EP1970461A1 - Turbinenbauteil mit Wärmedämmschicht - Google Patents

Turbinenbauteil mit Wärmedämmschicht Download PDFInfo

- Publication number

- EP1970461A1 EP1970461A1 EP07005301A EP07005301A EP1970461A1 EP 1970461 A1 EP1970461 A1 EP 1970461A1 EP 07005301 A EP07005301 A EP 07005301A EP 07005301 A EP07005301 A EP 07005301A EP 1970461 A1 EP1970461 A1 EP 1970461A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- iron

- weight

- based alloy

- layer

- powder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000009413 insulation Methods 0.000 title description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims abstract description 67

- 229910052742 iron Inorganic materials 0.000 claims abstract description 34

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 24

- 229910045601 alloy Inorganic materials 0.000 claims abstract description 23

- 239000000956 alloy Substances 0.000 claims abstract description 23

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 20

- 239000011241 protective layer Substances 0.000 claims abstract description 12

- 230000007797 corrosion Effects 0.000 claims abstract description 11

- 238000005260 corrosion Methods 0.000 claims abstract description 11

- 230000003647 oxidation Effects 0.000 claims abstract description 11

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 11

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 11

- 229910052727 yttrium Inorganic materials 0.000 claims abstract description 5

- 229910052684 Cerium Inorganic materials 0.000 claims abstract description 4

- 229910052735 hafnium Inorganic materials 0.000 claims abstract description 4

- 239000010410 layer Substances 0.000 claims description 23

- 239000012720 thermal barrier coating Substances 0.000 claims description 22

- 239000000843 powder Substances 0.000 claims description 20

- 238000000034 method Methods 0.000 claims description 11

- 230000003628 erosive effect Effects 0.000 claims description 8

- 238000007751 thermal spraying Methods 0.000 claims description 7

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 claims description 3

- 229910001928 zirconium oxide Inorganic materials 0.000 claims description 3

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 claims description 2

- 239000000203 mixture Substances 0.000 claims description 2

- 239000000758 substrate Substances 0.000 claims description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 abstract description 18

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 abstract description 18

- 239000011651 chromium Substances 0.000 abstract description 18

- 238000004519 manufacturing process Methods 0.000 abstract description 8

- 239000010703 silicon Substances 0.000 abstract description 6

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 abstract description 3

- GWXLDORMOJMVQZ-UHFFFAOYSA-N cerium Chemical compound [Ce] GWXLDORMOJMVQZ-UHFFFAOYSA-N 0.000 abstract description 2

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 abstract description 2

- 239000000463 material Substances 0.000 description 24

- 239000012790 adhesive layer Substances 0.000 description 17

- 238000000576 coating method Methods 0.000 description 8

- 239000000919 ceramic Substances 0.000 description 7

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 6

- 239000000126 substance Substances 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 229910000669 Chrome steel Inorganic materials 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 239000004411 aluminium Substances 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000005336 cracking Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 230000008646 thermal stress Effects 0.000 description 2

- 229910018487 Ni—Cr Inorganic materials 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 229910052729 chemical element Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 150000002505 iron Chemical class 0.000 description 1

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 1

- 239000000395 magnesium oxide Substances 0.000 description 1

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- SIWVEOZUMHYXCS-UHFFFAOYSA-N oxo(oxoyttriooxy)yttrium Chemical compound O=[Y]O[Y]=O SIWVEOZUMHYXCS-UHFFFAOYSA-N 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000007750 plasma spraying Methods 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C30/00—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/06—Metallic material

- C23C4/073—Metallic material containing MCrAl or MCrAlY alloys, where M is nickel, cobalt or iron, with or without non-metal elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05B—INDEXING SCHEME RELATING TO WIND, SPRING, WEIGHT, INERTIA OR LIKE MOTORS, TO MACHINES OR ENGINES FOR LIQUIDS COVERED BY SUBCLASSES F03B, F03D AND F03G

- F05B2220/00—Application

- F05B2220/30—Application in turbines

- F05B2220/301—Application in turbines in steam turbines

Definitions

- the invention relates to an iron-based alloy according to claim 1, a protective layer according to claim 10, a layer system according to claim 11 and a method for producing the iron-based layer according to claim 16.

- MCrAlY Protective layers for metallic components intended to increase their corrosion resistance and / or oxidation resistance are known in the art in large numbers. Most of these protective layers are known under the collective name MCrAlY, where M stands for at least one of the elements from the group consisting of iron, cobalt and nickel and further components chromium, aluminum and yttrium.

- Thermal barrier coatings that are applied to turbine components, for example, in the EP 1 541 810 A1 described.

- the effort to increase the inlet temperatures of the live steam in steam turbines is of great importance, because to achieve optimum thermal efficiency, the inlet temperature of the live steam is an important determinant.

- Due to the use of specially developed ferritic base materials for thermally highly stressed turbine components steam temperatures of approx. 620 ° C can currently be achieved.

- thermal barrier coatings on these base materials a fresh steam inlet temperature should be increased or the use of cost-effective materials should be made possible at the same steam temperature.

- a protective layer In order to achieve sufficient resistance to oxidation and corrosion of the ferritic base materials, protective coatings must be used. In addition to the sufficient chemical resistance of a protective layer, a protective layer must also be resistant to good mechanical properties Properties, not least in view of the mechanical interaction between the protective layer and the base material, have. In particular, the protective layer must be sufficiently ductile in order to be able to follow any deformations of the base material and not to break, since in this way points of attack for oxidation and corrosion would be created.

- the adhesive layer ensures good adhesion of the thermal barrier coating to the base material and, on the other hand, protection of the base material against oxidation and corrosion.

- top-coating In order to protect the thermal barrier coating against erosion and corrosion, a further protective layer can be arranged on the thermal barrier coating, which is referred to as top-coating.

- Adhesive layers and / or top coatings made of Ni-Cr 80/20 and / or MCrAlY are particularly suitable for the base materials used in steam turbine construction.

- these abovementioned adhesive layers are suitable for base materials such as, for example, Ni-base alloys, where suitability above 700 ° C. appears possible.

- a disadvantage of the use of these adhesive layers and / or top coatings is that their thermal expansion coefficient compared to the base materials or thermal barrier coatings is relatively high, which means that stresses and / or strains can lead to undesirable cracking.

- the object of the invention is therefore to provide a suitable material for the adhesive layer and / or top coatings.

- the object is also achieved by a method for producing a layer according to claim 16 and / or 19.

- the invention is based inter alia on the finding that the proportion of chromium content on the chemical and physical properties of the adhesive layer and / or the topcoat depends substantially on the chromium content, wherein the aluminum content plays an essential role.

- the invention is characterized in that the thermal spraying a spray powder is used with a chromium content of 25 wt .-% to 35 wt .-% chromium, whereby a chromium content of 15 wt .-% - 30 wt. % is achieved in the iron-based layer after the manufacturing process. It has been determined by experiments that the chromium content of the spray powder falls by up to 10% by weight during the manufacturing process.

- an aluminum content of 1% by weight to 5% by weight of aluminum can be added to the sprayed powder.

- the lowest possible silicon content ⁇ 0.2% by weight is used.

- the elements Ce, Y and / or Hf can be used.

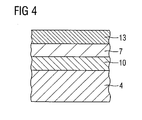

- FIG. 1 shows a first embodiment of an inventively designed component.

- the component 1 could, for example, be an inflow region of a turbine, in particular a steam turbine, and has a base material 4 and a thermal insulation layer 7 applied thereto.

- the thermal insulation layer 7 may be formed from a ceramic material.

- the thermal barrier coating 7 may be formed as a ceramic thermal barrier coating of zirconium oxide, wherein the zirconium oxide is unstabilized, partially stabilized or fully stabilized by yttrium oxide and / or magnesium oxide.

- the ceramic thermal barrier coating may be titanium oxide, the thickness being between 0.1 mm and 2 mm.

- the ceramic thermal barrier coating 7 by thermal spraying such as atmospheric plasma spraying (APS) and by chemical or physical coating methods such. As CVD or PVD can be used.

- thermal spraying such as atmospheric plasma spraying (APS)

- APS atmospheric plasma spraying

- CVD or PVD chemical or physical coating methods

- FIG. 2 shows a further embodiment of the inventively constructed component 1.

- the difference between the FIG. 1 and the FIG. 2 is that between the base material 4 and the thermal barrier coating 7 at least one adhesive layer 10, comprising an iron-based alloy is formed.

- the adhesive layer 10 serves firstly to protect against corrosion and / or oxidation of the base material and secondly to better bond the ceramic thermal barrier coating 7 to the base material 4. This is particularly the case when the ceramic thermal barrier coating and the base material consist of a metal.

- the iron-based adhesive layer in this case comprises 15 wt .-% to 30 wt .-% chromium. Furthermore, the iron-based alloy comprises 1.5 wt% to 2.5 wt% aluminum and less than 0.2 wt% silicon.

- the iron-based adhesive layer may comprise the element Y, the element hafnium and the element Cer with the following proportions by weight: 0.1 wt.% To 0.7 wt.% Y 0.1% by weight to 0.5% by weight of cerium 0.1 wt .-% to 0.5 wt .-% hafnium have.

- the thermal expansion coefficients of the base material 4 and the adhesive layer 10 are thereby very well matched or even equal, so that there is no or only low thermal stresses between the base material 4 and the adhesive layer 10, the chipping and / or cracking the adhesive layer 10 or could cause the thermal barrier coating. This is particularly important because in ferritic materials often no heat treatment for diffusion bonding is performed, but the thermal barrier coating 7 largely or only by adhesion to the base material adheres.

- the base material 4 may be a ferritic base alloy, a steel, in particular a 1% CrMoV steel or a 9% -13% chromium steel. Further advantageous ferritic substrates 4 of the component 1 consist of a 1% - 2% chromium steel for waves: such.

- the component 1 is manufactured by thermal spraying, using iron-based powder comprising 25% by weight to 35% by weight of chromium.

- oxygen uptake during the injection process leads to a more or less pronounced formation of Cr oxide, which in turn results in a strong localized Cr depletion up to a fraction below 12%.

- the use of the iron-based powder according to the invention ensures that the iron-based alloy has a proportion of 15% by weight to 30% by weight of chromium after the production process.

- the manufacturing process is improved in that aluminum is added to the powder with 1 wt% to 5 wt% aluminum. After thermal spraying, an aluminum content of 1.5 wt.% To 3 wt.% Aluminum in the iron-based alloy remains.

- the process uses a powder comprising 28% to 30% by weight of chromium, aluminum being added to the powder with 2.5 wt .-% to 3.5 wt .-% aluminum.

- the powder in this case has less than 0.2 wt .-% silicon.

- the method of producing the iron-based layer using thermal spraying can be improved so that the iron-based powder consists of 25 wt% to 35 wt% of chromium.

- the powder may consist of 25 wt% to 35 wt% chromium and 1 wt% to 5 wt% aluminum.

- the iron-based powder may consist of 28% to 30%, 2.5% to 3.5%, by weight, aluminum and silicon less than 0.2% by weight.

- FIG. 3 shows a further embodiment of the inventively designed component.

- the erosion protection layer 13 can also be referred to as a top coating. It consists in particular of a metal or a metal alloy and protects the component from erosion and / or wear, as is the case in particular in steam turbine power plants which have a scaling in the superheated steam region, where average flow velocities of about 50 m / sec and pressures of up to 350 bar occur.

- the erosion protection layer 13 may have substantially the same chemical elements as the adhesion layer 10. This achieves the advantage that the thermal stresses between a thermal barrier coating and the erosion control layer 13 are minimal.

- an adhesive layer 10 may be present.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Coating By Spraying Or Casting (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

- Powder Metallurgy (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07005301A EP1970461A1 (de) | 2007-03-14 | 2007-03-14 | Turbinenbauteil mit Wärmedämmschicht |

| JP2009553149A JP2010522823A (ja) | 2007-03-14 | 2008-03-13 | 断熱層付きタービン部品 |

| PCT/EP2008/053021 WO2008110607A1 (de) | 2007-03-14 | 2008-03-13 | Turbinenbauteil mit wärmedämmschicht |

| EP08717765A EP2132350A1 (de) | 2007-03-14 | 2008-03-13 | Turbinenbauteil mit wärmedämmschicht |

| CN200880008098A CN101631888A (zh) | 2007-03-14 | 2008-03-13 | 具有绝热层的涡轮机构件 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07005301A EP1970461A1 (de) | 2007-03-14 | 2007-03-14 | Turbinenbauteil mit Wärmedämmschicht |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1970461A1 true EP1970461A1 (de) | 2008-09-17 |

Family

ID=38050293

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07005301A Withdrawn EP1970461A1 (de) | 2007-03-14 | 2007-03-14 | Turbinenbauteil mit Wärmedämmschicht |

| EP08717765A Withdrawn EP2132350A1 (de) | 2007-03-14 | 2008-03-13 | Turbinenbauteil mit wärmedämmschicht |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08717765A Withdrawn EP2132350A1 (de) | 2007-03-14 | 2008-03-13 | Turbinenbauteil mit wärmedämmschicht |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP1970461A1 (enExample) |

| JP (1) | JP2010522823A (enExample) |

| CN (1) | CN101631888A (enExample) |

| WO (1) | WO2008110607A1 (enExample) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2309017A1 (de) * | 2009-10-09 | 2011-04-13 | Siemens Aktiengesellschaft | Dampfturbinenbauteil mit einer Schutzbeschichtung |

| EP2381006A1 (de) * | 2010-04-22 | 2011-10-26 | Siemens Aktiengesellschaft | Schichtsystem für eine Turbinenkomponente |

| EP2381005A1 (de) * | 2010-04-22 | 2011-10-26 | Siemens Aktiengesellschaft | Schichtsystem für Turbinenkomponente |

| EP2431572A1 (de) * | 2010-09-21 | 2012-03-21 | Siemens Aktiengesellschaft | Thermoisolationsschicht für eine Dampfturbinenkomponente |

| CN109162774A (zh) * | 2018-08-30 | 2019-01-08 | 江苏华强新能源科技有限公司 | 一种用于燃气轮机排气扩散段的内保温板 |

| CN113549865A (zh) * | 2021-07-27 | 2021-10-26 | 黑龙江省农业机械工程科学研究院 | 一种铁基合金粉末、棱纹型仿生减阻耐磨结构及其制备方法与应用 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9945036B2 (en) * | 2011-03-22 | 2018-04-17 | General Electric Company | Hot corrosion-resistant coatings and components protected therewith |

| EP2650398B8 (de) * | 2012-04-11 | 2015-05-13 | Oerlikon Metco AG, Wohlen | Spritzpulver mit einer superferritischen Eisenbasisverbindung, sowie ein Substrat, insbesondere Bremsscheibe mit einer thermischen Spritzschicht |

| CN102676972A (zh) * | 2012-05-30 | 2012-09-19 | 重庆国际复合材料有限公司 | 铂铑合金漏板的处理方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4101713A (en) * | 1977-01-14 | 1978-07-18 | General Electric Company | Flame spray oxidation and corrosion resistant superalloys |

| DE10002933C1 (de) * | 2000-01-25 | 2001-07-05 | Krupp Vdm Gmbh | Verfahren zur Herstellung einer formstabilen Eisen-Chrom-Aluminium-Folie sowie Verwendung derselben |

| DE10310865B3 (de) * | 2003-03-11 | 2004-05-27 | Thyssenkrupp Vdm Gmbh | Eisen-Chrom-Aluminium-Legierung |

| EP1541810A1 (de) * | 2003-12-11 | 2005-06-15 | Siemens Aktiengesellschaft | Verwendung einer Wärmedämmschicht für ein Bauteil einer Dampfturbine und eine Dampfturbine |

-

2007

- 2007-03-14 EP EP07005301A patent/EP1970461A1/de not_active Withdrawn

-

2008

- 2008-03-13 EP EP08717765A patent/EP2132350A1/de not_active Withdrawn

- 2008-03-13 JP JP2009553149A patent/JP2010522823A/ja active Pending

- 2008-03-13 WO PCT/EP2008/053021 patent/WO2008110607A1/de not_active Ceased

- 2008-03-13 CN CN200880008098A patent/CN101631888A/zh active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4101713A (en) * | 1977-01-14 | 1978-07-18 | General Electric Company | Flame spray oxidation and corrosion resistant superalloys |

| DE10002933C1 (de) * | 2000-01-25 | 2001-07-05 | Krupp Vdm Gmbh | Verfahren zur Herstellung einer formstabilen Eisen-Chrom-Aluminium-Folie sowie Verwendung derselben |

| DE10310865B3 (de) * | 2003-03-11 | 2004-05-27 | Thyssenkrupp Vdm Gmbh | Eisen-Chrom-Aluminium-Legierung |

| EP1541810A1 (de) * | 2003-12-11 | 2005-06-15 | Siemens Aktiengesellschaft | Verwendung einer Wärmedämmschicht für ein Bauteil einer Dampfturbine und eine Dampfturbine |

Non-Patent Citations (3)

| Title |

|---|

| T. B. MASSALSKI: "Binary alloy phase diagrams - volume 1", 1990, ASM INTERNATIONAL, XP002435437 * |

| T.B. MASSALSKI: "Binary alloy phase diagrams - volume 2", 1990, ASM INTERNATIONAL, XP002435436 * |

| Y. TAMARIN: "Protective coatings for turbine blades", 2002, ASM INTERNATIONAL, MATERIALS PARK, OHIO, XP002435435 * |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2309017A1 (de) * | 2009-10-09 | 2011-04-13 | Siemens Aktiengesellschaft | Dampfturbinenbauteil mit einer Schutzbeschichtung |

| WO2011042500A1 (de) * | 2009-10-09 | 2011-04-14 | Siemens Aktiengesellschaft | Dampfturbinenbauteil mit einer schutzbeschichtung |

| EP2381006A1 (de) * | 2010-04-22 | 2011-10-26 | Siemens Aktiengesellschaft | Schichtsystem für eine Turbinenkomponente |

| EP2381005A1 (de) * | 2010-04-22 | 2011-10-26 | Siemens Aktiengesellschaft | Schichtsystem für Turbinenkomponente |

| EP2431572A1 (de) * | 2010-09-21 | 2012-03-21 | Siemens Aktiengesellschaft | Thermoisolationsschicht für eine Dampfturbinenkomponente |

| CN109162774A (zh) * | 2018-08-30 | 2019-01-08 | 江苏华强新能源科技有限公司 | 一种用于燃气轮机排气扩散段的内保温板 |

| CN109162774B (zh) * | 2018-08-30 | 2021-05-18 | 江苏华强新能源科技有限公司 | 一种用于燃气轮机排气扩散段的内保温板 |

| CN113549865A (zh) * | 2021-07-27 | 2021-10-26 | 黑龙江省农业机械工程科学研究院 | 一种铁基合金粉末、棱纹型仿生减阻耐磨结构及其制备方法与应用 |

| CN113549865B (zh) * | 2021-07-27 | 2023-03-14 | 黑龙江省农业机械工程科学研究院 | 一种铁基合金粉末、棱纹型仿生减阻耐磨结构及其制备方法与应用 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010522823A (ja) | 2010-07-08 |

| WO2008110607A1 (de) | 2008-09-18 |

| EP2132350A1 (de) | 2009-12-16 |

| CN101631888A (zh) | 2010-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1970461A1 (de) | Turbinenbauteil mit Wärmedämmschicht | |

| DE69706850T2 (de) | Artikel mit schutzschicht, enthaltend eine verbesserte verankerungsschicht und seine herstellung | |

| EP1969156B1 (de) | Verfahren zum beschichten einer schaufel und schaufel einer gasturbine | |

| DE69615012T2 (de) | Erosions-korrosionsschutzschicht für hochtemperaturbauteile | |

| DE602005002334T2 (de) | Werkstück auf Superlegierungsbasis mit einer Gamma-Strich-Nickelaluminid-Beschichtung | |

| DE69606708T2 (de) | Bauteil aus superlegierung mit einem schutzschichtsystem | |

| WO2006133980A1 (de) | Schichtsystem für ein bauteil mit wärmedämmschicht und metallischer erosionsschutzschicht, verfahren zur herstellung und verfahren zum betreiben einer dampfturbine | |

| DE10056617C2 (de) | Werkstoff für temperaturbelastete Substrate | |

| EP2824220B1 (de) | CMAS-inerte Wärmedämmschicht und Verfahren zur ihrer Herstellung | |

| DE10126896A1 (de) | Schutzbeschichtigung für ein thermisch belastetes Bauteil, insbesondere Turbinenbauteil | |

| DE3740478C1 (de) | Hochtemperatur-Schutzschicht | |

| WO2007054265A2 (de) | Wärmedämmende schutzschicht für ein bauteil innerhalb des heissgasbereiches einer gasturbine | |

| EP1260602B1 (de) | Verfahren zum Erzeugen eines wärmedämmenden Schichtsystems auf einem metallischen Substrat | |

| EP3333281B1 (de) | Hochtemperaturschutzschicht für titanaluminid - legierungen | |

| EP0241807A2 (de) | Hochtemperatur-Schutzschicht | |

| EP0602233B1 (de) | Schutzschicht für titanbauteile und verfahren zu ihrer herstellung | |

| EP1382707A1 (de) | Schichtsystem | |

| WO2003060194A1 (de) | Hochtemperatur-schutzschicht | |

| EP1902160A1 (de) | Keramische wärmedämmschicht | |

| EP2714957A1 (de) | Verfahren zum aufbringen einer schutzschicht, mit einer schutzschicht beschichtetes bauteil und gasturbine mit einem solchen bauteil | |

| EP3728695A1 (de) | Korrosions- und erosionsbeständige beschichtung für turbinenschaufeln von gasturbinen | |

| DE102007016411A1 (de) | Halbzeug aus Refraktärmetallen, insbesondere aus Molybdän, welches mit einer Schutzschicht versehen ist und Verfahren zu dessen Herstellung | |

| EP0079077B1 (de) | Hochtemperaturschutzschicht | |

| EP1230429B1 (de) | Herstellungsverfahren für eine komponente mit schicht | |

| DE69835208T2 (de) | Haftbeschichtung für wärmedämmendes Beschichtungssystem |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090218 |

|

| R18D | Application deemed to be withdrawn (corrected) |

Effective date: 20090318 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |