EP1529902A1 - Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification - Google Patents

Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification Download PDFInfo

- Publication number

- EP1529902A1 EP1529902A1 EP03025510A EP03025510A EP1529902A1 EP 1529902 A1 EP1529902 A1 EP 1529902A1 EP 03025510 A EP03025510 A EP 03025510A EP 03025510 A EP03025510 A EP 03025510A EP 1529902 A1 EP1529902 A1 EP 1529902A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- gap

- filling

- filling gap

- application device

- feed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000853 adhesive Substances 0.000 title claims abstract description 59

- 230000001070 adhesive effect Effects 0.000 title claims abstract description 59

- 238000000034 method Methods 0.000 title claims abstract description 20

- 239000000565 sealant Substances 0.000 title claims description 43

- 238000007789 sealing Methods 0.000 claims abstract description 33

- 239000000463 material Substances 0.000 claims abstract description 22

- 239000011521 glass Substances 0.000 claims abstract description 14

- 238000003825 pressing Methods 0.000 claims description 15

- 229920003023 plastic Polymers 0.000 claims description 7

- 239000004033 plastic Substances 0.000 claims description 7

- 239000002184 metal Substances 0.000 claims description 5

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 238000006073 displacement reaction Methods 0.000 claims description 4

- 239000013013 elastic material Substances 0.000 claims description 4

- 241000276425 Xiphophorus maculatus Species 0.000 claims description 2

- 239000003566 sealing material Substances 0.000 abstract 1

- 239000000945 filler Substances 0.000 description 5

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 3

- 239000002131 composite material Substances 0.000 description 3

- 239000003292 glue Substances 0.000 description 3

- 229920002943 EPDM rubber Polymers 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 239000004809 Teflon Substances 0.000 description 2

- 229920006362 Teflon® Polymers 0.000 description 2

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000011449 brick Substances 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 239000004567 concrete Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- -1 polyethylene Polymers 0.000 description 2

- 239000004926 polymethyl methacrylate Substances 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000011435 rock Substances 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 229920002725 thermoplastic elastomer Polymers 0.000 description 2

- 239000002023 wood Substances 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 1

- 229920005372 Plexiglas® Polymers 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000004433 Thermoplastic polyurethane Substances 0.000 description 1

- 239000004676 acrylonitrile butadiene styrene Substances 0.000 description 1

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 1

- 239000013466 adhesive and sealant Substances 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 238000013008 moisture curing Methods 0.000 description 1

- 239000004570 mortar (masonry) Substances 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 229920013730 reactive polymer Polymers 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 1

- 230000009974 thixotropic effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C17/00—Hand tools or apparatus using hand held tools, for applying liquids or other fluent materials to, for spreading applied liquids or other fluent materials on, or for partially removing applied liquids or other fluent materials from, surfaces

- B05C17/005—Hand tools or apparatus using hand held tools, for applying liquids or other fluent materials to, for spreading applied liquids or other fluent materials on, or for partially removing applied liquids or other fluent materials from, surfaces for discharging material from a reservoir or container located in or on the hand tool through an outlet orifice by pressure without using surface contacting members like pads or brushes

- B05C17/00503—Details of the outlet element

- B05C17/00516—Shape or geometry of the outlet orifice or the outlet element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C21/00—Accessories or implements for use in connection with applying liquids or other fluent materials to surfaces, not provided for in groups B05C1/00 - B05C19/00

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/56—Fixing of glass panes or like plates by means of putty, cement, or adhesives only

Definitions

- the invention relates to an application device and a method for the Filling gaps with adhesives or sealants.

- the filling gap is preferably limited in depth. This can be done by a sealing lip 9 made, which from the material of the first or the second filler gap partner or represents another material, in particular a sealing lip made of an elastic material such as rubber, EPDM or other thermoplastic elastomers (TPE). Such Sealing lip can be glued or embedded in a groove. The However, the sealing lip may also be part of a filler gap partner, i. that this Racpaltpartner already has such a sealing lip, so that Artstoffpartner and sealing lip are one-piece. For example, let Such integral components can be achieved by extrusion or milling.

- the feed gap 3 has, at least at the level of the filling gap 1, a gap width d between 1 mm and 10 cm, in particular between 2 mm and 5 cm, preferably between 2 mm and 1 cm.

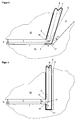

- FIG merely an example of inclined feed gaps.

- the flanks of the Feed gap can form different angles to each other. ever However, the larger the opening angle of the feed gap, the less usually covered is the filling gap. Typically this is through the Feeding edges formed opening angle not more than 60 °, preferably not more than 45 °, more preferably it is less than 20 °.

- the feed nip plane C with the fill column plane A forms one Angle ⁇ .

- This angle ⁇ typically has an absolute value between 45 and 135 degrees, in particular between 60 and 120 degrees. Preference is given to values for ⁇ between 80 and 100 degrees. Especially preferred the angle of ⁇ is about 90 degrees.

- the supply line is typically at least in the area the feed gap of a rigid material, in particular of a Plastic or metal.

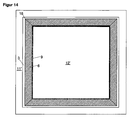

- FIG. 8 shows a partial cross section of a further embodiment an application device.

- the feed line is 2 directly connected to a support surface 10 and lies on the edge of the Zuersspaltes 3 or in the vicinity of.

- This bearing surface 10 is advantageously extended in the longitudinal direction of the feed gap 3 and has the Function of a stop.

- a drive device to be available.

- a drive device a wheel, a roller, a roller or a ball bearing with include.

- such a drive device also includes a motor, which moves the application device in the feed slot. This movement takes place, as already mentioned, advantageously coupled to the supply amount of Adhesive or sealant.

- This embodiment comprises a supply line, which of a rigid guide 7 is surrounded.

- This guide is in particular one made of machinable plastic or metal and has in the region of the opening. 4 the supply line also has an opening 8.

- this can be a Teflon tube 2 in a guide 7 made of aluminum or Plexiglas represent, wherein the guide 7, for example, a pipe or a block with a represents adapted to the hose 2 hole.

- This variant is advantageous because the hose can be easily replaced after use and is therefore due to frequent use of the application device For financial reasons, an advantageous embodiment of the invention.

Landscapes

- Physics & Mathematics (AREA)

- Geometry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Building Environments (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03025510A EP1529902A1 (fr) | 2003-11-06 | 2003-11-06 | Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification |

| PCT/EP2004/052834 WO2005045157A2 (fr) | 2003-11-06 | 2004-11-05 | Dispositif d'application et procede pour garnir des fentes de remplissage cachees, avec des adhesifs ou des materiaux d'etancheite |

| EP04817559A EP1697602A2 (fr) | 2003-11-06 | 2004-11-05 | Dispositif d'application et procede pour garnir des fentes de remplissage cachees, avec des adhesifs ou des materiaux d'etancheite |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03025510A EP1529902A1 (fr) | 2003-11-06 | 2003-11-06 | Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1529902A1 true EP1529902A1 (fr) | 2005-05-11 |

Family

ID=34429287

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03025510A Withdrawn EP1529902A1 (fr) | 2003-11-06 | 2003-11-06 | Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification |

| EP04817559A Withdrawn EP1697602A2 (fr) | 2003-11-06 | 2004-11-05 | Dispositif d'application et procede pour garnir des fentes de remplissage cachees, avec des adhesifs ou des materiaux d'etancheite |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04817559A Withdrawn EP1697602A2 (fr) | 2003-11-06 | 2004-11-05 | Dispositif d'application et procede pour garnir des fentes de remplissage cachees, avec des adhesifs ou des materiaux d'etancheite |

Country Status (2)

| Country | Link |

|---|---|

| EP (2) | EP1529902A1 (fr) |

| WO (1) | WO2005045157A2 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8057845B2 (en) | 2009-04-06 | 2011-11-15 | Sika Technology Ag | Method for glazing a sash |

| US8336483B2 (en) | 2009-04-06 | 2012-12-25 | Sika Technology Ag | System and method for glazing |

| EP2564941A1 (fr) * | 2011-08-31 | 2013-03-06 | Sika Technology AG | Tête d'applicateur, appareil d'application manuel, dispositif d'application et procédé de fabrication d'un module thermique solaire ou photovoltaïque |

| US8622018B2 (en) | 2009-04-06 | 2014-01-07 | Sika Technology Ag | System and method for glazing |

| WO2025083233A1 (fr) * | 2023-10-20 | 2025-04-24 | Saint-Gobain Glass France | Système amortisseur pour vitrage isolant sur mur |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014115466A1 (de) * | 2014-10-23 | 2016-04-28 | Airbus Operations Gmbh | Vorrichtung zum Aufbringen einer Materialspur |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4570834A (en) * | 1982-09-23 | 1986-02-18 | Evode Limited | Apparatus for extruding a fillet |

| FR2745028A1 (fr) * | 1996-02-21 | 1997-08-22 | Daetwyler France | Procede de realisation d'un joint espaceur pour vitrage colle |

| GB2352989A (en) * | 1999-08-03 | 2001-02-14 | Inbis Ltd | Extrusion nozzle |

| WO2002070620A1 (fr) | 2001-03-08 | 2002-09-12 | Sika Ag, Vorm. Kaspar Winkler & Co. | Compositions adhesives a base methacrylique faciles a fabriquer |

| DE20307227U1 (de) * | 2003-05-08 | 2003-08-14 | Rehau Ag + Co, 95111 Rehau | Gerahmtes Flächentragelement |

-

2003

- 2003-11-06 EP EP03025510A patent/EP1529902A1/fr not_active Withdrawn

-

2004

- 2004-11-05 EP EP04817559A patent/EP1697602A2/fr not_active Withdrawn

- 2004-11-05 WO PCT/EP2004/052834 patent/WO2005045157A2/fr not_active Ceased

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4570834A (en) * | 1982-09-23 | 1986-02-18 | Evode Limited | Apparatus for extruding a fillet |

| FR2745028A1 (fr) * | 1996-02-21 | 1997-08-22 | Daetwyler France | Procede de realisation d'un joint espaceur pour vitrage colle |

| GB2352989A (en) * | 1999-08-03 | 2001-02-14 | Inbis Ltd | Extrusion nozzle |

| WO2002070620A1 (fr) | 2001-03-08 | 2002-09-12 | Sika Ag, Vorm. Kaspar Winkler & Co. | Compositions adhesives a base methacrylique faciles a fabriquer |

| DE20307227U1 (de) * | 2003-05-08 | 2003-08-14 | Rehau Ag + Co, 95111 Rehau | Gerahmtes Flächentragelement |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8057845B2 (en) | 2009-04-06 | 2011-11-15 | Sika Technology Ag | Method for glazing a sash |

| US8336483B2 (en) | 2009-04-06 | 2012-12-25 | Sika Technology Ag | System and method for glazing |

| US8622018B2 (en) | 2009-04-06 | 2014-01-07 | Sika Technology Ag | System and method for glazing |

| EP2564941A1 (fr) * | 2011-08-31 | 2013-03-06 | Sika Technology AG | Tête d'applicateur, appareil d'application manuel, dispositif d'application et procédé de fabrication d'un module thermique solaire ou photovoltaïque |

| WO2013030272A1 (fr) * | 2011-08-31 | 2013-03-07 | Sika Technology Ag | Tête d'applicateur, appareil d'application portatif, dispositif d'application et procédé de fabrication d'un module héliothermique ou photovoltaïque |

| CN103764299A (zh) * | 2011-08-31 | 2014-04-30 | Sika技术股份公司 | 涂敷器头、手持式涂敷机具、涂敷设备和用于制造太阳能或光伏模块的方法 |

| CN103764299B (zh) * | 2011-08-31 | 2017-03-22 | Sika技术股份公司 | 涂敷器头、手持式涂敷机具、涂敷设备和用于制造太阳能或光伏模块的方法 |

| WO2025083233A1 (fr) * | 2023-10-20 | 2025-04-24 | Saint-Gobain Glass France | Système amortisseur pour vitrage isolant sur mur |

| FR3154428A1 (fr) * | 2023-10-20 | 2025-04-25 | Saint-Gobain Glass France | système amortisseur pour vitrage isolant sur mur |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2005045157A2 (fr) | 2005-05-19 |

| EP1697602A2 (fr) | 2006-09-06 |

| WO2005045157A3 (fr) | 2005-07-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2222930B2 (fr) | Procédé de fixation d'un panneau ou d'une vitre de verre dans un élément de cadre et élément de joint destiné à être employé dans un tel procédé | |

| DE3640887C2 (de) | Verfahren zur Einbringung von extrudierbaren Dichtungsprofilen | |

| EP2508377A2 (fr) | Unité de vitre avec un joint d'étanchéité pour fenêtre de véhicules automobiles | |

| EP0154121B1 (fr) | Procédé pour fabriquer des bandes d'étanchéité et des cordes profilées similaires en caoutchouc et en élastomères de type caoutchouc | |

| EP2691184B1 (fr) | Buse de collage avec plusieurs orifices de sortie | |

| DE102008061709A1 (de) | Dichtungsprofil, Verbindungsvorrichtung und Dichtung | |

| EP1529902A1 (fr) | Dispositif d'application et procédé pour le remplissage de cavités cachées avec agents adhésifs ou d' étanchéification | |

| DE4301026A1 (de) | Für die Verklebung mit einem Fensterrahmen vorgerüstete Autoglasscheibe und Verfahren zu ihrer Herstellung | |

| DE69509450T2 (de) | Seitenscheibe mit hohenverstellbarer Position für Kraftfahrzeuge | |

| DE102010049097A1 (de) | Verfahren zur Einbringung von Schaummaterial in Hohlkammerprofile sowie Hohlkammerprofil | |

| EP3034735B2 (fr) | Paroi coulissante ayant au moins un élément de battant de porte doté d'une vitre et procédé de fixation d'une vitre dans un système de porte coulissante | |

| DE9319329U1 (de) | Werkzeug zur Montage von Leisten | |

| DE4142661C2 (de) | Scheibeneinfassung für Fahrzeuge und Verfahren zu deren Herstellung | |

| DE102004018440A1 (de) | Tür- oder Fensterflügel mit einer Isolierglasscheibe | |

| DE102004056479B4 (de) | Vorrichtung zum Umschäumen und/oder Umspritzen eines im Wesentlichen plattenförmigen Werkstücks | |

| DE2359972A1 (de) | Profilleiste | |

| DE10117424B4 (de) | Rahmenanordnung aus massiven Profilwerkstücken | |

| DE10212229A1 (de) | Schwellenverbinder | |

| EP1342538B1 (fr) | Procédé et appareil pour la fixation d'un joint d'étanchéité sur le bord d'une plaque de verre | |

| DE19612285A1 (de) | Verfahren zur Herstellung von Fensterrahmen aus Kunststoff | |

| DE19508796A1 (de) | Verfahren zum Verbinden von Profilen aus elastomerem Werkstoff | |

| DE102018000141B4 (de) | Handwerkzeug zur Montage von Dichtungsprofilen | |

| DE2816005A1 (de) | Verfahren und werkzeug zur herstellung einer isolierglaskonstruktion | |

| DE4334560C2 (de) | Verfahren zum Abdichten von Böden oder Wänden | |

| DE7435947U (de) | Dichtung für eine Trocken-Druckverglasung von Glasscheiben |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20051114 |