EP3111153B1 - Metal heat exchanger tube - Google Patents

Metal heat exchanger tube Download PDFInfo

- Publication number

- EP3111153B1 EP3111153B1 EP15704718.4A EP15704718A EP3111153B1 EP 3111153 B1 EP3111153 B1 EP 3111153B1 EP 15704718 A EP15704718 A EP 15704718A EP 3111153 B1 EP3111153 B1 EP 3111153B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- channel

- heat exchanger

- additional structures

- ribs

- exchanger pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002184 metal Substances 0.000 title claims 2

- 239000000463 material Substances 0.000 claims description 15

- 239000012530 fluid Substances 0.000 claims description 12

- 239000007788 liquid Substances 0.000 description 21

- 238000001704 evaporation Methods 0.000 description 15

- 230000008020 evaporation Effects 0.000 description 15

- 238000000034 method Methods 0.000 description 13

- 239000011148 porous material Substances 0.000 description 11

- 230000008569 process Effects 0.000 description 10

- 238000012546 transfer Methods 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 7

- 230000011218 segmentation Effects 0.000 description 5

- 230000002349 favourable effect Effects 0.000 description 3

- 230000006911 nucleation Effects 0.000 description 3

- 238000010899 nucleation Methods 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003507 refrigerant Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 101100334009 Caenorhabditis elegans rib-2 gene Proteins 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 239000012267 brine Substances 0.000 description 1

- 230000005587 bubbling Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 238000005057 refrigeration Methods 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- HPALAKNZSZLMCH-UHFFFAOYSA-M sodium;chloride;hydrate Chemical compound O.[Na+].[Cl-] HPALAKNZSZLMCH-UHFFFAOYSA-M 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/34—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely

- F28F1/36—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely the means being helically wound fins or wire spirals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D21/0017—Flooded core heat exchangers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/42—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element

- F28F1/422—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element with outside means integral with the tubular element and inside means integral with the tubular element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/06—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by affecting the pattern of flow of the heat-exchange media

- F28F13/08—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by affecting the pattern of flow of the heat-exchange media by varying the cross-section of the flow channels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/18—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by applying coatings, e.g. radiation-absorbing, radiation-reflecting; by surface treatment, e.g. polishing

- F28F13/185—Heat-exchange surfaces provided with microstructures or with porous coatings

- F28F13/187—Heat-exchange surfaces provided with microstructures or with porous coatings especially adapted for evaporator surfaces or condenser surfaces, e.g. with nucleation sites

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F21/00—Constructions of heat-exchange apparatus characterised by the selection of particular materials

- F28F21/08—Constructions of heat-exchange apparatus characterised by the selection of particular materials of metal

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2339/00—Details of evaporators; Details of condensers

- F25B2339/02—Details of evaporators

- F25B2339/024—Evaporators with refrigerant in a vessel in which is situated a heat exchanger

- F25B2339/0242—Evaporators with refrigerant in a vessel in which is situated a heat exchanger having tubular elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

- F25B39/02—Evaporators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D2021/0019—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for

- F28D2021/0061—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for for phase-change applications

- F28D2021/0064—Vaporizers, e.g. evaporators

Definitions

- EP 1 223 400 B1 It is proposed to produce at the groove bottom between the ribs undercut secondary grooves which extend continuously along the primary groove.

- the cross section of these secondary grooves can remain constant or varied at regular intervals.

- the invention includes a metallic heat exchanger tube having integrally ribbed, ribbed and ribbed ribs formed on the tube exterior, the rib stem projecting substantially radially from the tube wall and a channel formed between the ribs in which spaced apart additional structures are disposed.

- the additional structures divide the channel between the ribs into segments.

- the additional structures locally reduce the flow-through cross-sectional area in the channel between two ribs by at least 60% and at least limit a fluid flow in the channel during operation.

- the combination of the segments according to the invention with a channel which is closed except for pores or slots gives a structure which has a very high efficiency in the evaporation of liquids over a very wide range of operating conditions.

- the heat transfer coefficient of the structure reaches a consistently high level.

- the first additional structures may be outwardly projecting radially outward protrusions from the channel bottom.

- the exchange of liquid and steam is determined locally.

- the segmentation of the channel over the groove base is particularly favorable for the evaporation process, since the excess temperature is greatest at the bottom of the groove and therefore there is the highest driving temperature difference for the bubble formation available.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Geometry (AREA)

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Description

Die Erfindung betrifft ein metallisches Wärmeaustauscherrohr nach dem Oberbegriff des Anspruchs 1.The invention relates to a metallic heat exchanger tube according to the preamble of

Ein derartiger Wärmeaustauscherrohr ist zum Beispiel aus der

Verdampfung tritt in vielen Bereichen der Kälte- und Klimatechnik sowie in der Prozess- und Energietechnik auf. Häufig werden Rohrbündelwärmeaustauscher verwendet, in denen Flüssigkeiten von Reinstoffen oder Mischungen auf der Rohraußenseite verdampfen und dabei auf der Rohrinnenseite eine Sole oder Wasser abkühlen. Solche Apparate werden als überflutete Verdampfer bezeichnet.Evaporation occurs in many areas of refrigeration and air conditioning technology as well as in process and energy technology. Frequently, shell-and-tube heat exchangers are used in which liquids of pure substances or mixtures evaporate on the outside of the pipe, cooling a brine or water on the inside of the pipe. Such apparatuses are referred to as flooded evaporators.

Durch die Intensivierung des Wärmeübergangs auf der Rohraußen- und der Rohrinnenseite lässt sich die Größe der Verdampfer stark reduzieren. Hierdurch nehmen die Herstellungskosten solcher Apparate ab. Außerdem sinkt die notwendige Füllmenge an Kältemittel, die bei den mittlerweile überwiegend verwendeten chlorfreien Sicherheitskältemitteln einen nicht zu vernachlässigenden Kostenanteil an den gesamten Anlagekosten ausmachen kann. Zudem sind die heute üblichen Hochleistungsrohre bereits etwa um den Faktor vier leistungsfähiger als glatte Rohre gleichen Durchmessers.By intensifying the heat transfer on the pipe outside and inside the pipe, the size of the evaporator can be greatly reduced. As a result, the production costs of such apparatuses decrease. In addition, the necessary filling quantity of refrigerant, which can account for a not inconsiderable share of the total system costs in the now predominantly used chlorine-free safety refrigerants, drops. In addition, today's conventional high-performance pipes are already about four times more efficient than smooth pipes of the same diameter.

Die leistungsstärksten, kommerziell erhältlichen Rippenrohre für überflutete Verdampfer besitzen auf der Rohraußenseite eine Rippenstruktur mit einer Rippendichte von 55 bis 60 Rippen pro Zoll (

Weiterhin ist bekannt, dass leistungsgesteigerte Verdampfungsstrukturen bei gleichbleibender Rippenteilung auf der Rohraußenseite erzeugt werden können, indem man zusätzliche Strukturelemente im Bereich des Nutengrundes zwischen den Rippen einbringt.Furthermore, it is known that performance-enhanced evaporation structures can be produced with the same fin pitch on the outside of the tube by introducing additional structural elements in the region of the groove bottom between the ribs.

In

Zudem sind aus

Weitere Beispiele für Strukturen am Nutengrund sind in

Der Erfindung liegt die Aufgabe zugrunde, ein leistungsgesteigertes Wärmeaustauscherrohr zur Verdampfung von Flüssigkeiten auf der Rohraußenseite weiterzubilden.The invention has the object of developing a performance-enhanced heat exchanger tube for the evaporation of liquids on the outside of the tube.

Die Erfindung wird durch die Merkmale des Anspruchs 1 wiedergegeben. Die weiteren rückbezogenen Ansprüche betreffen vorteilhafte Aus- und Weiterbildungen der Erfindung.The invention is represented by the features of

Die Erfindung schließt ein metallisches Wärmeaustauscherrohr ein, mit auf der Rohraußenseite ausgeformten integralen Rippen mit Rippenfuß, Rippenflanken und Rippenspitze, wobei der Rippenfuß im Wesentlichen radial von der Rohrwandung absteht und zwischen den Rippen ein Kanal ausgebildet ist, in dem voneinander beabstandete Zusatzstrukturen angeordnet sind. Die Zusatzstrukturen unterteilen den Kanal zwischen den Rippen in Segmente. Die Zusatzstrukturen reduzieren die durchströmbare Querschnittsfläche im Kanal zwischen zwei Rippen lokal um mindestens 60 % und begrenzen zumindest dadurch im Betrieb einen Fluidfluss im Kanal.The invention includes a metallic heat exchanger tube having integrally ribbed, ribbed and ribbed ribs formed on the tube exterior, the rib stem projecting substantially radially from the tube wall and a channel formed between the ribs in which spaced apart additional structures are disposed. The additional structures divide the channel between the ribs into segments. The additional structures locally reduce the flow-through cross-sectional area in the channel between two ribs by at least 60% and at least limit a fluid flow in the channel during operation.

Diese metallischen Wärmeaustauscherrohre dienen insbesondere zur Verdampfung von Flüssigkeiten aus Reinstoffen oder Gemischen auf der Rohraußenseite.These metallic heat exchanger tubes are used in particular for the evaporation of liquids from pure substances or mixtures on the tube outside.

Derartig leistungsfähige Rohre können auf der Basis von integral gewalzten Rippenrohren hergestellt werden. Unter integral gewalzten Rippenrohren werden berippte Rohre verstanden, bei denen die Rippen aus dem Wandmaterial eines Glattrohres geformt wurden. Typische auf der Rohraußenseite ausgeformten integralen Rippen sind beispielsweise spiralig umlaufend und weisen einen Rippenfuß, Rippenflanken und Rippenspitze auf, wobei der Rippenfuß im Wesentlichen radial von der Rohrwandung absteht. Die Anzahl der Rippen wird durch Zählung aufeinanderfolgender Ausbuchtungen in axialer Richtung eines Rohres festgelegt.Such efficient tubes can be manufactured on the basis of integrally rolled finned tubes. Integrally rolled finned tubes are understood to mean finned tubes in which the fins are formed from the wall material of a smooth tube. Typical integral ribs formed on the outside of the pipe are, for example, spirally encircling and have a fin root, rib flanks and fin tip, wherein the rib root protrudes substantially radially from the pipe wall. The number of ribs is determined by counting successive bulges in the axial direction of a tube.

Es sind hierbei verschiedene Verfahren bekannt, mit denen die zwischen benachbarten Rippen befindlichen Kanäle derart verschlossen werden, dass Verbindungen zwischen Kanal und Umgebung in Form von Poren oder Schlitzen bleiben. Insbesondere werden solche im Wesentlichen geschlossene Kanäle durch Umbiegen oder Umlegen der Rippen, durch Spalten und Stauchen der Rippen oder durch Kerben und Stauchen der Rippen erzeugt.Here, various methods are known with which the channels located between adjacent ribs are closed in such a way that Connections between channel and environment remain in the form of pores or slits. In particular, such substantially closed channels are created by bending or flipping the ribs, splitting and upsetting the ribs, or notching and upsetting the ribs.

Die Erfindung geht dabei von der Überlegung aus, dass zur Erhöhung des Wärmeüberganges bei der Verdampfung der Rippenzwischenraum durch Zusatzstrukturen segmentiert wird. Die Zusatzstrukturen können dabei zumindest zum Teil aus Material der Rohrwandung massiv aus dem Kanalgrund geformt sein. Hierbei werden die Zusatzstrukturen bevorzugt in regelmäßigen Abständen ausgehend vom Kanalgrund angeordnet und erstrecken sich quer zum Kanalverlauf, ausgehend von einem Rippenfuß einer Rippe zum benachbart liegenden nächsten Rippenfuß. Die Zusatzstrukturen können sich ausgehend vom Rippenfuß radial auch bis zur Rippenflanke und darüber hinaus erstrecken. Mit anderen Worten: Die Zusatzstrukturen verlaufen, ausgehend vom Kanalgrund, beispielsweise als massive Materialauskragungen quer zur Primärnut und trennen diese, wie ein Wehr als nur bedingt überströmbare Querbarriere, in einzelne Segmente ab. Auf diese Weise wird die Primärnut als Kanal zumindest teilweise in regelmäßigen Abständen bereits vom Kanalgrund ausgehend unterteilt.The invention is based on the consideration that the rib gap is segmented by additional structures to increase the heat transfer during evaporation. The additional structures can be formed at least partially from material of the pipe wall solid from the channel bottom. In this case, the additional structures are preferably arranged at regular intervals starting from the channel base and extend transversely to the channel course, starting from a ribbed foot of a rib to the adjacent next ribbed foot. The additional structures can extend radially from the rib foot to the rib flank and beyond. In other words, the additional structures extend, starting from the channel bottom, for example, as massive material projections transversely to the primary groove and separate them, as a weir as only partially überströmbare cross-barrier, into individual segments. In this way, the primary groove is at least partially subdivided as a channel at regular intervals already starting from the channel base.

Hierdurch werden lokale Überhitzungen in den Zwischenräumen erzeugt und der Vorgang des Blasensiedens intensiviert. Die Bildung von Blasen findet dann in erster Linie innerhalb der Segmente statt und beginnt an Keimstellen. An diesen Keimstellen bilden sich zunächst kleine Gas- oder Dampfblasen. Wenn die anwachsende Blase eine bestimmte Größe erreicht hat, löst sie sich von der Oberfläche ab. Im Zuge der Blasenablösung wird der verbleibende Hohlraum im Segment wieder mit Flüssigkeit geflutet und der Zyklus beginnt erneut. Die Oberfläche kann dabei derart gestaltet werden, dass beim Ablösen der Blase eine kleine Blase zurück bleibt, die dann als Keimstelle für einen neuen Zyklus der Blasenbildung dient.As a result, local overheating be generated in the interstices and intensified the process of bubble boiling. The formation of bubbles then takes place primarily within the segments and begins at germinal sites. Initially, small gas or vapor bubbles form at these nucleation sites. When the growing bubble reaches a certain size, it detaches from the surface. In the course of the bladder detachment, the remaining cavity in the segment is flooded with liquid again and the cycle begins again. The surface can be designed such that upon detachment of the bubble, a small bubble remains, which then serves as a germination point for a new cycle of bubble formation.

Bei der vorliegenden Erfindung wird durch die Segmentierung des Kanals zwischen zwei Rippen dieser in umlaufender Richtung immer wieder unterbrochen und so das Wandern der entstehenden Blasen im Kanal zumindest reduziert oder ganz verhindert. Ein Austausch von Flüssigkeit und Dampf entlang des Kanals ist durch die jeweilige Zusatzstruktur zunehmend weniger bis gar nicht mehr unterstützt.In the present invention is interrupted by the segmentation of the channel between two ribs in the circumferential direction over again and again and thus the migration of the resulting bubbles in the channel at least reduced or completely prevented. An exchange of liquid and vapor along the channel is increasingly less supported by the respective additional structure to no longer.

Der besondere Vorteil der Erfindung besteht darin, dass der Austausch von Flüssigkeit und Dampf lokal gezielt gesteuert und die Flutung der Blasenkeimstelle im Segment lokal erfolgt. Insgesamt können durch eine gezielte Wahl der Kanalsegmentierung die Verdampferrohrstrukturen in Abhängigkeit der Einsatzparameter zielführend optimiert werden, wodurch eine Steigerung des Wärmeübergangs erzielt wird. Da im Bereich des Nutengrundes die Temperatur des Rippenfußes höher ist als an der Rippenspitze, sind zudem Strukturelemente zur Intensivierung der Blasenbildung im Nutengrund besonders wirkungsvoll.The particular advantage of the invention is that the exchange of liquid and steam controlled locally targeted and the flooding of the nucleation site in the segment takes place locally. Overall, the evaporator tube structures can be optimized in a targeted manner as a function of the application parameters by a targeted choice of the channel segmentation, whereby an increase of the heat transfer is achieved. Since the temperature of the rib foot is higher in the region of the groove bottom than at the rib tip, structural elements for intensifying the formation of bubbles in the groove base are also particularly effective.

Zudem ist es auch möglich, dass die Zusatzstrukturen die durchströmbare Querschnittsfläche im Kanal zwischen zwei Rippen lokal um mindestens 80 % reduzieren. Insgesamt können durch eine zunehmende Abtrennung einzelner Kanalabschnitte bei der Kanalsegmentierung die Verdampferrohrstrukturen in Abhängigkeit der Einsatzparameter weiter zur Steigerung des Wärmeübergangs optimiert werden.In addition, it is also possible that the additional structures locally reduce the flow-through cross-sectional area in the channel between two ribs by at least 80%. Overall, by an increasing separation of individual channel sections in the channel segmentation, the evaporator tube structures can be further optimized depending on the application parameters to increase the heat transfer.

Bei einer vorteilhaften Ausführungsform der Erfindung können die Zusatzstrukturen die durchströmbare Querschnittsfläche im Kanal zwischen zwei Rippen lokal vollständig abschließen. Auf diese Weise werden die Segmente lokal für einen Fluiddurchtritt vollständig verschlossen. Der zwischen zwei Segmenten liegende Kanalabschnitt ist somit gegenüber benachbart liegenden Kanalabschnitten fluidseitig getrennt.In an advantageous embodiment of the invention, the additional structures can complete the flow-through cross-sectional area in the channel between two ribs locally completely. In this way, the segments are completely closed locally for a fluid passage. The channel section lying between two segments is thus separated from the adjacent channel sections on the fluid side.

In bevorzugter Ausgestaltung der Erfindung kann der Kanal radial nach außen bis auf einzelne lokale Öffnungen abgeschlossen sein. Dabei können die Rippen einen im Wesentlichen T-förmigen oder Γ-förmigen Querschnitt aufweisen, wodurch der Kanal zwischen den Rippen bis auf Poren als lokale Öffnungen verschlossen wird. Durch diese Öffnungen können die im Verdampfungsprozess entstehenden Dampfblasen entweichen. Das Verformen der Rippenspitzen geschieht mit Methoden, die dem Stand der Technik zu entnehmen sind.In a preferred embodiment of the invention, the channel can be completed radially outward to individual local openings. In this case, the ribs may have a substantially T-shaped or Γ-shaped cross-section, whereby the channel between the ribs is closed except for pores as local openings. Through these openings, the resulting vapor bubbles in the evaporation process can escape. The deformation of the rib tips is done with methods that can be found in the prior art.

Durch die Kombination der erfindungsgemäßen Segmente mit einem bis auf Poren oder Schlitze verschlossen Kanal erhält man eine Struktur, die über einen sehr weiten Bereich von Betriebsbedingungen eine sehr hohe Leistungsfähigkeit bei Verdampfung von Flüssigkeiten aufweist. Insbesondere erreicht bei Variation der Wärmestromdichte oder der treibenden Temperaturdifferenz der Wärmeübergangskoeffizient der Struktur ein gleichbleibend hohes Niveau.The combination of the segments according to the invention with a channel which is closed except for pores or slots gives a structure which has a very high efficiency in the evaporation of liquids over a very wide range of operating conditions. In particular, when the heat flow density or the driving temperature difference is varied, the heat transfer coefficient of the structure reaches a consistently high level.

In vorteilhafter Ausgestaltung der Erfindung kann zumindest eine lokale Öffnung pro Segment vorhanden sein. Diese Mindestanforderung gewährleistet noch, dass beim Verdampfungsprozess in einem Kanalsegment entstehende Gasblasen nach außen entweichen können. Die lokalen Öffnungen sind in Größe und Gestalt so ausgeführt, dass auch flüssiges Medium hindurchtreten und in den Kanalabschnitt nachströmen kann. Damit der Verdampfungsvorgang bei einer lokalen Öffnung aufrechterhalten werden kann, müssen die gleichen Mengen Flüssigkeit und Dampf folglich in zueinander entgegengesetzten Richtungen durch die Öffnung transportiert werden. Üblicherweise werden Flüssigkeiten verwendet, die den Rohrwerkstoff gut benetzen. Eine derartige Flüssigkeit kann aufgrund des Kapillareffekts durch jede Öffnung in der äußeren Rohroberfläche auch gegen einen Überdruck in die Kanäle eindringen.In an advantageous embodiment of the invention, at least one local opening per segment may be present. This minimum requirement still ensures that gas bubbles which form in a channel segment during the evaporation process can escape to the outside. The local openings are designed in size and shape so that even liquid medium can pass and flow into the channel section. Thus, to maintain the vaporization process at a local orifice, the same quantities of liquid and vapor must be transported through the orifice in mutually opposite directions. Usually liquids are used, which wet the pipe material well. Such a liquid can penetrate into the channels due to the capillary effect through each opening in the outer tube surface against an overpressure.

In besonders bevorzugter Ausgestaltung kann der Quotient der Anzahl der lokalen Öffnungen zur Anzahl der Segmente 1:1 bis 6:1 betragen. Weiter bevorzugt kann dieser Quotient 1:1 bis 3:1 betragen. Die zwischen den Rippen befindlichen Kanäle sind durch Material der oberen Rippenbereiche im Wesentlichen verschlossen, wobei die so entstehenden Hohlräume der Kanalsegmente durch Öffnungen mit dem umgebenden Raum verbunden sind. Diese Öffnungen können auch als Poren ausgestaltet sein, welche in gleicher Größe oder auch in zwei oder mehr Größenklassen ausgeführt sein können. Bei einem Verhältnis, bei dem mehrere lokale Öffnungen auf ein Segment ausgebildet sind, können sich besonders Poren mit zwei Größenklassen eignen. Nach einem regelmäßigen, sich wiederholenden Schema folgen entlang der Kanäle beispielsweise auf jede kleine eine große Öffnung. Durch diese Struktur wird eine gerichtete Strömung in den Kanälen erzeugt. Flüssigkeit wird bevorzugt durch die kleinen Poren mit Unterstützung des Kapillardrucks eingezogen und benetzt die Kanalwände, wodurch dünne Filme erzeugt werden. Der Dampf sammelt sich im Zentrum des Kanals an und entweicht an den Stellen mit dem geringsten Kapillardruck. Gleichzeitig müssen die großen Poren so dimensioniert werden, dass der Dampf ausreichend schnell entweichen kann und die Kanäle dabei nicht austrocknen. Die Größe und Häufigkeit der Dampfporen im Verhältnis zu den kleineren Flüssigkeitsporen sind dann aufeinander abzustimmen.In a particularly preferred embodiment, the quotient of the number of local openings to the number of segments can be 1: 1 to 6: 1. Further preferred may this quotient is 1: 1 to 3: 1. The channels located between the ribs are substantially closed by material of the upper rib areas, the resulting cavities of the channel segments being connected by openings to the surrounding space. These openings can also be designed as pores, which can be designed in the same size or in two or more size classes. In a ratio in which a plurality of local openings are formed on a segment, especially pores with two size classes may be suitable. For example, following a regular, repetitive pattern, each channel is followed by a large opening along the channels. This structure creates a directional flow in the channels. Liquid is preferentially drawn through the small pores with the aid of capillary pressure and wets the channel walls, producing thin films. The vapor accumulates in the center of the channel and escapes at the lowest capillary pressure points. At the same time, the large pores must be dimensioned so that the steam can escape sufficiently quickly and the channels do not dry out. The size and frequency of the vapor pores in relation to the smaller liquid pores are then matched.

Vorteilhafterweise können erste Zusatzstrukturen vom Kanalgrund ausgehende radial nach außen gerichtete Auskragungen sein. Hierdurch wird auch der Austausch von Flüssigkeit und Dampf lokal festgelegt. Die Segmentierung des Kanals über den Nutengrund ist dabei für den Verdampfungsprozess besonders günstig, da am Nutengrund die Übertemperatur am größten ist und deshalb dort die höchste treibende Temperaturdifferenz für die Blasenbildung zur Verfügung steht.Advantageously, the first additional structures may be outwardly projecting radially outward protrusions from the channel bottom. As a result, the exchange of liquid and steam is determined locally. The segmentation of the channel over the groove base is particularly favorable for the evaporation process, since the excess temperature is greatest at the bottom of the groove and therefore there is the highest driving temperature difference for the bubble formation available.

In bevorzugter Ausführungsform der Erfindung können die ersten Zusatzstrukturen zumindest aus Material des Kanalgrunds zwischen zwei integral umlaufenden Rippen ausgeformt sein. Hierdurch verbleibt eine stoffschlüssige Verbindung für einen guten Wärmeaustausch von der Rohrwandung in die jeweiligen Strukturelemente erhalten. Die Segmentierung des Kanals aus einem einheitlichen Material des Kanalgrunds ist für den Verdampfungsprozess besonders günstig.In a preferred embodiment of the invention, the first additional structures may be formed at least from material of the channel bottom between two integrally encircling ribs. This leaves a cohesive Get a connection for a good heat exchange from the pipe wall into the respective structural elements. The segmentation of the channel from a uniform material of the channel bottom is particularly favorable for the evaporation process.

In besonders bevorzugter Ausführungsform können die aus dem Kanalgrund geformten ersten Zusatzstrukturen eine Höhe zwischen 0,15 und 1 mm aufweisen. Diese Bemaßung der Zusatzstrukturen ist auf die Hochleistungsrippenrohre besonders gut abgestimmt und bringen zum Ausdruck, dass die Strukturgrößen der Außenstrukturen bevorzugt im Submillimeter- bis Millimeterbereich liegen.In a particularly preferred embodiment, the first additional structures formed from the channel base may have a height between 0.15 and 1 mm. This dimensioning of the additional structures is particularly well matched to the high-performance finned tubes and expresses that the structure sizes of the outer structures are preferably in the submillimeter to millimeter range.

In weiterer vorteilhafter Ausgestaltung der Erfindung können zweite Zusatzstrukturen zumindest aus den Rippenflanken der integral umlaufenden Rippen über seitliche Auskragungen ausgeformt sein. Dies kann alternativ oder zusätzlich zu weiteren Auskragungen aus dem Kanalgrundmaterial ausgeführt sein.In a further advantageous embodiment of the invention, second additional structures can be formed at least from the rib flanks of the integrally encircling ribs via lateral protrusions. This may be performed alternatively or in addition to further projections from the channel base material.

In bevorzugter Ausführungsform der Erfindung können die zweiten Zusatzstrukturen zumindest aus einer Rippe von der Rippenspitze ausgehend in Richtung Kanalgrund hin ausgeformt sein. Der Kanal kann folglich auch aus einer Kombination mehrerer sich ergänzender Strukturelemente von unten und/oder der Seite und/oder von oben um das gewünschte Maß verjüngt bis ganz geschlossen werden. Jedenfalls so, dass der Kanal zwischen den Rippen in diskrete Segmente unterteilt wird.In a preferred embodiment of the invention, the second additional structures can be formed, starting at least from one rib from the fin tip, in the direction of the channel bottom. Consequently, the channel can also be tapered or completely closed by a desired amount from a combination of several complementary structural elements from below and / or from the side and / or from above. In any case, so that the channel between the ribs is divided into discrete segments.

In weiterer ergänzender Ausführungsform können Zusatzstrukturen zumindest teilweise über zusätzliches Material eingebracht sein. Zusätzliches Material kann dabei in Beschaffenheit und in Bezug auf die Wechselwirkung mit dem zum Betrieb ausgewählten Fluids vom Material des übrigen Wärmeaustauscherrohres abweichen. Beispielsweise ist es dabei auch angedacht, Materialien mit unterschiedlichen Oberflächeneigenschaften gegenüber dem verwendeten Fluid einzusetzen.In a further supplementary embodiment, additional structures can be introduced at least partially via additional material. Additional material may be in nature and in relation to the interaction with the fluid selected for operation from the material of the remaining heat exchanger tube differ. For example, it is also contemplated to use materials with different surface properties compared to the fluid used.

Vorteilhafterweise können die Zusatzstrukturen asymmetrische Formen aufweisen. Die Asymmetrie der Strukturen erscheint hierbei in einer senkrecht zur Rohrachse verlaufenden Schnittebene. Asymmetrische Formen können, insbesondere wenn eine größere Oberfläche ausgebildet wird, einen zusätzlichen Beitrag zum Verdampfungsprozess leisten. Die Asymmetrie kann sowohl bei Zusatzstrukturen am Kanalgrund wie auch an der Rippenspitze ausgeprägt sein.Advantageously, the additional structures may have asymmetrical shapes. The asymmetry of the structures appears here in a plane perpendicular to the tube axis cutting plane. Asymmetrical shapes, especially if a larger surface is formed, can make an additional contribution to the evaporation process. The asymmetry can be pronounced both at additional structures at the channel bottom as well as at the rib tip.

In bevorzugter Ausführungsform der Erfindung können die Zusatzstrukturen in einer senkrecht zur Rohrachse verlaufenden Schnittebene einen trapezförmigen Querschnitt aufweisen. Trapezförmige Querschnitte sind im Zusammenhang mit integral gewalzten Rippenrohrstrukturen technologisch gut beherrschbare Strukturelemente. Geringfügige fertigungsbedingte Asymmetrien der sonst parallelen Grundseiten eines Trapezes können hierbei auftreten.In a preferred embodiment of the invention, the additional structures can have a trapezoidal cross section in a sectional plane running perpendicular to the tube axis. Trapezoidal cross sections are in the context of integrally rolled finned tube structures technologically well controllable structural elements. Minor manufacturing-related asymmetries of the otherwise parallel bases of a trapezoid can occur here.

Vorteilhafterweise kann die jeweilige durch Zusatzstrukturen reduzierte, durchströmbare Querschnittsfläche im Kanal zwischen zwei Rippen variieren. Auf diese Weise können im Kanal lokal mehr oder weniger durchgängige Bereiche geschaffen werden. Hierzu können beispielsweise Zusatzstrukturen am Kanalgrund eine unterschiedliche Höhe aufweisen.Advantageously, the respective reduced by cross-sectional structures, durchströmbare cross-sectional area in the channel between two ribs vary. In this way, more or less continuous areas can be created locally in the channel. For this purpose, for example, additional structures may have a different height at the channel bottom.

Ausführungsbeispiele der Erfindung werden anhand der schematischen Zeichnungen näher erläutert.Embodiments of the invention will be explained in more detail with reference to the schematic drawings.

Darin zeigen:

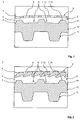

- Fig. 1

- schematisch eine Teilansicht eines Querschnitts eines Wärmeaustauscherrohrs mit durch Zusatzstrukturen unterteilten Segmenten,

- Fig. 2

- schematisch eine Teilansicht eines Querschnitts eines weiteren Wärmeaustauscherrohrs mit variierten Zusatzstrukturen im Bereich der Rippenspitze, und

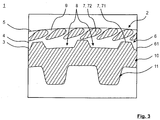

- Fig. 3

- schematisch eine Teilansicht eines Querschnitts eines Wärmeaustauscherrohrs mit nahezu abgeschlossenen Segmenten.

- Fig. 1

- 1 is a schematic partial view of a cross section of a heat exchanger tube with segments divided by additional structures;

- Fig. 2

- schematically a partial view of a cross section of another heat exchanger tube with varied additional structures in the rib tip, and

- Fig. 3

- schematically a partial view of a cross section of a heat exchanger tube with almost closed segments.

Einander entsprechende Teile sind in allen Figuren mit denselben Bezugszeichen versehen.Corresponding parts are provided in all figures with the same reference numerals.

Zusätzlich zur Bildung der Auskragungen 71 am Kanalgrund 61 sind zweckmäßigerweise die Rippenspitzen 5 als distaler Bereich der Rippen 2 derart verformt, dass sie den Kanal 6 in Radialrichtung teilweise als weitere zweite Zusatzstruktur 72 verschließen. Die Verbindung zwischen dem Kanal 6 und der Umgebung ist in Form von Poren 9 als lokale Öffnungen ausgestaltet, damit Dampfblasen aus der Kanal 6 entweichen können. Das Verformen der Rippenspitzen 5 geschieht mit Methoden, die dem Stand der Technik zu entnehmen sind. Die Primärnuten 6 stellen auf diese Weise hinterschnittene Nuten dar. Durch die Kombination der erfindungsgemäßen ersten und zweiten Zusatzstrukturen 71 und 72 erhält man ein Segment 8 in Form einer Kavität, die sich ferner dadurch auszeichnet, dass sie über einen sehr weiten Bereich von Betriebsbedingungen eine sehr hohe Leistungsfähigkeit bei Verdampfung von Flüssigkeiten aufweist. Die Flüssigkeit verdampft innerhalb des Segments 8. Der entstehende Dampf tritt an den lokalen Öffnungen 9 aus dem Kanal 6 aus, durch die auch flüssiges Fluid nachströmt. Zum Nachströmen des Fluid können auch gut benetzbare Rohroberflächen eine Hilfe sein.In addition to the formation of the projections 71 on the

Durch die Kombination der erfindungsgemäßen ersten und zweiten Zusatzstrukturen 71 und 72 erhält man ein Segment 8 in Form einer Kavität, die sich ferner dadurch auszeichnet, dass sie über einen sehr weiten Bereich von Betriebsbedingungen eine sehr hohe Leistungsfähigkeit bei Verdampfung von Flüssigkeiten aufweist. Insbesondere bleibt bei Variation der Wärmestromdichte oder der treibenden Temperaturdifferenz der Wärmeübergangskoeffizient der Struktur auf einem hohen Niveau nahezu konstant. Die erfindungsgemäße Lösung bezieht sich auf strukturierte Rohre, bei denen der Wärmeübergangskoeffizient auf der Rohraußenseite gesteigert wird. Um nicht den Hauptanteil des Wärmedurchgangswiderstandes auf die Innenseite zu verlagern, kann der Wärmeübergangskoeffizient auf der Innenseite durch eine geeignete Innenstrukturierung 11 zudem intensiviert werden. Die Wärmeaustauscherrohre 1 für Rohrbündelwärmeaustauscher besitzen üblicherweise mindestens einen strukturierten Bereich sowie glatte Endstücke und eventuell glatte Zwischenstücke. Die glatten End- bzw. Zwischenstücke begrenzen die strukturierten Bereiche. Damit das Wärmeaustauscherrohr 1 problemlos in den Rohrbündelwärmeaustauscher eingebaut werden kann, darf der äußere Durchmesser der strukturierten Bereiche nicht größer sein als der äußere Durchmesser der glatten End- und Zwischenstücke.The combination of the first and second additional structures 71 and 72 according to the invention results in a segment 8 in the form of a cavity, which is further characterized by having a very high performance in the evaporation of liquids over a very wide range of operating conditions. In particular, when the heat flow density or the driving temperature difference is varied, the heat transfer coefficient of the structure at a high level remains almost constant. The inventive Solution refers to structured pipes where the heat transfer coefficient on the outside of the pipe is increased. In order not to shift the majority of the heat transfer resistance to the inside, the heat transfer coefficient can be intensified on the inside by a suitable

- 11

- Wärmeaustauscherrohrheat exchanger tube

- 22

- Rippenribs

- 33

- Rippenfußfin base

- 44

- Rippenflankerib flank

- 55

- Rippenspitze, distale Bereiche der RippenRib tip, distal regions of the ribs

- 66

- Kanal, PrimärnutChannel, primary groove

- 6161

- Kanalgrundchannel base

- 77

- Zusatzstrukturenadditional structures

- 7171

- erste Zusatzstruktur als Auskragungen am Kanalgrundfirst additional structure as overhangs at the channel bottom

- 7272

- zweite Zusatzstruktur im Bereich der Rippenspitzesecond additional structure in the area of the rib tip

- 88th

- Segmentsegment

- 99

- lokale Öffnung, Poren, Röhrenlocal opening, pores, tubes

- 1010

- Rohrwandungpipe wall

- 1111

- Innenstrukturinternal structure

Claims (15)

- Metal heat exchanger pipe (1), having integral ribs (2) which are formed on the outer side of the pipe and which have a rib base (3), rib flanks (4) and a rib tip (5), wherein the rib base (3) protrudes substantially radially from the pipe wall and there is formed between the ribs (2) a channel (6) in which there are arranged additional structures (7, 71, 72) which are spaced apart from each other and which are arranged so as to extend least partially from the channel base (61) and which extend transversely relative to the path of the channel (6),

characterised in that- the additional structures (7, 71, 72) divide the channel (6) between the ribs (2) into segments (8), and- in that the additional structures (7, 71, 72) reduce the cross-sectional surface-area through which it is possible to flow in the channel (6) between two ribs (2) locally by at least 60% and thereby during operation at least to limit a fluid flow in the channel (6). - Heat exchanger pipe (1) according to claim 1, characterised in that the additional structures (7, 71, 72) reduce the cross-sectional surface-area through which it is possible to flow in the channel (6) between two ribs (2) locally by at least 80%.

- Heat exchanger pipe (1) according to claim 2, characterised in that the additional structures (7, 71, 72) locally completely close the cross-sectional surface-area through which it is possible to flow in the channel (6) between two ribs (2).

- Heat exchanger pipe (1) according to any one of claims 1 to 3, characterised in that the channel (6) is closed at the radially outer side with the exception of individual local openings (9).

- Heat exchanger pipe (1) according to any one of claims 1 to 4, characterised in that at least one local opening (9) is provided per segment (8).

- Heat exchanger pipe (1) according to any one of claims 1 to 5, characterised in that the quotient of the number of local openings (9) to the number of segments (8) is from 1:1 to 6:1.

- Heat exchanger pipe (1) according to any one of claims 1 to 6, characterised in that first additional structures (7, 71) are radially outwardly directed protrusions extending from the channel base (61).

- Heat exchanger pipe (1) according to any one of claims 1 to 7, characterised in that the first additional structures (7, 71) are formed at least from the material of the channel base (61) between two integrally circumferential ribs (2).

- Heat exchanger pipe (1) according to claim 8, characterised in that the first additional structures (7, 71) which are formed from the channel base (61) have a height between 0.15 and 1 mm.

- Heat exchanger pipe (1) according to any one of claims 1 to 7, characterised in that second additional structures (7, 72) are formed at least from the rib flanks (4) or rib tips (5) of the integrally circumferential ribs (2) by means of lateral protrusions.

- Heat exchanger pipe (1) according to claim 10, characterised in that the second additional structures (7, 72) are formed at least from a rib extending from the rib tip (6) in the direction towards the channel base (61).

- Heat exchanger pipe (1) according to any one of claims 1 to 11, characterised in that additional structures (7) are introduced at least partially by means of additional material.

- Heat exchanger pipe (1) according to any one of claims 1 to 12, characterised in that the additional structures (7, 72) have asymmetrical shapes.

- Heat exchanger pipe (1) according to any one of claims 1 to 12, characterised in that additional structures (7, 71) have a trapezoidal cross-section in a plane of section which extends perpendicularly to the pipe axis.

- Heat exchanger pipe (1) according to any one of claims 1 to 14, characterised in that the respective cross-sectional surface-area through which it is possible to flow in the channel (6) and which is reduced by additional structures (7, 71) varies between two ribs (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL15704718T PL3111153T3 (en) | 2014-02-27 | 2015-02-10 | Metal heat exchanger tube |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102014002829.1A DE102014002829A1 (en) | 2014-02-27 | 2014-02-27 | Metallic heat exchanger tube |

| PCT/EP2015/000278 WO2015128061A1 (en) | 2014-02-27 | 2015-02-10 | Metal heat exchanger tube |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3111153A1 EP3111153A1 (en) | 2017-01-04 |

| EP3111153B1 true EP3111153B1 (en) | 2019-04-24 |

Family

ID=52473867

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15704718.4A Active EP3111153B1 (en) | 2014-02-27 | 2015-02-10 | Metal heat exchanger tube |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US11073343B2 (en) |

| EP (1) | EP3111153B1 (en) |

| JP (1) | JP6197121B2 (en) |

| KR (1) | KR102367582B1 (en) |

| CN (1) | CN106030233B (en) |

| BR (1) | BR112016019767B1 (en) |

| DE (1) | DE102014002829A1 (en) |

| HU (1) | HUE044830T2 (en) |

| MX (1) | MX2016006294A (en) |

| PL (1) | PL3111153T3 (en) |

| PT (1) | PT3111153T (en) |

| TR (1) | TR201906855T4 (en) |

| WO (1) | WO2015128061A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202020005625U1 (en) | 2020-10-31 | 2021-11-10 | Wieland-Werke Aktiengesellschaft | Metallic heat exchanger tube |

| DE202020005628U1 (en) | 2020-10-31 | 2021-11-11 | Wieland-Werke Aktiengesellschaft | Metallic heat exchanger tube |

| WO2022089772A1 (en) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Metal heat exchanger tube |

| WO2022089773A1 (en) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Metal heat exchanger tube |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107421160B (en) * | 2017-08-28 | 2020-11-10 | 华北电力大学(保定) | High-efficient controllable cooling device |

Family Cites Families (78)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE791216A (en) * | 1972-11-03 | 1973-05-10 | American Cyanamid Co | WALL CLADDING AND ITS PREPARATION PROCESS, |

| US4313248A (en) * | 1977-02-25 | 1982-02-02 | Fukurawa Metals Co., Ltd. | Method of producing heat transfer tube for use in boiling type heat exchangers |

| DE2808080C2 (en) * | 1977-02-25 | 1982-12-30 | Furukawa Metals Co., Ltd., Tokyo | Heat transfer tube for boiling heat exchangers and process for its manufacture |

| US4159739A (en) * | 1977-07-13 | 1979-07-03 | Carrier Corporation | Heat transfer surface and method of manufacture |

| US4179911A (en) * | 1977-08-09 | 1979-12-25 | Wieland-Werke Aktiengesellschaft | Y and T-finned tubes and methods and apparatus for their making |

| US4168618A (en) * | 1978-01-26 | 1979-09-25 | Wieland-Werke Aktiengesellschaft | Y and T-finned tubes and methods and apparatus for their making |

| US4324844A (en) * | 1980-04-28 | 1982-04-13 | Westinghouse Electric Corp. | Variable area fuel cell cooling |

| US4359086A (en) * | 1981-05-18 | 1982-11-16 | The Trane Company | Heat exchange surface with porous coating and subsurface cavities |

| US4438807A (en) * | 1981-07-02 | 1984-03-27 | Carrier Corporation | High performance heat transfer tube |

| US4549606A (en) * | 1982-09-08 | 1985-10-29 | Kabushiki Kaisha Kobe Seiko Sho | Heat transfer pipe |

| JPS5946490A (en) * | 1982-09-08 | 1984-03-15 | Kobe Steel Ltd | Heat transmitting tube for heat exchanger of boiling type |

| JPS5984095A (en) * | 1982-11-04 | 1984-05-15 | Hitachi Ltd | Heat exchanging wall |

| JPS5993190A (en) * | 1982-11-17 | 1984-05-29 | Hitachi Ltd | Heat exchange wall |

| US4577381A (en) * | 1983-04-01 | 1986-03-25 | Kabushiki Kaisha Kobe Seiko Sho | Boiling heat transfer pipes |

| JPS6064196A (en) * | 1983-09-19 | 1985-04-12 | Hitachi Cable Ltd | Evaporation and heat transfer wall |

| US4653163A (en) * | 1984-09-14 | 1987-03-31 | Hitachi, Ltd. | Method for producing a heat transfer wall for vaporizing liquids |

| JPS6189497A (en) * | 1984-10-05 | 1986-05-07 | Hitachi Ltd | Heat transfer pipe |

| US4660630A (en) * | 1985-06-12 | 1987-04-28 | Wolverine Tube, Inc. | Heat transfer tube having internal ridges, and method of making same |

| EP0222100B1 (en) | 1985-10-31 | 1989-08-09 | Wieland-Werke Ag | Finned tube with a notched groove bottom and method for making it |

| US4819719A (en) * | 1987-01-20 | 1989-04-11 | Mcdonnell Douglas Corporation | Enhanced evaporator surface |

| US4921042A (en) * | 1987-10-21 | 1990-05-01 | Carrier Corporation | High performance heat transfer tube and method of making same |

| US4866830A (en) * | 1987-10-21 | 1989-09-19 | Carrier Corporation | Method of making a high performance, uniform fin heat transfer tube |

| US4799543A (en) * | 1987-11-12 | 1989-01-24 | Arthur H. Iversen | Means for temperature control of heated surfaces |

| JPH0495453A (en) * | 1990-08-10 | 1992-03-27 | Matsushita Electric Ind Co Ltd | House management system |

| JP2788793B2 (en) * | 1991-01-14 | 1998-08-20 | 古河電気工業株式会社 | Heat transfer tube |

| JP2730824B2 (en) * | 1991-07-09 | 1998-03-25 | 三菱伸銅株式会社 | Heat transfer tube with inner groove and method of manufacturing the same |

| US5203404A (en) * | 1992-03-02 | 1993-04-20 | Carrier Corporation | Heat exchanger tube |

| DE4301668C1 (en) * | 1993-01-22 | 1994-08-25 | Wieland Werke Ag | Heat exchange wall, in particular for spray evaporation |

| KR0134557B1 (en) * | 1993-07-07 | 1998-04-28 | 가메다카 소키치 | Heat exchanger tube for falling film evaporator |

| US5415225A (en) * | 1993-12-15 | 1995-05-16 | Olin Corporation | Heat exchange tube with embossed enhancement |

| US6067712A (en) * | 1993-12-15 | 2000-05-30 | Olin Corporation | Heat exchange tube with embossed enhancement |

| DE4404357C2 (en) * | 1994-02-11 | 1998-05-20 | Wieland Werke Ag | Heat exchange tube for condensing steam |

| US5482744A (en) * | 1994-02-22 | 1996-01-09 | Star Fabrication Limited | Production of heat transfer element |

| US5597039A (en) * | 1994-03-23 | 1997-01-28 | High Performance Tube, Inc. | Evaporator tube |

| US5832995A (en) * | 1994-09-12 | 1998-11-10 | Carrier Corporation | Heat transfer tube |

| EP0713072B1 (en) | 1994-11-17 | 2002-02-27 | Carrier Corporation | Heat transfer tube |

| JP3323682B2 (en) * | 1994-12-28 | 2002-09-09 | 株式会社日立製作所 | Heat transfer tube with internal cross groove for mixed refrigerant |

| US5697430A (en) | 1995-04-04 | 1997-12-16 | Wolverine Tube, Inc. | Heat transfer tubes and methods of fabrication thereof |

| US6427767B1 (en) * | 1997-02-26 | 2002-08-06 | American Standard International Inc. | Nucleate boiling surface |

| US5933953A (en) * | 1997-03-17 | 1999-08-10 | Carrier Corporation | Method of manufacturing a heat transfer tube |

| DE19757526C1 (en) | 1997-12-23 | 1999-04-29 | Wieland Werke Ag | Heat exchanger tube manufacturing method |

| US6176302B1 (en) * | 1998-03-04 | 2001-01-23 | Kabushiki Kaisha Kobe Seiko Sho | Boiling heat transfer tube |

| US6056048A (en) * | 1998-03-13 | 2000-05-02 | Kabushiki Kaisha Kobe Seiko Sho | Falling film type heat exchanger tube |

| CN1161586C (en) * | 1998-12-25 | 2004-08-11 | 株式会社神户制钢所 | Tube having inner surface trough, and method for producing same |

| DE10024682C2 (en) * | 2000-05-18 | 2003-02-20 | Wieland Werke Ag | Heat exchanger tube for evaporation with different pore sizes |

| US20020074114A1 (en) * | 2000-09-01 | 2002-06-20 | Fijas David F. | Finned heat exchange tube and process for forming same |

| US6601299B2 (en) * | 2000-10-19 | 2003-08-05 | Ibc Corporation | Tapered fin and method of forming the same |

| DE10101589C1 (en) * | 2001-01-16 | 2002-08-08 | Wieland Werke Ag | Heat exchanger tube and process for its production |

| US20020096314A1 (en) * | 2001-01-25 | 2002-07-25 | Carrier Corporation | High performance micro-rib tube |

| DE10159860C2 (en) * | 2001-12-06 | 2003-12-04 | Sdk Technik Gmbh | Heat transfer surface with an electroplated microstructure of protrusions |

| DE60317506T2 (en) * | 2002-06-10 | 2008-09-18 | Wolverine Tube Inc. | HEAT EXCHANGE TUBE AND METHOD AND TOOL FOR THE PRODUCTION THEREOF |

| US7254964B2 (en) | 2004-10-12 | 2007-08-14 | Wolverine Tube, Inc. | Heat transfer tubes, including methods of fabrication and use thereof |

| CA2591683C (en) * | 2004-10-22 | 2013-12-10 | Aleris Aluminum Koblenz Gmbh | Tube made of a profile rolled metal product and method of producing the same |

| CN100365369C (en) * | 2005-08-09 | 2008-01-30 | 江苏萃隆铜业有限公司 | Heat exchange tube of evaporator |

| CN100458344C (en) * | 2005-12-13 | 2009-02-04 | 金龙精密铜管集团股份有限公司 | Copper condensing heat-exchanging pipe for flooded electric refrigerator set |

| CN100437011C (en) * | 2005-12-13 | 2008-11-26 | 金龙精密铜管集团股份有限公司 | Flooded copper-evaporating heat-exchanging pipe for electric refrigerator set |

| CN100498187C (en) * | 2007-01-15 | 2009-06-10 | 高克联管件(上海)有限公司 | Evaporation and condensation combined type heat-transfer pipe |

| US20080236803A1 (en) * | 2007-03-27 | 2008-10-02 | Wolverine Tube, Inc. | Finned tube with indentations |

| CN101338987B (en) * | 2007-07-06 | 2011-05-04 | 高克联管件(上海)有限公司 | Heat transfer pipe for condensation |

| CA2644003C (en) * | 2007-11-13 | 2014-09-23 | Dri-Steem Corporation | Heat transfer system including tubing with nucleation boiling sites |

| CN101338959B (en) * | 2008-01-11 | 2011-06-08 | 高克联管件(上海)有限公司 | Efficient shell and tube type condenser |

| DE102008013929B3 (en) * | 2008-03-12 | 2009-04-09 | Wieland-Werke Ag | Metallic heat exchanger pipe i.e. integrally rolled ribbed type pipe, for e.g. air-conditioning and refrigeration application, has pair of material edges extending continuously along primary grooves, where distance is formed between edges |

| CN100547339C (en) * | 2008-03-12 | 2009-10-07 | 江苏萃隆精密铜管股份有限公司 | A kind of intensify heat transfer pipe and preparation method thereof |

| US9844807B2 (en) * | 2008-04-16 | 2017-12-19 | Wieland-Werke Ag | Tube with fins having wings |

| US9038710B2 (en) * | 2008-04-18 | 2015-05-26 | Wieland-Werke Ag | Finned tube for evaporation and condensation |

| DE102009007446B4 (en) * | 2009-02-04 | 2012-03-29 | Wieland-Werke Ag | Heat exchanger tube and method for its production |

| US20100282456A1 (en) * | 2009-05-06 | 2010-11-11 | General Electric Company | Finned tube heat exchanger |

| DE102009021334A1 (en) * | 2009-05-14 | 2010-11-18 | Wieland-Werke Ag | Metallic heat exchanger tube |

| JP4638951B2 (en) * | 2009-06-08 | 2011-02-23 | 株式会社神戸製鋼所 | Metal plate for heat exchange and method for producing metal plate for heat exchange |

| US20110083619A1 (en) * | 2009-10-08 | 2011-04-14 | Master Bashir I | Dual enhanced tube for vapor generator |

| DE102009060395A1 (en) * | 2009-12-22 | 2011-06-30 | Wieland-Werke AG, 89079 | Heat exchanger tube and method for producing a heat exchanger tube |

| US20120325443A1 (en) * | 2010-03-11 | 2012-12-27 | Sumitomo Heavy Industries Process Equipment Co., Ltd. | Tube Type Heat Exchanger and Manufacturing Method of the Same |

| CN102589337B (en) * | 2011-01-13 | 2016-02-03 | 摩丁制造公司 | Heat-exchange tube and use the method for this heat-exchange tube |

| CN102679791B (en) * | 2011-03-10 | 2015-09-23 | 卢瓦塔埃斯波公司 | For the heat-transfer pipe of heat exchanger |

| CN102130622A (en) * | 2011-04-07 | 2011-07-20 | 上海威特力焊接设备制造股份有限公司 | High-efficiency photovoltaic inverter |

| CN102121805A (en) * | 2011-04-07 | 2011-07-13 | 金龙精密铜管集团股份有限公司 | Enhanced heat transfer tube used for falling film evaporator |

| DE102011121436A1 (en) * | 2011-12-16 | 2013-06-20 | Wieland-Werke Ag | Condenser tubes with additional flank structure |

| DE102011121733A1 (en) * | 2011-12-21 | 2013-06-27 | Wieland-Werke Ag | Evaporator tube with optimized external structure |

-

2014

- 2014-02-27 DE DE102014002829.1A patent/DE102014002829A1/en not_active Withdrawn

-

2015

- 2015-02-10 PL PL15704718T patent/PL3111153T3/en unknown

- 2015-02-10 PT PT15704718T patent/PT3111153T/en unknown

- 2015-02-10 TR TR2019/06855T patent/TR201906855T4/en unknown

- 2015-02-10 WO PCT/EP2015/000278 patent/WO2015128061A1/en active Application Filing

- 2015-02-10 MX MX2016006294A patent/MX2016006294A/en active IP Right Grant

- 2015-02-10 HU HUE15704718 patent/HUE044830T2/en unknown

- 2015-02-10 JP JP2016537534A patent/JP6197121B2/en active Active

- 2015-02-10 CN CN201580002855.0A patent/CN106030233B/en active Active

- 2015-02-10 KR KR1020167014382A patent/KR102367582B1/en active IP Right Grant

- 2015-02-10 EP EP15704718.4A patent/EP3111153B1/en active Active

- 2015-02-10 BR BR112016019767-4A patent/BR112016019767B1/en active IP Right Grant

- 2015-02-10 US US15/103,193 patent/US11073343B2/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202020005625U1 (en) | 2020-10-31 | 2021-11-10 | Wieland-Werke Aktiengesellschaft | Metallic heat exchanger tube |

| DE202020005628U1 (en) | 2020-10-31 | 2021-11-11 | Wieland-Werke Aktiengesellschaft | Metallic heat exchanger tube |

| WO2022089772A1 (en) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Metal heat exchanger tube |

| WO2022089773A1 (en) | 2020-10-31 | 2022-05-05 | Wieland-Werke Ag | Metal heat exchanger tube |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20160125348A (en) | 2016-10-31 |

| HUE044830T2 (en) | 2019-11-28 |

| JP2017501362A (en) | 2017-01-12 |

| WO2015128061A1 (en) | 2015-09-03 |

| PL3111153T3 (en) | 2019-09-30 |

| BR112016019767A2 (en) | 2017-10-24 |

| JP6197121B2 (en) | 2017-09-13 |

| MX2016006294A (en) | 2016-12-08 |

| KR102367582B1 (en) | 2022-02-25 |

| EP3111153A1 (en) | 2017-01-04 |

| US11073343B2 (en) | 2021-07-27 |

| PT3111153T (en) | 2019-07-30 |

| US20160305717A1 (en) | 2016-10-20 |

| TR201906855T4 (en) | 2019-05-21 |

| CN106030233B (en) | 2019-06-21 |

| BR112016019767B1 (en) | 2020-12-08 |

| CN106030233A (en) | 2016-10-12 |

| DE102014002829A1 (en) | 2015-08-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10101589C1 (en) | Heat exchanger tube and process for its production | |

| DE69302668T2 (en) | Heat exchanger tube | |

| DE4404357C1 (en) | Heat exchange core for condensing vapour (steam) | |

| EP3111153B1 (en) | Metal heat exchanger tube | |

| EP2795233B1 (en) | Evaporator pipe with optimised external structure | |

| EP2101136B1 (en) | Metallic heat exchanger tube | |

| DE60303306T2 (en) | HEAT TRANSFER TUBES AND METHOD FOR THE PRODUCTION AND USE THEREOF | |

| DE10024682C2 (en) | Heat exchanger tube for evaporation with different pore sizes | |

| EP2253922A2 (en) | Metallic heat exchange pipe | |

| EP2791609B1 (en) | Condenser tubes with additional flank structure | |

| EP3465057B1 (en) | Heat exchanger tube | |

| EP3465056B1 (en) | Heat exchanger tube | |

| EP3465055B1 (en) | Heat exchanger tube | |

| EP3581871B1 (en) | Metallic heat exchange pipe | |

| EP4237782B1 (en) | Metal heat exchanger tube | |

| EP4237781B1 (en) | Metal heat exchanger tube | |

| DE202020005628U1 (en) | Metallic heat exchanger tube | |

| DE202020005625U1 (en) | Metallic heat exchanger tube |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20160714 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20181123 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1124641 Country of ref document: AT Kind code of ref document: T Effective date: 20190515 Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015008794 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 3111153 Country of ref document: PT Date of ref document: 20190730 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20190723 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E044830 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190725 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190824 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502015008794 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20200127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200210 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1124641 Country of ref document: AT Kind code of ref document: T Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190424 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20231212 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20240111 Year of fee payment: 10 Ref country code: DE Payment date: 20240229 Year of fee payment: 10 Ref country code: PT Payment date: 20240211 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240209 Year of fee payment: 10 Ref country code: PL Payment date: 20231212 Year of fee payment: 10 Ref country code: IT Payment date: 20240111 Year of fee payment: 10 |