EP2159293A2 - Kriechbeständige Magnesiumlegierung - Google Patents

Kriechbeständige Magnesiumlegierung Download PDFInfo

- Publication number

- EP2159293A2 EP2159293A2 EP09168253A EP09168253A EP2159293A2 EP 2159293 A2 EP2159293 A2 EP 2159293A2 EP 09168253 A EP09168253 A EP 09168253A EP 09168253 A EP09168253 A EP 09168253A EP 2159293 A2 EP2159293 A2 EP 2159293A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- magnesium alloy

- magnesium

- weight

- alloy

- calcium

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C23/00—Alloys based on magnesium

- C22C23/02—Alloys based on magnesium with aluminium as the next major constituent

Definitions

- the present invention relates to a creep resistant magnesium alloy.

- Magnesium containing metal alloys are widely used in the automotive, electronics, aerospace, and other engineering industries.

- such alloys are advantageous, which are high temperature creep resistant and therefore can be used in a high temperature environment.

- magnesium alloys have already been developed and standardized, such as the magnesium alloys JIS H 5203 (MC1-MC10) and JIS H 5303 (MDC1A, MDC1B).

- alloy A developed by Dow Chemical of composition Mg-4% Al-2% SE (SE - rare earth elements) is also well known.

- the DE 44 46 898 A1 discloses creep resistant magnesium alloys containing: 1.5 to 10% by weight of aluminum (Al), less than 2% by weight of rare earth elements (SE), 0.25 to 5.5% by weight of calcium (Ca) and magnesium In addition, the alloy may contain 0.2 to 2.5% by weight of copper and / or zinc.

- the DE 22 01 460 A1 also discloses creep resistant magnesium alloys containing aluminum and optionally another element selected from calcium, zirconium, titanium, silicon, strontium, yttrium, cerium or barium. A combination of barium and calcium as additional elements is not disclosed.

- the object of the present invention is therefore to provide a magnesium alloy, with which the disadvantages of the above-mentioned prior art can be overcome and also has a higher creep resistance.

- the object is achieved by a magnesium-containing metal alloy or magnesium alloy, based on the total weight of the alloy 1 to 9 wt .-% aluminum (Al), 0.5 to 5 wt.% Barium (Ba), 0.5 to 5 wt % Calcium (Ca) as well as magnesium (Mg) and unavoidable manufacturing impurities as balance.

- the unavoidable manufacturing impurities are present in a total amount based on the total weight of the alloy of not more than 2% by weight.

- the proportion of aluminum is preferably 2 to 7% by weight, more preferably 3 to 6% by weight.

- the proportion of barium is preferably 1 to 4% by weight, more preferably 1.5 to 3% by weight.

- the proportion of calcium is preferably 1 to 4% by weight, more preferably 1.5 to 3% by weight.

- the magnesium alloy according to the invention may additionally contain zinc, tin, lithium, manganese, yttrium, neodymium, cerium and / or praseodymium in proportions of in each case up to 7% by weight.

- the magnesium alloy of the invention has a variety of applications; preferably, it can be used for the manufacture of components of automobiles, ships and / or aircraft, more preferably for the production of drive trains or their components.

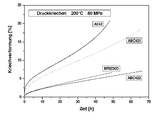

- FIG. 1 shows the creep deformation as a function of time at an applied stress of 80 MPa and a temperature of 200 ° C of two magnesium alloys (ABC alloys) according to the invention containing about 4 wt.% Aluminum, about 2 wt.% Barium and about 1 % By weight of calcium (ABC421) or about 4% by weight of aluminum, about 2% by weight of barium and about 2% by weight of calcium (ABC422) in comparison to the conventional alloy AE42, where E stands for rare earth elements, or an alloy with the designation MRI230D the company Dead Sea Magnesium, which contains in addition to aluminum and calcium Seltenderdmaschine.

- the alloys according to the invention have a significantly lower creep deformation than the respective comparative alloys. It follows that you can either increase the temperature at constant voltage or that you can load a component much longer.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Powder Metallurgy (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Compounds Of Alkaline-Earth Elements, Aluminum Or Rare-Earth Metals (AREA)

- Gears, Cams (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Abstract

Description

- Die vorliegende Erfindung betrifft eine kriechbeständige Magnesiumlegierung.

- Magnesium enthaltende Metallegierungen werden in grossem Umfang in der Automobilindustrie, der Elektronikindustrie, der Luft/Raumfahrt-Industrie und auf verschiedenen anderen Gebieten der Technik eingesetzt. Dabei sind insbesondere solche Legierungen von Vorteil, die hochtemperaturkriechfest sind und daher in einer Umgebung mit hoher Temperatur eingesetzt werden können.

- Es sind bereits verschiedene Magnesiumlegierungen entwickelt und genormt worden, wie die Magnesiumlegierungen JIS H 5203 (MC1-MC10) und JIS H 5303 (MDC1A, MDC1B). Für den Einsatz bei hohen Temperaturen ist die von der Firma Dow Chemical entwikkelte Legierung A mit der Zusammensetzung Mg-4%Al-2%SE (SE - Seltene Erdelemente) ebenfalls gut bekannt.

- Solche wärmebeständigen Magnesiumlegierungen sind jedoch beim Formguss schlecht anwendbar, wo nach dem Formen eines Metallgegenstandes eine schnelle Abkühlung bewirkt werden muss.

- Die

DE 44 46 898 A1 offenbart kriechbeständige Magnesiumlegierungen, enthaltend: 1,5 bis 10 Gew.-% Aluminium (Al), weniger als 2 Gew.-% Seltene Erdelemente (SE), 0,25 bis 5,5 Gew.-% Calcium (Ca) und Magnesium als Rest. Zusätzlich kann die Legierung 0,2 bis 2,5 Gew.-% Kupfer und/oder Zink enthalten. - Die in solchen Legierungen enthaltenen Seltenen Erdelemente erhöhen allerdings die Kosten der Legierung.

- Die

DE 22 01 460 A1 offenbart ebenfalls kriechbeständige Magnesiumlegierungen mit einem Gehalt an Aluminium und gegebenenfalls einem weiteren Element, ausgewählt aus Kalzium, Zirkon, Titan, Silizium, Strontium, Yttrium, Cer oder Barium. Eine Kombination von Barium und Kalzium als zusätzliche Elemente ist nicht offenbart. - Die Aufgabe der vorliegenden Erfindung besteht somit darin, eine Magnesiumlegierung anzugeben, mit der die Nachteile des oben angesprochenen Standes der Technik überwunden werden können und die zudem eine höhere Kriechbeständigkeit aufweist.

- Die Aufgabe wird durch eine Magnesium enthaltende Metallegierung oder Magnesiumlegierung gelöst, die bezogen auf das Gesamtgewicht der Legierung 1 bis 9 Gew.-% Aluminium (Al), 0,5 bis 5 Gew.% Barium (Ba), 0,5 bis 5 Gew.-% Kalzium (Ca) sowie Magnesium (Mg) und unvermeidbare herstellungsbedingte Verunreinigungen als Rest enthält. Vorzugsweise sind die unvermeidbaren herstellungsbedingten Verunreinigungen in einer Gesamtmenge bezogen auf das Gesamtgewicht der Legierung von nicht über 2 Gew.% vorhanden. Der Anteil an Aluminium beträgt vorzugsweise 2 bis 7 Gew.%, bevorzugter 3 bis 6 Gew.%. Der Anteil an Barium beträgt vorzugsweise 1 bis 4 Gew.%, bevorzugter 1,5 bis 3 Gew.%. Der Anteil an Kalzium beträgt vorzugsweise 1 bis 4 Gew.%, bevorzugter 1,5 bis 3 Gew.%.

- Die erfindungsgemäße Magnesiumlegierung kann zusätzlich Zink, Zinn, Lithium, Mangan, Yttrium, Neodym, Cer und/oder Praseodym in Anteilen von jeweils bis zu 7 Gew.% enthalten.

- Die erfindungsgemäße Magnesiumlegierung findet vielfältige Anwendungsbereiche; vorzugsweise kann sie zur Herstellung von Bauteilen von Automobilen, Schiffen und/oder Flugzeugen, bevorzugter zur Herstellung von Antriebssträngen oder deren Bauteilen verwendet werden.

- Die Erfindung wird im folgenden unter Bezugnahme auf die beigefügte Figur näher erläutert.

Figur 1 zeigt die Kriechverformung in Abhängigkeit der Zeit bei einer anliegenden Spannung von 80 MPa und einer Temperatur von 200°C von zwei erfindungsgemäßen Magnesiumlegierungen (ABC-Legierungen) mit einem Gehalt von etwa 4 Gew.% Aluminium, etwa 2 Gew.% Barium und etwa 1 Gew.% Kalzium (ABC421) bzw. etwa 4 Gew.% Aluminium, etwa 2 Gew.% Barium und etwa 2 Gew.% Kalzium (ABC422) im Vergleich zur herkömmlichen Legierung AE42, wobei E für Seltenerdelemente steht, bzw. einer Legierung mit der Bezeichnung MRI230D der Firma Dead Sea Magnesium, die neben Aluminium und Kalzium Seltenderdelemente enthält. - Die erfindungsgemäßen Legierungen weisen eine deutlich geringere Kriechverformung als die jeweiligen Vergleichslegierungen auf. Daraus folgt, dass man bei konstanter Spannung entweder die Temperatur noch erhöhen darf oder dass man ein Bauteil deutlich länger belasten kann.

Claims (7)

- Magnesiumlegierung, die bezogen auf das Gesamtgewicht der Legierung folgende Bestandteile enthält:1 bis 9 Gew.% Aluminium0,5 bis 5 Gew.% Barium0,5 bis 5 Gew.% Kalzium undMagnesium als Rest.

- Magnesiumlegierung nach Patentanspruch 1, dadurch gekennzeichnet, dass sie zusätzlich Zink, Zinn, Lithium, Mangan, Yttrium, Neodym, Cer und/oder Praseodym in Anteilen von jeweils bis zu 7 Gew.% enthält.

- Magnesiumlegierung nach einem der vorgehenden Patentansprüche, dadurch gekennzeichnet, dass der Anteil an Aluminium 2 bis 7 Gew.%, vorzugsweise 3 bis 6 Gew.% beträgt.

- Magnesiumlegierung nach einem der vorgehenden Patentansprüche, dadurch gekennzeichnet, dass der Anteil an Barium 1 bis 4 Gew.%, vorzugsweise 1,5 bis 3 Gew.% beträgt.

- Magnesiumlegierung nach einem der vorgehenden Patentansprüche, dadurch gekennzeichnet, dass der Anteil an Kalzium 1 bis 4 Gew.%, vorzugsweise 1,5 bis 3 Gew.% beträgt.

- Verwendung einer Magnesiumlegierung gemäß einem der Patentansprüche 1 bis 5 zur Herstellung von Bauteilen von Automobilen, Schiffen und/oder Flugzeugen.

- Verwendung einer Magnesiumlegierung gemäß einem der Patentansprüche 1 bis 5 zur Herstellung von Antriebssträngen oder deren Bauteile.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008039683A DE102008039683B4 (de) | 2008-08-26 | 2008-08-26 | Kriechbeständige Magnesiumlegierung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2159293A2 true EP2159293A2 (de) | 2010-03-03 |

| EP2159293A3 EP2159293A3 (de) | 2012-05-30 |

| EP2159293B1 EP2159293B1 (de) | 2015-07-08 |

Family

ID=41404299

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09168253.4A Not-in-force EP2159293B1 (de) | 2008-08-26 | 2009-08-20 | Kriechbeständige Magnesiumlegierung |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20100054985A1 (de) |

| EP (1) | EP2159293B1 (de) |

| JP (1) | JP2010065318A (de) |

| CN (1) | CN101676423A (de) |

| AU (1) | AU2009208050A1 (de) |

| CA (1) | CA2675863A1 (de) |

| DE (1) | DE102008039683B4 (de) |

| ES (1) | ES2548582T3 (de) |

| IL (1) | IL200309A0 (de) |

| PT (1) | PT2159293E (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8435444B2 (en) | 2009-08-26 | 2013-05-07 | Techmag Ag | Magnesium alloy |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101080164B1 (ko) | 2011-01-11 | 2011-11-07 | 한국기계연구원 | 발화저항성과 기계적 특성이 우수한 마그네슘 합금 및 그 제조방법 |

| CN102242298A (zh) * | 2011-07-04 | 2011-11-16 | 四川大学 | 一种Al、Zn强化Mg-Sn-RE基高强韧耐热镁合金 |

| CN103789589B (zh) * | 2014-03-04 | 2015-09-09 | 南京信息工程大学 | 一种高阳极利用率电池材料及制备方法 |

| CN104087803B (zh) * | 2014-07-28 | 2016-08-24 | 王雨晴 | 一种抗蠕变镁合金及其制备方法 |

| CN105543522A (zh) * | 2016-01-06 | 2016-05-04 | 安徽祈艾特电子科技股份有限公司 | 一种用于铸造汽车零部件的纳米硼化锆改性的Mg-Al-Zn系镁合金材料及其制备方法 |

| CN106521274A (zh) * | 2016-10-27 | 2017-03-22 | 江苏理工学院 | 一种高强度镁‑锂‑铝‑钇‑钙合金及其制备方法 |

| CN106566966B (zh) * | 2016-11-18 | 2018-06-26 | 哈尔滨理工大学 | 一种高熵合金作为增强基的镁基复合材料及其制备方法 |

| US20200232070A1 (en) | 2019-01-18 | 2020-07-23 | Divergent Technologies, Inc. | Aluminum alloy compositions |

| CN111726655B (zh) * | 2020-07-02 | 2022-09-06 | 中影华夏寰宇(北京)电影科技有限公司 | 视频处理装置、方法和系统 |

| CN112442620B (zh) * | 2020-10-29 | 2021-10-01 | 航天材料及工艺研究所 | 一种300MPa级镁锂合金材料及其制备方法 |

| US12365965B2 (en) | 2021-07-01 | 2025-07-22 | Divergent Technologies, Inc. | Al—Mg—Si based near-eutectic alloy composition for high strength and stiffness applications |

| DE102022109070A1 (de) | 2022-04-13 | 2023-10-19 | Soluterials Verwaltungs und Verwertungs UG (haftungsbeschränkt) | Leichtmetall-Matrixverbundwerkstoff auf Magnesiumbasis und Verfahren zu seiner Herstellung |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2201460A1 (de) | 1972-01-13 | 1973-07-19 | Erdmann Jesnitzer Friedrich Pr | Magnesiumlegierungen mit hohem kriechwiderstand bei erhoehten temperaturen |

| DE4446898A1 (de) | 1993-06-28 | 1996-07-04 | Ube Industries | Magnesiumlegierung |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT123225B (de) * | 1927-11-09 | 1931-06-10 | Anton Ing Kratky | Verfahren zur Reinigung von Cer-Aluminium-Magnesium-Legierungen durch Behandlung mit Fluoriden. |

| US2747991A (en) * | 1945-09-14 | 1956-05-29 | Olin Mathieson | Magnesium-base alloys |

| DE1259578B (de) * | 1959-05-01 | 1968-01-25 | Dow Chemical Co | Verfahren zur pulvermetallurgischen Herstellung einer dispersionsverfestigten Magnesiumlegierung |

| US3182390A (en) * | 1959-05-01 | 1965-05-11 | Dow Chemical Co | Method of die-expressing a magnesiumbase alloy |

| US3119684A (en) * | 1961-11-27 | 1964-01-28 | Dow Chemical Co | Article of magnesium-base alloy and method of making |

| JP2705996B2 (ja) * | 1990-06-13 | 1998-01-28 | 健 増本 | 高力マグネシウム基合金 |

| JP3110117B2 (ja) * | 1991-12-26 | 2000-11-20 | 健 増本 | 高強度マグネシウム基合金 |

| JP3522963B2 (ja) * | 1996-04-04 | 2004-04-26 | 三井金属鉱業株式会社 | 耐熱マグネシウム合金部材の製造方法およびそれに用いるマグネシウム合金、並びにマグネシウム合金成形部材 |

| JP3611759B2 (ja) * | 1999-10-04 | 2005-01-19 | 株式会社日本製鋼所 | 耐熱性と鋳造性に優れたマグネシウム合金およびマグネシウム合金耐熱部材 |

| JP3592659B2 (ja) * | 2001-08-23 | 2004-11-24 | 株式会社日本製鋼所 | 耐食性に優れたマグネシウム合金およびマグネシウム合金部材 |

| JP3852769B2 (ja) * | 2002-11-06 | 2006-12-06 | 三菱製鋼株式会社 | 耐食性に優れた室温成形可能なマグネシウム合金 |

| JP2004162090A (ja) * | 2002-11-11 | 2004-06-10 | Toyota Industries Corp | 耐熱性マグネシウム合金 |

| KR101127113B1 (ko) * | 2004-01-09 | 2012-03-26 | 켄지 히가시 | 다이캐스트용 마그네슘 합금 및 이것을 사용한 마그네슘다이캐스트 제품 |

-

2008

- 2008-08-26 DE DE102008039683A patent/DE102008039683B4/de not_active Expired - Fee Related

-

2009

- 2009-08-07 AU AU2009208050A patent/AU2009208050A1/en not_active Abandoned

- 2009-08-10 IL IL200309A patent/IL200309A0/en unknown

- 2009-08-13 US US12/540,581 patent/US20100054985A1/en not_active Abandoned

- 2009-08-18 CA CA2675863A patent/CA2675863A1/en not_active Abandoned

- 2009-08-20 ES ES09168253.4T patent/ES2548582T3/es active Active

- 2009-08-20 EP EP09168253.4A patent/EP2159293B1/de not_active Not-in-force

- 2009-08-20 PT PT91682534T patent/PT2159293E/pt unknown

- 2009-08-24 CN CN200910166342A patent/CN101676423A/zh active Pending

- 2009-08-25 JP JP2009193787A patent/JP2010065318A/ja not_active Withdrawn

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2201460A1 (de) | 1972-01-13 | 1973-07-19 | Erdmann Jesnitzer Friedrich Pr | Magnesiumlegierungen mit hohem kriechwiderstand bei erhoehten temperaturen |

| DE4446898A1 (de) | 1993-06-28 | 1996-07-04 | Ube Industries | Magnesiumlegierung |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8435444B2 (en) | 2009-08-26 | 2013-05-07 | Techmag Ag | Magnesium alloy |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2159293B1 (de) | 2015-07-08 |

| CN101676423A (zh) | 2010-03-24 |

| DE102008039683A1 (de) | 2010-03-04 |

| JP2010065318A (ja) | 2010-03-25 |

| IL200309A0 (en) | 2010-05-31 |

| AU2009208050A1 (en) | 2010-03-18 |

| CA2675863A1 (en) | 2010-02-26 |

| PT2159293E (pt) | 2015-09-16 |

| DE102008039683B4 (de) | 2010-11-04 |

| US20100054985A1 (en) | 2010-03-04 |

| ES2548582T3 (es) | 2015-10-19 |

| EP2159293A3 (de) | 2012-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2159293B1 (de) | Kriechbeständige Magnesiumlegierung | |

| DE4446898A1 (de) | Magnesiumlegierung | |

| EP1025270B1 (de) | Neue schweissbare, korrosionsbeständige hochmagnesiumhaltige aluminium-magnesium-legierung, insbesondere für die automobilanwendung | |

| DE19838017C2 (de) | Schweißbare, korrosionsbeständige AIMg-Legierungen, insbesondere für die Verkehrstechnik | |

| EP0419789B1 (de) | Formgedächtnislegierung | |

| DE03740568T1 (de) | Produkte aus al-zn-mg-cu-legierungen | |

| EP3176275B2 (de) | Aluminium-silizium-druckgusslegierung, verfahren zur herstellung eines druckgussbauteils aus der legierung und karosseriekomponente mit einem druckgussbauteil | |

| DE102009038449B4 (de) | Magnesiumlegierung | |

| WO2017182101A1 (de) | Druckgusslegierung | |

| DE102005033835A1 (de) | Magnesiumsekundärlegierung | |

| EP3363924B1 (de) | Aluminiumlegierung | |

| DE102008020523A1 (de) | Duktile Magnesiumlegierung | |

| DE2010055C3 (de) | Verfahren zum Herstellen eines Werkstoffs mit hoher Zeitstandfestigkeit und Zähigkeit | |

| DE102012108590A1 (de) | Gussstück | |

| EP1747298B1 (de) | Titan-aluminium-legierung | |

| EP2984201B1 (de) | Verfahren zur hestellung einer aluminiumfreien magnesiumlegierung | |

| DE202015100698U1 (de) | Gusslegierung | |

| DE2201460A1 (de) | Magnesiumlegierungen mit hohem kriechwiderstand bei erhoehten temperaturen | |

| DE102019128675B3 (de) | Aluminiumlegierung, deren Verwendung sowie Zylinderkopf | |

| AT509343B1 (de) | Aluminiumlegierung | |

| EP1748088B1 (de) | Verfahren zur Herstellung eines Halbzeugs oder Bauteils von Fahrwerk- oder Strukturanwendungen im Kraftfahrzeug | |

| DE102019202676A1 (de) | Gussbauteile mit hoher Festigkeit und Duktilität und geringer Heißrissneigung | |

| DE2261315A1 (de) | Untereutektische alsi-basis-legierung | |

| DE1903712C3 (de) | ||

| DE20202591U1 (de) | Magnesiumlegierung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090820 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HELMHOLTZ-ZENTRUM GEESTHACHT ZENTRUM FUER MATERIAL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: C22C 23/02 20060101AFI20120420BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150210 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 735491 Country of ref document: AT Kind code of ref document: T Effective date: 20150715 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009011218 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20150731 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2548582 Country of ref document: ES Kind code of ref document: T3 Effective date: 20151019 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151009 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151108 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009011218 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150831 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150831 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| 26N | No opposition filed |

Effective date: 20160411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150820 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20160824 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 735491 Country of ref document: AT Kind code of ref document: T Effective date: 20150820 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20160823 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150820 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20160816 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150831 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150820 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20170901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170820 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190919 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210823 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210824 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200821 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220822 Year of fee payment: 14 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220820 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502009011218 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240301 |