EP1567705B1 - Device for the hydrodynamic entanglement of the fibers of a fiber web - Google Patents

Device for the hydrodynamic entanglement of the fibers of a fiber web Download PDFInfo

- Publication number

- EP1567705B1 EP1567705B1 EP03811392A EP03811392A EP1567705B1 EP 1567705 B1 EP1567705 B1 EP 1567705B1 EP 03811392 A EP03811392 A EP 03811392A EP 03811392 A EP03811392 A EP 03811392A EP 1567705 B1 EP1567705 B1 EP 1567705B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- endless belt

- fiber web

- rollers

- endless

- drum

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000835 fiber Substances 0.000 title claims abstract description 64

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 26

- 238000009736 wetting Methods 0.000 claims abstract description 5

- 230000006835 compression Effects 0.000 claims description 7

- 238000007906 compression Methods 0.000 claims description 7

- 229920002994 synthetic fiber Polymers 0.000 claims description 2

- 239000012209 synthetic fiber Substances 0.000 claims 1

- 241001295925 Gegenes Species 0.000 description 4

- 238000004080 punching Methods 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 2

- 238000011282 treatment Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000011369 optimal treatment Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H18/00—Needling machines

- D04H18/04—Needling machines with water jets

Definitions

- a device of this kind is by the EP-A-0 859 076 known. It has the advantage that the voluminous fleece arriving on an endless belt for water needling is compacted between the needling drum and the belt and at the same time is wetted by a first curtain of water from the jet bar whose water streams first pass through the endless belt and then through the fiber web and finally the needling drum.

- the device further has the advantage that the voluminous leading fiber web between the two endless belts is slowly compressed increasingly and with uniform pressure from above and below without shearing and only if it is held firmly between the two endless belts, if necessary over a longer press section, is being stopped.

- the outlet-side roller for the first endless belt for stronger contact pressure of the endless belt is arranged adjustable to the needling drum.

- an endless belt guided initially tangentially on the needling drum, with a correspondingly low contact pressure can be brought into contact with the needling drum with a larger wrap angle on the needling drum.

- the nozzle bar is pivoted about the needling drum so that the curtain of water from the nozzles of the water bar will strike the fiber web and the needling drum in line between the center and the end of the compression area ,

- the known devices are ideally suited to the task of slowly compressing the fibrous web consisting of loose non-bonded fibers and also of the upstream net in the pressed state.

- fibrous web is compressed and necked in this loose state, individual fibers remain in the endless compressive band after netting, at least after loosening from the fiber web to be further needled, which soil the band and ultimately hinder durable optimal treatment of the following lengths of fiber web .

- the invention has for its object to find a device with which the cleaning of the endless belt of the lint takes place by itself during the treatment and at the same time the dissolution of the fiber web is advantageously influenced by the endless belt.

- the fiber web should therefore not be stopped when it is held by two endless belts form-fitting, but only shortly thereafter when the two endless belts on the top and bottom move away from each other.

- the separation line of the two endless belts from each other should be only a few cm in front of the point of contact of the water jets, about 20 to 50 mm, in order to achieve a trouble-free meshing.

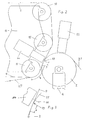

- a compacting water needling device with only one needling drum 2 is shown. It corresponds essentially to the disclosure of Fig. 1 after EP-A-0 859 076 ,

- This unit is usually the first unit of a larger watering system for a loose fiber web, in which so several more needling drums, which are meandering wrapped and then the fiber web is processed on both sides, can connect.

- this unit consists of a first endless belt 3, which is deflected over several in a holding frame 4 rotatably arranged rollers 2, 5 and kept taut.

- this endless belt runs in the direction of arrow 6 to be needled initially voluminous fiber web 7. It may also be a fiber web, which initially has no strength and is thus stored by a card, not shown directly on the endless belt 3.

- the roller 2 is formed in this embodiment as the needling drum. This means that it is larger in diameter and designed as a permeable drum, which is set at least at the Wasseraufschreiberie under induced draft (arrows 8).

- the first endless belt 3 is assigned a second endless belt 9 in opposite directions such that the working strand 3 'of the first endless belt 3 is opposite the working belt 9' of the second endless belt, there the strands 3 ', 9' rotate in the same direction and conically in this area to run.

- rollers 11 and 12 ' Two of the rollers of the second endless belt 9, namely the rollers 11 and 12 ', are directly associated with the needling drum 2 of the first endless belt 3. That is, the rollers 11 and 12 'press the tensioned guided endless belt 9 against the endless belt 3 with the fiber web 7 and then all together against the needle-punching drum 2. For this purpose, they are arranged close to each other and leave only about as much space between them that the nozzle bar 14 can be advanced to the endless belt 9. In this way, the delivered and carried by the strand 3 'of the endless belt 3 fiber web 7 is not only slowly compressed between the endless belts 3 and 9, but over the distance y between the two endless belts 3, 9 and then in the area x to the needling drum 2nd pressed. In this pressing state, the fiber web 7 is wetted by means of the water bar 14 and can then be further needled.

- the present Fig. 1 is different from the Fig. 1 after EP-A 0 859 076 only slightly by changing the arrangement of the guide roller 12 'with respect to the roller 11 and / or needling drum 2.

- the more accurate Arrangement goes out of the Fig. 2 out. So far, both endless belts 3 and 9 were guided by means of the guide rollers a longer distance to the needling drum 2 and wetted approximately in the middle of this distance with the Wasserstahlen of the nozzle beam 14.

- This route is according to Fig. 2 reduced to the pressing area x, which of course begins shortly behind the guide roller 11, but now ends before the point of impact of the water jets 18. The exact situation goes out Fig. 3 out.

- the upper endless belt 9 detaches more from the needling drum 2, namely at the line 19, so that the original pressing pressure during meshing with the water jets 18 no longer acts on the fiber web 7.

- the endless belt 9 lifts off slightly from the upper side of the fibrous web, with the result that the fibrous web is still held on both sides by the endless belts 3, 9 but not pressed, the water jets will continue to wet the fibrous web unchanged, the endless belt 9 free of fibers hanging from this, lead back these residual fibers in the fiber composite of the fiber web 7 and ultimately press the fiber web 7 to the needling drum 2, deliver to this without a longitudinal tension on the fiber web 7 can arise.

- the distance from the end 19 of the press line to the impingement of the water jets 18 from the nozzle bar 14 is about 20 - 50 mm, preferably 30 mm.

- the measure may differ slightly from this data.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Nonwoven Fabrics (AREA)

- Glass Compositions (AREA)

- Ropes Or Cables (AREA)

Abstract

Description

Die Erfindung bezieht sich auf eine Vorrichtung zum hydrodynamischen Verschlingen zum vorzugsweise bindemittelfreien Verfestigen der Fasern einer Faserbahn aus natürlichen und/oder künstlichen Fasern jeglicher Art, bestehend

- a) aus einem die Faserbahn unterstützenden ersten Endlosband, das zwischen mindesten zwei Walzen gespannt geführt und umgelenkt ist,

- b) einer zugeordneten Vernadelungstrommel, der über die Arbeitsbreite zumindest ein Düsenbalken achsparallel zugeordnet ist,

- c) zumindest einem weiteren Düsenbalken, dessen Wasserstrahlen gegen die Rückseite eines Endlosbandes und durch das Endlosband gegen die Faserbahn zumindest zum Netzen desselben gerichtet sind,

- d) dem ersten Endlosband ein zweites ebenfalls zwischen mindesten zwei Walzen gespannt geführtes Endlosband gegenläufig zugeordnet ist, dessen dem Arbeitstrum des ersten Endlosbandes gegenüber liegendes Arbeitstrum in der gleichen Richtung angetrieben umläuft wie das des ersten Endlosbandes,

- e) die beiden Arbeitstrums der beiden Endlosbänder in ihrer Längserstreckung konisch aufeinander zu gerichtet sind, so dass die auf dem Arbeitstrum des ersten Endlosbandes liegende Faserbahn zwischen den vorlaufenden Endlosbändern zunehmend verdichtet wird, bis zu einem quer über die Faserbahn verlaufenden Kompressionsbereich, in dem die Endlosbänder mit der dazwischen liegenden Faserbahn aneinander liegen,

- f) das erste oder zweite Endlosband von zwei Walzen gegen die Vernadelungstrommel des zweiten oder ersten Endlosbandes vorzugsweise auch zur stärkeren Umschlingung der Vernadelungstrommel von beiden Endlosbändern gedrückt ist und

- g) zwischen diesen beiden Walzen der Düsenbalken zur Netzung der Faserbahn gegen die zwischen den beiden Endlosbändern verdichtet gehaltene Faserbahn gerichtet ist.

- a) from a fiber web supporting the first endless belt, which is guided and deflected stretched between at least two rollers,

- b) an associated needling drum, which is associated axially parallel to the working width at least one nozzle beam,

- c) at least one further nozzle bar whose jets of water are directed against the rear side of an endless belt and through the endless belt against the fiber web at least for meshing thereof;

- d) the first endless belt a second also between at least two rollers tensioned guided endless belt is assigned in opposite directions, the working strand of the first endless belt opposite working strand driven in the same direction rotates as that of the first endless belt,

- e) the two working strands of the two endless belts are directed conically towards one another in their longitudinal extent, so that the fiber web lying on the working strand of the first endless belt is increasingly compressed between the leading endless belts, up to a compression region extending transversely across the fiber web, in which the endless belts with the intermediate fiber web lie against each other,

- f) the first or second endless belt of two rollers is pressed against the needling drum of the second or first endless belt, preferably also for stronger wrapping of the needling drum of both endless belts and

- g) is directed between these two rollers of the nozzle beam for meshing the fiber web against the held compacted between the two endless belts fiber web.

Eine Vorrichtung dieser Art ist durch die

Weiterhin ist die vorbekannte

Die bekannten Vorrichtungen erfüllen bestens die Aufgabe des langsamen Komprimierens der aus losen untereinander nicht verfestigten Fasern bestehenden Faserbahn und auch der vorgeordneten Netzung im gepressten Zustand. Da die Faserbahn aber in diesem lockeren Zustand komprimiert und genetzt wird, verbleiben in dem komprimierenden Endlosband nach dem Netzen, jedenfalls nach dem Lösen von der weiter zu vernadelnden Faserbahn einzelne Fasern hängen, die das Band verschmutzen und letztendlich eine dauerhafte optimale Behandlung der folgenden Faserbahnlängen behindert. Es ist möglich, eine Reinigungseinrichtung dem freilaufenden Endlosband zuzuordnen, jedoch ist dieses aufwendig und kostenintensiv.The known devices are ideally suited to the task of slowly compressing the fibrous web consisting of loose non-bonded fibers and also of the upstream net in the pressed state. However, since the fibrous web is compressed and necked in this loose state, individual fibers remain in the endless compressive band after netting, at least after loosening from the fiber web to be further needled, which soil the band and ultimately hinder durable optimal treatment of the following lengths of fiber web , It is possible to assign a cleaning device to the free-running endless belt, but this is expensive and expensive.

Ausgehend von der anfangs genannten Vorrichtung liegt der Erfindung die Aufgabe zugrunde, eine Vorrichtung zu finden, mit der die Reinigung des Endlosbandes von den Flusen von alleine bei der Behandlung erfolgt und gleichzeitig das Lösen der Faserbahn von dem Endlosband vorteilhaft beeinflusst wird.Starting from the initially mentioned device, the invention has for its object to find a device with which the cleaning of the endless belt of the lint takes place by itself during the treatment and at the same time the dissolution of the fiber web is advantageously influenced by the endless belt.

Zur Lösung der gestellten Aufgabe sieht die Erfindung vor, dass

- a) der zwischen den das eine Endlosband führenden Walzen angeordnete Düsenbalken dort derart angeordnet und ausgerichtet ist, dass die Wasserstrahlen dieses Düsenbalkens die Faserbahn in Transportrichtung der Faserbahn erst hinter dem Kompressionsbereich treffen, also die Auftrefflinie der Wasserstrahlen in dem Bereich liegt, in dem die beiden mittels der beiden Walzen aufeinander zu geführten Endlosbänder wieder durch zwei weitere Walzen od. dgl. voneinander weg geführt sind.

- a) between the one endless belt leading rollers arranged nozzle beam is arranged and aligned there such that the water jets of this nozzle bar hit the fiber web in the transport direction of the fiber web only behind the compression area, so the impingement of the water jets in the area is in which the two towards each other by means of the two rollers guided endless belts od again by two more rolls. Like. Are led away from each other.

Diese Anordnung des Düsenbalkens in dem Vorrichtungsgestell bzw. die Austrittsstelle der Düsenstrahlen aus dem Düsenbalken außerhalb des Kompressionsbereichs bewirkt die unverändert wirksame Netzung der gepressten Faserbahn, aber gleichzeitig wird die Faserbahn durch die Wasserstrahlen von dem pressenden Endlosband gelöst, die Faserbahn wird durch das netzende Wasser gegen die weiter transportierende Vernadelungstrommel gedrückt und gleichzeitig wird das Endlosband von evtl. ansonsten daran hängen bleibenden Fasern frei gespült und diese Fasern zurück in den Faserverband geführt.This arrangement of the nozzle beam in the device frame or the exit point of the nozzle jets from the nozzle beam outside the compression area causes the unchanged effective network of the pressed fiber web, but at the same time the fiber web is released from the pressing endless belt by the water jets, the fiber web is counteracted by the wetting water the further transporting needling drum is pressed and at the same time the endless belt is rinsed free of fibers otherwise possibly stuck on it and these fibers are guided back into the fiber structure.

Die Faserbahn soll also dann nicht genetzt werden, wenn sie formschlüssig von beiden Endlosbändern gehalten ist, sondern erst kurz danach wenn sich die beiden Endlosbänder auf der Ober- und Unterseite voneinander weg bewegen. Die Ablöselinie der beiden Endlosbänder voneinander sollte nur wenige cm vor dem Treffpunkt der Wasserstrahlen liegen, etwa 20 bis 50 mm, um ein problemloses Netzen zu erzielen.The fiber web should therefore not be stopped when it is held by two endless belts form-fitting, but only shortly thereafter when the two endless belts on the top and bottom move away from each other. The separation line of the two endless belts from each other should be only a few cm in front of the point of contact of the water jets, about 20 to 50 mm, in order to achieve a trouble-free meshing.

Eine Vorrichtung der erfindungsgemäßen Art ist in der Zeichnung beispielhaft dargestellt. Es zeigt:

- Fig. 1

- in der Seitenansicht aus einer größeren Anlage eine Kompaktier-Vernadelungseinrichtung, bei der eine Umlenkwalze des ersten Endlosbandes als Benetzungstrommel und gleichzeitig als Vernadelungstrommel ausgebildet ist, und das zweite Endlosband mit dem Netzungs-Düsenbalken oberhalb zugeordnet ist,

- Fig. 2

- eine Ausschnittvergrößerung von

Fig. 1 im Bereich der Netz-und Vernadelungstrommel und - Fig. 3

- wiederum eine Ausschnittvergrößerung jetzt von

Fig. 2 im Bereich der Auftreffstelle der Wasserstrahlen and der Net-zungsstelle.

- Fig. 1

- in the side view from a larger plant a compacting needling, in which a guide roller of the first endless belt is formed as a wetting drum and at the same time as needle punching drum, and the second endless belt is associated with the net nozzle bar above,

- Fig. 2

- a section enlargement of

Fig. 1 in the field of netting and needle punching and - Fig. 3

- again a section enlargement of now

Fig. 2 in the area of impact of the water jets at the network.

In einem Rahmengestell 1 ist eine Kompaktier-Wasservernadelungseinrichtung mit nur einer Vernadelungstrommel 2 dargestellt. Sie entspricht im Wesentlichen der Offenbarung der

Grundsätzlich besteht diese Einheit aus einem ersten Endlosband 3, das über mehrere in einem Haltegestell 4 drehbar angeordnete Walzen 2, 5 umgelenkt und gespannt gehalten ist. Auf dieses Endlosband läuft in Richtung des Pfeils 6 eine zu vernadelnde zunächst voluminösere Faserbahn 7. Es kann auch eine Faserbahn sein, die zunächst keine Festigkeit hat und somit von einer nicht dargestellten Krempel direkt auf das Endlosband 3 abgelegt wird. Die Walze 2 ist in diesem Ausführungsbeispiel als die Vernadelungstrommel ausgebildet. Dies bedeutet, dass sie im Durchmesser größer und als durchlässige Trommel ausgebildet ist, die zumindest an den Wasserauftreffstellen unter Saugzug (Pfeile 8) gesetzt ist.Basically, this unit consists of a first endless belt 3, which is deflected over several in a

Dem ersten Endlosband 3 ist ein zweites Endlosband 9 gegenläufig derart zugeordnet, dass das Arbeitstrum 3' des ersten Endlosbandes 3 dem Arbeitstrum 9' des zweiten Endlosbandes gegenüberliegt, dort die Trums 3', 9' in der gleichen Richtung umlaufen und in diesem Bereich konisch aufeinander zu laufen. Dies ist beim zweiten Endlosband 9 wiederum durch mehrere Walzen 10 - 12' bewirkt, die an dem am Rahmengestell 1 befestigten Haltegestell 13 drehbar gelagert sind.The first endless belt 3 is assigned a second endless belt 9 in opposite directions such that the working strand 3 'of the first endless belt 3 is opposite the working belt 9' of the second endless belt, there the strands 3 ', 9' rotate in the same direction and conically in this area to run. This is the second endless belt 9 in turn by a plurality of rollers 10 - 12 'causes, which are rotatably mounted on the frame 1 fixed to the frame 1.

Zwei der Walzen des zweiten Endlosbandes 9, nämlich die Walzen 11 und 12', sind der Vernadelungstrommel 2 des ersten Endlosbandes 3 unmittelbar zugeordnet. Das heißt, dass die Walzen 11 und 12' das gespannt geführte Endlosband 9 gegen das Endlosband 3 mit der Faserbahn 7 und dann alles zusammen gegen die Vernadelungstrommel 2 pressen. Dazu sind sie dicht beieinander angeordnet und lassen zwischen sich etwa nur soviel Platz, dass der Düsenbalken 14 bis zum Endlosband 9 vorgeschoben werden kann. Auf diese Weise ist die gelieferte und von dem Trum 3' des Endlosbandes 3 vorgetragene Faserbahn 7 nicht nur zwischen den Endlosbänder 3 und 9 langsam verdichtet, sondern über die Strecke y zwischen den beiden Endlosbändern 3, 9 und dann im Bereich x an die Vernadelungstrommel 2 gepresst. In diesem Presszustand wird die Faserbahn 7 mittels des Wasserbalkens 14 genässt und kann dann weiter vernadelt werden.Two of the rollers of the second endless belt 9, namely the

Im Ausführungsbeispiel nach

Das gleiche Prinzip ist beibehalten, wenn - wie in dem Ausführungsbeispiel nach

Die vorliegende

Der Punkt der Netzung der zwischen den Endlosbändern 3, 9 gehaltenen Faserbahn 7 ist also außerhalb der Pressstrecke x gelegt, der Abstand vom Ende 19 der Pressstrecke bis zum Auftreffen der Wasserstrahlen 18 vom Düsenbalken 14 ist etwa 20 - 50 mm, vorzugsweise 30 mm bemessen. Selbstverständlich kann das Maß auch geringfügig von diesen Daten differieren.The point of network of held between the endless belts 3, 9

Claims (2)

- Device for hydrodynamic entanglement for preferably binder-free bonding of fibers in a fiber web (7) made of natural and/or synthetic fibers of any kind, consisting ofa) a first endless belt (3) supporting the fiber web (7), guided in tensioned condition and deflected between at least two rollers (2, 5),b) an assigned spunlacing drum (2) which is combined with at least one jet head (15 - 16) arranged in parallel with its axis along the working width,c) at least one more jet head (14) whose water jets are directed against the back of an endless belt (9) and through the endless belt (9) against the fiber web (7), at least for wetting of the latter,d) the first endless belt (3), which is combined with a second endless belt (9) also guided in tensioned condition between at least two rollers and rotating in opposite direction, with its taut side (9') located opposite the taut side (3') of the first endless belt (3) being driven to rotate in the same direction as that of the first endless belt (3),e) the two taut sides (3', 9') of the two endless belts (3, 9), which are converging conically over their length so that the fiber web (7) lying on the taut side (3') of the first endless belt (3) is increasingly condensed between the advancing endless belts (3, 9) up to a compression section arranged at right angles across the fiber web where the endless belts lie one against the other with the fiber web in between,f) while the first or second endless belt (9) is pressed by two rollers (11, 12; 11, 12') against the spunlacing drum (2) of the second or first endless belt (3), preferably also for stronger wrapping of the spunlacing drum (2), andg) the jet head (14) between these two rollers (11, 12; 11, 12') is directed against the fiber web (7) held in compressed condition between the two endless belts (3, 9) for wetting of the fiber web (7),

characterized in thath) the jet head (14) arranged between the rollers (11, 12') guiding the one endless belt (9) is positioned and directed in such a way that the water jets (18) of this jet head (14) hit the fiber web (7) in transport direction (6) of the fiber web (7) only behind the compression section (x), so that the impact line of the water jets (18) is in the area where the two endless belts (3, 9) caused to converge by means of the two rollers (11, 12') are separated again from each other by two more rollers (12', 2) or similar equipment. - Device in conformity with claim 1, characterized in that the jet head (14) arranged between the rollers (11, 12') guiding the one endless belt (9) is positioned in such a way that the impact line of the water jets (18) is located some 10 to 50 mm, preferably 30 mm, behind the end of the compression section (x).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10254563 | 2002-11-21 | ||

| DE10254563A DE10254563A1 (en) | 2002-11-21 | 2002-11-21 | Device for hydrodynamically intertwining the fibers of a fibrous web |

| PCT/EP2003/050799 WO2004046444A1 (en) | 2002-11-21 | 2003-11-07 | Device for the hydrodynamic entanglement of the fibers of a fiber web |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1567705A1 EP1567705A1 (en) | 2005-08-31 |

| EP1567705B1 true EP1567705B1 (en) | 2009-01-07 |

Family

ID=32240294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03811392A Expired - Lifetime EP1567705B1 (en) | 2002-11-21 | 2003-11-07 | Device for the hydrodynamic entanglement of the fibers of a fiber web |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1567705B1 (en) |

| CN (1) | CN100482874C (en) |

| AT (1) | ATE420234T1 (en) |

| DE (2) | DE10254563A1 (en) |

| ES (1) | ES2318203T3 (en) |

| WO (1) | WO2004046444A1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004030413A1 (en) | 2004-06-23 | 2006-02-23 | Fleissner Gmbh | Device for hydrodynamically entangling the fibers of a fibrous web |

| DE102009012607A1 (en) | 2009-03-11 | 2010-09-16 | Fleissner Gmbh | Apparatus for processing a fiber web, comprises a roller, which receives the web provided by a web producer and is driven with a peripheral speed different to a feed speed of the web, first and second transport rollers, and buckling roller |

| DE102009017729A1 (en) | 2009-04-11 | 2010-10-14 | Fleissner Gmbh | Device for strengthening material web made of fibers and/or filaments, comprises first and second endless belts tightly revolving around deflection rollers carrying the web, where second endless belt counter-rotates to first endless belt |

| DE102009016996A1 (en) | 2009-04-08 | 2010-10-14 | Fleissner Gmbh | Non-woven fibrous sheet consolidation apparatus, includes contrarotating supporting and compacting belts running non-parallel to each other in fluid jet application region |

| JP5787236B2 (en) * | 2009-04-08 | 2015-09-30 | トリュッツシュラー ノンヴォーフェンス ゲーエムベーハー | Device for compressing a fiber web |

| DE102010009275A1 (en) * | 2010-02-25 | 2011-08-25 | Trützschler Nonwovens GmbH, 63329 | Device for solidifying a material web |

| DE102021107902A1 (en) * | 2021-03-29 | 2022-09-29 | Andritz Küsters Gmbh | Plant for consolidating at least one wet-laid or dry-laid fiber layer to form a fleece web, with a conveyor that includes a circulating belt with an upper run, on which the at least one fiber layer can be placed and displaced in a production direction |

| DE102021107900B4 (en) | 2021-03-29 | 2023-02-02 | Andritz Küsters Gmbh | Plant for consolidating layers comprising fibers to form a fleece web |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2734285B1 (en) * | 1995-05-17 | 1997-06-13 | Icbt Perfojet Sa | PROCESS FOR THE MANUFACTURE OF A NON-WOVEN TEXTILE TABLECLOTH BY PRESSURIZED WATER JETS, AND INSTALLATION FOR CARRYING OUT SAID METHOD |

| DE19627256A1 (en) * | 1996-07-08 | 1998-01-15 | Fleissner Maschf Gmbh Co | Method and device for the hydromechanical interlacing of the fibers of a fiber web |

| EP0859076B1 (en) * | 1997-02-12 | 2002-08-28 | Fleissner GmbH & Co. Maschinenfabrik | Apparatus for hydroentangling the fibres of a fibre web |

| DE10006763A1 (en) * | 2000-02-15 | 2001-08-16 | Fleissner Gerold | Hydrodynamic consolidation of non-woven involves fluid jet treatment of non-woven while held between continuous conveying bands |

| FR2821866B1 (en) * | 2001-03-06 | 2003-05-16 | Rieter Perfojet | DEVICE AND METHOD FOR COMPACTING A FIBER PATCH WITH PRESSURE ADJUSTMENT APPLIED TO THE PATCH |

-

2002

- 2002-11-21 DE DE10254563A patent/DE10254563A1/en not_active Withdrawn

-

2003

- 2003-11-07 WO PCT/EP2003/050799 patent/WO2004046444A1/en active Application Filing

- 2003-11-07 EP EP03811392A patent/EP1567705B1/en not_active Expired - Lifetime

- 2003-11-07 AT AT03811392T patent/ATE420234T1/en not_active IP Right Cessation

- 2003-11-07 CN CN200380102409.4A patent/CN100482874C/en not_active Expired - Lifetime

- 2003-11-07 DE DE50311070T patent/DE50311070D1/en not_active Expired - Lifetime

- 2003-11-07 ES ES03811392T patent/ES2318203T3/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1567705A1 (en) | 2005-08-31 |

| CN100482874C (en) | 2009-04-29 |

| ATE420234T1 (en) | 2009-01-15 |

| DE50311070D1 (en) | 2009-02-26 |

| CN1708612A (en) | 2005-12-14 |

| ES2318203T3 (en) | 2009-05-01 |

| WO2004046444A1 (en) | 2004-06-03 |

| DE10254563A1 (en) | 2004-06-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0818568B1 (en) | Method and apparatus for hydrodynamically entangling the fibres of a web | |

| EP0859076B1 (en) | Apparatus for hydroentangling the fibres of a fibre web | |

| EP1759044B1 (en) | Device for hydrodynamically entangling the fibres of a fibre web | |

| EP1126064A2 (en) | Device for hydraulically needling a fibrous web by projecting a fluid | |

| EP2417290B1 (en) | Apparatus for compacting a fibrous web | |

| DE29521570U1 (en) | Device for producing a non-woven textile cloth by means of pressurized water jets | |

| EP1567705B1 (en) | Device for the hydrodynamic entanglement of the fibers of a fiber web | |

| DE102008008549A1 (en) | Apparatus for producing and solidifying a pure spunbonded nonwoven | |

| DE3735235A1 (en) | Harvesting machine for green flax | |

| EP3061855B1 (en) | Roller card and method for fixing at least one fibre web | |

| DE3685539T2 (en) | PROTECTIVE ENVELOPE FOR THE SEAM OF TECHNICAL NEEDLE FELTS. | |

| WO2008110134A1 (en) | Device for the compaction of stable fibers or a non-woven material comprised of filaments | |

| DE2731269C2 (en) | Fiber fleece and method and device for producing the fleece | |

| EP1063332A1 (en) | Method and apparatus for producing patterned nonwovens by hydrodynamic needling | |

| DE102009016996A1 (en) | Non-woven fibrous sheet consolidation apparatus, includes contrarotating supporting and compacting belts running non-parallel to each other in fluid jet application region | |

| DE102009017729A1 (en) | Device for strengthening material web made of fibers and/or filaments, comprises first and second endless belts tightly revolving around deflection rollers carrying the web, where second endless belt counter-rotates to first endless belt | |

| DE19706610A1 (en) | Device for hydrodynamically intertwining the fibers of a fibrous web | |

| EP1692957A1 (en) | Treating a strip of filter material in the tobacco industry | |

| EP2539498B1 (en) | Device for solidifying a material web | |

| DE1817758A1 (en) | Method and device for converting and aligning at least two strands of continuous fibers into staple fibers of uniform length | |

| DE69202424T2 (en) | Process and device for fleece separation at the exit of a straight-line combing machine for long fibers. | |

| DE1502249A1 (en) | Fruit press | |

| DE102009032343A1 (en) | Device for solidifying material web made of fiber and/or filaments, comprises filter band, girder duct for fluidic application of material web, and device for compressing fibers and filaments of material web | |

| DE4203360A1 (en) | Binding device for pressed bales - uses bands and closing devices connecting adjoining strands by sleeves | |

| EP1522622A1 (en) | Device for removing a web from the needles of a tenter frame |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050621 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20061201 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50311070 Country of ref document: DE Date of ref document: 20090226 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2318203 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090608 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| 26N | No opposition filed |

Effective date: 20091008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090407 |

|

| BERE | Be: lapsed |

Owner name: FLEISSNER G.M.B.H. Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090408 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20131121 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20141126 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141107 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20161228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151108 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20211122 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230504 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50311070 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221130 |