of condensers

- F25B2339/02—Details of evaporators

- F25B2339/024—Evaporators with refrigerant in a vessel in which is situated a heat exchanger

- F25B2339/0242—Evaporators with refrigerant in a vessel in which is situated a heat exchanger having tubular elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

- F25B39/02—Evaporators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D2021/0019—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for

- F28D2021/0061—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for for phase-change applications

- F28D2021/0064—Vaporizers, e.g. evaporators

Definitions

- EP 1 223 400 B1 It is proposed to produce at the groove bottom between the ribs undercut secondary grooves which extend continuously along the primary groove.

- the cross section of these secondary grooves can remain constant or varied at regular intervals.

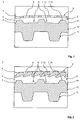

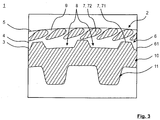

- the invention includes a metallic heat exchanger tube having integrally ribbed, ribbed and ribbed ribs formed on the tube exterior, the rib stem projecting substantially radially from the tube wall and a channel formed between the ribs in which spaced apart additional structures are disposed.

- the additional structures divide the channel between the ribs into segments.

- the additional structures locally reduce the flow-through cross-sectional area in the channel between two ribs by at least 60% and at least limit a fluid flow in the channel during operation.

- the combination of the segments according to the invention with a channel which is closed except for pores or slots gives a structure which has a very high efficiency in the evaporation of liquids over a very wide range of operating conditions.

- the heat transfer coefficient of the structure reaches a consistently high level.

- the first additional structures may be outwardly projecting radially outward protrusions from the channel bottom.

- the exchange of liquid and steam is determined locally.

- the segmentation of the channel over the groove base is particularly favorable for the evaporation process, since the excess temperature is greatest at the bottom of the groove and therefore there is the highest driving temperature difference for the bubble formation available.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Geometry (AREA)

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Claims (15)

- Tube d'échangeur de chaleur métallique (1), comprenant des nervures (2) intégrales faisant saillie sur la face extérieure du tube et pourvues d'une base de nervure (3), de flancs de nervure (4) et d'une pointe de nervure (5), dans lequel la base de nervure (3) fait saillie sensiblement radialement de la paroi du tube et un canal (6), dans lequel des structures additionnelles (7, 71, 72) espacées les unes des autres sont agencées, lesquelles sont agencées au moins en partie de manière à partir de la base (61) du canal et s'étendent transversalement à l'étendue du canal (6), est formé entre les nervures (2),

caractérisé- en ce que les structures additionnelles (7, 71, 72) divisent le canal (6) entre les nervures (2) en segments (8), et- en ce que les structures additionnelles (7, 71, 72) réduisent la superficie de section pouvant être traversée dans le canal (6) entre deux nervures (2) localement d'au moins 60 % et délimitent au moins de ce fait, durant l'utilisation, un écoulement de fluide dans le canal (6). - Tube d'échangeur de chaleur métallique (1) selon la revendication 1, caractérisé en ce que les structures additionnelles (7, 71, 72) réduisent la superficie de section pouvant être traversée dans le canal (6) entre deux nervures (2) localement d'au moins 80 %.

- Tube d'échangeur de chaleur métallique (1) selon la revendication 2, caractérisé en ce que les structures additionnelles (7, 71, 72) isolent complètement localement la superficie de section pouvant être traversée dans le canal (6) entre deux nervures (2).

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 3, caractérisé en ce que le canal (6) est fermé radialement vers l'extérieur jusqu'à différents orifices locaux (9).

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 4, caractérisé en ce qu'au moins un orifice local (9) est présent par segment (8).

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 5, caractérisé en ce que le quotient du nombre des orifices locaux (9) sur le nombre des segments (8) atteint 1/1 à 6/1.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 6, caractérisé en ce que les premières structures additionnelles (7, 71) sont des parties saillantes partant de la base (61) du canal et dirigées radialement vers l'extérieur.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 7, caractérisé en ce que les premières structures additionnelles (7, 71) font saillie au moins du matériau de la base (61) du canal entre deux nervures (2) intégralement périphériques.

- Tube d'échangeur de chaleur métallique (1) selon la revendication 8, caractérisé en ce que les premières structures additionnelles (7, 71) faisant saillie de la base (61) du canal présentent une hauteur comprise entre 0,15 et 1 mm.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 7, caractérisé en ce que des deuxièmes structures additionnelles (7, 72) font saillie au moins des flancs de nervure (4) ou des pointes de nervure (5) des nervures (2) intégralement périphériques par l'intermédiaire de parties saillantes latérales.

- Tube d'échangeur de chaleur métallique (1) selon la revendication 10, caractérisé en ce que les deuxièmes structures additionnelles (7, 72) font saillie au moins d'une nervure en allant de la pointe de nervure (5) en direction de la base (61) du canal.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 11, caractérisé en ce que les structures additionnelles (7) sont introduites au moins en partie par l'intermédiaire d'un matériau additionnel.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 12, caractérisé en ce que les structures additionnelles (7, 72) présentent des formes asymétriques.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 12, caractérisé en ce que les structures additionnelles (7, 71) présentent une section transversale trapézoïdale dans un plan de coupe s'étendant perpendiculairement à l'axe du tube.

- Tube d'échangeur de chaleur métallique (1) selon l'une quelconque des revendications 1 à 14, caractérisé en ce que la superficie de section respective dans le canal (6), pouvant être traversée et réduite par des structures additionnelles (7, 71), varie entre deux nervures (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL15704718T PL3111153T3 (pl) | 2014-02-27 | 2015-02-10 | Metalowa rura wymiennika ciepła |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102014002829.1A DE102014002829A1 (de) | 2014-02-27 | 2014-02-27 | Metallisches Wärmeaustauscherrohr |

| PCT/EP2015/000278 WO2015128061A1 (fr) | 2014-02-27 | 2015-02-10 | Tube d'échangeur de chaleur métallique |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3111153A1 EP3111153A1 (fr) | 2017-01-04 |

| EP3111153B1 true EP3111153B1 (fr) | 2019-04-24 |

Family

ID=52473867

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15704718.4A Active EP3111153B1 (fr) | 2014-02-27 | 2015-02-10 | Tube d'échangeur de chaleur métallique |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US11073343B2 (fr) |

| EP (1) | EP3111153B1 (fr) |

| JP (1) | JP6197121B2 (fr) |

| KR (1) | KR102367582B1 (fr) |

| CN (1) | CN106030233B (fr) |

| BR (1) | BR112016019767B1 (fr) |

| DE (1) | DE102014002829A1 (fr) |

| HU (1) | HUE044830T2 (fr) |

| MX (1) | MX2016006294A (fr) |

| PL (1) | PL3111153T3 (fr) |

| PT (1) | PT3111153T (fr) |

| TR (1) | TR201906855T4 (fr) |

| WO (1) | WO2015128061A1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202020005625U1 (de) | 2020-10-31 | 2021-11-10 | Wieland-Werke Aktiengesellschaft | Metallisches Wärmeaustauscherrohr |

| DE202020005628U1 (de) | 2020-10-31 | 2021-11-11 | Wieland-Werke Aktiengesellschaft | Metallisches Wärmeaustauscherrohr |

| WO2022089773A1 (fr) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Tube métallique d'échangeur de chaleur |

| WO2022089772A1 (fr) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Tube métallique d'échangeur de chaleur |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107421160B (zh) * | 2017-08-28 | 2020-11-10 | 华北电力大学(保定) | 一种高效可控冷却装置 |

Family Cites Families (78)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE791216A (fr) * | 1972-11-03 | 1973-05-10 | American Cyanamid Co | Revetement mural et son procede de preparation, |

| DE2808080C2 (de) * | 1977-02-25 | 1982-12-30 | Furukawa Metals Co., Ltd., Tokyo | Wärmeübertragungs-Rohr für Siedewärmetauscher und Verfahren zu seiner Herstellung |

| US4313248A (en) * | 1977-02-25 | 1982-02-02 | Fukurawa Metals Co., Ltd. | Method of producing heat transfer tube for use in boiling type heat exchangers |

| US4159739A (en) * | 1977-07-13 | 1979-07-03 | Carrier Corporation | Heat transfer surface and method of manufacture |

| US4179911A (en) * | 1977-08-09 | 1979-12-25 | Wieland-Werke Aktiengesellschaft | Y and T-finned tubes and methods and apparatus for their making |

| US4168618A (en) * | 1978-01-26 | 1979-09-25 | Wieland-Werke Aktiengesellschaft | Y and T-finned tubes and methods and apparatus for their making |

| US4324844A (en) * | 1980-04-28 | 1982-04-13 | Westinghouse Electric Corp. | Variable area fuel cell cooling |

| US4359086A (en) * | 1981-05-18 | 1982-11-16 | The Trane Company | Heat exchange surface with porous coating and subsurface cavities |

| US4438807A (en) * | 1981-07-02 | 1984-03-27 | Carrier Corporation | High performance heat transfer tube |

| JPS5946490A (ja) * | 1982-09-08 | 1984-03-15 | Kobe Steel Ltd | 沸騰型熱交換器用伝熱管 |

| US4549606A (en) * | 1982-09-08 | 1985-10-29 | Kabushiki Kaisha Kobe Seiko Sho | Heat transfer pipe |

| JPS5984095A (ja) * | 1982-11-04 | 1984-05-15 | Hitachi Ltd | 熱交換壁 |

| JPS5993190A (ja) * | 1982-11-17 | 1984-05-29 | Hitachi Ltd | 熱交換壁 |

| US4577381A (en) * | 1983-04-01 | 1986-03-25 | Kabushiki Kaisha Kobe Seiko Sho | Boiling heat transfer pipes |

| JPS6064196A (ja) * | 1983-09-19 | 1985-04-12 | Hitachi Cable Ltd | 蒸発伝熱壁 |

| US4653163A (en) * | 1984-09-14 | 1987-03-31 | Hitachi, Ltd. | Method for producing a heat transfer wall for vaporizing liquids |

| JPS6189497A (ja) * | 1984-10-05 | 1986-05-07 | Hitachi Ltd | 伝熱管 |

| US4660630A (en) * | 1985-06-12 | 1987-04-28 | Wolverine Tube, Inc. | Heat transfer tube having internal ridges, and method of making same |

| DE3664959D1 (en) | 1985-10-31 | 1989-09-14 | Wieland Werke Ag | Finned tube with a notched groove bottom and method for making it |

| US4819719A (en) * | 1987-01-20 | 1989-04-11 | Mcdonnell Douglas Corporation | Enhanced evaporator surface |

| US4866830A (en) * | 1987-10-21 | 1989-09-19 | Carrier Corporation | Method of making a high performance, uniform fin heat transfer tube |

| US4921042A (en) * | 1987-10-21 | 1990-05-01 | Carrier Corporation | High performance heat transfer tube and method of making same |

| US4799543A (en) * | 1987-11-12 | 1989-01-24 | Arthur H. Iversen | Means for temperature control of heated surfaces |

| JPH0495453A (ja) * | 1990-08-10 | 1992-03-27 | Matsushita Electric Ind Co Ltd | ハウス管理システム |

| JP2788793B2 (ja) * | 1991-01-14 | 1998-08-20 | 古河電気工業株式会社 | 伝熱管 |

| JP2730824B2 (ja) * | 1991-07-09 | 1998-03-25 | 三菱伸銅株式会社 | 内面溝付伝熱管およびその製造方法 |

| US5203404A (en) * | 1992-03-02 | 1993-04-20 | Carrier Corporation | Heat exchanger tube |

| DE4301668C1 (de) * | 1993-01-22 | 1994-08-25 | Wieland Werke Ag | Wärmeaustauschwand, insbesondere für Sprühverdampfung |

| KR0134557B1 (ko) * | 1993-07-07 | 1998-04-28 | 가메다카 소키치 | 유하액막식 증발기용 전열관 |

| US6067712A (en) * | 1993-12-15 | 2000-05-30 | Olin Corporation | Heat exchange tube with embossed enhancement |

| US5415225A (en) * | 1993-12-15 | 1995-05-16 | Olin Corporation | Heat exchange tube with embossed enhancement |

| DE4404357C2 (de) * | 1994-02-11 | 1998-05-20 | Wieland Werke Ag | Wärmeaustauschrohr zum Kondensieren von Dampf |

| US5482744A (en) * | 1994-02-22 | 1996-01-09 | Star Fabrication Limited | Production of heat transfer element |

| US5597039A (en) * | 1994-03-23 | 1997-01-28 | High Performance Tube, Inc. | Evaporator tube |

| US5832995A (en) * | 1994-09-12 | 1998-11-10 | Carrier Corporation | Heat transfer tube |

| DE69525594T2 (de) | 1994-11-17 | 2002-08-22 | Carrier Corp., Syracuse | Wärmeaustauschrohr |

| JP3323682B2 (ja) * | 1994-12-28 | 2002-09-09 | 株式会社日立製作所 | 混合冷媒用内面クロス溝付き伝熱管 |

| US5697430A (en) | 1995-04-04 | 1997-12-16 | Wolverine Tube, Inc. | Heat transfer tubes and methods of fabrication thereof |

| US6427767B1 (en) * | 1997-02-26 | 2002-08-06 | American Standard International Inc. | Nucleate boiling surface |

| US5933953A (en) * | 1997-03-17 | 1999-08-10 | Carrier Corporation | Method of manufacturing a heat transfer tube |

| DE19757526C1 (de) * | 1997-12-23 | 1999-04-29 | Wieland Werke Ag | Verfahren zur Herstellung eines Wärmeaustauschrohres, insbesondere zur Verdampfung von Flüssigkeiten aus Reinstoffen oder Gemischen auf der Rohraußenseite |

| US6176302B1 (en) * | 1998-03-04 | 2001-01-23 | Kabushiki Kaisha Kobe Seiko Sho | Boiling heat transfer tube |

| MY121045A (en) * | 1998-03-13 | 2005-12-30 | Kobe Steel Ltd | Falling film type heat exchanger tube. |

| CN1161586C (zh) * | 1998-12-25 | 2004-08-11 | 株式会社神户制钢所 | 内表面带槽管及其生产方法 |

| DE10024682C2 (de) * | 2000-05-18 | 2003-02-20 | Wieland Werke Ag | Wärmeaustauscherrohr zur Verdampfung mit unterschiedlichen Porengrößen |

| AU2001288633A1 (en) * | 2000-09-01 | 2002-03-13 | Api Heat Transfer Inc. | Finned heat exchange tube and process for forming same |

| CA2426678A1 (fr) * | 2000-10-19 | 2002-04-25 | Ibc Corporation | Ailette effilee et son procede de formation |

| DE10101589C1 (de) | 2001-01-16 | 2002-08-08 | Wieland Werke Ag | Wärmeaustauscherrohr und Verfahren zu dessen Herstellung |

| US20020096314A1 (en) * | 2001-01-25 | 2002-07-25 | Carrier Corporation | High performance micro-rib tube |

| DE10159860C2 (de) * | 2001-12-06 | 2003-12-04 | Sdk Technik Gmbh | Wärmeübertragungsfläche mit einer aufgalvanisierten Mikrostruktur von Vorsprüngen |

| CA2489104C (fr) * | 2002-06-10 | 2011-10-18 | Wolverine Tube, Inc. | Methode de fabrication d'un tube |

| US7254964B2 (en) | 2004-10-12 | 2007-08-14 | Wolverine Tube, Inc. | Heat transfer tubes, including methods of fabrication and use thereof |

| EP1802932B1 (fr) * | 2004-10-22 | 2009-06-03 | Aleris Aluminum Koblenz GmbH | Tube en produit metallique profile et procede de production |

| CN100365369C (zh) * | 2005-08-09 | 2008-01-30 | 江苏萃隆铜业有限公司 | 蒸发器热交换管 |

| CN100458344C (zh) * | 2005-12-13 | 2009-02-04 | 金龙精密铜管集团股份有限公司 | 一种电制冷满液式机组用铜冷凝换热管 |

| CN100437011C (zh) * | 2005-12-13 | 2008-11-26 | 金龙精密铜管集团股份有限公司 | 一种电制冷机组用满液式铜蒸发换热管 |

| CN100498187C (zh) * | 2007-01-15 | 2009-06-10 | 高克联管件(上海)有限公司 | 一种蒸发冷凝兼备型传热管 |

| US20080236803A1 (en) * | 2007-03-27 | 2008-10-02 | Wolverine Tube, Inc. | Finned tube with indentations |

| CN101338987B (zh) * | 2007-07-06 | 2011-05-04 | 高克联管件(上海)有限公司 | 一种冷凝用传热管 |

| US8505497B2 (en) * | 2007-11-13 | 2013-08-13 | Dri-Steem Corporation | Heat transfer system including tubing with nucleation boiling sites |

| CN101338959B (zh) * | 2008-01-11 | 2011-06-08 | 高克联管件(上海)有限公司 | 一种高效的壳管式冷凝器 |

| CN100547339C (zh) * | 2008-03-12 | 2009-10-07 | 江苏萃隆精密铜管股份有限公司 | 一种强化传热管及其制作方法 |

| DE102008013929B3 (de) * | 2008-03-12 | 2009-04-09 | Wieland-Werke Ag | Verdampferrohr mit optimierten Hinterschneidungen am Nutengrund |

| US9844807B2 (en) * | 2008-04-16 | 2017-12-19 | Wieland-Werke Ag | Tube with fins having wings |

| US9038710B2 (en) * | 2008-04-18 | 2015-05-26 | Wieland-Werke Ag | Finned tube for evaporation and condensation |

| DE102009007446B4 (de) * | 2009-02-04 | 2012-03-29 | Wieland-Werke Ag | Wärmeübertragerrohr und Verfahren zu dessen Herstellung |

| US20100282456A1 (en) * | 2009-05-06 | 2010-11-11 | General Electric Company | Finned tube heat exchanger |

| DE102009021334A1 (de) * | 2009-05-14 | 2010-11-18 | Wieland-Werke Ag | Metallisches Wärmeaustauscherrohr |

| JP4638951B2 (ja) * | 2009-06-08 | 2011-02-23 | 株式会社神戸製鋼所 | 熱交換用の金属プレート及び熱交換用の金属プレートの製造方法 |

| US20110083619A1 (en) * | 2009-10-08 | 2011-04-14 | Master Bashir I | Dual enhanced tube for vapor generator |

| DE102009060395A1 (de) * | 2009-12-22 | 2011-06-30 | Wieland-Werke AG, 89079 | Wärmeübertragerrohr und Verfahren zur Herstellung eines Wämeübertragerrohrs |

| US20120325443A1 (en) * | 2010-03-11 | 2012-12-27 | Sumitomo Heavy Industries Process Equipment Co., Ltd. | Tube Type Heat Exchanger and Manufacturing Method of the Same |

| CN102589337B (zh) * | 2011-01-13 | 2016-02-03 | 摩丁制造公司 | 热交换管及使用该热交换管的方法 |

| CN102679791B (zh) * | 2011-03-10 | 2015-09-23 | 卢瓦塔埃斯波公司 | 用于热交换器的传热管 |

| CN102121805A (zh) * | 2011-04-07 | 2011-07-13 | 金龙精密铜管集团股份有限公司 | 降膜蒸发器用强化传热管 |

| CN102130622A (zh) * | 2011-04-07 | 2011-07-20 | 上海威特力焊接设备制造股份有限公司 | 一种高效率光伏逆变器 |

| DE102011121436A1 (de) * | 2011-12-16 | 2013-06-20 | Wieland-Werke Ag | Verflüssigerrohre mit zusätzlicher Flankenstruktur |

| DE102011121733A1 (de) * | 2011-12-21 | 2013-06-27 | Wieland-Werke Ag | Verdampferrohr mit optimierter Außenstruktur |

-

2014

- 2014-02-27 DE DE102014002829.1A patent/DE102014002829A1/de not_active Withdrawn

-

2015

- 2015-02-10 PL PL15704718T patent/PL3111153T3/pl unknown

- 2015-02-10 PT PT15704718T patent/PT3111153T/pt unknown

- 2015-02-10 WO PCT/EP2015/000278 patent/WO2015128061A1/fr active Application Filing

- 2015-02-10 BR BR112016019767-4A patent/BR112016019767B1/pt active IP Right Grant

- 2015-02-10 MX MX2016006294A patent/MX2016006294A/es active IP Right Grant

- 2015-02-10 TR TR2019/06855T patent/TR201906855T4/tr unknown

- 2015-02-10 EP EP15704718.4A patent/EP3111153B1/fr active Active

- 2015-02-10 CN CN201580002855.0A patent/CN106030233B/zh active Active

- 2015-02-10 US US15/103,193 patent/US11073343B2/en active Active

- 2015-02-10 JP JP2016537534A patent/JP6197121B2/ja active Active

- 2015-02-10 KR KR1020167014382A patent/KR102367582B1/ko active IP Right Grant

- 2015-02-10 HU HUE15704718 patent/HUE044830T2/hu unknown

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202020005625U1 (de) | 2020-10-31 | 2021-11-10 | Wieland-Werke Aktiengesellschaft | Metallisches Wärmeaustauscherrohr |

| DE202020005628U1 (de) | 2020-10-31 | 2021-11-11 | Wieland-Werke Aktiengesellschaft | Metallisches Wärmeaustauscherrohr |

| WO2022089773A1 (fr) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Tube métallique d'échangeur de chaleur |

| WO2022089772A1 (fr) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Tube métallique d'échangeur de chaleur |

Also Published As

| Publication number | Publication date |

|---|---|

| CN106030233B (zh) | 2019-06-21 |

| CN106030233A (zh) | 2016-10-12 |

| BR112016019767B1 (pt) | 2020-12-08 |

| BR112016019767A2 (pt) | 2017-10-24 |

| US11073343B2 (en) | 2021-07-27 |

| JP2017501362A (ja) | 2017-01-12 |

| HUE044830T2 (hu) | 2019-11-28 |

| US20160305717A1 (en) | 2016-10-20 |

| PT3111153T (pt) | 2019-07-30 |

| TR201906855T4 (tr) | 2019-05-21 |

| EP3111153A1 (fr) | 2017-01-04 |

| MX2016006294A (es) | 2016-12-08 |

| KR20160125348A (ko) | 2016-10-31 |

| DE102014002829A1 (de) | 2015-08-27 |

| KR102367582B1 (ko) | 2022-02-25 |

| WO2015128061A1 (fr) | 2015-09-03 |

| PL3111153T3 (pl) | 2019-09-30 |

| JP6197121B2 (ja) | 2017-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10101589C1 (de) | Wärmeaustauscherrohr und Verfahren zu dessen Herstellung | |

| DE69302668T2 (de) | Wärmetauscherrohr | |

| DE4404357C1 (de) | Wärmeaustauschrohr zum Kondensieren von Dampf | |

| EP3111153B1 (fr) | Tube d'échangeur de chaleur métallique | |

| EP2795233B1 (fr) | Tube pour évaporateur avec structure externe optimisée | |

| EP2101136B1 (fr) | Tube d'échangeur de chaleur métallique | |

| DE60303306T2 (de) | Wärmeübertragungsrohre und verfahren zur herstellung und verwendung davon | |

| EP2253922B1 (fr) | Tuyau d'échange thermique métallique | |

| DE10024682C2 (de) | Wärmeaustauscherrohr zur Verdampfung mit unterschiedlichen Porengrößen | |

| EP2791609B1 (fr) | Tuyaus pour condenseur avec structure de flanc complémentaire | |

| EP3465057B1 (fr) | Tube d'échangeur de chaleur | |

| EP3465056B1 (fr) | Tube échangeur de chaleur | |

| EP3465055B1 (fr) | Tube d'échangeur de chaleur | |

| EP3581871B1 (fr) | Tuyau d'échange thermique métallique | |

| EP4237782B1 (fr) | Tube métallique d'échangeur de chaleur | |

| EP4237781B1 (fr) | Tube métallique d'échangeur de chaleur | |

| DE202020005628U1 (de) | Metallisches Wärmeaustauscherrohr | |

| DE202020005625U1 (de) | Metallisches Wärmeaustauscherrohr |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20160714 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20181123 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1124641 Country of ref document: AT Kind code of ref document: T Effective date: 20190515 Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015008794 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 3111153 Country of ref document: PT Date of ref document: 20190730 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20190723 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E044830 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190725 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190824 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502015008794 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20200127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200210 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1124641 Country of ref document: AT Kind code of ref document: T Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20231212 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20240111 Year of fee payment: 10 Ref country code: DE Payment date: 20240229 Year of fee payment: 10 Ref country code: PT Payment date: 20240211 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240209 Year of fee payment: 10 Ref country code: PL Payment date: 20231212 Year of fee payment: 10 Ref country code: IT Payment date: 20240111 Year of fee payment: 10 |