EP1353126A2 - Hydraulisch geregelte Gasarmatur - Google Patents

Hydraulisch geregelte Gasarmatur Download PDFInfo

- Publication number

- EP1353126A2 EP1353126A2 EP03007464A EP03007464A EP1353126A2 EP 1353126 A2 EP1353126 A2 EP 1353126A2 EP 03007464 A EP03007464 A EP 03007464A EP 03007464 A EP03007464 A EP 03007464A EP 1353126 A2 EP1353126 A2 EP 1353126A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- gas

- water

- hydraulically controlled

- sleeve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N1/00—Regulating fuel supply

- F23N1/08—Regulating fuel supply conjointly with another medium, e.g. boiler water

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2235/00—Valves, nozzles or pumps

- F23N2235/12—Fuel valves

- F23N2235/16—Fuel valves variable flow or proportional valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2235/00—Valves, nozzles or pumps

- F23N2235/12—Fuel valves

- F23N2235/24—Valve details

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2241/00—Applications

- F23N2241/04—Heating water

Definitions

- the invention relates to a hydraulic regulated gas valve for one fuel gas heated once-through water heater.

- Such gas fittings are characterized in that they depend on the heating water volume and a control knob the amount of fuel gas that leads to a Burner arrives, adjust.

- a gain factor can be set using the control knob (Fuel gas volume flow to water volume flow) can be set, that is to say that ultimately the water temperature is set approximately using the button.

- these gas fittings must have at least two seals Valves that have different control signals have.

- the ionization current is used in a flame. Is a flame on the burner surface is present, an ionization current can be tapped in the area of the flame. With This ionization current can be opened by means of a coil, a valve, the safety valve become.

- the other sealing valve is usually that Low water valve. With this valve, a water switch is used Water volume flow equivalent stroke movement generated. By means of this lifting movement the water shortage valve open and thus one of the water volume flow flow the equivalent amount of fuel gas through the gas valve.

- gas fittings often have an additional valve with which a Gain factor set between fuel gas volume flow and water volume flow can be. This setting is usually done manually by the operator, who frequently A cone valve opens linearly by means of a redirection knob or closes.

- the aim of the invention is to provide a gas fitting for a fuel gas-fired once-through water heater create, which is characterized by simple and reliable construction.

- valve for setting the gain factor does not have to be a sealing one Be a cone valve, the cone of which is displaced linearly by means of deflection. Rather there is According to the invention the valve from a guide with an opening and one located therein Sleeve with slot, the sleeve is guided in the guide and slot and opening are superimposed. In this way, the setting of the valve can be done directly without deflection take place, which simplifies the structure and thus reduces the susceptibility to failure.

- valve is sensitive can be dosed. It is particularly advantageous if the slot at one end of its Translation path is very narrow and its width is continuously widening.

- the leadership Part of the housing which receives the components of the gas valve, is what a Component reduction is achieved. It is particularly advantageous if the opening is part of a inserted socket, because in this way an exchange of the socket (e.g. because of Power limitation, gas type change, etc.) and higher manufacturing accuracy (Housing is usually a die-cast part that is reworked) is possible.

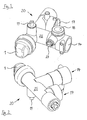

- FIG. 1 and 2 show a gas valve 20 according to the invention with a housing 25, a knob 1, fuel gas inlet 17, fuel gas outlet 18 with screw 29 for Setting the burner pressure, pilot gas outlet 19 and water switch connection 14.

- the Water switch not shown, is separated by a membrane in two pressure chambers. When dispensing hot water, a Venturi nozzle in the water switch generates a differential pressure generated between the chambers; the diaphragm rises due to the differential pressure. As a result, a steadily growing signal is delivered to the amount of water, in the form of a Lifting movement is transmitted to the control pin 15.

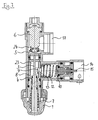

- Fig. 3 is a section through this gas fitting 20 in the initial state (i.e. none Fuel gas flow) to see.

- the fuel gas inlet 17 opens into a chamber 24 in which a Safety valve 5 and a thermomagnet 6, which are coupled together, are located.

- a sleeve 8 with a slot 9.

- Ignition gas bolt 3 which ends in the adjusting knob 1.

- a portion of the sleeve 8 forms a portion of the pilot gas bolt 3, a pilot gas valve 4, which connects to a Seals annular channel 26.

- a spring 7 is tensioned between the sleeve 8 and the adjusting knob 1.

- the pilot gas bolt 3 is connected to the adjusting knob 1.

- the sleeve 8 lies on a socket 11, which has an opening 13.

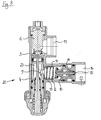

- Fig. 4 shows the gas fitting 20 in another section. From this perspective, the Connection of the pilot gas outlet 19 and the mechanism for actuating the Gas fitting 20 clearly.

- the ignition gas bolt 3 is one Control curve 2 (see FIG. 13) in the adjusting knob 1 in connection with a screw 16 available; the function will be described later.

- Fig. 5 shows the same perspective in another working position, in the ignition position the connection of the ring channel 26 to the pilot gas outlet 19 via the bore 27 becomes clear.

- FIG. 6 shows part of the gas fitting 20 in a further working step.

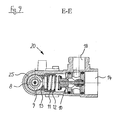

- Fig. 8 shows a part of the gas fitting 20 in the operating state in which the fuel gas from Fuel gas inlet 17 can flow to the fuel gas outlet 18.

- Fig. 11 shows the sleeve 8 in detail with the slot 9 and sealing rings 28.

- Fig. 12 is the Ignition gas bolts shown in detail.

- 13 shows the inside view of the adjusting knob 1 with the control curve.

- Fig. 14 shows the sleeve 11 with opening 13 and Fig. 15 shows that Low water valve 10 with control pin 15.

- the gas fitting 20 is in the initial state, in which no fuel gas streams to see.

- the adjusting button 1 is manually pushed further, whereby the tip of the Ignition gas bolt 3 opens the valve plate on the safety valve 5.

- the print movement ends as soon as an anchor plate on the iron core of an inside the thermomagnet 6 Electromagnet is present.

- Fuel gas can now flow from the fuel gas inlet 17 via the chamber 24, through the opened safety valve 5 into the chamber 23, from there via the open Ignition gas valve 4 in the ring channel 26 and from there via the bore 27 in the Pilot gas outlet 19, from which a connection to a pilot burner, not shown exists, flow.

- a mechanically generated spark ignites the fuel gas on the pilot burner. If the Pilot flame has sufficiently heated a thermocouple is generated by the Thermost current the anchor plate held on the iron core.

- the setting button After releasing the setting button 1, the setting button is - as shown in Fig. 7 1 pushed back together with the ignition gas bolt 3 by the spring 7, wherein the safety valve 5 in the presence of an ignition flame and a corresponding one ionization current through the thermomagnet 6 remains open.

- the gas valve 20 By turning the Adjustment button 1, the gas valve 20 is brought into the ready position. While the Axial position remains unchanged, the sleeve 8 can be rotated and the variable designed slot 9 overlies the opening 13 to the water shortage valve 10, which after as before is closed.

- the bushing 11 which is matched to the outer surface of the sleeve 8 on one side, is axial used floating and is pressed by a spring 12 to the sleeve 8.

- the Bushing 11 with the opening 13 in connection with the position of the slot 9 of the sleeve 9 determine the possible flowing amount of gas (when the low water valve 10 is open) or the so-called performance selection.

- the water shortage valve 10 blocks the fuel gas flow through the Fuel gas outlet 18 to the burner, not shown.

- a signal to open the water shortage valve can 10 be given to the control pin 15.

- the water switch not shown, transmits a stroke dependent on the water flow to the control pin 15, which finally Low water valve plate presses against the gas flow and thus the low water valve 10 opens.

- Fig. 8 The fuel gas can now from the chamber 23 the slot 9 and the opening 13 through the open water shortage valve 10 in the Flow fuel gas outlet 18.

- the opening cross section of the water shortage valve 10 and thus the fuel gas volume flow is dependent on the stroke of the control pin 15.

- Fig. 9 shows the gas valve, in particular the open water shortage valve 10 with the Fuel gas outlet 18.

- pilot gas valve 4 and safety valve 5 means that Compared to the prior art redirections.

- function integration simplifies that Build and reduce costs.

- the spring 12 fulfills two functions. On the one hand, it represents a concern of the socket 11 on the Sleeve 8 secure; on the other hand, it closes the water shortage valve 10. An expansion of the Socket 11 e.g. for a gas type change is after dismantling the water shortage valve 10 possible.

- the pilot gas valve 4 is without the usual flat gasket and without a turned valve seat designed so that the number of parts is reduced and assembly is simplified.

- the low water valve 4 closes in the direction of fuel gas flow. Because of that smaller closing spring force 12, the membrane on the water switch can be reduced.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Feeding And Controlling Fuel (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

- Magnetically Actuated Valves (AREA)

- Fluid-Driven Valves (AREA)

- Valve Device For Special Equipments (AREA)

- Details Of Valves (AREA)

Abstract

Description

Claims (8)

- Hydraulisch geregelte Gasarmatur (20) für einen gasbeheizten Durchlauf-Wasserheizer mit einem Ventil zur Einstellung des Verstärkungsfaktors, welcher das Verhältnis von Brenngasvolumenstrom zu Wasservolumenstrom festlegt, dadurch gekennzeichnet, dass das Ventil zur Einstellung des Verstärkungsfaktors von einer Hülse (8) mit Schlitz (9) und einer Führung (21) mit Öffnung (13) gebildet wird, wobei die Hülse (8) derart in der Führung (21) geführt wird, dass der Schlitz (9) kontinuierlich über die Öffnung (13) führbar ist.

- Hydraulisch geregelte Gasarmatur (20) gemäß Anspruch 1, dadurch gekennzeichnet, dass die Hülse (8) und die Führung (21) rotationssymmetrisch ausgeführt sind und über die selbe Rotationsachse (22) verfügen.

- Hydraulisch geregelte Gasarmatur (20) gemäß Anspruch 1 oder 2, dadurch gekennzeichnet, dass der Schlitz (9) in Translationsrichtung eine nicht konstante Breite aufweist.

- Hydraulisch geregelte Gasarmatur (20) gemäß einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass die Führung (21) Teil eines Gehäuses (25), vorzugsweise mit eingesetzter Buchse (11), welche die Öffnung (13) besitzt, ist.

- Hydraulisch geregelte Gasarmatur (20) gemäß einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass die Hülse (8) aus Kunststoff, vorzugsweise Polyamid hergestellt ist.

- Hydraulisch geregelte Gasarmatur (20) gemäß einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass die Führung (8) beziehungsweise das Gehäuse (25) aus Metall, vorzugsweise Messing, Zink oder Aluminium hergestellt ist.

- Hydraulisch geregelte Gasarmatur (20) gemäß einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, dass die Gasarmatur (20) über ein Wassermangelventil (10) verfügt, welches die Brenngasmenge in Abhängigkeit der Wassermenge steuert, und die Öffnungsrichtung des Wassermangelventils (10) gegen die Strömungsrichtung des Brenngases gerichtet ist.

- Hydraulisch geregelte Gasarmatur (20) gemäß einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, dass die Gasarmatur (20) über ein Zündgasventil (23) und ein Sicherheitsventil (5) verfügt, deren Translationsachse (22) identisch ist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT03007464T ATE439553T1 (de) | 2002-04-11 | 2003-04-04 | Hydraulisch geregelte gasarmatur |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10217030 | 2002-04-11 | ||

| DE10217030 | 2002-04-11 | ||

| AT0183902A AT412232B (de) | 2002-12-10 | 2002-12-10 | Hydraulisch geregelte gasarmatur |

| AT18392002 | 2002-12-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1353126A2 true EP1353126A2 (de) | 2003-10-15 |

| EP1353126A3 EP1353126A3 (de) | 2004-06-23 |

| EP1353126B1 EP1353126B1 (de) | 2009-08-12 |

Family

ID=28455342

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03007464A Expired - Lifetime EP1353126B1 (de) | 2002-04-11 | 2003-04-04 | Hydraulisch geregelte Gasarmatur |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1353126B1 (de) |

| AT (1) | ATE439553T1 (de) |

| DE (2) | DE50311791D1 (de) |

| DK (1) | DK1353126T3 (de) |

| ES (1) | ES2329022T3 (de) |

| PT (1) | PT1353126E (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1528320A1 (de) * | 2003-10-31 | 2005-05-04 | Vaillant GmbH | Gasarmatur |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2525327A1 (fr) * | 1982-04-20 | 1983-10-21 | Sdecc | Mecanisme du type a membrane pour appareils a gaz muni d'un systeme d'ouverture et de fermeture brusque a fonctionnement hydraulique |

| EP0252252A3 (de) * | 1986-05-15 | 1988-09-21 | Joh. Vaillant GmbH u. Co. | Brauchwasserheizer |

-

2003

- 2003-04-04 DE DE50311791T patent/DE50311791D1/de not_active Expired - Lifetime

- 2003-04-04 EP EP03007464A patent/EP1353126B1/de not_active Expired - Lifetime

- 2003-04-04 ES ES03007464T patent/ES2329022T3/es not_active Expired - Lifetime

- 2003-04-04 DK DK03007464T patent/DK1353126T3/da active

- 2003-04-04 DE DE10315543A patent/DE10315543A1/de not_active Withdrawn

- 2003-04-04 PT PT03007464T patent/PT1353126E/pt unknown

- 2003-04-04 AT AT03007464T patent/ATE439553T1/de active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1528320A1 (de) * | 2003-10-31 | 2005-05-04 | Vaillant GmbH | Gasarmatur |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1353126A3 (de) | 2004-06-23 |

| ES2329022T3 (es) | 2009-11-20 |

| EP1353126B1 (de) | 2009-08-12 |

| DE50311791D1 (de) | 2009-09-24 |

| ATE439553T1 (de) | 2009-08-15 |

| DK1353126T3 (da) | 2009-12-14 |

| DE10315543A1 (de) | 2003-10-30 |

| PT1353126E (pt) | 2009-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1025395B1 (de) | Gasregelarmatur | |

| DE3790806C2 (de) | Brennstoffregelventilanordnung | |

| DE10309469B3 (de) | Gasregelarmatur | |

| DE2926320C2 (de) | Elektromagnetisch betätigtes Membran-Wasserventil mit einer hydraulischen Servoeinheit für die Regelung des Wasserkreislaufes in Heiz- bzw. Klimaanlagen | |

| DE3619840C2 (de) | Gashahn | |

| AT412232B (de) | Hydraulisch geregelte gasarmatur | |

| EP1353126A2 (de) | Hydraulisch geregelte Gasarmatur | |

| DE2941543C2 (de) | Vorrichtung zur Steuerung der Gaszufuhr | |

| DE102007013505A1 (de) | Armaturenkombination zur Regelung der Durchflussmenge oder des Differenzdruckes | |

| DE2742755C2 (de) | Magnetventil | |

| DE102013218014B4 (de) | Gasventileinrichtung und Gasgerät mit einer Gasventileinrichtung | |

| DE29905204U1 (de) | Gasregelarmatur | |

| EP0834043B1 (de) | Armatur, insbesondere für einen durchlauf-wassererhitzer | |

| DE2317382C3 (de) | Sicherheits- und Regelanordnung für gasbeheizte Geräte | |

| EP0997685A2 (de) | Düsenstock für einen Öldruckzerstäubungsbrenner sowie Abschlussventil für einen solchen Düsenstock | |

| EP1598543A1 (de) | Regelbare Zwei-Wege-Ventilvorrichtung | |

| AT394267B (de) | Wasserschalter | |

| DE1529055C (de) | ||

| EP1528320B1 (de) | Gasarmatur | |

| DE1429094C (de) | Sicherheitsventil | |

| DE102005037049B3 (de) | Ventil-Steuerungsvorrichtung | |

| DE2953785A1 (de) | Vorrichtung zur steuerung der gaszufuhr | |

| DE19534909A1 (de) | Gerät zum Erwärmen von Heizungswasser und Bereiten von Brauchwasser | |

| CH344978A (de) | Regelvorrichtung für Brenner | |

| DES0031138MA (de) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20041116 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 50311791 Country of ref document: DE Date of ref document: 20090924 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20090921 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2329022 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20100517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100404 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20150401 Year of fee payment: 13 Ref country code: DK Payment date: 20150401 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20150330 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20160430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 439553 Country of ref document: AT Kind code of ref document: T Effective date: 20160404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160404 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180313 Year of fee payment: 16 Ref country code: NL Payment date: 20180313 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20180326 Year of fee payment: 16 Ref country code: PT Payment date: 20180327 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180326 Year of fee payment: 16 Ref country code: ES Payment date: 20180518 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180426 Year of fee payment: 16 Ref country code: IT Payment date: 20180430 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50311791 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20190501 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190430 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190501 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190404 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191004 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190430 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190404 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200828 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190405 |