EP2003233B1 - Aiguille à coulisse avec voie bordée pour coulisse - Google Patents

Aiguille à coulisse avec voie bordée pour coulisse Download PDFInfo

- Publication number

- EP2003233B1 EP2003233B1 EP07011848A EP07011848A EP2003233B1 EP 2003233 B1 EP2003233 B1 EP 2003233B1 EP 07011848 A EP07011848 A EP 07011848A EP 07011848 A EP07011848 A EP 07011848A EP 2003233 B1 EP2003233 B1 EP 2003233B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- needle

- thickness

- edge

- slider

- slide channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 150000001875 compounds Chemical class 0.000 claims 11

- 238000009940 knitting Methods 0.000 description 4

- 238000005452 bending Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 239000000314 lubricant Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 230000004308 accommodation Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B35/00—Details of, or auxiliary devices incorporated in, knitting machines, not otherwise provided for

- D04B35/02—Knitting tools or instruments not provided for in group D04B15/00 or D04B27/00

- D04B35/06—Sliding-tongue needles

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B35/00—Details of, or auxiliary devices incorporated in, knitting machines, not otherwise provided for

Definitions

- the invention relates to a slider needle for use in stitch-forming machines, in particular knitting machines such as circular knitting machines, crochet galloon machines, knitting machines or other stitch-forming textile machines.

- Sliding needles have a needle body with a hook, which is used for stitching.

- the hook defines a hook interior, which must be opened and closed controlled. This is done by a slider mounted on the needle body which is slidably mounted along the needle body.

- the needle body and the slider each have a foot which is actuated by a needle lock. A relative movement between the slider and the needle body opens and closes the hook interior.

- Such slide needles are for example from the DE 1 635 847 A1 known.

- This document discloses a needle with a needle body having a tubular portion formed. This tubular portion encloses a longitudinally directed oval channel, which serves to receive the slider.

- the the tubular section surrounding walls have a uniform thickness around the circumference of the pipe section.

- slide channel open for example, at the top, in order to create more space for the slide and to avoid rounded surfaces, which could otherwise lead to jamming of the slider. Because with open slide channels slide can fall out of the needle, for example, when the needle is inserted into a machine or taken out of it.

- a slider needle with a limited by two walls slide channel.

- the upper edges of the walls are bent towards each other to close the slide channel at the top. This results in a top-rounded closed slide channel.

- the cross-sectional shape of the slide is adapted to the rounding of the slide channel.

- the slider needle according to the invention has a needle body with a slide channel in which a slider is slidably disposed.

- the slide channel is bounded by two side walls. At least one of the sidewalls has a reduced thickness edge at its upper end. This edge is curved towards the other side wall to close the slide channel at the top.

- the slide channel is thus formed largely rectangular.

- the slide mounted in the slide channel may have a relatively large height, whereby on the one hand, on the one hand, it can be precisely guided and, on the other hand, it can be made stable.

- the height of the slider can be selected to be greater than in the case of needles with a uniform sidewall thickness and crimped on top of one another Sidewalls.

- the reduction of the thickness of the side wall at its respective upper edge creates a free space that the slider can take. If a lower slide height is sufficient, however, the additional free space gained permits an overall lower dimensioning of the height of the shaft of the knitting machine needle in the stitch-forming area (jaw height).

- the upper edges of the slider needle may together form a joint, e.g. in the form of a gap where they can touch each other. This opens up the possibility of mutual connection, for example by laser welding points or other means of connection. It is also possible to form the upper edges of the slider needle overlapping each other. This also makes it possible on the one hand to produce a mechanically particularly secure closure of the slide channel and to connect the edges of the side walls to one another. But it is also possible to leave a gap between the two edges, but this is narrower than the slide channel. Such a gap may be desired if, for example, lubricant should penetrate into and out of the slide channel.

- the thickness of the sidewall is reduced by a step, ramp or similar means.

- the step, ramp or other form used to change the wall thickness is preferably arranged on the inside of the side wall.

- Both sidewalls preferably have a reduced thickness at their respective upper edge, so that the two thickness-reduced edges can be bent toward one another.

- the side walls of the needle are formed symmetrical to each other with respect to a median plane. This avoids distortion of the needle under load or prolonged use.

- the thickness of the side walls in the settled area should not be less than 0.1 mm. In special cases, however, it may also be lower. A reduction in thickness of 0.05 mm is sufficient so that the slider can also use the space above the step. Thus, the slider may have a height that exceeds 2/3 of the total height of the slide channel.

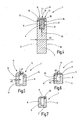

- a slider needle 1 adapted for use in a stitch forming machine.

- the slider needle 1 has a needle body 2, which is elongate and has a hook 3 at one end. This is associated with a slide 4, which is mounted longitudinally movable relative to the needle body 2 on or in the needle body 2.

- the end of the slider 4 protrudes from a example Fig. 2 or 4 apparent slide channel 5 and can be moved towards the tip of the hook 3 and away from this.

- the needle body 2 and the slider 4 are each provided with a foot 6, 7, which is in operation respectively with a needle bar or a needle lock engaged.

- the slide channel 5 passes through the needle body 2, as Fig. 2 shows, in the longitudinal direction. It is bounded by side walls 8, 9 ( Fig. 4 ) between which a preferably substantially flat or flat bottom 10 is formed.

- the side walls 8, 9 define a slot between each other. They have flat inner sides and are preferably oriented parallel to one another. Between the side walls 8, 9 of the slide 4 is mounted with little play.

- the thickness d1 or d2 is, as in the example of Fig. 5 can be seen, measured in each case perpendicular to the relevant wall section.

- a corresponding shaped element for example in the form of a step 13, 14, is provided, preferably on the inside of each Side wall 8, 9 is attached.

- the thickness d2 of the wall 8, 9 changes to a dimension d1, preferably ⁇ 0.1 mm. In some cases, however, the dimension d1 can also be reduced to lower values, such as 0.05 mm.

- Both the edge 11 (12) and the side wall 8 (9) each have mutually parallel flat sides. However, the edge 11 (12) can also be wedge-shaped, ie taper or thicken from the step 13 (14) to its final edge.

- edges 11, 12 are curved towards each other, as in particular Fig. 4 shows. They put on their inside a throat 15, 16 fixed, which faces the slide channel 5.

- the radius of this cylindrically curved surface or throat 15, 16 is preferably less than half the thickness d3 of the needle body 2.

- the thickness d3 is according to FIG Fig. 4 to measure as a distance between its preferably flat side surfaces 17, 18.

- the two edges 11, 12 can touch each other or how Fig. 3 and 4 show, with each other limit a gap 19.

- This gap 19 can serve to let lubricant enter and leave the slide channel 5.

- the needle body 2 is initially provided on its narrow upper side with a slot. During or after the upper edges 11, 12 are formed with reduced thickness. It is then the slider 4 with preferably rectangular or oval or even only rounded at its top cross-section in the slide channel 5 is used. Subsequently, the edges 11, 12 are bent towards each other to complete the slide channel 5 upwards.

- Embodiments are also possible in which the slide 4 is inserted into the slide channel 5 only after the edges 11, 12 have been formed.

- the steps 13, 14 are arranged at the same height, wherein the slide 4, the steps 13, 14 project beyond.

- the steps 13, 14 can also be arranged at different heights. This may be advantageous when the edges 11, 12, as Fig. 5 shows overlap.

- the edges 11, 12 may have a greater height or length, as in the embodiment at Fig. 4 , While there the side walls 8, 9 are arranged symmetrically to a median plane M including their edges 11, 12, the side walls 8, 9 of the needle needle 1 after Fig. 5 formed asymmetrically with respect to the same center plane.

- the steps 13, 14 may be formed at different heights.

- the edges 11, 12 may overlap each other.

- the edges 11, 12 may be loose on each other, include a distance from each other or be connected to each other over their entire length, in sections or at points.

- FIG. 6 Another embodiment shows Fig. 6 ,

- the side wall 8 is provided with the edge 11, while the side wall 9 has no edge 12 with reduced thickness.

- the transition from the thickness d2 to the thickness d1 of the side wall 8 can take place in one stage or, as shown, also with another form element, for example in the form of a curve 20.

- the edge 11 may overlap a portion of the slide channel 5 or as shown, rest on the upper flat end face 21 of the side wall 9. He can loosely rest there or by suitable means of connection such as a laser welding along its entire length, in sections or pointwise connected to the end face 21.

- the edge 11, for example, in his in FIG. 6 flat lying portion has a thickness that coincides with the thickness d2 or at least approximately matches.

- the thickness reduction of the edge 11 may be limited to one place, eg the rounding 20.

- This "location" can be attached as a line-like groove on the inside and / or the outside of the side wall 8 in the longitudinal direction. This type of thickness reduction may also find application in all other embodiments described herein.

- a modification according to Fig. 7 possible.

- the side walls 8, 9 again formed asymmetrically to each other, wherein the side wall 8 is provided with a long edge 11 and the side wall 9 with a short edge 12.

- the short edge 12 engages over the long edge 11 and holds it firmly on the side wall 9.

- the feet 6, 7, unlike drawn may also be oriented differently, the tip of the slider 4 or the hook 3 may have a shape other than that shown, and the needle body 2 may be provided with other shaped elements, such as recesses, Openings or the like may be provided.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Knitting Machines (AREA)

Claims (10)

- Aiguille à coulisse, ou piston, (1)

comportant un fût d'aiguille (2) qui présente un canal de coulissement (5) dans lequel est disposé de façon coulissante un piston (4) et qui est limité par deux parois latérales (8, 9),

au moins une des parois latérales (8, 9) étant courbée par son bord supérieur (11, 12) en direction du bord (12, 11 ; 21) de l'autre paroi latérale (9, 8), en vue de fermer le canal de coulissement (5),

caractérisée en ce que

la paroi latérale (8, 9) présente une épaisseur réduite (d1), au niveau de son bord recourbé (11, 12) au moins à un certain emplacement. - Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que les bords supérieurs (11, 12) forment ensemble une jointure (19) où ils se touchent mutuellement.

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que les bords supérieurs (11, 12) se chevauchent.

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que les bords supérieurs (11, 12) forment ensemble une fente (19) qui est plus étroite que le canal de coulissement (5).

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée

en ce que la paroi latérale (8, 9) présente un degré (13, 14) au niveau duquel

l'épaisseur (d2) de la paroi latérale (8, 9) se trouve réduite jusqu'à atteindre l'épaisseur plus faible (d1) du bord (11, 12). - Aiguille à coulisse, ou piston, selon la revendication 5, caractérisée en ce que le degré (13, 14) est formé sur le côté de la paroi latérale (8, 9) orienté vers le canal de coulissement (5).

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en

ce que les deux parois latérales (8, 9) présentent une épaisseur réduite (d1) au niveau du bord supérieur (11, 12) de chacune d'elles. - Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que les parois latérales (8, 9) de l'aiguille à coulisse, ou piston, (1) sont conformées de manière à être symétriques l'une de l'autre par rapport à un plan médian (M).

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que la paroi latérale (8, 9) est courbée exclusivement au niveau de son bord (11, 12) dont l'épaisseur est réduite, et que pour le reste elle n'est pas courbée.

- Aiguille à coulisse, ou piston, selon la revendication 1, caractérisée en ce que l'épaisseur réduite (d1) du bord supérieur (11, 12) est supérieure à 0,1 mm.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE502007003153T DE502007003153D1 (de) | 2007-06-16 | 2007-06-16 | Schiebernadel mit gebördeltem Schieberkanal |

| EP07011848A EP2003233B1 (fr) | 2007-06-16 | 2007-06-16 | Aiguille à coulisse avec voie bordée pour coulisse |

| KR1020080054465A KR100948008B1 (ko) | 2007-06-16 | 2008-06-11 | 플랜지형 슬라이더 채널을 구비한 복합 바늘 |

| CN2008101255619A CN101324010B (zh) | 2007-06-16 | 2008-06-13 | 具有凸缘滑杆通道的复合针 |

| JP2008155448A JP2008308811A (ja) | 2007-06-16 | 2008-06-13 | フランジ付きスライダチャネルを有する複合針 |

| US12/213,169 US7555920B2 (en) | 2007-06-16 | 2008-06-16 | Compound needle with flanged slider channel |

| JP2011127114A JP5398783B2 (ja) | 2007-06-16 | 2011-06-07 | フランジ付きスライダチャネルを有する複合針 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07011848A EP2003233B1 (fr) | 2007-06-16 | 2007-06-16 | Aiguille à coulisse avec voie bordée pour coulisse |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2003233A1 EP2003233A1 (fr) | 2008-12-17 |

| EP2003233B1 true EP2003233B1 (fr) | 2010-03-17 |

Family

ID=38475953

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07011848A Active EP2003233B1 (fr) | 2007-06-16 | 2007-06-16 | Aiguille à coulisse avec voie bordée pour coulisse |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7555920B2 (fr) |

| EP (1) | EP2003233B1 (fr) |

| JP (2) | JP2008308811A (fr) |

| KR (1) | KR100948008B1 (fr) |

| CN (1) | CN101324010B (fr) |

| DE (1) | DE502007003153D1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013105239A1 (de) * | 2013-05-22 | 2014-11-27 | Groz-Beckert Kg | Schiebernadel |

| JP6249660B2 (ja) * | 2013-07-29 | 2017-12-20 | 株式会社島精機製作所 | 横編機の複合針 |

| EP3587645B1 (fr) * | 2018-06-29 | 2020-05-13 | KARL MAYER R&D GmbH | Aiguille pour machine à tricoter chaîne et procédé pour sa fabrication |

| EP3670725A1 (fr) * | 2018-12-21 | 2020-06-24 | Ulrich Hofmann | Aiguille de formation de mailles sur un métier à tricoter ou un métier à mailles jetées et métier à tricoter ou métier à mailles jetées doté d'une pluralité de telles aiguilles |

| EP3904578B1 (fr) * | 2020-04-29 | 2024-11-06 | Groz-Beckert KG | Aiguille à coulisse pour métiers à tricoter |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1398813A (en) * | 1920-01-10 | 1921-11-29 | Spartan Needle Company | Knitting-needle |

| US1727769A (en) * | 1926-05-29 | 1929-09-10 | Finch Corp | Run-repair needle |

| US2129327A (en) * | 1937-07-13 | 1938-09-06 | Kataja Niilo | Knitting machine needle |

| US2778211A (en) | 1951-10-08 | 1957-01-22 | Nanco Inc | Knitting machine needle of the sliding tongue type |

| GB734976A (en) * | 1953-05-11 | 1955-08-10 | Nanco Inc | Knitting machine needle of the sliding tongue type |

| CH398860A (de) | 1961-11-28 | 1966-03-15 | Vyzk Ustav Bavlnarsky | Zweiteilige Nadel zum Durchwirken und Verfahren zur Herstellung derselben |

| FR1330775A (fr) * | 1962-05-04 | 1963-06-28 | Vyzk Ustav Bavlnarsky | Aiguille en deux parties pour travaux de tissage, notamment pour brochage et procédés de fabrication de cette aiguille |

| US3584481A (en) * | 1969-03-06 | 1971-06-15 | Teihichi Kayashi | Knitting needle for transferring stitches |

| DE2705605C3 (de) * | 1976-03-05 | 1981-10-22 | Tecnología Industrial, Proyectos y Promociones, S.A., Tippsa, Mataro, Barcelona | Schiebernadel für Strickmaschinen |

| ES8102221A2 (es) * | 1980-02-20 | 1980-12-16 | Tecnologia Ind Proyectos Y Pro | Perfeccionamientos en las maquinas tricotosas de hacer punto |

| DE3325767C1 (de) | 1983-07-16 | 1984-11-08 | Theodor Groz & Söhne & Ernst Beckert Nadelfabrik KG, 7470 Albstadt | Schiebernadel fuer maschenbildende Textilmaschinen |

| JPS6164189U (fr) * | 1984-10-01 | 1986-05-01 | ||

| JPS6269865A (ja) * | 1985-09-20 | 1987-03-31 | 福原ニ−ドル株式会社 | 複合針及びその製造方法 |

| KR101062665B1 (ko) * | 2002-12-20 | 2011-09-06 | 가부시키가이샤 시마세이키 세이사쿠쇼 | 복합바늘 |

-

2007

- 2007-06-16 DE DE502007003153T patent/DE502007003153D1/de active Active

- 2007-06-16 EP EP07011848A patent/EP2003233B1/fr active Active

-

2008

- 2008-06-11 KR KR1020080054465A patent/KR100948008B1/ko active IP Right Grant

- 2008-06-13 JP JP2008155448A patent/JP2008308811A/ja active Pending

- 2008-06-13 CN CN2008101255619A patent/CN101324010B/zh active Active

- 2008-06-16 US US12/213,169 patent/US7555920B2/en active Active

-

2011

- 2011-06-07 JP JP2011127114A patent/JP5398783B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008308811A (ja) | 2008-12-25 |

| JP2011196011A (ja) | 2011-10-06 |

| US7555920B2 (en) | 2009-07-07 |

| DE502007003153D1 (de) | 2010-04-29 |

| EP2003233A1 (fr) | 2008-12-17 |

| US20080307832A1 (en) | 2008-12-18 |

| KR100948008B1 (ko) | 2010-03-18 |

| JP5398783B2 (ja) | 2014-01-29 |

| KR20080110708A (ko) | 2008-12-19 |

| CN101324010B (zh) | 2013-02-06 |

| CN101324010A (zh) | 2008-12-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1589136B1 (fr) | Elément de système ayant un ressort freinant | |

| DE102013209775B3 (de) | Speisereinsatz | |

| EP2003233B1 (fr) | Aiguille à coulisse avec voie bordée pour coulisse | |

| AT501706A1 (de) | Flachschlüssel sowie zugehöriges zylinderschloss | |

| EP2896732B1 (fr) | Aiguille à coudre avec double nervurage | |

| EP2355673B1 (fr) | Dispositif pour remplir des tubes à cigarette | |

| EP3087337B1 (fr) | Échangeur de chaleur à joint périphérique | |

| EP2999815B1 (fr) | Aguille à coulisse | |

| EP3643823A1 (fr) | Aiguille coulissante d'un métier à mailles jetées | |

| EP3568604B1 (fr) | Soufflet comportant au moins une rainure interne | |

| EP2619463B1 (fr) | Plaque coulissante pour fermeture à excentrique | |

| EP1999396B1 (fr) | Maillon de chaine indeformable | |

| EP1887117B1 (fr) | Aiguille à clapet pour machine textile à former des mailles | |

| AT518889B1 (de) | Bewehrungselement | |

| EP2019157B1 (fr) | Lisse coudée et étroite | |

| EP2202175A1 (fr) | Serre-câbles | |

| DE102008024200B4 (de) | Schaltwelle | |

| DE19729145C1 (de) | Gestanztes Strickwerkzeug für Textilmaschinen, insbesondere für Strick- und Wirkmaschinen | |

| EP3012363B1 (fr) | Aiguille a tricoter pour machine, systeme de formation de maille et utilisation dudit agencement dans un procédé sur une machine a tricoter | |

| DE102013208572A1 (de) | Vorrichtung zur Herstellung von Bauteilen aus Beton | |

| DE3705722C2 (fr) | ||

| EP1965956B1 (fr) | Pince coupante laterale | |

| DE102010056425B3 (de) | Strickmaschine | |

| DE69500079T2 (de) | Schiffslukendeckel | |

| DE102008015867B4 (de) | Verfahren zum Stanzen von Grifflöchern für ein Einlassgetriebe in ein Fensterprofil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090114 |

|

| RTI1 | Title (correction) |

Free format text: SLIDING-TONGUE NEEDLE WITH EDGED SLIDING CHANNEL |

|

| AKX | Designation fees paid |

Designated state(s): DE IT RO TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE IT RO TR |

|

| REF | Corresponds to: |

Ref document number: 502007003153 Country of ref document: DE Date of ref document: 20100429 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20101220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100616 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230530 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240630 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20240513 Year of fee payment: 18 Ref country code: IT Payment date: 20240513 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240527 Year of fee payment: 18 |