EP1533262B1 - Procédé pour enrouler une bande de matière - Google Patents

Procédé pour enrouler une bande de matière Download PDFInfo

- Publication number

- EP1533262B1 EP1533262B1 EP03405823A EP03405823A EP1533262B1 EP 1533262 B1 EP1533262 B1 EP 1533262B1 EP 03405823 A EP03405823 A EP 03405823A EP 03405823 A EP03405823 A EP 03405823A EP 1533262 B1 EP1533262 B1 EP 1533262B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- winding core

- winding

- gel

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 title claims abstract description 34

- 238000004804 winding Methods 0.000 title claims abstract description 34

- 238000000034 method Methods 0.000 title claims abstract description 17

- 239000000123 paper Substances 0.000 claims abstract description 5

- 229910052751 metal Inorganic materials 0.000 claims abstract description 3

- 239000002184 metal Substances 0.000 claims abstract description 3

- 239000000499 gel Substances 0.000 claims description 14

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 12

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 3

- 239000004115 Sodium Silicate Substances 0.000 claims description 3

- 229920002472 Starch Polymers 0.000 claims description 3

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 claims description 3

- 235000010338 boric acid Nutrition 0.000 claims description 3

- 239000004327 boric acid Substances 0.000 claims description 3

- 239000004033 plastic Substances 0.000 claims description 3

- NTHWMYGWWRZVTN-UHFFFAOYSA-N sodium silicate Chemical compound [Na+].[Na+].[O-][Si]([O-])=O NTHWMYGWWRZVTN-UHFFFAOYSA-N 0.000 claims description 3

- 229910052911 sodium silicate Inorganic materials 0.000 claims description 3

- 108010010803 Gelatin Proteins 0.000 claims description 2

- 229920002678 cellulose Polymers 0.000 claims description 2

- 235000010980 cellulose Nutrition 0.000 claims description 2

- 229920000159 gelatin Polymers 0.000 claims description 2

- 239000008273 gelatin Substances 0.000 claims description 2

- 235000019322 gelatine Nutrition 0.000 claims description 2

- 235000011852 gelatine desserts Nutrition 0.000 claims description 2

- 235000019794 sodium silicate Nutrition 0.000 claims description 2

- 235000019698 starch Nutrition 0.000 claims description 2

- 239000001913 cellulose Substances 0.000 claims 1

- 239000003795 chemical substances by application Substances 0.000 claims 1

- 239000000377 silicon dioxide Substances 0.000 claims 1

- 235000012239 silicon dioxide Nutrition 0.000 claims 1

- 239000008107 starch Substances 0.000 claims 1

- 239000011888 foil Substances 0.000 abstract 1

- 239000002985 plastic film Substances 0.000 abstract 1

- 229920006255 plastic film Polymers 0.000 abstract 1

- 239000000853 adhesive Substances 0.000 description 7

- 230000001070 adhesive effect Effects 0.000 description 7

- 239000002390 adhesive tape Substances 0.000 description 5

- 230000007423 decrease Effects 0.000 description 2

- 239000003349 gelling agent Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229920002261 Corn starch Polymers 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 229920000663 Hydroxyethyl cellulose Polymers 0.000 description 1

- 239000004354 Hydroxyethyl cellulose Substances 0.000 description 1

- 229920002153 Hydroxypropyl cellulose Polymers 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000008120 corn starch Substances 0.000 description 1

- 229940099112 cornstarch Drugs 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 229910021485 fumed silica Inorganic materials 0.000 description 1

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 description 1

- 239000001863 hydroxypropyl cellulose Substances 0.000 description 1

- 235000010977 hydroxypropyl cellulose Nutrition 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 239000012785 packaging film Substances 0.000 description 1

- 229920006280 packaging film Polymers 0.000 description 1

- 229920001592 potato starch Polymers 0.000 description 1

- 229940116317 potato starch Drugs 0.000 description 1

- -1 rice starch Polymers 0.000 description 1

- 229940100486 rice starch Drugs 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 229940100445 wheat starch Drugs 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H19/00—Changing the web roll

- B65H19/22—Changing the web roll in winding mechanisms or in connection with winding operations

- B65H19/28—Attaching the leading end of the web to the replacement web-roll core or spindle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/41—Winding, unwinding

- B65H2301/414—Winding

- B65H2301/41419—Starting winding process

- B65H2301/41423—Starting winding process involving liquid, e.g. wetting core by water

Definitions

- the invention relates to a method for winding a material web according to the preamble of claim 1.

- the present invention is based on the object in a method of the type mentioned to set the adhesion between the material web and the winding core so that it generates during winding during the first one to two complete revolutions of the winding core sufficient adhesive force between the material web and lateral surface.

- the adhesive force should drop sharply in a relatively short time, so that the material web unwinds easily from the core during subsequent processing.

- the use of a gel greatly reduces the mobility of the water bound in it. This effect leads to the formation of a stress in the interface between the gel and the material web or the lateral surface of the winding core and thus to an instantaneous adhesion between the material web and the lateral surface.

- the migration of the water from the gel into the winding core or into the material web begins and the adhesive force between the material web and the lateral surface decreases continuously.

- At least one region of the winding core which forms the lateral surface preferably consists of cardboard or paper.

- a hollow cylinder made of cardboard has proven.

- the material web consists for example of a film of plastic, metal, paper or of a multilayer film of at least two layers of said materials.

- the chemical composition of the gelling agent is of minor importance for the process according to the invention.

- the sole purpose of the gel is to reduce the mobility of the water during the first phase of winding a web.

- gel formers for example, fumed silica, sodium silicate and boric acid, gelatin, celluloses such as pure cellulose powder, hydroxyethyl cellulose, hydroxypropyl cellulose, etc. and starches such as corn starch, rice starch, potato starch or wheat starch can be used.

- a gel that is as firm as possible ie a gel whose water content is smaller than its maximum possible water content, is used.

- the webs of material wound with the method according to the invention can be automatically and uninterruptedly hung together in a continuous further processing.

- a particular area of application of the method according to the invention relates to the winding up of material webs which are cut from a material strip in a cutting device.

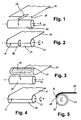

- an end 11 of a material web 10 is fastened by means of an adhesive tape 16 to the cylindrical jacket surface 14 of a winding core 12 with a cylindrical or rotational axis s.

- the adhesive force of the adhesive tape 16 is dependent on its length.

- the adhesive force to the lateral surface 14 of the winding core 12 may be so large that the material web does not readily dissolve during subsequent unwinding of the lateral surface, which can lead to problems especially in Autosplicing machines.

- a gel 18 is applied to the water-based on the winding core 12 side facing the web 10 and the gel with the 18th provided end 11 is applied to the cylindrical surface 14 of the winding core 12.

- the winding core 12 is, for example, a hollow cylinder made of cardboard and the material web is e.g. an 80 ⁇ m thick packaging film made of an aluminum / plastic composite material.

- the water-based gel contains, for example, a mixture of sodium silicate and boric acid as gelling agent.

- the resulting adhesion between web 10 and winding core 12 is sufficiently high that the web is taken during the first revolution of the winding core 12 of this.

- the water migrates completely over time in the winding core 12 and the adhesive force decreases continuously.

- the adhesive force is practically zero and the end 11 of the material web 10 firmly adhering during winding is easily detached from the lateral surface 14 of the winding core 12.

Landscapes

- Storage Of Web-Like Or Filamentary Materials (AREA)

- Replacement Of Web Rolls (AREA)

- Winding Of Webs (AREA)

- Laminated Bodies (AREA)

Claims (7)

- Procédé d'enroulement d'une bande de matière (10) sur un axe d'enroulement (12), avec une surface d'enveloppe (14) cylindrique, la bande de matière (10) et/ou l'axe d'enroulement (12) présentant des propriétés d'absorption d'eau, lors duquel procédé par l'intermédiaire d'un gel (18) sur base aqueuse appliqué sur l'extrémité (11) de la bande de matière (10) et/ou sur la surface d'enveloppe (14), une extrémité (11) de la bande de matière (10) est reliée par adhérence amovible avec la surface d'enveloppe (14) de l'axe d'enroulement (12) et la bande de matière est enroulée par rotation de l'axe d'enroulement (12) autour de son axe de cylindre (s),

caractérisé en ce que

la teneur en eau du gel (18) est inférieure à sa teneur en eau maximale possible. - Procédé selon la revendication 1, caractérisé en ce que, au moins une zone de l'axe d'enroulement (12) formant la surface d'enveloppe (14) est en carton ou en papier.

- Procédé selon la revendication 2, caractérisé en ce que l'axe d'enroulement (12) est un cylindre creux fabriqué en carton.

- Procédé selon l'une quelconque des revendications 1 à 3, caractérisé en ce que la bande de matière (10) est en un film de matière plastique, de métal ou de papier ou en un film multicouches d'au moins deux couches des matières citées.

- Procédé selon l'une quelconque des revendications 1 à 4, caractérisé en ce que, on utilise en tant que gélifiant du dioxyde de silicium, du silicate de sodium et de l'acide borique à haute dispersion, de la gélatine, de la cellulose ou de l'amidon.

- Procédé selon l'une quelconque des revendications 1 à 5, caractérisé en ce que la bande de matière (10) est un lé d'une bande de matière coupée dans un sens de coupe par rapport au lé.

- Procédé selon l'une quelconque des revendications 1 à 6, caractérisé en ce que les bandes de matière (10) enroulées sur des axes d'enroulement (12) sont automatiquement mises bout à bout sans interruption, au cours d'une mise en oeuvre ultérieure.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PT03405823T PT1533262E (pt) | 2003-11-19 | 2003-11-19 | ''processo para enrolar uma fita de material'' |

| ES03405823T ES2281616T3 (es) | 2003-11-19 | 2003-11-19 | Procedimiento para el arrollamiento de una banda de material. |

| DK03405823T DK1533262T3 (da) | 2003-11-19 | 2003-11-19 | Fremgangsmåde til opvikling af en materialebane |

| AT03405823T ATE357397T1 (de) | 2003-11-19 | 2003-11-19 | Verfahren zum wickeln einer materialbahn |

| DE50306861T DE50306861D1 (de) | 2003-11-19 | 2003-11-19 | Verfahren zum Wickeln einer Materialbahn |

| SI200330823T SI1533262T1 (sl) | 2003-11-19 | 2003-11-19 | Postopek navijanja traka materiala |

| EP03405823A EP1533262B1 (fr) | 2003-11-19 | 2003-11-19 | Procédé pour enrouler une bande de matière |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03405823A EP1533262B1 (fr) | 2003-11-19 | 2003-11-19 | Procédé pour enrouler une bande de matière |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1533262A1 EP1533262A1 (fr) | 2005-05-25 |

| EP1533262B1 true EP1533262B1 (fr) | 2007-03-21 |

Family

ID=34429623

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03405823A Expired - Lifetime EP1533262B1 (fr) | 2003-11-19 | 2003-11-19 | Procédé pour enrouler une bande de matière |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP1533262B1 (fr) |

| AT (1) | ATE357397T1 (fr) |

| DE (1) | DE50306861D1 (fr) |

| DK (1) | DK1533262T3 (fr) |

| ES (1) | ES2281616T3 (fr) |

| PT (1) | PT1533262E (fr) |

| SI (1) | SI1533262T1 (fr) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3951890A (en) * | 1974-07-22 | 1976-04-20 | Unitech Chemical Inc. | Tail control and transfer adhesives for rolled paper products |

| US5646090A (en) * | 1995-04-06 | 1997-07-08 | Dai Nippon Printing Co., Ltd. | Thermal transfer image-receiving sheet |

| AT406255B (de) * | 1998-01-13 | 2000-03-27 | Andritz Patentverwaltung | Verfahren und vorrichtung zum wechseln von rollen bei papiermaschinen |

| US6705560B1 (en) * | 2000-11-28 | 2004-03-16 | Metso Paper Karlstad Aktiebolg (Ab) | Method for winding a tissue web in a reel-up in a paper machine |

| CA2417294C (fr) * | 2002-02-25 | 2011-04-12 | Tesa Ag | Production d'un rouleur de toile plate |

-

2003

- 2003-11-19 ES ES03405823T patent/ES2281616T3/es not_active Expired - Lifetime

- 2003-11-19 DK DK03405823T patent/DK1533262T3/da active

- 2003-11-19 SI SI200330823T patent/SI1533262T1/sl unknown

- 2003-11-19 AT AT03405823T patent/ATE357397T1/de not_active IP Right Cessation

- 2003-11-19 PT PT03405823T patent/PT1533262E/pt unknown

- 2003-11-19 EP EP03405823A patent/EP1533262B1/fr not_active Expired - Lifetime

- 2003-11-19 DE DE50306861T patent/DE50306861D1/de not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DK1533262T3 (da) | 2007-07-30 |

| ES2281616T3 (es) | 2007-10-01 |

| SI1533262T1 (sl) | 2007-08-31 |

| ATE357397T1 (de) | 2007-04-15 |

| DE50306861D1 (de) | 2007-05-03 |

| EP1533262A1 (fr) | 2005-05-25 |

| PT1533262E (pt) | 2007-06-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5323981A (en) | Splicer tape system | |

| DE69829884T2 (de) | Anbringen einer lasche auf einer klebebandrolle und artikel | |

| DE2319542A1 (de) | Verfahren und vorrichtung zur alternierenden abgabe einzelner bahnabschnitte | |

| DE69900817T2 (de) | Verbindungsstreifen, verbindungsverfahren und einheit, die diesen verbindungs-streifen beinhaltet | |

| DE60124850T2 (de) | Verfahren und Vorrichtung zum Verpacken von Papierbahnrollen und Rollverpackung | |

| DE10058956A1 (de) | Klebeband | |

| WO2020229215A1 (fr) | Fabrication de pailles en papier | |

| EP2742105B1 (fr) | Procédé de fabrication d'une bande adhésive munie d'un revêtement en saillie | |

| EP1104795A2 (fr) | Ruban adhésif | |

| DE3743656C2 (fr) | ||

| WO2003024850A1 (fr) | Ruban adhesif conçu pour le remplacement automatique de rouleaux | |

| EP1533262B1 (fr) | Procédé pour enrouler une bande de matière | |

| DE2041069A1 (de) | Spleissstreifen zum Verbinden der stumpf aneinanderstossenden Enden von Klebstreifen auf deren nichtklebender Seite oder von Abziehstreifen auf beidseitig klebende Klebstreifen | |

| EP0683122B1 (fr) | Moyen adhésif pour raccorder des bandes de matériau embobinées en rouleaux entraínés | |

| DE4222880C2 (de) | Splicevorrichtung | |

| EP1046602B1 (fr) | Procédé de préparation d'une épissure | |

| EP2641471B1 (fr) | Procéd'e et dispositif pour recouvrir internement un boyau à épice serrable | |

| DE2953552C1 (de) | Wickelpackung und Verfahren zur Herstellung derselben | |

| EP1340703B1 (fr) | Procédé de fabrication d'un rouleau de bande plate | |

| DE60225882T2 (de) | Aufzeichnungspapierrolle | |

| EP1645533B1 (fr) | Ruban adhésif pour relier les rouleaux lors d'un échange | |

| DE2345260B2 (de) | Wickelsicherung für Rollfilme | |

| EP0399488B1 (fr) | Mandrin pour matière à enrouler de faible épaisseur | |

| DE19652448C1 (de) | Vorrichtung zum Verpacken einer Materialbahnrolle mit einer Verpackungsbahn | |

| DE102005004109B4 (de) | Verfahren zur Herstellung eines flachen Umwickelungsmaterials |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20051125 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT SE SI SK |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT SE SI SK |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070321 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50306861 Country of ref document: DE Date of ref document: 20070503 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20070606 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20070401916 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2281616 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20071227 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E002823 Country of ref document: HU |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20081125 Year of fee payment: 6 Ref country code: CZ Payment date: 20081104 Year of fee payment: 6 Ref country code: DK Payment date: 20081125 Year of fee payment: 6 Ref country code: EE Payment date: 20081105 Year of fee payment: 6 Ref country code: IE Payment date: 20081125 Year of fee payment: 6 Ref country code: LU Payment date: 20081204 Year of fee payment: 6 Ref country code: MC Payment date: 20081103 Year of fee payment: 6 Ref country code: NL Payment date: 20081124 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20081103 Year of fee payment: 6 Ref country code: ES Payment date: 20081126 Year of fee payment: 6 Ref country code: FI Payment date: 20081128 Year of fee payment: 6 Ref country code: PT Payment date: 20081031 Year of fee payment: 6 Ref country code: SK Payment date: 20081103 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20081125 Year of fee payment: 6 Ref country code: SE Payment date: 20081128 Year of fee payment: 6 Ref country code: BG Payment date: 20081127 Year of fee payment: 6 Ref country code: CY Payment date: 20081112 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081117 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081223 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081128 Year of fee payment: 6 Ref country code: GR Payment date: 20081127 Year of fee payment: 6 Ref country code: SI Payment date: 20081118 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20090128 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20081113 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20100519 |

|

| BERE | Be: lapsed |

Owner name: ALCAN TECHNOLOGY & MANAGEMENT LTD. Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20100601 |

|

| EUG | Se: european patent has lapsed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: FAILURE TO ELECT DOMICILE IN THE NATIONAL COUNTRY Effective date: 20100531 Ref country code: EE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091120 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100519 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 1952 Country of ref document: SK Effective date: 20091119 |

|

| REG | Reference to a national code |

Ref country code: EE Ref legal event code: MM4A Ref document number: E001214 Country of ref document: EE Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20100825 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100602 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100421 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091120 |