EP1598477B1 - Drucksortierer zum Sieben einer Faserstoffsuspension - Google Patents

Drucksortierer zum Sieben einer Faserstoffsuspension Download PDFInfo

- Publication number

- EP1598477B1 EP1598477B1 EP05006347A EP05006347A EP1598477B1 EP 1598477 B1 EP1598477 B1 EP 1598477B1 EP 05006347 A EP05006347 A EP 05006347A EP 05006347 A EP05006347 A EP 05006347A EP 1598477 B1 EP1598477 B1 EP 1598477B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- screen

- pressure grader

- suspension

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21D—TREATMENT OF THE MATERIALS BEFORE PASSING TO THE PAPER-MAKING MACHINE

- D21D5/00—Purification of the pulp suspension by mechanical means; Apparatus therefor

- D21D5/02—Straining or screening the pulp

- D21D5/023—Stationary screen-drums

- D21D5/026—Stationary screen-drums with rotating cleaning foils

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21D—TREATMENT OF THE MATERIALS BEFORE PASSING TO THE PAPER-MAKING MACHINE

- D21D1/00—Methods of beating or refining; Beaters of the Hollander type

- D21D1/20—Methods of refining

- D21D1/34—Other mills or refiners

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21D—TREATMENT OF THE MATERIALS BEFORE PASSING TO THE PAPER-MAKING MACHINE

- D21D5/00—Purification of the pulp suspension by mechanical means; Apparatus therefor

- D21D5/02—Straining or screening the pulp

- D21D5/16—Cylinders and plates for screens

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21D—TREATMENT OF THE MATERIALS BEFORE PASSING TO THE PAPER-MAKING MACHINE

- D21D5/00—Purification of the pulp suspension by mechanical means; Apparatus therefor

- D21D5/18—Purification of the pulp suspension by mechanical means; Apparatus therefor with the aid of centrifugal force

- D21D5/22—Purification of the pulp suspension by mechanical means; Apparatus therefor with the aid of centrifugal force in apparatus with a vertical axis

Definitions

- the invention relates to a pressure sorter according to the preamble of claim 1 and to a use of a pressure sorter according to claims 13 and 15.

- Pressure sorters are used in the processing of paper fiber suspensions, in order to process the pulp suspension in a wet sieving.

- a pressure sorter contains at least one screen, which is provided with a plurality of openings.

- the fibers contained in the suspension are to pass through the openings, while rejecting the unwanted solid constituents thereto and are led out of the sorter again.

- sorting holes round holes or slots are usually used.

- pressure sorters of the type considered here are equipped with screen scrapers that are moved close to the screen. As a result, clogging of the screen openings is prevented in a manner known per se.

- the separation effect of a pressure sorter is therefore attributable to the fact that at least some of the impurities contained in the paper pulp suspension fed can not pass through the sieve, that is to say it is separated from the paper fibers due to its size, shape or flexibility.

- pressure sorters are known in which additionally targeted to the density of the impurities separation is made by the different forces of the impurities are used in a centrifugal field.

- the separation effect can only be optimally achieved in hydrocyclones and centrifuges, it can still be useful in pressure sorters. Although a large part of the heavy parts would not pass through the screen openings usually used, so be rejected there, but there is a risk of damage or wear when they come into contact with the sieve. This risk is aggravated by the fact that almost always used are Sieblusterr that move very close to the screen at a relatively high speed.

- pressure graders which in highly contaminated paper fiber suspensions be used by upstream hydrocyclones, so-called thicker scavenger, to protect against coarse heavy particles. This is effective, but with additional effort.

- Another way to reduce wear on the screen of the sorter is to place the sifter on the accept side of the screen.

- the rejected parts on the screen have a lower speed and can not be detected by the sieve scraper.

- the damage caused by pinching of metal parts between the sieve and Siebêtrn is very unlikely.

- the invention is based on the object of further improving the known pressure sorters, so that even a considerable part of the contaminants can be removed from the paper fiber suspension before they strike the screen. In particular wear-promoting heavy parts and sensitive lightweight parts should be removed early.

- the inlet chamber This is generally annular and is supplied by a tangentially attached inlet with the pulp suspension to be sorted, whereby a rotational flow is formed.

- the heavy parts are thrown radially outward, so that they can not or hardly come into contact with the sieve. They drive in the direction of the inner wall of the housing and are partly further dragged by the suspension flow and partly transported by gravity into a part of the Zulaufraumes, from which they can be easily removed.

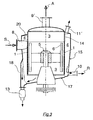

- FIG. 1 A typical embodiment of the pressure sorter according to the invention is shown in FIG. 1.

- This contains in a housing 2 a sieve 1 in the form of a cylindrical screen basket.

- the center line of the screen 1 is perpendicular here in the position of use of the device.

- the sieve openings are advantageously cylindrical along their entire length with a diameter between one and three millimeters.

- the pulp suspension S to be screened is introduced into the housing 2 through an inlet 8. In the process, it first passes into the inlet space 4, which extends substantially annularly and radially outside the screen 1 as part of the housing 2.

- the inlet 8 is connected tangentially to the inlet chamber 4, so that a rotational flow forms during operation of the machine in the inlet chamber 4, which runs in the clockwise direction in this illustration.

- the supplied pulp suspension S moves in the inlet space 4 helically downwards, with a considerable part of this suspension pass through the sieve opening of the sieve 1 and can reach into the accepts space 3 located radially inside the sieve 1.

- a conically tapering portion 15 of the inlet chamber 4 the peripheral velocity of the suspension is maintained or increased, even if their amount decreases due to the outflow through the wire 1.

- the fibrous suspension S to be screened is contaminated not only with heavy but also with light parts, which include, in particular, polystyrene or other light foams. These are quickly separated from the heavy parts due to the centrifugal forces and can be removed early because they move due to their tendency to rise in the liquid-filled feed space 4 in the upper part. There they are discharged through thechtteilauslass 11. This can, as here, lead vertically upwards or obliquely upwards, or also tangentially connected.

- an impermeable cylinder wall 14 lying above the screen 1 for the purpose of separating the inlet space 4 and the accepts space 3, so that a lightweight part collecting space is formed in the upper part of the inlet space 4.

- This can cause a significant calming of the flow, whereby the lightweight parts and possibly air can be separated even better.

- the axial length of this cylinder wall 14 is only a fraction of the axial length of the screen 1, for example, about 20%.

- the climbing effect of the lightweight parts can be additionally supported in this area by a fixed helix, which deflects the circumferential movement into a rising motion.

- reject R The largest part of the suspension rejected at the sieve 1, in particular the contaminants entrained by flow forces, are removed from the housing 2 at the reject outlet 10 as reject R. It is usually sorted to avoid fiber loss.

- the accepts space 3 has here at its uppermost part a vent line 12 through which air and possibly also very fine lightweight parts can be removed from the accepts.

- Figures 3 and 4 serve to show even more solutions with specific details.

- the device according to FIG. 3 has a modified flow guidance in that the accept A from the accept chamber 3 is not discharged downwards, as in FIG. 1, but upwards, ie, that the Gutstoffauslass 9 'is centrally connected to the upper wall of Acceptance space 3.

- the deducted accepts A then contains in addition to the sorted fibers and air, which is why a further vent line can be omitted.

- the ejected in the inlet space 4 to the outside heavy parts are guided by a vertical or oblique on the housing 2 radially projecting Schwerteilkanal 18 directly down to the heavy section lock 13.

- the pressure sorter in Fig. 4 is provided with an inlet space 4 ', whose cross section over the axial height is kept substantially constant, since it was dispensed with a tapered portion. Also, a special separate light parts collection space above the screen 1 can be omitted if necessary, to save height.

- the lightweight parts are immediately dissipated by thechtteilauslass 11.

- In the lower part of the inlet chamber 4 ' is a downwardly sloping end wall 19, which leads out there arrived heavy parts together with the reject R through the reject outlet 10 from the housing. Conveniently, the reject outlet 10 is connected at the lowest point. Another Schwerteilauslass can then be saved.

- the end wall 19 may have an arcuate shape.

- this device is the pre or coarse sorting of dissolved pulp.

- This may typically be a recovered paper pulp suspension formed in a pulper 21 from recovered paper P and water W and withdrawn through a coarse pulp screen 22, as shown in FIG.

- a Pulpersieb 22 is kept free by a rotor 23 and usually has holes with a diameter between 10 and 25 mm.

- the withdrawn by this waste paper suspension is pumped without further screening device via fuel pump 24 into the inlet 8 of an inventively designed pressure sorter. Therefore, this suspension S may be mixed with a larger amount of impurities, which can easily be retained on screen openings whose diameter, for example, in a range between 1 and 3 mm lies.

- such soiled waste paper suspensions may be prepared in a high consistency pulper or in a downstream open wire disintegrating drum, such as an open sorting drum, and diluted.

- a dissolving drum that is suitable for the process shows the German patent application DE 197 36 143 ,

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Paper (AREA)

- Separation Of Solids By Using Liquids Or Pneumatic Power (AREA)

- Combined Means For Separation Of Solids (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004025149A DE102004025149A1 (de) | 2004-05-21 | 2004-05-21 | Drucksortierter zum Sieben einer Faserstoffsuspension |

| DE102004025149 | 2004-05-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1598477A1 EP1598477A1 (de) | 2005-11-23 |

| EP1598477B1 true EP1598477B1 (de) | 2007-11-14 |

Family

ID=34934447

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05006347A Not-in-force EP1598477B1 (de) | 2004-05-21 | 2005-03-23 | Drucksortierer zum Sieben einer Faserstoffsuspension |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20050258079A1 (es) |

| EP (1) | EP1598477B1 (es) |

| JP (1) | JP2005336698A (es) |

| KR (1) | KR20060048053A (es) |

| AT (1) | ATE378458T1 (es) |

| CA (1) | CA2508066A1 (es) |

| DE (2) | DE102004025149A1 (es) |

| ES (1) | ES2295994T3 (es) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITUD20050063A1 (it) * | 2005-04-18 | 2006-10-19 | Pal Srl | Apparecchiatura e procedimento per separare particelle di granulometria finissima da una massa incoerente di materiale legnoso |

| CN102191710B (zh) * | 2011-04-06 | 2013-04-03 | 李�昊 | 一种经改造的间歇式压力筛浆机 |

| DE102011115354B4 (de) | 2011-10-07 | 2017-01-05 | Telejet Kommunikations Gmbh | Navigation anhand von zufälligen Mustern |

| JP2019060056A (ja) * | 2017-09-28 | 2019-04-18 | 相川鉄工株式会社 | スクリ−ン装置及びスクリ−ン装置の異物分離方法 |

| CN110013955A (zh) * | 2018-01-09 | 2019-07-16 | 宝山钢铁股份有限公司 | 一种用于过滤粉剂中大颗粒杂物的过滤装置 |

| CN112108237B (zh) * | 2020-09-09 | 2021-12-21 | 湖南连心科技有限公司 | 一种粉末涂料颗粒控制的过筛设备 |

| JP7317153B1 (ja) * | 2021-09-01 | 2023-07-28 | 三菱電機株式会社 | 異物除去装置 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1231539B (de) * | 1960-07-08 | 1966-12-29 | Lamort E & M | Sichter fuer Papierstoffsuspensionen |

| FR1546515A (fr) * | 1967-06-14 | 1968-11-22 | Lamort E & M | Appareil pour l'épuration de liquides contenant en suspension des matières solides telles que les pâtes à papier |

| DE2830386C2 (de) * | 1978-07-11 | 1982-09-02 | Hermann Finckh, Maschinenfabrik GmbH & Co, 7417 Pfullingen | Verfahren zum Sortieren von Fasersuspensionen sowie Drucksortierer zur Durchführung des Verfahrens |

| DE3911234A1 (de) * | 1989-04-07 | 1990-10-11 | Voith Gmbh J M | Sortierer |

| US5221437A (en) * | 1991-07-08 | 1993-06-22 | The Black Clawson Company | Screening apparatus for paper making stock |

| US20050115690A1 (en) * | 2003-11-25 | 2005-06-02 | Casella Waste Systems, Inc. | Methods for producing recycled pulp from waste paper |

-

2004

- 2004-05-21 DE DE102004025149A patent/DE102004025149A1/de not_active Ceased

-

2005

- 2005-03-23 DE DE502005001926T patent/DE502005001926D1/de active Active

- 2005-03-23 AT AT05006347T patent/ATE378458T1/de not_active IP Right Cessation

- 2005-03-23 ES ES05006347T patent/ES2295994T3/es active Active

- 2005-03-23 EP EP05006347A patent/EP1598477B1/de not_active Not-in-force

- 2005-05-17 JP JP2005144441A patent/JP2005336698A/ja active Pending

- 2005-05-18 US US11/131,358 patent/US20050258079A1/en not_active Abandoned

- 2005-05-20 CA CA002508066A patent/CA2508066A1/en not_active Abandoned

- 2005-05-21 KR KR1020050042754A patent/KR20060048053A/ko not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| CA2508066A1 (en) | 2005-11-21 |

| ES2295994T3 (es) | 2008-04-16 |

| US20050258079A1 (en) | 2005-11-24 |

| DE102004025149A1 (de) | 2005-12-15 |

| ATE378458T1 (de) | 2007-11-15 |

| KR20060048053A (ko) | 2006-05-18 |

| DE502005001926D1 (de) | 2007-12-27 |

| JP2005336698A (ja) | 2005-12-08 |

| EP1598477A1 (de) | 2005-11-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0034780B1 (de) | Rotationssortierer | |

| EP1598477B1 (de) | Drucksortierer zum Sieben einer Faserstoffsuspension | |

| EP1215335B1 (de) | Drucksortierer zum Entfernen von Störstoffen aus einer störstoffhaltigen Papierfasersuspension | |

| WO2011076660A1 (de) | Verfahren und siebvorrichtung zum sieben einer faserstoffsuspension | |

| AT511367B1 (de) | Pulperanordnung und Verfahren zum Auflösen von Fasermaterial | |

| DE102011088102A1 (de) | Siebvorrichtung zum Sieben einer Faserstoffsuspension | |

| DE2753413C3 (de) | Drucksortierer | |

| DE2818029A1 (de) | Vorrichtung zum sortieren von faserstoffsuspensionen | |

| DE102004051327B4 (de) | Verfahren zur Entgasung und Zuführung einer Faserstoffsuspension zu einem Stoffauflauf sowie Entgasungsvorrichtung | |

| DE602004011346T2 (de) | Sortierer zur Reinigung von Fasersuspensionen | |

| DE69116513T2 (de) | Sortiervorrichtung zum Entfernen von Knoten aus einer flüssigen Suspension von Fasern und Knoten | |

| AT408770B (de) | Sortierer zur reinigung einer faserstoffsuspension | |

| WO2010124911A2 (de) | Verfahren zur behandlung einer faserstoffsuspension sowie siebvorrichtungen zu seiner durchführung | |

| EP1749923B1 (de) | Apparat zur Behandlung einer Faserstoffsuspension | |

| EP1860231A2 (de) | Verfahren und Vorrichtung zum Reiningen von störstoffhaltingen Papierrohstoffen | |

| EP1612326B1 (de) | Drucksortierer zum Sieben einer Faserstoffsuspension | |

| AT15802U1 (de) | Drucksortierer | |

| DE102005016192A1 (de) | Verfahren zum Auflösen und Reinigen von störstoffhaltigen Papierrohrstoffen | |

| DE3001448A1 (de) | Drucksortierer | |

| EP0616072B1 (de) | Verfahren zur Sortierung von Faserstoffsuspension sowie Sortiervorrichtung zu seiner Durchführung | |

| EP1122358B1 (de) | Sortierer zur Reinigung einer Faserstoffsuspension | |

| DE10233364C1 (de) | Drucksortierer zum Sieben einer Faserstoffsuspension | |

| DE19825669B4 (de) | Siebapparat für eine verschmutzte Faserstoffsuspension | |

| DE102004051887B3 (de) | Drucksortierer zum Sieben einer Faserstoffsuspension | |

| EP0427802B1 (de) | Gerät zum sortieren und entstippen von fasersuspensionen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060523 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VOITH PATENT GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20071114 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502005001926 Country of ref document: DE Date of ref document: 20071227 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2295994 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080214 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080314 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| BERE | Be: lapsed |

Owner name: VOITH PATENT G.M.B.H. Effective date: 20080331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080414 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| 26N | No opposition filed |

Effective date: 20080815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080215 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20100324 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20100312 Year of fee payment: 6 Ref country code: FR Payment date: 20100402 Year of fee payment: 6 Ref country code: IT Payment date: 20100325 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20100311 Year of fee payment: 6 Ref country code: GB Payment date: 20100322 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080323 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100324 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20100312 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110323 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110323 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110323 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110323 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20120423 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005001926 Country of ref document: DE Effective date: 20111001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110324 |