EP1790784A2 - Assembling method and assembly jig of building structure composed of pipe structure - Google Patents

Assembling method and assembly jig of building structure composed of pipe structure Download PDFInfo

- Publication number

- EP1790784A2 EP1790784A2 EP06405481A EP06405481A EP1790784A2 EP 1790784 A2 EP1790784 A2 EP 1790784A2 EP 06405481 A EP06405481 A EP 06405481A EP 06405481 A EP06405481 A EP 06405481A EP 1790784 A2 EP1790784 A2 EP 1790784A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pipes

- unit

- joint portion

- pipe structure

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1924—Struts specially adapted therefor

- E04B2001/1927—Struts specially adapted therefor of essentially circular cross section

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1924—Struts specially adapted therefor

- E04B2001/1927—Struts specially adapted therefor of essentially circular cross section

- E04B2001/193—Struts specially adapted therefor of essentially circular cross section with flattened connecting parts, e.g. ends

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1924—Struts specially adapted therefor

- E04B2001/1936—Winged profiles, e.g. with a L-, T-, U- or X-shaped cross section

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1975—Frameworks where the struts are directly connected to each other, i.e. without interposed connecting nodes or plates

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1993—Details of framework supporting structure, e.g. posts or walls

Definitions

- the present invention relates to an assembling method and an assembly jig of a building structure composed of a pipe structure unit formed by joining a plurality of pipes.

- building structures such as large-scale halls, factories, exhibition halls and the like have a structure in which the ceiling is supported by a large span, so that a space having no pillars is formed in the interior thereof.

- One method is adopted to create such large-scale building structure in which metal pipes are assembled in a trussed structure.

- a method is adopted to manufacture in advance a joint member corresponding to the shape of pipes to be joined, and to fix the ends of the pipes via welding to the joint member.

- the present applicant has disclosed in Japanese patent application No. 2005-301233 a joint structure for joining a plurality of pipes by subjecting the pipes to high-precision processing via a laser beam machine to create tenons, mortises and tenon grooves to the pipes, and joining the plurality of pipes by assembling the tenons, mortises and tenon grooves on the pipes directly.

- the object of the present invention is to provide an assembling method and an assembly jig of a building structure utilizing the above-mentioned joint structure of pipes.

- the present invention provides an assembling method comprising the steps of preparing a plurality of pipes having an end face and a necessary tenon, mortise or tenon groove for joining formed on one end thereof, and a mounting unit disposed on the other end thereof for mounting to a corresponding member; temporarily tightening the mounting unit of each pipe to the corresponding member; joining the joining end faces of the pipes on an assembly jig to form a joint portion; compressing a gap formed between the joint portion and the mounting units by lifting the assembly jig; fully tightening the mounting unit of each pipe; and fixing the joint portion via welding.

- the present invention also provides an assembly jig comprising a base, a table provided on the base and capable of being lifted and lowered via a jack, and a jig unit mounted on the table, wherein the jig unit is composed of orthogonally arranged panel members, a profile of the upper surface of the panel members formed to have a shape enabling to support from underneath a joint portion of the pipe structure unit being assembled.

- the pipes can be connected directly to form a trussed structure, so that large-scale building structures can be built inexpensively and in a short time.

- FIG. 1 is an explanatory view showing a portion of the building structure to which the present invention is applied.

- the structure denoted as a whole by reference symbol B constitutes a large-scale exhibition hall or other types of halls, for example, which enables to create therein a large space without pillars.

- FIG. 1 shows a view in which a roof portion of the structure B is viewed from the floor in the direction of arrow L, having a main pillar 1, sub pillars 2 branched from the upper portion of the main pillar 1, girders 3 disposed above the sub pillars 2, and beams 4 connecting the girders 3 disposed at both sides of the structure B, wherein the respective structures are composed for example of metal pipes.

- An assembly 5 mainly composed of pipes having a trussed structure is fixed between the girders and the beams, constituting a ceiling and reinforcing the roof of the building structure.

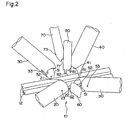

- FIG. 2 is an explanatory view showing a joint portion of a pipe structure unit 10 used in the present invention.

- the joint portion is formed by having the ends of seven pipes connected to a channel member 12.

- the seven pipes are composed of four large-diameter pipes 20, 30, 40 and 50, and three small-diameter pipes 60, 70 and 80.

- the joining end face of each pipe is processed via a laser beam machine to have an end face shape capable of realizing a surface contact with the joining plane of the joint. Then, simultaneously when performing the end face processing, a tenon, a mortise and a tenon groove for joining pipes are processed.

- the processing data for these processes are computed based on the three-dimensional CAD and CAM data of the joint portion.

- An end face 21 and a tenon 22 are processed on the first large-diameter pipe 20. Further, a mortise 23 for receiving a tenon 62 of the first small-diameter pipe 60 described later is processed. Similarly, an end face 31, a tenon 32, a tenon groove 33 to which the channel member 12 is inserted and the like are processed on the second large-diameter pipe 30.

- An end face 41, a tenon and a mortise not shown are processed on the third large-diameter pipe 40.

- An end face 51, a tenon 52, a mortise 53 and the like are processed on the fourth large-diameter pipe 50.

- An end face 61 and a tenon 62 are processed on the first small-diameter pipe 60.

- An end face 71 and a mortise 73 are processed on the second small-diameter pipe 70.

- An end face 81 and a tenon 82 are processed on the third small-diameter pipe 80.

- FIG. 3 illustrates a state in which a pipe structure unit 10 is joined according to the present invention.

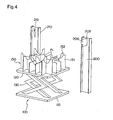

- FIGS. 4 and 5 are explanatory views showing an assembly jig 100 used for assembling the above-mentioned pipe structure unit 10, and the step of assembling the assembled pipe structure unit 10 to pillars 200 and 210 of the building structure.

- the assembly jig 100 comprises a base 110 and a table 120 capable of being lifted and lowered via a jack 130 having a pantograph mechanism.

- a jig unit 150 placed in an exchangeable manner on the table 120 is composed of multiple plate members 151 and 152 arranged orthogonally.

- a profile P 1 defined on the upper surface constitutes a shape for supporting the pipe structure unit 10 from underneath.

- the processing data of this profile are computed based on the three-dimensional CAD and CAM data of the joint portion.

- FIG. 5 illustrates the step of assembling the pipe structure unit 10 on the assembly jig 100.

- each pipe structure unit 10 has their respective upper end faces fixed to pillars, girders and beams.

- FIG. 5 illustrates a state in which the upper ends of the third large-diameter pipe 40 and the fourth large-diameter pipe 50 are fixed to the two pillars 200 and 210, respectively.

- a plate-like mounting unit 45 is disposed on the upper end of the pipe 40, and a similar mounting unit 55 is disposed on the pipe 50.

- Mounting plate members 205 and 215 are also welded in advance to the pillars 200 and 210.

- the plate member 205 has bolt holes 206 for mounting, and similar bolt holes are provided on the plate member 215.

- the bolt holes 56 on the mounting unit 55 disposed on the upper end of the large-diameter pipe 50 are positioned to correspond to the bolt holes 206 on the plate member 205 of the pillar 200, and they are temporarily tightened via bolts and nuts.

- the lower ends of the pipes and the channel member are assembled on the assembly jig 100 using the tenons, mortises and tenon grooves formed in advance via laser machining, by which the joint portion is formed.

- the height of the table 120 of the assembly jig 100 is adjusted to facilitate assembly of the joint portion.

- the jack 130 is operated to lift the table 120 in the direction of arrow Z.

- the gaps formed at the joints of the pipe structure unit 10 and the gaps formed at the temporarily tightened portions on the upper ends of the pipes are compressed.

- FIG. 6 shows a state in which the completed pipe structure unit 10 is viewed from below.

- the ends of the pipes are fixed securely via bolts and nuts to the structure such as pillars, girders and beams. Further, the joint portion of the pipe structure unit 10 is also securely formed via spot welding W 1 and the like.

- the channel member 12 can be used for example as a member for supporting the ceiling member, or for attaching lighting equipments.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Joining Of Building Structures In Genera (AREA)

- Conveying And Assembling Of Building Elements In Situ (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005338082A JP4813874B2 (ja) | 2005-11-24 | 2005-11-24 | パイプ構造建造物の組立工法及び組立治具 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1790784A2 true EP1790784A2 (en) | 2007-05-30 |

Family

ID=37808259

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06405481A Withdrawn EP1790784A2 (en) | 2005-11-24 | 2006-11-15 | Assembling method and assembly jig of building structure composed of pipe structure |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20070144108A1 (zh) |

| EP (1) | EP1790784A2 (zh) |

| JP (1) | JP4813874B2 (zh) |

| CN (1) | CN1970910A (zh) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006348734A (ja) * | 2006-06-05 | 2006-12-28 | Takenaka Komuten Co Ltd | 建築用トラス構造 |

| CN101691797B (zh) * | 2009-09-14 | 2010-12-29 | 江苏沪宁钢机股份有限公司 | 一种屋面桁架的制作方法 |

| CN101851957A (zh) * | 2010-06-02 | 2010-10-06 | 中建钢构有限公司 | 多管相贯节点的制作方法 |

| CN104153516B (zh) * | 2014-07-10 | 2016-05-04 | 百安力钢结构应用科技有限公司 | 桁架系统、快速夹具及移动式金属成型设备 |

| CN113216373B (zh) * | 2021-04-12 | 2022-11-18 | 中安海博(重庆)集团有限公司 | 一种多层装配式异型柱框架支撑体系 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US616073A (en) * | 1898-12-20 | Crank-hanger | ||

| GB1206399A (en) * | 1966-12-09 | 1970-09-23 | Stewarts & Lloyds Ltd | Improvements relating to tubular structures |

| US3751792A (en) * | 1971-06-23 | 1973-08-14 | Gazer Corp | Method of forming a welded joint construction |

| JPS58551A (ja) * | 1981-06-22 | 1983-01-05 | 株式会社日立製作所 | トラス構造の製作方法およびその装置 |

| US4660345A (en) * | 1984-10-10 | 1987-04-28 | Mr. Gasket Company | Vehicle space frame, castings therefor and method for remote construction |

| US5249818A (en) * | 1991-07-26 | 1993-10-05 | Cannondale Corporation | Method of making frames from tubular members and frames made by the method |

| US5361495A (en) * | 1992-11-05 | 1994-11-08 | Pyle S H | Roof truss fabrication method |

| US5605309A (en) * | 1995-04-07 | 1997-02-25 | Ireco, Inc. | Pipe anchoring means |

| US5700102A (en) * | 1996-02-20 | 1997-12-23 | Feleppa; Richard | Shelter frame connector system |

| JPH1066910A (ja) * | 1996-08-29 | 1998-03-10 | Central Motor Co Ltd | バンパー塗装用治具 |

| US6817090B1 (en) * | 1998-10-13 | 2004-11-16 | Mcadoo David L. | Truss fabrication method and apparatus |

| US6560858B1 (en) * | 2000-10-20 | 2003-05-13 | Alpine Engineered Products, Inc. | Truss table apparatus with automatic truss movement assembly and method |

| AUPR666701A0 (en) * | 2001-07-27 | 2001-08-23 | Mitek Holdings, Inc. | Structural framework, method for forming the framework and webs therefor |

| CA2490104C (en) * | 2002-06-21 | 2010-10-12 | Skyline Displays, Inc. | Framework connection system |

| US20050251986A1 (en) * | 2002-07-09 | 2005-11-17 | Tsutomu Katayama | Method of joining pipe-shaped articles |

-

2005

- 2005-11-24 JP JP2005338082A patent/JP4813874B2/ja active Active

-

2006

- 2006-11-13 US US11/558,946 patent/US20070144108A1/en not_active Abandoned

- 2006-11-15 EP EP06405481A patent/EP1790784A2/en not_active Withdrawn

- 2006-11-21 CN CNA2006101492564A patent/CN1970910A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007146365A (ja) | 2007-06-14 |

| JP4813874B2 (ja) | 2011-11-09 |

| US20070144108A1 (en) | 2007-06-28 |

| CN1970910A (zh) | 2007-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7114605B2 (ja) | モジュール式建物用コネクタ | |

| AU2018204197B2 (en) | Modular building units, and methods of constructing and transporting same | |

| KR102690732B1 (ko) | 모듈러 빌딩용 커넥터 | |

| CN109642424B (zh) | 用于预制的体积建筑模块的连接系统和方法 | |

| EP1790784A2 (en) | Assembling method and assembly jig of building structure composed of pipe structure | |

| JP2022540440A (ja) | 多機能コネクタ | |

| JP4748637B2 (ja) | 建物ユニットの接合構造 | |

| JPH08311989A (ja) | 鉄骨建築用シグチ構造 | |

| JP4528177B2 (ja) | 床形成方法および床形成構造 | |

| WO1997017504A1 (fr) | Rattachement d'un montant et d'une poutre ou de deux montants entre eux | |

| JP4713291B2 (ja) | 大型鉄骨h型梁の分割構造と組み立て方法 | |

| JP2002227425A (ja) | 既存建物への免震装置設置工事仮設構造および免震装置設置方法 | |

| JP3768404B2 (ja) | 建物の施工方法 | |

| JP3199658B2 (ja) | 床パネルの取付構造 | |

| JP6972803B2 (ja) | 接合構造及び面構造の施工方法 | |

| JPH11256688A (ja) | 梁接合構造 | |

| JPH0941564A (ja) | 鉄骨組立柱およびその柱・梁接合構造 | |

| JP6696814B2 (ja) | 輸送用接続部材及びユニット建物の構築方法 | |

| JP3948884B2 (ja) | 木質構造物形成方法 | |

| JPS59224740A (ja) | 柱とはりの接合方法および接合用金物 | |

| JP2022113205A (ja) | 柱材、仕口、建築物、柱材の製法及び建築物の工法 | |

| JP2893578B2 (ja) | 建築部材用継手装置 | |

| JP3083420B2 (ja) | 建物ユニットの製造方法 | |

| JPH11172769A (ja) | ユニット建物及びその構築方法 | |

| KR20220014501A (ko) | 보강편을 이용한 금속부재들의 연결구조 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: YAMAZAKI MAZAK CORPORATION |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20100601 |