EP2467214B1 - Flächenreinigungskopf - Google Patents

Flächenreinigungskopf Download PDFInfo

- Publication number

- EP2467214B1 EP2467214B1 EP09781919.7A EP09781919A EP2467214B1 EP 2467214 B1 EP2467214 B1 EP 2467214B1 EP 09781919 A EP09781919 A EP 09781919A EP 2467214 B1 EP2467214 B1 EP 2467214B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning head

- surface cleaning

- accordance

- rotation

- axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004140 cleaning Methods 0.000 title claims description 68

- 230000001681 protective effect Effects 0.000 claims description 48

- 239000007921 spray Substances 0.000 claims description 37

- 230000003014 reinforcing effect Effects 0.000 claims description 35

- 239000012530 fluid Substances 0.000 claims description 14

- 239000000463 material Substances 0.000 claims description 7

- 230000007423 decrease Effects 0.000 claims description 4

- 239000007788 liquid Substances 0.000 description 41

- 238000001746 injection moulding Methods 0.000 description 5

- 230000001788 irregular Effects 0.000 description 5

- 230000002787 reinforcement Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 238000010137 moulding (plastic) Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

- B08B3/024—Cleaning by means of spray elements moving over the surface to be cleaned

Definitions

- the invention relates to a surface cleaning head for cleaning a surface, with a hood-shaped, downwardly open housing, in which at least one spray arm is rotatably mounted about an axis of rotation, wherein the spray arm at a distance from the axis of rotation carries a nozzle which can be acted upon with pressurized cleaning liquid and rotates together with the spray arm about the axis of rotation to act on the surface to be cleaned with a liquid jet, and with a protective disc covering the at least one spray arm to the open bottom of the housing and an annular, characterized by holding webs liquid passage defined for passage of the liquid jet, wherein the at least one spray arm is rotatable relative to the protective disk.

- Such a surface cleaning head is from the US 3,832,069 known. It is suitable for example for cleaning hard surfaces, such as patio floors, garage entrances and garage doors.

- the pressure line of a high-pressure cleaning device can be connected to the surface cleaning head. Pressurized cleaning fluid may then be supplied to the nozzle located at the at least one spray arm. With the help of the nozzle, the cleaning liquid can be applied to the surface to be cleaned.

- the nozzle undergoes a recoil, under the effect of the spray arm is rotated about the rotation axis in rotation. This makes it possible to apply a relatively large area within a short time with cleaning liquid.

- Object of the present invention is to develop a surface cleaning head of the type mentioned in such a way that it has a lower noise.

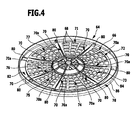

- This object is achieved in a surface cleaning head of the generic type according to the invention that the holding webs are arranged distributed unevenly in the circumferential direction.

- the holding webs that pass through the liquid passage are distributed unevenly in the circumferential direction. This has the consequence that the liquid jet emanating from the nozzle at irregular intervals on a holding web meets. Due to the temporally irregular loading of adjacent retaining webs with pressurized liquid, no vibration resonance can form in the protective disk and this in turn means that the noise development of the surface cleaning head according to the invention is relatively low.

- an odd number of retaining webs is used, for example, three, five, seven or nine retaining webs may be provided which are arranged distributed unevenly in the circumferential direction.

- the protective disc forms in an advantageous embodiment of the invention, a central shield, which is arranged below the at least one spray arm and which is connected via the holding webs with a protective shield surrounding in the circumferential direction retaining ring. It has been shown that the use of the retaining ring makes it possible to mechanically stabilize the central protective shield, particularly in its outer edge region adjoining the fluid passage.

- the protective shield is configured in a grid or net shape.

- the shield includes a plurality of reinforcing ribs that mechanically stabilize the shield.

- the reinforcing ribs form a mechanical reinforcement of the protective shield.

- the latter is preferably produced as a plastic molding in an injection molding process.

- the upwardly and downwardly projecting from the shield reinforcing portions flow channels, which ensure that sufficient plastic material can flow to the outer edge regions of the injection mold.

- the reinforcing ribs thus also have an injection molding function in addition to their reinforcing function.

- the retaining ring is arranged at a distance from the housing.

- the distance of the retaining ring to the housing in the radial direction is preferably less than the radial extent of the liquid passage.

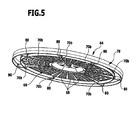

- the retaining ring in the axial direction with respect to the axis of rotation of the at least one Sprüharms has an upper end portion which is disposed within the housing, and a lower end portion which projects beyond the lower edge of the housing.

- the upper end portion of the retaining ring is thus circumferentially surrounded by the housing. This allows the housing form a guide for the retaining ring in the Assembly of the protective disk by the protective disk, whose outer edge region is formed by the retaining ring, is inserted from below into the housing.

- the lower end portion of the retaining ring may protrude from the housing in the axial direction.

- the retaining ring can thereby form a shock protection, which protects the housing against damage in an unintentional approach of the surface cleaning head to the surface to be cleaned, since in such an approach, the retaining ring with its axially projecting area touches the surface to be cleaned, even before the housing on can open the area.

- a flexible splash guard is arranged, which protrudes in the axial direction over the lower edge of the retaining ring is particularly advantageous.

- a flexible splash guard for example, a rubber lip or a bristle ring can be used.

- the flexible splash guard surrounds the lower end portion of the retaining ring in the circumferential direction, and as the surface cleaning head passes along the surface to be cleaned, the splash guard may contact the surface without causing the retaining ring to contact the surface.

- the material thickness of the retaining ring is less than its axial extent.

- the retaining ring thus forms a kind of pipe section or sleeve.

- the sleeve surrounds the central shield of the protective disk in the circumferential direction and forms a mechanical stabilization.

- the surface cleaning head comprises at least one further nozzle, which is arranged radially offset from the shield, that is, a greater radial distance from the axis of rotation than the outer edge of the protective disk.

- the additional nozzle can be rotatably held in the housing and used, for example, for cleaning corner areas of a surface used.

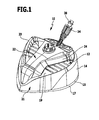

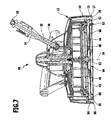

- FIGS. 1 to 5 shows a first embodiment of a total occupied by the reference numeral 10 surface cleaning head according to the invention.

- This includes a hood-shaped, downwardly open housing 12 with an annular in plan view, self-contained cylinder wall 14 which carries at its lower edge 15 a circumferential flexible splash guard in the form of a bristle ring 17.

- the cylinder wall 14 is covered by a ceiling wall 19.

- a substantially V-shaped attachment part 21 is attached to the cylinder wall 14, to which a cover 22 covering the ceiling wall 19 in a central area adjoins above the ceiling wall 19.

- a first handle 23 and a second handle 24 are arranged, which can be encompassed by the user for supporting the surface cleaning head 10th

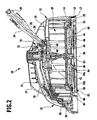

- the central distributor part 32 is connected via a first supply line 40 with two diametrically opposed spray arms 42, 44 in fluid communication, each having a flow channel 46 and 48 and carry at its free end a nozzle 50 and 52, respectively.

- the flow channels 46, 48 extend through the spray arms 42 and 44, respectively. In FIG. 2 the flow channels 46, 48 are only partially shown.

- the nozzles 50, 52 are acted upon by the supply pipe 34 and the distributor part 32 and the first supply line 40 and the flow channels 46 and 48 with pressurized cleaning liquid and produce an obliquely downwardly directed liquid jet of a cleaning liquid.

- the liquid jets Upon exiting the nozzles 50, 52, the liquid jets exert a torque on the spray arms 42, 44 by reaction forces and cause them to rotate about a rotation axis 54 aligned coaxially with the longitudinal axis of the first lead 40.

- a first liquid jet and a second liquid jet are directed to a surface to be cleaned.

- a second supply line 56 which dips on the upper side in the additional space 30 and carries at its free end an additional nozzle 58.

- the additional nozzle 58 is designed in the form of a spray nozzle and held in the housing 12 in a fixed manner in contrast to the rotating nozzles 50, 52. From the additional nozzle 58, pressurized cleaning fluid can be dispensed, for example for cleaning a corner region of a surface to be cleaned.

- the supply of cleaning liquid from the supply pipe 34 via the distributor part 32 is carried out selectively either only to each of a spray arm 52, 54 arranged nozzles 50, 52 or to the additional nozzle 58.

- the distributor part 32 has a switching device 60 shown only schematically in the drawing which in a first switching position releases the flow path between the supply pipe 34 and the first supply line 40 and in a second switching position the flow path between the supply pipe 34 and the second supply line 56.

- the retaining ring 78 is designed in the manner of a very short piece of pipe or in the manner of a sleeve by its material thickness is considerably less than its extension in the axial direction with respect to the axis of rotation 54 of the spray arms 42, 44.

- An axial upper end portion 84 of the retaining ring 78 is within of the housing 12 is arranged by being circumferentially surrounded by the free end portion of the cylinder wall 14, whereas an axial lower end portion 86 projects downwardly beyond the lower edge 15 of the cylinder wall 14 and thus over the housing 12.

- the protective plate 64 When mounting the surface cleaning head 10, the protective plate 64 can be inserted from below into the housing 12. In this case, the lower end region of the cylinder wall 14 forms a guide for the protective disk 64.

- the annular fluid passage 82 is arranged in alignment with the nozzles 50 and 52, so that the liquid jets emanating from the nozzles 50, 52 through the Liquid passage 82 can pass to act on the surface to be cleaned.

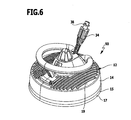

- the in the FIGS. 6 and 7 surface cleaning head 90 shown differs from the above-described surface cleaning head 10 in that it has only the two nozzles 50, 52, which are respectively held at the free end of a spray arm 42 and 44 and rotate upon application of pressurized cleaning fluid about the axis of rotation 54.

- a non-rotatable additional nozzle is not used in the surface cleaning head 90.

Landscapes

- Nozzles (AREA)

- Cleaning By Liquid Or Steam (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL09781919T PL2467214T3 (pl) | 2009-08-17 | 2009-08-17 | Głowica do czyszczenia powierzchni |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2009/060633 WO2011020492A1 (de) | 2009-08-17 | 2009-08-17 | Flächenreinigungskopf |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2467214A1 EP2467214A1 (de) | 2012-06-27 |

| EP2467214B1 true EP2467214B1 (de) | 2013-05-08 |

Family

ID=42173903

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09781919.7A Not-in-force EP2467214B1 (de) | 2009-08-17 | 2009-08-17 | Flächenreinigungskopf |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9027579B2 (pl) |

| EP (1) | EP2467214B1 (pl) |

| JP (1) | JP5336661B2 (pl) |

| CN (1) | CN102470401B (pl) |

| BR (1) | BR112012003594A2 (pl) |

| DK (1) | DK2467214T3 (pl) |

| PL (1) | PL2467214T3 (pl) |

| RU (1) | RU2503510C2 (pl) |

| WO (1) | WO2011020492A1 (pl) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3833490B1 (de) | 2018-08-09 | 2022-10-05 | Alfred Kärcher SE & Co. KG | Flächenreinigungskopf |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK2817104T3 (da) | 2012-02-20 | 2023-05-30 | Kaercher Alfred Se & Co Kg | Fladerengøringshoved og strømningsmodstandselement til et fladerengøringshoved |

| WO2014144929A2 (en) * | 2013-03-15 | 2014-09-18 | James Crocker | Orbital spray bar assembly for surface cleaning apparatus |

| CN105120994B (zh) * | 2013-04-19 | 2017-05-10 | 阿尔弗雷德·凯驰两合公司 | 作为高压清洁设备附件的清洁剂混合设备 |

| GB2546238B (en) * | 2015-11-18 | 2021-07-07 | Glenalmond Timber Company Ltd | Single leaf separating wall |

| CN113695343A (zh) * | 2021-09-26 | 2021-11-26 | 青岛炬荣工程科技有限公司 | 一种针对旋转水射流机构的防松保护网罩 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3748050A (en) * | 1971-11-12 | 1973-07-24 | Chaska Chem Co Inc | Cleaner assembly |

| US3832069A (en) * | 1972-02-02 | 1974-08-27 | Chaska Chem Co Inc | Cleaning apparatus |

| DE2548432C2 (de) * | 1974-10-30 | 1986-10-02 | Bernard Eaton Salisbury Wiltshire Hart | Vorrichtung zum Erzeugen eines gegen eine Fläche gerichteten rotierenden Sprühstrahls |

| JPS5883705A (ja) * | 1981-11-12 | 1983-05-19 | 日本インデスコ株式会社 | 滑走路面附着ゴム除去方法 |

| SU1123731A1 (ru) * | 1982-11-24 | 1984-11-15 | Сумский Филиал Харьковского Ордена Ленина Политехнического Института Им.В.И.Ленина | Распылитель жидкости |

| JPH05228091A (ja) * | 1991-04-03 | 1993-09-07 | Kuroki:Kk | 水煙等飛散防止具 |

| RU2026116C1 (ru) * | 1991-04-09 | 1995-01-09 | Виктор Игнатьевич Тумченок | Дисковый распылитель |

| JPH06165972A (ja) * | 1992-11-30 | 1994-06-14 | Hitachi Kyowa Kogyo Co Ltd | 洗浄装置 |

| US6514354B2 (en) * | 1993-09-08 | 2003-02-04 | Cyclone Surface Cleaning, Inc. | Surface cleaner and retrieval unit |

| JPH07250796A (ja) * | 1994-03-16 | 1995-10-03 | Tootaru Service:Kk | 壁面の清掃方法 |

| RU2151651C1 (ru) * | 1998-01-26 | 2000-06-27 | Производственно-инновационное предприятие "Агротехнология" | Распылитель |

| JP3592204B2 (ja) * | 2000-01-26 | 2004-11-24 | ヤンマー株式会社 | 水中清掃ロボット |

| DE20210073U1 (de) | 2002-06-28 | 2002-09-19 | Alfred Kärcher GmbH & Co., 71364 Winnenden | Reinigungsgerät |

| JP2004174173A (ja) * | 2002-11-25 | 2004-06-24 | Suezo Iwata | 電動床磨機用回転ブラシ |

| US7040830B2 (en) * | 2003-09-26 | 2006-05-09 | Helen Of Troy Limited | Soap dispensing apparatus |

| JP2005169262A (ja) * | 2003-12-11 | 2005-06-30 | Mets:Kk | 洗浄液噴射装置 |

| US7308900B2 (en) * | 2004-04-01 | 2007-12-18 | Robert Otterson | Flat surface washing apparatus |

| JP2006312155A (ja) * | 2005-05-09 | 2006-11-16 | Sankoo Techno:Kk | 水中洗滌装置 |

| CN2890161Y (zh) * | 2006-03-22 | 2007-04-18 | 王德生 | 洗地盘 |

| DE102007029245A1 (de) * | 2007-06-13 | 2008-12-18 | Alfred Kärcher Gmbh & Co. Kg | Flächenreinigungskopf |

-

2009

- 2009-08-17 PL PL09781919T patent/PL2467214T3/pl unknown

- 2009-08-17 JP JP2012525046A patent/JP5336661B2/ja not_active Expired - Fee Related

- 2009-08-17 DK DK09781919.7T patent/DK2467214T3/da active

- 2009-08-17 BR BR112012003594A patent/BR112012003594A2/pt not_active Application Discontinuation

- 2009-08-17 WO PCT/EP2009/060633 patent/WO2011020492A1/de not_active Ceased

- 2009-08-17 RU RU2012110124/05A patent/RU2503510C2/ru not_active IP Right Cessation

- 2009-08-17 EP EP09781919.7A patent/EP2467214B1/de not_active Not-in-force

- 2009-08-17 CN CN200980161011.5A patent/CN102470401B/zh not_active Expired - Fee Related

-

2012

- 2012-01-26 US US13/358,770 patent/US9027579B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3833490B1 (de) | 2018-08-09 | 2022-10-05 | Alfred Kärcher SE & Co. KG | Flächenreinigungskopf |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2503510C2 (ru) | 2014-01-10 |

| RU2012110124A (ru) | 2013-09-27 |

| EP2467214A1 (de) | 2012-06-27 |

| US9027579B2 (en) | 2015-05-12 |

| BR112012003594A2 (pt) | 2016-03-15 |

| JP5336661B2 (ja) | 2013-11-06 |

| CN102470401A (zh) | 2012-05-23 |

| CN102470401B (zh) | 2014-02-12 |

| DK2467214T3 (da) | 2013-07-22 |

| JP2013502305A (ja) | 2013-01-24 |

| WO2011020492A1 (de) | 2011-02-24 |

| PL2467214T3 (pl) | 2013-09-30 |

| US20130019911A1 (en) | 2013-01-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2467214B1 (de) | Flächenreinigungskopf | |

| EP0731229A2 (de) | Brausehalter | |

| CH659563A5 (de) | Vorrichtung zum maehen von erntegut. | |

| DE2619344A1 (de) | Maehvorrichtung | |

| WO2011160742A2 (de) | Peltonturbine mit einem wasserabfuhrsystem | |

| EP1677646B1 (de) | Waschbürste | |

| DE202010013512U1 (de) | Walzenförmige Vorrichtung zur Bodenbearbeitung | |

| DE19505787C2 (de) | Reinigungswalze für die Saugdüse eines Saugreinigungsgerätes | |

| EP2415380A2 (de) | Tellerbesen | |

| EP2247393B1 (de) | Flächenreinigungskopf | |

| DE4405795C2 (de) | Stabwalze | |

| EP1133910A1 (de) | Lagerschild eines Mähtellers | |

| EP2153746A2 (de) | Waschbürste | |

| EP3689186B1 (de) | Rolle für apparate, möbel, mit einem ein kopfteil und ein fussteil aufweisendes tragteil | |

| DE29623235U1 (de) | Spritzschutz für ein Hochdruckreinigungsgerät | |

| DE19736206C1 (de) | Gerät zum Schneiden von Pflanzen | |

| EP4252502B1 (de) | Bodenbearbeitungswerkzeug | |

| AT9727U1 (de) | Werkzeug mit mehreren werkzeugköpfen | |

| DE4322990C2 (de) | Fahrzeugwascheinrichtung | |

| DE202005021574U1 (de) | Behälterreinigungsvorrichtung | |

| CH685916A5 (de) | Fussbodenreinigungsmaschine. | |

| DE2841085C2 (de) | Gerät, insbesondere Handgerät, mit einer Stachelwalze | |

| EP1674783B1 (de) | Brauserohrschutz | |

| EP1382287A2 (de) | Sprühvorrichtung für einen Geschirrspülautomaten | |

| EP1698400A1 (de) | Spritzschutzeinrichtung für Hochdruckreinigungsgeräte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120124 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 610809 Country of ref document: AT Kind code of ref document: T Effective date: 20130515 Ref country code: CH Ref legal event code: NV Representative=s name: ISLER AND PEDRAZZINI AG, CH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009007062 Country of ref document: DE Effective date: 20130704 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130819 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130809 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130909 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130808 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130808 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009007062 Country of ref document: DE Effective date: 20140211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009007062 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130817 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130508 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090817 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009007062 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502009007062 Country of ref document: DE Owner name: ALFRED KAERCHER SE & CO. KG, DE Free format text: FORMER OWNER: ALFRED KAERCHER GMBH & CO. KG, 71364 WINNENDEN, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20180612 Year of fee payment: 10 Ref country code: BE Payment date: 20180614 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180712 Year of fee payment: 10 Ref country code: IT Payment date: 20180823 Year of fee payment: 10 Ref country code: NL Payment date: 20180815 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20180817 Year of fee payment: 10 Ref country code: DK Payment date: 20180810 Year of fee payment: 10 Ref country code: AT Payment date: 20180725 Year of fee payment: 10 Ref country code: GB Payment date: 20180815 Year of fee payment: 10 Ref country code: SE Payment date: 20180810 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180926 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009007062 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502009007062 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20190831 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20190901 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 610809 Country of ref document: AT Kind code of ref document: T Effective date: 20190817 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190818 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190831 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190901 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200303 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190831 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190831 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190817 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190817 |