EP1316632B1 - Fil avec codage et procédé de fabrication d'un fil codé - Google Patents

Fil avec codage et procédé de fabrication d'un fil codé Download PDFInfo

- Publication number

- EP1316632B1 EP1316632B1 EP02023315A EP02023315A EP1316632B1 EP 1316632 B1 EP1316632 B1 EP 1316632B1 EP 02023315 A EP02023315 A EP 02023315A EP 02023315 A EP02023315 A EP 02023315A EP 1316632 B1 EP1316632 B1 EP 1316632B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- coding

- accordance

- coded

- jacket

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 13

- 239000002904 solvent Substances 0.000 claims abstract description 9

- 238000000034 method Methods 0.000 claims description 15

- 239000000463 material Substances 0.000 claims description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 4

- 238000009958 sewing Methods 0.000 description 5

- 239000000835 fiber Substances 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 206010039203 Road traffic accident Diseases 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000007743 anodising Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 238000013031 physical testing Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 1

- 238000007738 vacuum evaporation Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02G—CRIMPING OR CURLING FIBRES, FILAMENTS, THREADS, OR YARNS; YARNS OR THREADS

- D02G3/00—Yarns or threads, e.g. fancy yarns; Processes or apparatus for the production thereof, not otherwise provided for

- D02G3/44—Yarns or threads characterised by the purpose for which they are designed

- D02G3/46—Sewing-cottons or the like

Definitions

- the invention relates to a thread with a coding according to the preamble of claim 1, a method for producing a coded thread according to the preamble of claim 8, as well as uses of a coded thread.

- a yarn which contains at least one legible fiber identifiable by a suitable reading sensor which is hidden inside the yarn.

- This fiber is used to ensure the authenticity of the yarn and product, e.g. of a garment in which the yarn was processed. So with the help of the fiber conclusions can be drawn on the manufacturer of the yarn or the garment.

- the object of the invention is to provide a thread with a coding that allows the simplest possible identification, processing and testing of the thread, the coded thread should be as easy to produce.

- the object is achieved in particular in that the surface of the thread is formed as the coding and the coding comprises length information.

- the fact that the surface of the thread forms the coding a simple method for reading the coding is sufficient.

- this makes it possible that after the production of the thread, the coding can be applied subsequently in a simple manner.

- the length information causes the coding to serve not only as information about the thread or about the product in which the thread is processed, the associated manufacturer and the associated batch, but also for detecting changes in the length of the thread during or after its processing z. B. caused by an accident.

- the thread consumption during the processing of the thread can be determined and controlled and thus the stitch formation with effects, e.g. on seam strength or elongation.

- the coding may have a marking which extends at predetermined intervals, preferably at intervals of about 5-100 mm, along the Thread repeated.

- the distances can be chosen so that they are characteristic both for the manufacturer of the thread, for the thread and its batch, as well as for the length of individual sections of the thread.

- the coding may be configured such that each mark contains information about the manufacturer, the thread and its charge, for example in the form of a bar code, a magnetic code or a two-dimensional dot code, and the distances form a length information with which the thread consumption and the the thread acting forces can be determined.

- the distances can be used so that portions of the thread that are less damaged and contain a mark, can be used to identify the thread and its batch.

- it can be determined by determining the distances during processing, whether the thread consumption changes.

- the forces acting on the thread forces can be determined by determining the distances, for example, before and after a stress with a corresponding change in length without destroying the thread.

- the surface of the thread may have a sheath which is formed as the coding.

- the surface of the thread is formed by the sheath.

- the coding may be provided in or on the sheathing of the thread. This avoids that the thread itself is changed.

- the sheath may be provided in the form of a film applied to the thread.

- the sheath may further be at least partially removable, especially with a solvent.

- the coding in particular with a solvent, can be removable.

- the uncoded state of the thread is restored, or in the case of a thread with a sheathing on which the coding is applied, the sheathed thread remains after the coding has been removed.

- the coding can be formed by deformation of the surface of the thread, in particular by plastic deformation.

- the thread or - in a thread with sheath - its sheath plastically deformable and the coding be obtainable in that the thread z. B. is processed with heated dies in such a way that the outer surface receives a structure containing the desired information.

- the coding may be formed by an optically readable encoding material on the surface of the thread.

- the coding can z. B. consist of a printed dye that is visible only under UV irradiation. Thus, the recognizable under normal lighting appearance of the thread is not changed by the coding.

- the object is also achieved by the features of the independent method claim, and in particular by the fact that the surface of the thread is formed as an encoding, wherein by means of the coding length information is encoded. As explained above, it can be achieved that a simple method for reading the coding is sufficient. In addition, by forming the surface of the thread as the coding allows that after manufacture the thread coding can be applied subsequently in a simple manner.

- the coding of a length information allows a simple determination of the thread length or the thread supply during the processing of the thread.

- the thread may be provided with a marking repeated at predetermined intervals, preferably at intervals of about 5-100 mm, along the thread to form the code.

- the surface of the thread can be deformed, in particular plastically deformed. This can be z. Example be done by the surface of the thread, which consists of plastically deformable material, or a sheath of plastically deformable material by means of stamping is structured such that the desired information is included.

- an adhesive on the surface of the thread coding material can be applied.

- an optically readable encoding material can be used.

- the surface of the thread can be provided with a coding forming the sheath.

- the coding can be provided in or on the sheath of the thread.

- a, in particular with a solvent, at least partially removable and preferably water-soluble sheath can be used. Therefore, the thread z. B. after its processing by Removing the sheath be restored to its original state or in its original appearance.

- a coded thread can be used to identify the thread or a product comprising the thread. If the surface of the thread is formed in a plurality of areas as coding, in case of damage to the thread or an associated garment, the identification of the thread is facilitated because undamaged areas can be used for identification. So each thread has its own identity and the complex registration of batches for tracing in case of complaints is eliminated. The identity of the thread can also be used in the prosecution of product piracy.

- the surface formed as coding is easily accessible from the outside, which means that the coding is simple, d. H. is readable with a simple reading method. Furthermore, the coding after the manufacture of the thread, i. be provided subsequently.

- a coded thread can be used to determine and / or control the thread consumption in the thread processing and in particular in the production of seams.

- An encoding with a length information allows accurate statements about the thread consumption based on a given seam length, but also z. B. in Nähstichtypen with more than one thread statements about the thread ratio of z. B. needle to looper thread. From this it can then be detected by means of appropriate readers during the sewing process, whether the stitch formation is optimal in terms of seam strength and seam elongation. So can be controlled by controlling the thread consumption of the thread supply in the seam and thus the seam behavior.

- the invention may further comprise a coded thread for the determination of acting on the thread or on a product comprising the thread comprehensive and in particular to thread expansions leading forces are used.

- the coding contains a length information, by determining the length before and after the sewing, excessive stretching of the thread during the sewing process can be determined. Even after a traffic accident, the length of a section of a z. B. processed in the safety belt coded thread with the original length and from an accidental elongation of the thread and thus the seat belt can be determined. As a result, the effects of force can be determined without physical destruction of the thread and length changes can be assigned to the forces and their possible causes. This can be advantageously used in criminalistics.

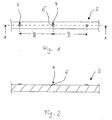

- a thread 2 has a marking 4 on its surface at constant intervals B.

- the marking 4 consists of a visible only in UV light dye, which is applied in the form of a characteristic of the manufacturer, the thread and its batch bar code 6 on the thread 2.

- the distances B serve as length information for controlling the thread consumption during the sewing process and for realizing a controlled seam behavior. Since the bar code is greatly reduced selectively provided as so-called micro-coding and also only visible in UV light, the appearance of the thread is virtually unaffected.

- the bar code 6 is printed with a corresponding plunger after the production of the uncoded thread 2 at the intervals B on the unclaimed and unstretched thread.

- Conventional production lines for threads can be easily and inexpensively converted by installing a corresponding coding station.

- the encoded thread is irradiated with UV light by a reading device, the strip code is detected and read by a sensor active in the wavelength range of the UV dye, and the distances B are determined along the thread.

- the surface of the thread 8 consists of a sheath 10 which encloses the core 12 of the thread 8.

- the sheath 10 is made of a material soluble in water or other solvent.

- the sheath 10 is provided at intervals C and D with recesses 14, wherein the different sized distances C and D are characteristic of the manufacturer, the thread and its batch as a code.

- the recesses 14 are provided only in the sheath 10, so that the core 12 of the thread 8 remains unchanged. This allows for after reading the code information contained the sheath 10 dissolved in water or the solvent and the uncoded core 12 of the thread 8 can be exposed.

- the manufacture of the thread 8 begins with the production of the core 12, which is a conventional uncoded thread. This is then provided by immersion in a solution of the plasticizable material of the sheath and by evaporation of the solvent with the sheath 10. Furthermore, the sheath 10 may be e.g. be generated by static charging of the thread in the manner of flocking or by vacuum evaporation (anodizing). After the sheath 10 has dried, it is z. B. structured with heated dies by the depressions 14 are imprinted in the distances C and D.

- a reading device When reading the coding of the second embodiment, a reading device is used, along the thread, the recesses 14 z. B. with a height difference sensor detecting, for example, has a laser registered, and thus determines the distances C and D.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Decoration Of Textiles (AREA)

- Seeds, Soups, And Other Foods (AREA)

- Sewing Machines And Sewing (AREA)

- Iron Core Of Rotating Electric Machines (AREA)

Claims (18)

- Fil avec un codage, dans lequel la surface du fil (2 ; 8) est réalisée en tant que codage (4 ; 14), caractérisé en ce que le codage (4 ; 14) comprend une information de longueur.

- Fil selon la revendication 1, caractérisé en ce que le codage (4 ; 14) présente un marquage (4) qui se répète le long du fil (2 ; 8) à des distances prédéterminées, de préférence à des distances d'approximativement 5 à 100 mm.

- Fil selon l'une des revendications précédentes, caractérisé en ce que la surface du fil (2 ; 8) présente un enrobage (10) qui est réalisé sous forme de codage (4 ; 14).

- Fil selon la revendication 3, caractérisé en ce que l'enrobage (10) est prévu sous la forme d'un film appliqué sur le fil (8).

- Fil selon l'une ou l'autre des revendications 3 et 4, caractérisé en ce que l'enrobage peut être enlevé au moins partiellement, en particulier au moyen d'un solvant, et en ce qu'il est de préférence soluble à l'eau.

- Fil selon l'une des revendications précédentes, caractérisé en ce que le codage (4 ; 14) est formé par déformation de la surface du fil (2 ; 8), en particulier par déformation plastique.

- Fil selon l'une des revendications précédentes, caractérisé en ce que le codage (4 ; 14) est formé par un matériau de codage (7) optiquement lisible sur la surface du fil (2 ; 8).

- Procédé de fabrication d'un fil codé, en particulier selon l'une des revendications précédentes, dans lequel la surface du fil (2 ; 8) est réalisée sous forme de codage (4 ; 14), caractérisé en ce qu'une information de longueur est codée au moyen du codage (4 ; 14).

- Procédé selon la revendication 8, caractérisé en ce que pour former le codage (4 ; 14), le fil (2 ; 8) est pourvu d'un marquage (4) qui se répète le long du fil à des distances prédéterminées, de préférence à des distance d'approximativement 5 à 100 mm.

- Procédé selon l'une des revendications 8 à 9, caractérisé en ce que pour former le codage (4 ; 14), la surface du fil (2 ; 8) est déformée, en particulier déformée plastiquement.

- Procédé selon l'une des revendications 8 à 10, caractérisé en ce que pour former le codage (4 ; 14), un matériau de codage (6 ; 10) adhérent est appliqué sur la surface du fil (2 ; 8).

- Procédé selon la revendication 11, caractérisé en ce qu'on utilise un matériau de codage (6) optiquement lisible.

- Procédé selon l'une des revendications 8 à 12, caractérisé en ce que la surface du fil (2 ; 8) est pourvue d'un enrobage (10) formant le codage.

- Procédé selon la revendication 13, caractérisé en ce qu'on utilise un enrobage (10) qui peut être enlevé au moins partiellement au moyen d'un solvant et qui est de préférence soluble à l'eau.

- Procédé selon l'une des revendications 8 à 14, caractérisé en ce que le codage (4 ; 14) est appliqué après la fabrication du fil (2 ; 8), en particulier dans un état non sollicité ou non étiré du fil (2 ; 8).

- Utilisation d'un fil codé selon l'une des revendications 1 à 7, pour identifier le fil (2 ; 8) ou un produit contenant le fil (2 ; 8).

- Utilisation d'un fil codé selon l'une des revendications 1 à 7, pour déterminer et/ou pour commander la consommation du fil lors du traitement du fil et en particulier lors de la réalisation de coutures.

- Utilisation d'un fil codé selon l'une des revendications 1 à 7, pour déterminer des forces agissant sur le fil (2 ; 8) ou sur un produit comprenant le fil (2 ; 8) et entraînant en particulier des étirements du fil.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10159047 | 2001-11-30 | ||

| DE10159047A DE10159047A1 (de) | 2001-11-30 | 2001-11-30 | Faden mit einer Codierung und Verfahren zur Herstellung eines codierten Fadens |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1316632A1 EP1316632A1 (fr) | 2003-06-04 |

| EP1316632B1 true EP1316632B1 (fr) | 2006-01-04 |

Family

ID=7707695

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02023315A Expired - Lifetime EP1316632B1 (fr) | 2001-11-30 | 2002-10-17 | Fil avec codage et procédé de fabrication d'un fil codé |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1316632B1 (fr) |

| AT (1) | ATE315117T1 (fr) |

| DE (2) | DE10159047A1 (fr) |

| DK (1) | DK1316632T3 (fr) |

| ES (1) | ES2251557T3 (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005047786A1 (de) * | 2005-10-05 | 2007-04-19 | Urs Isler | Verfahren zur Behandlung von Gamen zur Authentifizierung und Vorrichtung zum Nachweis der Authentizität |

| DE102007030017A1 (de) * | 2007-06-29 | 2009-01-08 | Matthias Lydike | Kennzeichnen von Textilien |

| AT506966B1 (de) | 2008-12-29 | 2010-01-15 | Matthias Lydike | Verfahren und vorrichtung zum kennzeichnen einer kunststofffaser |

| DE102017101742A1 (de) | 2017-01-30 | 2018-08-02 | Trw Automotive Gmbh | Gassack für ein Fahrzeuginsassen-Rückhaltesystem sowie Verfahren zur Qualitätskontrolle und/oder Ermittlung des Garnverbrauchs für eine Gassacknaht eines solchen Gassacks |

| EP3476617A1 (fr) | 2017-10-25 | 2019-05-01 | Österreichische Staatsdruckerei GmbH | Document comportant une couture |

| CN111237593A (zh) * | 2020-01-15 | 2020-06-05 | 杭州淘控电子商务有限公司 | 一种电商用条码自动识别装置 |

| DE102023115011A1 (de) * | 2023-06-07 | 2024-12-12 | Silana Gmbh | Kleidungsstück mit informationscodierter Naht |

| DE102023115021A1 (de) * | 2023-06-07 | 2024-12-12 | SeamBit GmbH | Textilprodukt mit fälschungssicherem Zertifikat |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1822098A (en) * | 1927-06-02 | 1931-09-08 | Plymouth Cordage Co | Marking device |

| CH309531A (de) * | 1952-06-30 | 1955-09-15 | Bindfadenfabrik Schweizerische | Verfahren zum Markieren von Garn oder dergleichen. |

| US4397142A (en) * | 1981-12-07 | 1983-08-09 | Minnesota Mining And Manufacturing Company | Coded threads and sheet material useful for making such coded threads |

| US4527383A (en) * | 1983-03-28 | 1985-07-09 | Minnesota Mining And Manufacturing Company | Threads for identification of garments |

| US5573851A (en) * | 1994-05-16 | 1996-11-12 | U.S. Textile Corporation | Ultraviolet-detectable marking yarn and a textile fabric product therewith |

| DE19518231A1 (de) * | 1995-05-12 | 1996-11-14 | Bornemann & Bick Kg | Textiles Gewebe |

-

2001

- 2001-11-30 DE DE10159047A patent/DE10159047A1/de not_active Withdrawn

-

2002

- 2002-10-17 EP EP02023315A patent/EP1316632B1/fr not_active Expired - Lifetime

- 2002-10-17 AT AT02023315T patent/ATE315117T1/de active

- 2002-10-17 DK DK02023315T patent/DK1316632T3/da active

- 2002-10-17 DE DE50205508T patent/DE50205508D1/de not_active Expired - Lifetime

- 2002-10-17 ES ES02023315T patent/ES2251557T3/es not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DK1316632T3 (da) | 2006-03-06 |

| DE10159047A1 (de) | 2003-06-12 |

| EP1316632A1 (fr) | 2003-06-04 |

| ATE315117T1 (de) | 2006-02-15 |

| DE50205508D1 (de) | 2006-03-30 |

| ES2251557T3 (es) | 2006-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3634857C2 (de) | Ausweiskarte mit visuell sichtbarem Echtheitsmerkmal und Verfahren zur Herstellung derselben | |

| EP0354362B1 (fr) | Procédé de marquage et de lecture de codes lisibles optiquement, et bouteilles pourvues de telles marques | |

| DE69429266T3 (de) | Prägen von wertscheinbogen mit echtheitsmerkmalen | |

| EP0548858A1 (fr) | Carte d'identité ainsi que la méthode et le dispositif pour son assemblage | |

| DE2905441A1 (de) | Wertpapier mit gedruckten echtheitskennzeichen in einer papierschicht | |

| WO2009003587A1 (fr) | Signe de sécurité et son procédé de réalisation | |

| EP1316632B1 (fr) | Fil avec codage et procédé de fabrication d'un fil codé | |

| EP1646507B1 (fr) | Corps multicouche, dispositif et procede pour produire un motif sur une surface avec une haute resolution | |

| DE3628353A1 (de) | Verfahren zur unauffaelligen markierung von dokumenten und verfahren zur pruefung solcher dokumente | |

| WO1998033659A1 (fr) | Document de valeur et mode de fabrication | |

| DE3820348A1 (de) | Verfahren und vorrichtung zum herstellen eines gehaeuses fuer einen sensor und katheter mit sensorgehaeuse | |

| DE1961013A1 (de) | Elektrische Mustervorrichtung fuer mehrsystemige Rundstrickmaschinen mit umlaufendem Nadelzylinder | |

| EP3291999B1 (fr) | Caractéristique de sécurité et procédé de production de celle-ci | |

| DE3307411C2 (de) | Verfahren und Vorrichtung zum Erkennen von Kennzeichnungsmarken auf einer Materialbahn | |

| EP0897784A1 (fr) | Carte à puce, procédé de fabrication de cartes à puce ainsi que dispositif pour la mise en oeuvre du procédé | |

| EP2992539B1 (fr) | Procédé de production d'un élément à induction et élément à induction | |

| DE10242565A1 (de) | Verfahren und Vorrichtung zur Werkstückbezeichnung | |

| AT525543A4 (de) | Lichtleiterfaserband und Verfahren zu dessen Herstellung | |

| DE69600763T2 (de) | Verfahren sowie vorrichtung zum perforieren | |

| DE29807638U1 (de) | Prägefolie mit individualisiert gekennzeichneten Sicherheitsmerkmalen | |

| EP1112159B1 (fr) | Procede permettant de produire un cadre hybride ou des boitiers hybrides et cadre hybride ou boitier hybride ainsi obtenus | |

| EP4114149A1 (fr) | Connexion transversale dans une feuille porteuse imprimée des deux côtés | |

| EP1858605A1 (fr) | Securisation d'informations | |

| DE2611687B2 (de) | Verfahren und Vorrichtung zur Herstellung eines Zählmusters für die Anfertigung von Gobelinbildern und anderen Stickarbeiten | |

| WO2002000993A1 (fr) | Article de bonneterie, dispositif et procede pour produire un article de bonneterie et fil pour produire un article de bonneterie |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20031127 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20040326 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GUETERMANN & CO. AG |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060104 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060104 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: DR. BRUNO HAMMER |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060222 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20060400140 Country of ref document: GR |

|

| REF | Corresponds to: |

Ref document number: 50205508 Country of ref document: DE Date of ref document: 20060330 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060404 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2251557 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061031 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20061005 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060104 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101014 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20101018 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20110926 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20111013 Year of fee payment: 10 Ref country code: LU Payment date: 20111024 Year of fee payment: 10 Ref country code: FI Payment date: 20111013 Year of fee payment: 10 Ref country code: IE Payment date: 20111020 Year of fee payment: 10 Ref country code: DK Payment date: 20111019 Year of fee payment: 10 Ref country code: SE Payment date: 20111021 Year of fee payment: 10 Ref country code: NL Payment date: 20111025 Year of fee payment: 10 Ref country code: CH Payment date: 20111024 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: *GUTERMANN & CO. A.G. Effective date: 20121031 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130501 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 315117 Country of ref document: AT Kind code of ref document: T Effective date: 20121017 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: ML Ref document number: 20060400140 Country of ref document: GR Effective date: 20130508 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121018 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121017 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130508 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130501 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121017 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20141028 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20141016 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20151021 Year of fee payment: 14 Ref country code: IT Payment date: 20151028 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20151023 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20160418 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20151230 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160418 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20161125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151018 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50205508 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20161017 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170503 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161017 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161017 |