EP1593506A2 - Machine d'impression - Google Patents

Machine d'impression Download PDFInfo

- Publication number

- EP1593506A2 EP1593506A2 EP05009567A EP05009567A EP1593506A2 EP 1593506 A2 EP1593506 A2 EP 1593506A2 EP 05009567 A EP05009567 A EP 05009567A EP 05009567 A EP05009567 A EP 05009567A EP 1593506 A2 EP1593506 A2 EP 1593506A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- printing

- lifting device

- frame

- printing machine

- rails

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F27/00—Devices for attaching printing elements or formes to supports

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2227/00—Mounting or handling printing plates; Forming printing surfaces in situ

- B41P2227/60—Devices for transferring printing plates

Definitions

- the invention relates to a printing press according to the preamble of the claim 1.

- Printing presses are on the printing cylinders two printing sleeves on top of each other positioned, wherein an outer pressure sleeve forms a pressure surface, and wherein an inner pressure sleeve the diameter balance between the outer pressure sleeve and the respective impression cylinder of the printing press.

- the one printing surface forming, outer pressure sleeve has usually a low Wall thickness

- the printing sleeves to feed the printing units of the printing press come after the state of the art lifting equipment used on one Floor of a machine hall or workshop in the area of the printing press or the printing units are positioned the same. It can be fixed Lifting devices or to act on movable lifting devices. These lifting devices However, it is common that they are available at the printing units Adjust or build space or space and thus retooling the printing units of the printing press because of difficult accessibility hinder it. Furthermore, it is already known from the prior art to use a hall crane on conversion work on printing presses a ceiling of a workshop or machine hall is attached. It is, however, immediate Obviously, that the use of a hall crane for retooling Printing machines is only possible if already the factory floor with a equipped such hall crane.

- the present invention is based on the problem, a to create a novel printing machine, in the refitting without waiver the known from the prior art lifting devices can be performed.

- the printing machine according to the invention has at least one of the printing units associated lifting device for transporting or exchanging printing unit modules, in particular of compression sleeves, wherein the or each lifting device displaceable on an upper side of the printing press or the printing units and / or is pivotally mounted.

- the Changing of printing unit modules during conversion work on the printing units of the Printing machine can be used.

- the lifting devices are at the top the printing units of the printing press slidably and / or pivotally mounted, so that they are within a certain radius of action relative to the printing units can be moved to any position in the room.

- lifting devices that close the printing room adjust or build and thus hinder the retooling of the printing press can be dispensed with the printing machine according to the invention.

- a first advantageous embodiment of the invention are on the top the printing units attached rails for the or each lifting device, wherein a first frame of the or each lifting device over rollers such in the rails is guided, that the or each lifting device displaceable in a first direction is, and wherein at the first frame, a second frame so guided is that the or each lifting device continues in one to the first direction vertically extending, second direction is displaceable.

- each printing unit in each case a lifting device rotatable about a pivot point or pivotally mounted, wherein the lifting devices telescopically movable Have boom, with an outer arm on the pivot point on a Printing unit is rotatably mounted, and wherein inner boom via rollers into each other and nested in the outer boom and are movably guided.

- rails on the top of the printing units are for the or each lifting device attached, wherein a frame of the or each lifting device is guided over rollers in the rails so that the or each lifting device is displaceable in one direction, and wherein the lifting devices having telescopically movable boom, wherein an outer arm via a pivot point is rotatably mounted on the frame, and wherein inner arms are interleaved via roles and movably guided.

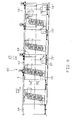

- Fig. 1, 2, 3, 5 and 7 show a first embodiment of an inventive Printing machine 1.

- the printing machine 1 is according to the embodiment Fig. 1 designed as a web-fed printing press and has a reel changer 2, a total of four printing units 3, a dryer 4, a cooling unit 5, a Cutting unit 6 and a folding unit 7.

- the four printing units 3 is a substrate imprinted simultaneously on an upper side and a lower side thereof, wherein in each of the four printing units 3, for example, one for the autotypic se-tenant required process color yellow, cyan, magenta or black on the Substrate is applied.

- the paster 2 is the four printing units. 3 upstream.

- the dryer 4, the cooling unit 5, the cutting unit 6 and the Folder 7, however, are the four printing units 3 downstream.

- a printing machine for the purposes of the present invention, the at least one of the printing units 3 associated lifting device for Changing of printing unit modules, in particular of printing sleeves, having, the or each lifting device on an upper side 8 of the printing units 3 slidably and / or is pivotally mounted.

- the lifting device according to the embodiment of FIGS. 1, 2, 3, 5 and 7 is as Unit numbered with the reference numeral 9.

- Rails 18 are attached, wherein the or each lifting device 9 is guided in the rails 18 and slidable along the rails 18 is.

- the rails 18 extend at least over the area of all printing units 3, ie at least between the reel splitter 2 and the dryer 4.

- the in the Rails 18 guided lifting devices 9 are therefore along the rails 18 over the range of all printing units 3 movable.

- the handling of printing sleeves 14 serves.

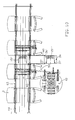

- Fig. 2 are in the area each Printing unit 3 two forme cylinder 10 and 11 and two transfer cylinders 12th and 13 positioned.

- the forme cylinder 10 interacts with the transfer cylinder 12 together and serves to print on the underside of the substrate.

- the Form cylinder 11 cooperates with the transfer cylinder 13 and serves the Printing a top side of the substrate.

- the compression sleeves 14 are preferably positioned on the form cylinders 10 and 11, with format variables Printing presses on each of the forme cylinder 10 and 11, preferably two Compression sleeves 14 are positioned.

- an outer pressure sleeve then forms a pressure surface

- an inner pressure sleeve serves to balance the diameter between the outer pressure sleeve and the forme cylinder 10 or 11.

- the pressure sleeves 14 of the Form sleeves 10 and 11 dismantled and therefore from the field of printing units 3 are moved away.

- each of the printing units 3 are two Ink units 15 and 16 assigned.

- the inking units 15 and 16 can be used for maintenance or retooling of the printing units 3 of the printing machine 1 in the proceed with the reference numerals 15 ', 16', 15 "and 16" marked positions become. Also, this serves the or each lifting device. 9

- the lifting devices 9 are on the upper side 8 of the printing units 3 slidably mounted.

- 8 extend on the top Printing 3 rails 18, according to FIG. 3 on all printing units 3 between the paster 2 and the dryer 4 extend.

- the lifting device 9 of the embodiment of Figs. 1, 2, 3, 5 and 7 has a first Frame 25, which rolls over 17 in the rails 18 along by the arrows 23 and 24 visualized directions of movement is displaceable.

- Transverse waves 20 are deflected or guided. At one of the transverse waves 20 engages over a gear 21 to a crank 22, on the end of the toothed belt 19th driven and the frame 25 along the arrows 23 and 24 are moved can.

- FIGS. 5 and 7 are on the second Frame 28 of the lifting devices 9 two winches 32 and 33 stored or attached.

- the inking units 15 and 16 are in the direction of Arrows 34 and 35 movable (Fig. 2). So are the inking 15 and 16 in the with the reference numerals 15 'and 16' marked positions to the larger Attached winch 32 and lifted in the direction of arrow 34 from a base.

- the crank 22 By means of the crank 22, the inking units 15 and 16 are then in the direction of Arrows 23 and 24 moves and in the direction of arrow 35 in the reference numerals 15 "or 16" marked positions where the inking 15 and 16 placed on a platform 36 by means of guide pins 37 positionally accurate can be.

- the platforms 36 are supported by rollers 38 on the 3 printing units and on rollers 39 on a floor of a workshop from. This facilitates the horizontal setting of the platforms 36, since only the rollers 39 must be adjusted relative to the floor.

- Fig. 3 are the platforms 36 between the printing units 3 telescopically extendable and together with the inking in the designated by the reference numeral 36 '(see Fig. 3) Position can be brought.

- Rails 40 the platforms 36 to the Movement 3 slidably attached.

- the second, smaller winch 33 serves to transport the pressure sleeves 14, wherein For this purpose in a hook of the winch 33 a hitch 41 and 44 (see Fig. 14 to 18) can be suspended.

- a hitch 41 and 44 Using the hitch 41 and 44 are the pressure sleeves 14 of a transport device 42 (see Fig. 3) for the printing sleeves removable and then in the direction of the printing units 3 of the printing machine movable.

- the hitch 41 designed to transport the pressure sleeves 14 as a fork-shaped element, by means of which the pressure sleeve 14 from a tray 43 of the transport device 42 in the horizontal orientation of the printing sleeves shown in FIGS. 14 and 15 14 can be removed.

- the fork-shaped grips Towing device 41 for this purpose on an inner wall of the pressure sleeve 14th at.

- FIG. 16 to 18 An alternative embodiment for a towing device 44, Fig. 16 to 18.

- the hitch 44 of FIG. 16 to 18 has a bar 45, wherein at the ends of the beam 45 in each case a loop 46 is mounted.

- the loops 46 are fixed by spring-loaded pressure pins 47, so that the loops 46 are interchangeable in a simple way, but at the same time against Slipping out are secured.

- FIGS. 17 and 18 taken can be with the hitch 44 pressure sleeves with different Diameter to be picked up and transported.

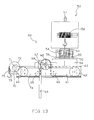

- a second embodiment of a printing machine according to the invention is will be described below with reference to Figs. 4, 6 and 8. Also with this Embodiment are the printing units 3 a printing press lifting devices 50 for changing printing unit modules, in particular of printing sleeves 14 associated with the lifting devices 50 in turn on a top 8 of the printing units 3 of the printing press are stored.

- the following will be for the embodiment of Figs. 4, 6 and 8, only the differences from the embodiment 1, 2, 3, 5 and 7 described. To avoid unnecessary Repetitions are used for identical components with the same reference numbers.

- each Printing unit 3 each have a lifting device 50 via a pivot point 51 rotatable or pivotally mounted.

- the lifting devices 50 are telescopic movable arms 52, 53 and 54, wherein an outer arm 52 on the Fulcrum 51 is rotatably mounted on the upper side 8 of a printing unit 3, and wherein inner arms 53 and 54 via rollers 55 and 56 (see Fig. 8) into each other and nested in the outer boom 52 and are movably guided.

- About the Rolls 55 and 56 is therefore a relative movement between the arms 53, 54 and 55 possible.

- the innermost cantilever 54 is at one Hook 57 a winch 58 stored.

- Fig. 4 shows the lifting devices 50 in different positions, wherein the indicated by the reference numeral 50 ' Position of the rest position of the lifting device 50 corresponds. In the rest shown positions of the lifting device, the boom are telescopic extended and optionally to the fulcrum 51 and the corresponding Swivel pivot.

- FIGS. 9 to 13 A third embodiment of a printing press according to the invention show 9 to 13.

- the embodiment of FIGS. 9 to 13 is a kind of a Combination of the two embodiments described above. It will also Here again the differences to the previously described embodiments so as to avoid unnecessary repetition same reference numbers are used here for the same components.

- FIGS. 9 to 13 are on a top 8 of the printing units 3 rails 63 mounted, extending over the entire range of printing units 3 extend and on which lifting devices 60 slidable or movable are stored.

- the lifting devices 60 have a frame 61, the frame 61 is guided movably over rollers 62 in the rails 63.

- the movement the frame 61 along the rails 63 again takes place via toothed belt 64, which are laid firmly on the top 8 of the printing units 3 and rollers 65 as well Drive rollers 66 (see Fig. 12) are deflected.

- the drive rollers 66 are connected by a shaft 67, wherein on the shaft 67 via a transmission 68 a crank 69 attacks.

- a crank 69 attacks.

- About the operation of the crank 69 can be Accordingly, the frame 61 and thus ultimately the lifting device 60 along of the rails 63 move.

- FIG. 13 are on the frame 61, the telescopically interleaved beams 52, 53 and 54 via a fulcrum 51 pivoted.

- the embodiment corresponds 9 to 13 of the embodiment of FIGS. 4, 6 and 8, so that on the referenced in this regard.

- 60 bearing blocks 70 are provided on the frame 61 of the lifting devices fastened, in which a shaft 71 is mounted with sprockets 72.

- the shaft 71 is via a preferably self-locking gear 73 and a motor 74th driven.

- the inking modules 15 and 16 are attached and as in connection with the embodiment of FIGS. 1, 2, 3, 5 and 7 described, be moved. In this regard, will be back to the above directed.

- the lifting device could be 60 via the gear 61 quickly in the directions of the arrows 23 and 24 move so as to quickly move the lifting devices to the use position.

- About the gear 68 would then be an exact positioning or movement the lifting device with visual inspection under load possible.

- the transmission 21 In this case would have a translation geared to a fast moving of the lifting equipment 60 is tuned without load, the transmission 68 would have a translation for slowly moving the lifting devices 60 with load.

Landscapes

- Rotary Presses (AREA)

- Replacement Of Web Rolls (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004022086A DE102004022086A1 (de) | 2004-05-05 | 2004-05-05 | Druckmaschine |

| DE102004022086 | 2004-05-05 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1593506A2 true EP1593506A2 (fr) | 2005-11-09 |

| EP1593506A3 EP1593506A3 (fr) | 2006-06-21 |

Family

ID=36741369

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05009567A Withdrawn EP1593506A3 (fr) | 2004-05-05 | 2005-05-02 | Machine d'impression |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7228798B2 (fr) |

| EP (1) | EP1593506A3 (fr) |

| JP (1) | JP2005319796A (fr) |

| CA (1) | CA2506335A1 (fr) |

| DE (1) | DE102004022086A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10223414B4 (de) * | 2002-05-25 | 2013-04-25 | Windmöller & Hölscher Kg | Wechselstation für Sleeves von Druckmaschinen |

| DE102007003975B4 (de) | 2007-01-26 | 2021-08-12 | Koenig & Bauer Ag | Druckmaschine in Aggregatbauweise mit in Reihe angeordneten Werken |

| DE102010000994B4 (de) | 2010-01-19 | 2014-05-22 | Koenig & Bauer Aktiengesellschaft | Verfahren zum Zuführen und/oder Abführen von Material einer Druckmaschine |

| WO2017167357A1 (fr) * | 2016-03-30 | 2017-10-05 | Krones Ag | Dispositif et procédé pour emballer des articles, notamment des contenants |

| DE102020207420A1 (de) * | 2020-01-20 | 2021-07-22 | Heidelberger Druckmaschinen Aktiengesellschaft | Vorrichtung zur Druckplatten-Handhabung an einer Druckmaschine |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5549044A (en) * | 1994-04-20 | 1996-08-27 | Windmoller & Holscher | Printing press including a mechanism for exchanging cylinders |

| EP1110721A1 (fr) * | 1999-12-22 | 2001-06-27 | MAN Roland Druckmaschinen AG | Dispositif pour remplacer une pièce à symétrie de revolution |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4616564A (en) * | 1978-12-14 | 1986-10-14 | Didde-Glaser, Inc. | Modular offset lithographic printing tower |

| JPS60244556A (ja) * | 1984-05-17 | 1985-12-04 | Rengo Co Ltd | 多色刷輪転印刷機の版胴交換装置 |

| FR2585287B1 (fr) * | 1985-07-26 | 1988-07-08 | Martin Sa | Machine pour le traitement de feuilles de carton defilant successivement notamment machine d'impression |

| DE3712703A1 (de) * | 1987-04-14 | 1988-11-03 | Heidelberger Druckmasch Ag | Bogenrotations-druckmaschinen fuer mehrfarbendruck |

| DE4309658C1 (de) * | 1993-03-25 | 1994-10-27 | Roland Man Druckmasch | Vorrichtung zum automatischen Wechseln von Druckplatten bei Bogenoffsetdruckmaschinen mit mehreren Druckwerken |

| DE4328058A1 (de) * | 1993-08-20 | 1995-02-23 | Roland Man Druckmasch | Druckmaschine mit mindestens einem auswechselbaren Zylinder, insbesondere einem auswechselbaren Formzylinder, oder mit einer auswechselbaren Druckform |

| DE4344090B4 (de) * | 1993-12-23 | 2006-06-08 | Koenig & Bauer Ag | Vorrichtung zum automatischen Zu- und Abführen von Druckplatten |

| US6082257A (en) * | 1998-08-19 | 2000-07-04 | Howard W. DeMoore | Printing unit with anilox roller bearer positioning |

| DE19849633A1 (de) * | 1998-10-28 | 2000-05-04 | Heidelberger Druckmasch Ag | Positioniervorrichtung in einer Druckmaschine |

| DE29822104U1 (de) * | 1998-12-14 | 1999-02-18 | AGRAMA Logistik+Materialfluß-Technik GmbH & Co. KG, 86167 Augsburg | Transportvorrichtung für eine Druckmaschine |

| US6401608B1 (en) * | 2000-05-05 | 2002-06-11 | Halm Industries, Co., Inc. | Printing press with perfecting station |

| DE10050750A1 (de) * | 2000-10-13 | 2002-04-25 | Kaspar Walter Gmbh & Co Kg | Kompakte Bearbeitungsanlage für Druckzylinder |

| DE10112522C2 (de) * | 2001-03-15 | 2003-10-09 | Windmoeller & Hoelscher | Wechselstation für Sleeves von Druckmaschinen |

| DE10223414B4 (de) * | 2002-05-25 | 2013-04-25 | Windmöller & Hölscher Kg | Wechselstation für Sleeves von Druckmaschinen |

-

2004

- 2004-05-05 DE DE102004022086A patent/DE102004022086A1/de not_active Withdrawn

-

2005

- 2005-05-02 EP EP05009567A patent/EP1593506A3/fr not_active Withdrawn

- 2005-05-02 JP JP2005134663A patent/JP2005319796A/ja not_active Ceased

- 2005-05-03 US US11/121,733 patent/US7228798B2/en not_active Expired - Fee Related

- 2005-05-04 CA CA002506335A patent/CA2506335A1/fr not_active Abandoned

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5549044A (en) * | 1994-04-20 | 1996-08-27 | Windmoller & Holscher | Printing press including a mechanism for exchanging cylinders |

| EP1110721A1 (fr) * | 1999-12-22 | 2001-06-27 | MAN Roland Druckmaschinen AG | Dispositif pour remplacer une pièce à symétrie de revolution |

Also Published As

| Publication number | Publication date |

|---|---|

| US20050263023A1 (en) | 2005-12-01 |

| JP2005319796A (ja) | 2005-11-17 |

| DE102004022086A1 (de) | 2005-12-01 |

| CA2506335A1 (fr) | 2005-11-05 |

| US7228798B2 (en) | 2007-06-12 |

| EP1593506A3 (fr) | 2006-06-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AT407508B (de) | Druckmaschine | |

| DE4327278C5 (de) | Traggestell für eine Rollenrotationsdruckmaschine | |

| EP2285572B1 (fr) | Machine a imprimer a mecanismes d'encrage multiples | |

| DE102006048140B3 (de) | Antrieb einer Hülsenaufnahmeeinrichtung in einem Magazin | |

| DE10008215A1 (de) | Druckwerk für eine Rotationsmaschine mit Kreuzschlitten | |

| DE19937796A1 (de) | Druckwerk | |

| DE10338373A1 (de) | Vorrichtung zum Wechseln von Druckplatten | |

| DE102006061452A1 (de) | Druckplattenkassette | |

| DE3609086A1 (de) | Vorrichtung zum be- bzw. entladen eines rollenstaenders einer rollenrotationsdruckmaschine mit bzw. von papierrollen | |

| EP0782920A2 (fr) | Contrepoids et mécanisme de levage | |

| DE3738973C1 (de) | Vorrichtung zum Auswechseln elastischer Superkalander-Walzen | |

| DE19814661A1 (de) | Zusatzeinrichtung für ein Druckwerk | |

| EP1593506A2 (fr) | Machine d'impression | |

| DE10261999B4 (de) | Druckmaschine mit Trittblech zum Erreichen der oberen Farbwerke | |

| DE3235646A1 (de) | Vorrichtung zur foerderung von gegenstaenden | |

| DE4308712B4 (de) | Druckmaschine | |

| DE102004021621B3 (de) | Transportsystem zum Transport eines Moduls einer Druckeinheit für eine Druckmaschine und ein Verfahren zum Betrieb des Transportsystems | |

| CH698673B1 (de) | Druckeinheit einer Druckmaschine sowie Druckmaschine. | |

| EP3851279A1 (fr) | Dispositif de manipulation des plaques d'impression sur une machine d'impression | |

| EP1099549A2 (fr) | Dispositif et procédé pour l'étaiement d'un cylindre en porte-à-faux | |

| WO2005037552A1 (fr) | Unites d'impression et procede de deplacement d'un element structurel | |

| DE4139343C2 (de) | Probedruckmaschine | |

| CH698061B1 (de) | Druckeinheit einer Druckmaschine. | |

| DE10209536A1 (de) | Druckmaschine, vorzugsweise Flexodruckmaschine | |

| DE29920153U1 (de) | Schwellengreifer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20061218 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE FR GB LI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MANROLAND AG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20101201 |