EP1517836B1 - Dispositif de cerclage - Google Patents

Dispositif de cerclage Download PDFInfo

- Publication number

- EP1517836B1 EP1517836B1 EP03720077A EP03720077A EP1517836B1 EP 1517836 B1 EP1517836 B1 EP 1517836B1 EP 03720077 A EP03720077 A EP 03720077A EP 03720077 A EP03720077 A EP 03720077A EP 1517836 B1 EP1517836 B1 EP 1517836B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- strapping

- loop

- channel

- guide

- strapped

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009434 installation Methods 0.000 claims abstract 23

- 238000003825 pressing Methods 0.000 claims description 27

- 230000000630 rising effect Effects 0.000 claims description 6

- 238000000034 method Methods 0.000 claims description 5

- 210000003127 knee Anatomy 0.000 claims description 3

- 238000007599 discharging Methods 0.000 abstract 1

- 239000000463 material Substances 0.000 description 41

- 239000000969 carrier Substances 0.000 description 3

- 238000004904 shortening Methods 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012536 packaging technology Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B27/00—Bundling particular articles presenting special problems using string, wire, or narrow tape or band; Baling fibrous material, e.g. peat, not otherwise provided for

- B65B27/08—Bundling paper sheets, envelopes, bags, newspapers, or other thin flat articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B13/00—Bundling articles

- B65B13/02—Applying and securing binding material around articles or groups of articles, e.g. using strings, wires, strips, bands or tapes

- B65B13/04—Applying and securing binding material around articles or groups of articles, e.g. using strings, wires, strips, bands or tapes with means for guiding the binding material around the articles prior to severing from supply

- B65B13/06—Stationary ducts or channels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B27/00—Bundling particular articles presenting special problems using string, wire, or narrow tape or band; Baling fibrous material, e.g. peat, not otherwise provided for

- B65B27/08—Bundling paper sheets, envelopes, bags, newspapers, or other thin flat articles

- B65B27/086—Bundling paper sheets, envelopes, bags, newspapers, or other thin flat articles using more than one tie, e.g. cross-ties

Definitions

- the strapping device like the strapping devices according to EP-1207107 and US-5078057 in the strapping position on a closing area under the support surface in which a loop channel begins and ends, in which the strapping material for looping is fed into the loop channel in which the the loop channel guided, free loop end is held, in which the strapping material is withdrawn to reduce the tension and the loop of the loop channel and in which closed the strapping and separated from further supplied strapping material becomes.

- the loop channel which is substantially formed as a groove in the support surface, runs in two opposite directions from the Schliess Scheme starting from the Umreifungsposition and closes around the Umreifungsposition (or to the largest floor plan of an object to be strapped) around.

- the closing area is located, for example, in the center under an object to be strapped and, for longitudinal strapping, the beginning and end of the loop channel run parallel to the conveying direction.

- a longitudinal strapping using the device according to the invention is carried out in the following manner.

- the groove-shaped loop channel for example, by inserting a free end of the strapping material from the closing area forth until the closing area where the loop end is held, presented a loop.

- means may also be provided for pulling the strapping material into the loop channel.

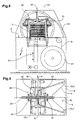

- FIG. 1 shows the strapping position of an exemplary embodiment of the strapping device according to the invention.

- This is equipped for a central L Lucassumreifung an object 1, which is conveyed in a substantially horizontal conveying direction F on a support surface 2 in the Umreifungsposition and after strapping back in the conveying direction F from the Umreifungsposition addition.

- the closing area 3 is set in a corresponding recess of the support surface 2 below the level of the support surface. From the closing area 3 extends parallel to the conveying direction F in both directions a recessed into the support surface 2, groove-shaped loop channel 4, which closes on one side to the floor plan 5 of a largest object to be strapped around.

- the loop guide 10 can also have a plurality of slide rails instead of the two slide rails 10.1 and 10.2 shown in FIG. 1, or it can be designed as a single, flat element.

- the loop guide 10 rises within the loop channel 4 and on one side of the strapping position from the support surface 2 and arches over or against the strapping position, such that its upper end is positioned approximately above the closure region 3, for example.

- the outside of the loop guide 10 is equipped for a sliding movement of the strapping material.

- Figures 4A and 4B show a plan view of the support surface two variants, according to which a band-shaped strapping material 6 can be arranged in the loop channel and through the closing area. It is ever a belt loop shown and very schematically the closing area 3, in which the strapping material 6 fed into the loop channel (direction Z), the free end 7 held and the strapping material 6 is withdrawn from the loop channel (direction R) is. The loop channel is not shown.

- the rotatability of the tape holder may be active or passive depending on the stiffness of the strapping.

- the rotatable band holder advantageously has elastic return means, by which the band holder, as soon as the strapping band is removed therefrom, is rotated back into the starting position.

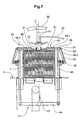

- the pressing elements 42 can be lowered by means of a common drive 41 onto the object 1 to be strapped.

- the drive 41 is realized, for example, as a chain hoist 43 arranged below the bearing surface 2 with traverses 44 coupled thereto and with a respective vertical carrier 45 arranged laterally of the strapping position for each pressing element 42.

- the pressing members 42 may be formed as simple relative to the vertical supports 45 stationarily arranged pressing plates.

- they are, as shown in Figure 7, configured as angled toggle 46, which are arranged tiltable about an axis 47 in the region of the upper ends of the vertical support 45 and each one extending over the Umreifungsposition, pressing part 46.1 and a have laterally extending part 46.2.

- the knee lever part 46.2 is distanced for example by means of spring 48 from the vertical support 45, such that the toggle lever part 46.1 is directed at uncompressed spring 48 from the axis of rotation 47 from below.

- the pressing elements 42 can simultaneously also assume a guiding function for a loop released from the loop guide 10.

- freely rotatable rollers 50 are arranged at the two ends of the toggle parts 46.1 and 46.2 and optionally also between them, of which a guide band 51, whose both ends are fixed to stationary parts of the device is held in a predetermined position.

- Each of the four pressing elements 42 is associated with at least one such guide band 51.

- the guide bands 51 extend on one side of the Lfitsumreifungsebene L from the loop channel 30 for Querumreifung on the other side of the Lnaturereifungsebene L from the end of the loop guide 10 to the end of the pressing toggle 46.1, from there to the end of the side toggle 46.2 and from there against the supporting surface.

- the guide bands 51 are optionally held slightly stretched with suitable means, not shown.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Basic Packing Technique (AREA)

- Finger-Pressure Massage (AREA)

- Thermotherapy And Cooling Therapy Devices (AREA)

- Microwave Tubes (AREA)

- Saccharide Compounds (AREA)

Claims (17)

- Dispositif de cerclage pour le cerclage d'objets (1), en particulier de piles de produits imprimés, par exemple des périodiques ou des journaux, par un matériau de cerclage (6), lequel dispositif présente une position de cerclage dotée d'une surface de pose (2), des moyens de positionnement des objets à cercler dans la position de cerclage et des moyens d'enlèvement des objets cerclés dans une direction de transport (F), essentiellement en parallèle à la surface de pose (2), pour les sortir de la position de cerclage, lequel dispositif présente en outre une zone de fermeture (3) disposée dans la position de cerclage, conçue pour amener le matériau de cerclage (6) dans un canal de boucle (4), pour maintenir une extrémité (7) de la boucle, pour extraire le matériau de cerclage (6) hors du canal de boucle (4) et pour fermer et découper un cerclage terminé, le canal de boucle (4) s'étendant des deux côtés de la zone de fermeture (3) en formant une rainure dans la surface de pose (2),

caractérisé en ce que le dispositif présente en outre un guide de boucle (10) qui est stationnaire pendant le cerclage, qui remonte de la surface de pose (2) à l'intérieur du canal de boucle (4) et d'un côté de la position de cerclage et qui est cintré au-dessus ou contre la position de cerclage de telle sorte qu'il ne gène pas le positionnement de l'objet (1) à cercler dans la position de cerclage et de telle sorte qu'une boucle (6.2) de matériau de cerclage (6) glisse sur le côté extérieur du guide de boucle (10) et qu'une boucle (6.2) maintenue et guidée d'une part au début et à la fin du canal de boucle (4) et d'autre part par le guide de boucle (10) soit d'autant plus courte qu'elle repose plus haut sur le guide de boucle (10). - Dispositif de cerclage selon la revendication 1, caractérisé en ce que les moyens de positionnement de l'objet (1) à cercler dans la position de cerclage sont conçus pour assurer un positionnement orienté vers le haut contre la position de cerclage ou essentiellement dans la direction de transport (F) et en ce que le guide de boucle (10) est cintré vers la position de cerclage.

- Dispositif de cerclage selon la revendication 1, caractérisé en ce que les moyens de positionnement de l'objet (1) à cercler dans la position de cerclage sont conçus pour réaliser un positionnement orienté essentiellement dans la direction de transport (F) et en ce que le guide de boucle (10) se courbe au-dessus de la position de cerclage.

- Dispositif de cerclage selon l'une des revendications 1 à 3, caractérisé en ce que le début et la fin du canal de boucle (4) en forme de rainure pour le cerclage longitudinal sont orientés parallèlement à la direction de transport (F) et en ce que le dispositif est en plus conçu pour réaliser un cerclage transversal dans la position de cerclage ou dans une autre position de cerclage qui se raccorde dans la direction de transport (F) à la position de cerclage.

- Dispositif de cerclage selon la revendication 4, caractérisé en ce qu'il présente pour le cerclage transversal un autre canal de boucle (30) qui s'étend transversalement à la direction de transport (F)

- Dispositif de cerclage selon l'une des revendications 1 à 5, caractérisé en ce que le guide de boucle (10) présente deux ou plus de deux rails de glissement (10.1, 10.2).

- Dispositif de cerclage selon la revendication 6, caractérisé en ce que le canal de boucle (4) en forme de rainure présente entre les rails de glissement (10.1 et 10.2) une courbure concave et en ce qu'un élément qui remonte de la surface de pose (2) à l'extérieur du canal de boucle (4) est prévu dans la zone de la courbure concave du canal de boucle (4) en forme de rainure.

- Dispositif de cerclage selon les revendications 5 et 7, caractérisé en ce que l'autre canal de boucle (30) est l'élément qui remonte de la surface de pose (2) à l'extérieur du canal de boucle (4) en forme de rainure et s'étend au-dessus du guide de boucle (10) à travers la position de cerclage.

- Dispositif de cerclage selon l'une des revendications 1 à 8, caractérisé en ce que le canal de boucle (4) en forme de rainure présente au moins dans les zones où le guide de boucle (10) remonte de la surface de poste (2) une paroi intérieure (4.1) orientée obliquement par rapport à la surface de pose (2).

- Dispositif de cerclage selon l'une des revendications 1 à 9, caractérisé en ce qu'au moins certaines parties du canal de boucle (4) en forme de rainure peuvent être fermées.

- Dispositif de cerclage selon l'une des revendications 1 à 10, caractérisé en ce que la zone de fermeture (3) est conçue pour maintenir un matériau de cerclage (6) en forme de ruban avec sa largeur parallèle à la surface de pose (2) et en ce que le canal de boucle (4) présente des torsions de telle sorte que le matériau de cerclage (6) en forme de ruban soit orienté avec sa largeur perpendiculaire à la surface de pose (2) dans les parties courbées du canal.

- Dispositif de cerclage selon l'une des revendications 1 à 10, caractérisé en ce que la zone de fermeture (3) présente un support rotatif (13, 14) pour le matériau de cerclage (6), par lequel un matériau de cerclage (6) en forme de ruban peut être tourné d'une position dans laquelle sa largeur est perpendiculaire à la surface de pose (2) jusque dans une position dans laquelle sa largeur est parallèle à une surface de pose (2).

- Dispositif de cerclage selon l'une des revendications 1 à 10, caractérisé en ce que la zone de fermeture (3) est conçue pour maintenir et fermer de manière non-modifiable un matériau de cerclage (6) en forme de ruban dont la largeur est perpendiculaire à la surface de pose (2).

- Dispositif de cerclage selon l'une des revendications 1 à 13, caractérisé en ce qu'il présente en outre deux ou quatre éléments de poussée (42) qui peuvent être abaissés.

- Dispositif de cerclage selon la revendication 14, caractérisé en ce que les éléments de poussée (42) sont configurés comme leviers à genouillère (46) qui peut tourner autour d'un axe (47).

- Dispositif de cerclage selon l'une des revendications 14 ou 15, caractérisé en ce que les éléments de poussée (42) sont conçus pour guider la boucle (6) à l'aide de bandes de guidage (51), lesquelles bandes de guidage (51) forment au-dessus de la position de cerclage un canal de guidage (55) qui s'étend de l'extrémité du guide de boucle (10) vers la position de cerclage et est ouvert au-dessus de l'extrémité du guide de boucle (10).

- Dispositif de cerclage selon l'une des revendications 14 à 16, caractérisé en ce qu'il présente en outre des moyens de positionnement d'une feuille de recouvrement (60) sur l'objet (1) à cercler et en ce que les éléments de poussée (42) sont conçus pour déplacer la feuille de recouvrement (60) pendant qu'ils sont abaissés sur l'objet (1) à cercler.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH11272002 | 2002-06-28 | ||

| CH112702 | 2002-06-28 | ||

| PCT/CH2003/000325 WO2004002829A1 (fr) | 2002-06-28 | 2003-05-22 | Dispositif de cerclage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1517836A1 EP1517836A1 (fr) | 2005-03-30 |

| EP1517836B1 true EP1517836B1 (fr) | 2006-08-16 |

Family

ID=29783981

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03720077A Expired - Lifetime EP1517836B1 (fr) | 2002-06-28 | 2003-05-22 | Dispositif de cerclage |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US7086213B2 (fr) |

| EP (1) | EP1517836B1 (fr) |

| AT (1) | ATE336430T1 (fr) |

| AU (1) | AU2003223825B2 (fr) |

| CA (1) | CA2490910A1 (fr) |

| DE (1) | DE50304670D1 (fr) |

| DK (1) | DK1517836T3 (fr) |

| ES (1) | ES2270007T3 (fr) |

| WO (1) | WO2004002829A1 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004051029B3 (de) * | 2004-10-08 | 2005-12-08 | Schneider & Ozga Ohg | Vorrichtung zum Längsumreifen eines Gegenstandes |

| DE102006038319B4 (de) * | 2006-08-15 | 2018-02-22 | Mosca Gmbh | Längsumreifungsvorrichtung und Verfahren zum Umreifen |

| DE102006038318A1 (de) * | 2006-08-15 | 2008-02-21 | Maschinenfabrik Gerd Mosca Ag | Bandumreifungsmaschine |

| ES2397264T3 (es) * | 2010-09-08 | 2013-03-05 | Titan Umreifungstechnik Gmbh & Co.Kg | Procedimiento para la colocación de bandas de zunchado alrededor de piezas de embalaje |

| US8443723B2 (en) * | 2010-10-27 | 2013-05-21 | Tekpak Corporation | Cross-strapping device |

| CH705743A2 (de) | 2011-11-14 | 2013-05-15 | Illinois Tool Works | Umreifungsvorrichtung. |

| CH705745A2 (de) * | 2011-11-14 | 2013-05-15 | Illinois Tool Works | Umreifungsvorrichtung. |

| US10820526B2 (en) * | 2018-07-10 | 2020-11-03 | Deere & Company | Agricultural baler including crop package banding system and method |

| CN116119082B (zh) * | 2023-04-17 | 2023-06-13 | 烟台安信机电科技有限公司 | 一种用于快速捆扎零件的料仓 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4077313A (en) * | 1976-12-20 | 1978-03-07 | Signode Corporation | Method of tensioning and joining a formed strap loop about a package |

| USRE31353E (en) * | 1976-12-20 | 1983-08-23 | Signode Corporation | Expanding strap loop forming and friction fusion machine |

| US4062278A (en) * | 1976-12-20 | 1977-12-13 | Signode Corporation | Expanding strap loop forming and friction fusion machine |

| US4079667A (en) * | 1976-12-20 | 1978-03-21 | Signode Corporation | Method of forming and tensioning a strap loop about a package |

| US4378262A (en) * | 1981-02-04 | 1983-03-29 | Signode Corporation | Method and apparatus for forming and tensioning a strap loop about a package |

| US5078057A (en) | 1990-01-05 | 1992-01-07 | Illinois Tool Works Inc. | Binding machine, such as strapping machine |

| DE4237787A1 (fr) * | 1991-11-30 | 1993-06-03 | Georg Lang | |

| DE4230730B4 (de) | 1992-09-14 | 2005-05-25 | Georg Lang | Umreifungsmaschine mit einem Bandführungsrahmen |

| DE19615009B4 (de) * | 1996-04-16 | 2005-09-29 | Smb Schwede Maschinenbau Gmbh | Kreuzleger mit Umreifungsvorrichtung |

| ES2149535T3 (es) | 1997-09-27 | 2000-11-01 | Ssb Strapping Systeme Bindlach | Dispositivo flejador. |

| ATE273840T1 (de) | 2000-11-20 | 2004-09-15 | Ferag Ag | Umreifungsvorrichtung |

| DE10357829A1 (de) * | 2003-12-09 | 2005-07-28 | Signode Bernpak Gmbh | Vorrichtung zum Längsumreifen eines Packstücks wie insbesondere eines Stapels von Zeitungen, Magazinen oder dgl. |

-

2003

- 2003-05-22 US US10/519,296 patent/US7086213B2/en not_active Expired - Fee Related

- 2003-05-22 WO PCT/CH2003/000325 patent/WO2004002829A1/fr active IP Right Grant

- 2003-05-22 DE DE50304670T patent/DE50304670D1/de not_active Expired - Lifetime

- 2003-05-22 ES ES03720077T patent/ES2270007T3/es not_active Expired - Lifetime

- 2003-05-22 EP EP03720077A patent/EP1517836B1/fr not_active Expired - Lifetime

- 2003-05-22 AT AT03720077T patent/ATE336430T1/de not_active IP Right Cessation

- 2003-05-22 AU AU2003223825A patent/AU2003223825B2/en not_active Ceased

- 2003-05-22 CA CA002490910A patent/CA2490910A1/fr not_active Abandoned

- 2003-05-22 DK DK03720077T patent/DK1517836T3/da active

Also Published As

| Publication number | Publication date |

|---|---|

| DE50304670D1 (de) | 2006-09-28 |

| AU2003223825B2 (en) | 2008-11-06 |

| ATE336430T1 (de) | 2006-09-15 |

| WO2004002829A1 (fr) | 2004-01-08 |

| ES2270007T3 (es) | 2007-04-01 |

| EP1517836A1 (fr) | 2005-03-30 |

| US7086213B2 (en) | 2006-08-08 |

| CA2490910A1 (fr) | 2004-01-08 |

| US20050229551A1 (en) | 2005-10-20 |

| DK1517836T3 (da) | 2007-02-12 |

| AU2003223825A1 (en) | 2004-01-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2710474C2 (fr) | ||

| DE3512737C2 (de) | Aufgeber von Heftlagen, Bogen und ähnlichen Erzeugnissen für Zuführvorrichtungen in Packmaschinen, Buchbindereimaschinen u.dgl. | |

| DE69505767T2 (de) | Verfahren und Vorrichtung für eine Umschnürungsmaschine | |

| EP0144861A2 (fr) | Dispositif de pliage en zig-zag et d'empilage des bandes de matériaux | |

| EP0968919B1 (fr) | Procédé et dispositif d'enveloppement d'objets quadrangulaires avec un matériau d'emballage sous forme de bande | |

| DE2615560A1 (de) | Maschine zum aufreihen verschiedenartiger bauelemente | |

| EP1184283A1 (fr) | Procédé et dispositif pour le cerclage de produits de l'imprimerie | |

| EP0890509A1 (fr) | Procédé et dispositif pour lier des objets unitaires ou des piles d'objets | |

| EP1517836B1 (fr) | Dispositif de cerclage | |

| DE3315495C2 (de) | Vorrichtung zum Lagern von Papierbogen o.dgl. | |

| EP1541470B1 (fr) | Dispositif pour appliquer une bande de cerclage longitudinale autour d'un objet, comme en particulier une pile de journaux ou magazines | |

| DE3708267A1 (de) | Bandbogenfuehrung fuer eine umschnuerungsmaschine | |

| DE19533086A1 (de) | Verfahren und Vorrichtung zum Stapeln von flächigen Erzeugnissen, insbesondere Druckereiprodukten | |

| DE3619939C2 (de) | Verfahren und Vorrichtung zum Zwischenspeichern von in Schuppenformation anfallenden Druckprodukten | |

| EP0680881B1 (fr) | Dispositif pour banderoler des objets | |

| DE68912280T2 (de) | Klebestreifen-Anbringeinheit für Pappschachtelklebestreifen-Anbringmaschinen mit einer verbesserten Rückstellbewegung der Eingangsandruckrolle. | |

| DE4016484C2 (de) | Verpackungsvorrichtung für Bahnrollen | |

| EP0937647B1 (fr) | Dispositif pour cercler des marchandises avec une bande de cerclage | |

| DE2403155A1 (de) | Bindemaschine zum zusammenheften perforierter blaetter | |

| DE29917881U1 (de) | Umreifungsmaschine zum Umreifen eines Gutstapels | |

| EP1515894B1 (fr) | Installation servant a emballer une bande souple disposee en couches de boucles en zigzag, en particulier d'une bande textile | |

| EP2678171B1 (fr) | Station et procédé d'insertion dans une enveloppe | |

| WO2007107267A1 (fr) | Procede et dispositif pour transporter des bandes d'etiquettes | |

| DE3902297A1 (de) | Verfahren und vorrichtung zum umwandeln gebuendelter signaturen in einen aufgefaecherten strom | |

| EP1050463B1 (fr) | Machine de liage pour lier une pile d'objets |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20041210 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060816 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50304670 Country of ref document: DE Date of ref document: 20060928 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: FREI PATENTANWALTSBUERO AG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061116 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070116 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070131 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2270007 Country of ref document: ES Kind code of ref document: T3 |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070518 |

|

| BERE | Be: lapsed |

Owner name: FERAG AG Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070511 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20090521 Year of fee payment: 7 Ref country code: NL Payment date: 20090527 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070522 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090523 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070217 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060816 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090522 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20101201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101201 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100522 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110711 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110629 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110518 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100523 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20120521 Year of fee payment: 10 Ref country code: DE Payment date: 20120523 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20120522 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100522 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130523 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131203 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20130531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50304670 Country of ref document: DE Effective date: 20131203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 |