EP0864683A2 - Verfahren und Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren - Google Patents

Verfahren und Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren Download PDFInfo

- Publication number

- EP0864683A2 EP0864683A2 EP98103994A EP98103994A EP0864683A2 EP 0864683 A2 EP0864683 A2 EP 0864683A2 EP 98103994 A EP98103994 A EP 98103994A EP 98103994 A EP98103994 A EP 98103994A EP 0864683 A2 EP0864683 A2 EP 0864683A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- goods

- dye

- fixing

- temperature

- seconds

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06P—DYEING OR PRINTING TEXTILES; DYEING LEATHER, FURS OR SOLID MACROMOLECULAR SUBSTANCES IN ANY FORM

- D06P1/00—General processes of dyeing or printing textiles, or general processes of dyeing leather, furs, or solid macromolecular substances in any form, classified according to the dyes, pigments, or auxiliary substances employed

- D06P1/0032—Determining dye recipes and dyeing parameters; Colour matching or monitoring

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B19/00—Treatment of textile materials by liquids, gases or vapours, not provided for in groups D06B1/00 - D06B17/00

- D06B19/0005—Fixing of chemicals, e.g. dyestuffs, on textile materials

- D06B19/0047—Fixing of chemicals, e.g. dyestuffs, on textile materials by air steam

- D06B19/0052—Fixing of chemicals, e.g. dyestuffs, on textile materials by air steam the textile material passing through a chamber

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06P—DYEING OR PRINTING TEXTILES; DYEING LEATHER, FURS OR SOLID MACROMOLECULAR SUBSTANCES IN ANY FORM

- D06P3/00—Special processes of dyeing or printing textiles, or dyeing leather, furs, or solid macromolecular substances in any form, classified according to the material treated

- D06P3/58—Material containing hydroxyl groups

- D06P3/60—Natural or regenerated cellulose

Definitions

- the most widely used dyeing method for dyeing circular knitting or Round knitwear is the discontinuous pull-out process.

- Semi-continuous and continuous dyeing processes have opposite Extraction process the advantages of high productivity and high fixation values, so that also for dyeing circular knitted and circular knitted fabrics semi-continuous and fully continuous block processes have been developed are, for example, the semi-continuous dyeing after Block dwell process.

- One disadvantage of this dyeing process is that Bug marking by placing the impregnated goods in boxes that the Reduces the quality of the finished article. They also move Fixing times in the hour range, which is high on the disposition of the dyeing Demands.

- Circular knitted and circular knitted goods can also be made using the fully continuous pad-steam process be colored.

- the disadvantage here is the formation of wrinkles, limited color yield, problems with the product image and two-sidedness of the Coloring.

- markings are made by running fleet observed.

- EP-A1-0 087 740 describes a continuous process for dyeing textiles Material webs - but not textile tubular knitted fabrics - described

- the centerpiece is a fusing unit, in which the web without prior Intermediate drying during a certain dwell time of a steam / air atmosphere exposed to temperatures between 110 and 140 ° C.

- the Wet temperature of the wet web is 50 to 95 ° C and the Fixing time is in the range of 20 to 200 seconds.

- the task set was thus a process for dyeing cellulosic Circular knitting and circular knitting to develop the above Disadvantages, especially the bow fold and drain markings, avoided and allows a good dye fixation with a good color.

- a Another object of the invention was to carry out a to provide suitable machine for such a method.

- this task is accomplished through a continuous Coloring process solved, which is characterized in that the textile Tubular goods in a foulard with a dye solution that too if necessary, necessary fixing alkali as well as if necessary further ones Contains auxiliary chemicals, treated and then without Introduces intermediate drying in a device in which the strand of goods first opened wrinkle-free and then the moisture of the goods through thermal Actuation is reduced in such a way that already at the first point, on the the web is again subjected to a train or pressure, e.g. by a Deflection roller or roller, no markings by running Treatment fleet arise more.

- a train or pressure e.g. by a Deflection roller or roller

- the present invention relates in particular to a method for continuous dyeing of cellulosic circular knitted or knitted fabrics, characterized in that the line of goods is mixed with an aqueous liquor, the one or more dissolved and / or dispersed dyes, if appropriate contains required fixative alkali and, if necessary, other auxiliaries impregnated, squeezed and at a temperature between 20 and 95 ° C then introduced into a device in which the Line of goods opened wrinkle-free and the dye in an unsaturated Steam-air mixture from 100 to 160 ° C, preferably 110 to 130 ° C, at a wet temperature between 50 and 95 ° C, preferably 60 to 80 ° C, and the fixing time is at least 20 Seconds.

- the dye is fixed at a temperature of 50 to 95 ° C of the moist tissue (so-called Wet temperature ) over a period of at least 20 seconds, usually not more than 300 seconds, preferably 40 to 240 seconds, in particular 60 to 180 seconds.

- the specified temperature range of 50 to 95 ° C of the damp tissue is set by the ratio of water vapor and air in the steam-air mixture.

- the temperature of the damp product line corresponds to the temperature of a thermometer kept moist in the existing steam-air mixture.

- Psychrometers work according to the same principle to determine the air content in a steam-air mixture.

- the temperature of the steam-air mixture from 100 to 160 ° C is measured with a dry thermometer.

- the moisture content in the steam-air mixture should not exceed 80% by volume. 10 to 80% by volume, preferably 10 to 50% by volume, particularly preferably 15 to 35% by volume, of water vapor are expedient.

- the steam injection to produce the desired steam-air ratio can be controlled by a psychrometer.

- Measuring the humidity in volume percent is in and of itself Known in the art and can in addition to the process described above also by determining the oxygen partial pressures in the fixing chamber against the outside air.

- the evaporation process reduces the moisture on the opened strand of goods to such an extent that at the first point at which a pull or pressure is again exerted on the goods, there are no longer any markings from the treatment liquor running off.

- the intensity of the air circulation, or the drying temperature this can also be done by a longer fixing time.

- An extension of the fixing time can be achieved, for example, by reducing the running speed of the goods and / or by means of suitable design devices in the fixing unit, for example by several and / or longer ones floating cigars .

- a moisture content of the goods of 10 to 25% by weight, preferably 15 to 20% by weight, based on the weight of the goods, is required at the end of the fixing process.

- the speed of the goods is expediently regulated via the measured residual moisture of the goods after they exit the fixing chamber.

- Cellulosic fiber material can, for example, only be made from cellulose fibers such as Cotton, from regenerated cellulose or from those containing amino groups Compounds modified cellulose fibers, as described for example in US-PS 5,507,840, U.S. Patent 5,565,007, EP-A-0 665 311, U.S. Patent 5,529,585 and DE-A-19 519 023 are described.

- the cellulosic fiber material can also be mixed with synthetic fibers, especially polyester fibers.

- the product strand is impregnated by a one-step process Block process, expediently on a foulard, with an aqueous liquor, the contains all the chemicals required for the dyeing process, with a Fleet absorption of 80 to 120%, based on the weight of the goods, and at a temperature of 10 to 95 ° C, preferably 20 to 40 ° C.

- the dyes used for the process according to the invention can fiber-reactive dyes, acid dyes, direct dyes, sulfur dyes or vat dyes.

- a fiber-reactive component on the reactive dyes are especially the Sulfatoethylsulfonyl, vinylsulfonyl, chlorotriazinyl and fluorotriazinyl radical and Combinations of these "anchor systems" called.

- Examples of common ones Reactive substances are known to the person skilled in the art and, for example, in EP-A-0 513 656.

- acid or direct dyes are the diamine dyes, ®Sirius lightfast dyes, ®Alphanol dyes, ®Cotonerol dyes and ®Duasyn dyes are suitable, e.g. C.I. Acid Black 27 (C.I. No. 26 310), C.I. Acid Black 35 (C.I. No. 26 320), C.I. Acid Blue 113 (C.I. No. 26 360), C.I. Direct Orange 49 (C.I. No. 29 050), C.I. Direct Orange 69 (C.I. No. 29 055), C.I. Direct Yellow 34 (C.I. No. 29 060), C.I. Direct Red 79 (C.I. No. 29 065), C.I.

- Direct Yellow 67 (C.I. No. 29 080), C.I. Direct Brown 126 (C.I. No. 29 085), C.I. Direct Red 84 (C.I. No. 35 760), C.I. Direct Red 80 (C.I. No. 35 780), C.I. Direct Red 194 (C.I. No. 35 785), C.I. Direct Red 81 (C.I. No. 28 160), C.I. Direct Red 32 (C.I. No. 35 790), C.I. Direct Blue 162 (C.I. No. 35 770), C.I. Direct Blue 159 (C.I. No. 35 775), C.I. Direct black 162: 1 and C.I. Direct Violet 9 (C.I. No. 27 885).

- the dyes mentioned are dissolved and / or dispersed in the aqueous liquor in concentrations of 1 to 120 g / l, based on the total liquor volume.

- the aqueous liquor further contains the amount of fixing alkali required for fixing fiber-reactive dyes, advantageously from 0.1 to 4% by weight, based on the weight of the liquor.

- Sodium hydroxide solution, soda, water glass, potassium hydroxide solution, potash and nabicarbonate are usually suitable as fixing alkali.

- the aqueous liquor can contain other auxiliaries, for example electrolyte salts, such as NaCl, KCl, Na 2 SO 4 , K 2 SO 4 , impregnation aids, wetting agents, such as alkanesulfonates, nonionic or anionic surfactants or thickeners, such as polyacrylic acid derivatives or alginates.

- electrolyte salts such as NaCl, KCl, Na 2 SO 4 , K 2 SO 4

- impregnation aids such as alkanesulfonates, nonionic or anionic surfactants or thickeners, such as polyacrylic acid derivatives or alginates.

- wetting agents such as alkanesulfonates, nonionic or anionic surfactants or thickeners, such as polyacrylic acid derivatives or alginates.

- the method according to the invention is characterized by a very good one Through-coloring of the goods in both light and deep colors from and leaves no crease marks or color sequences after completion detect.

- the surface of the material is not mechanically destroyed, completely smooth and lint-free.

- the present invention also relates to a device for continuous dyeing of cellulosic circular knitted or knitted fabrics, consisting essentially of an impregnation device for the dyeing textile fabric strand and a fusing unit consisting of a Fixing chamber, which contains at least one hose stabilizer, and a measuring and Control device for setting defined humidity and Temperature conditions in the fixing chamber.

- Fig. 1 shows a possible embodiment of such a device.

- the circular knitted or circular knitted fabric is transported according to FIG. 1 into an impregnation device (1), for example a padding chassis, and, as described above, is charged with the aqueous liquor there.

- the strand of goods leaving the impregnation device has a moisture content of 80 to 120% by weight, based on the weight of the dry goods.

- the goods can be passed through a wetting device (2) before entering the fixing chamber (3), where water may be sprayed on. After entering the fixing chamber (3), the goods are opened wrinkle-free by a hose stabilizer (4).

- a hose stabilizer expediently consists of several vertically arranged circular spreader bars, which are infinitely adjustable in diameter and allow individually controlled width and longitudinal tension for each product and hose width, which is distributed evenly over the entire circumference.

- two or more such tube stabilizers can be arranged one behind the other. The goods hose is closed again at the opposite end of each hose stabilizer. If two or more hose stabilizers are arranged one after the other in order to extend the dwell time in the fixing chamber, neither pressure nor tension should be exerted on the line of goods located between two hose stabilizers, which could lead to markings by the treatment liquor running off.

- a suitable transport device is, for example, a deflecting roller or roller with its own drive (9).

- a suitable measuring and control device for setting defined atmospheric humidity and drying temperatures consists, for example, of a psychrometer (5), a steam injection valve (6) and a circulating fan (10).

- the humidity value (actual value) measured by the psychrometer is converted into a digital signal and compared with the specified target value.

- the air or live steam supply is actuated by a suitable control technology in such a way that the chamber climate adjusts itself according to the desired conditions.

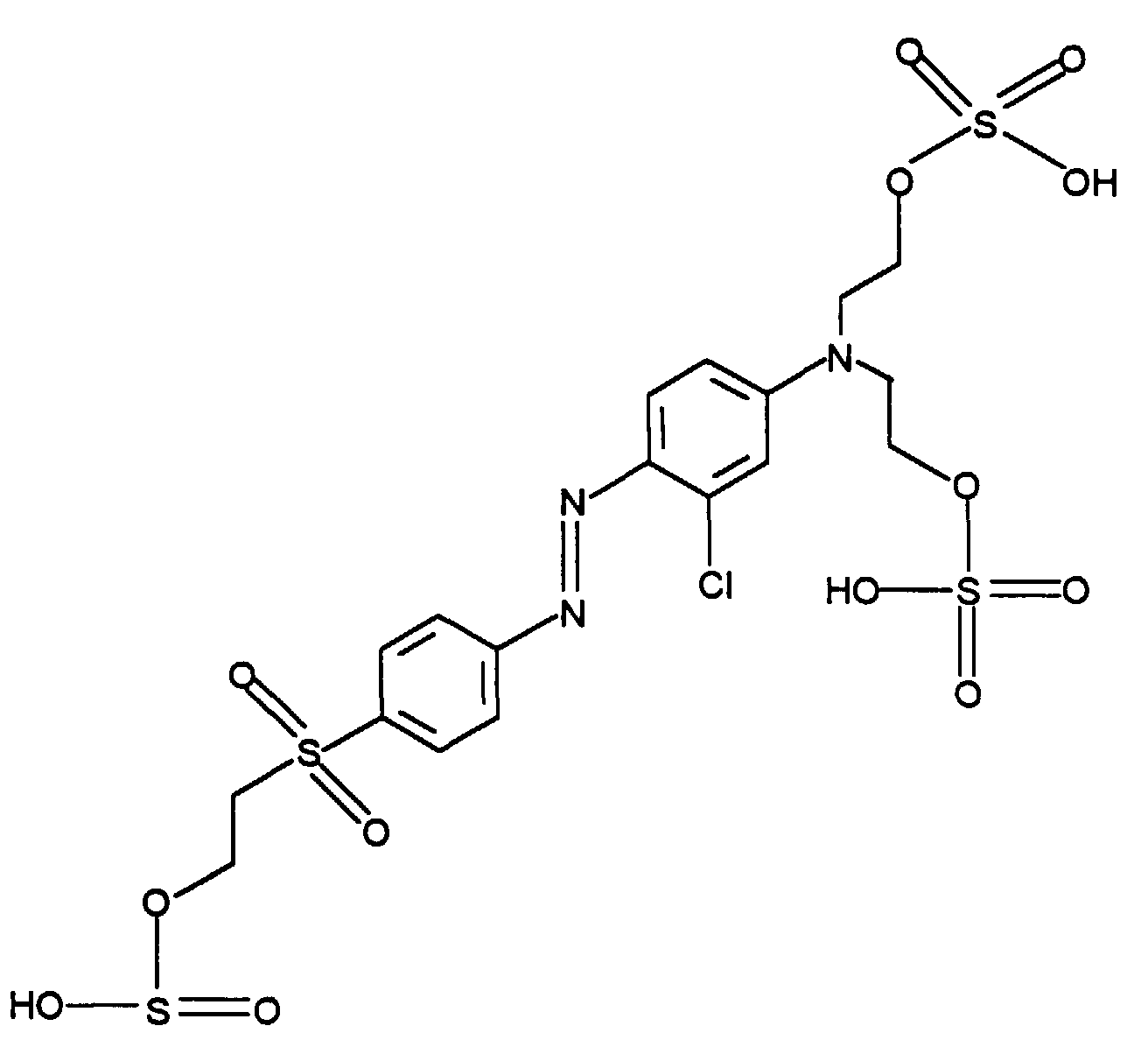

- a cotton jersey in tubular form, weight about 180 g / m 2 is passed through a padding chassis and with an aqueous liquor consisting of 50 g / l of the reactive dye CI Reactive Red 180 of the formula 18 ml / l 32.5% strength by weight sodium hydroxide solution and 2 g / l of an anionic wetting agent, such as, for example, ®Leonil SRP, padded with a liquor absorption of 90% at a temperature of about 20 ° C.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 2.5 minutes at a wet temperature of 70 ° C. and a dry temperature of 120 ° C.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

- a cotton jersey in tubular form, weight about 150 g / m 2 is passed through a padding chassis and with an aqueous liquor consisting of 50 g / l of the reactive dye CI Reactive Black 5 of the formula 18 ml / l 32.5% strength by weight sodium hydroxide solution and 3 g / l of an anionic wetting agent, such as Leonil SRP, padded with a liquor absorption of 100% at a temperature of 20 ° C.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 2 minutes at a wet temperature of 70 ° C. and a dry temperature of 120 ° C.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 3 minutes at 70 ° C. wet temperature and 120 ° C. drying temperature.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

- a cotton-linen round fabric, weight about 180 g / m 2 is passed through a padding chassis and with an aqueous liquor consisting of 30 g / l of the reactive dye of the formula 20 g / l sodium bicarbonate and 3 g / l of an anionic wetting agent, padded with a liquor absorption of 80% at a temperature of 20 ° C.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 2 minutes at a wet temperature of 70 ° C. and a dry temperature of 120 ° C.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 2 minutes at a wet temperature of 70 ° C. and a dry temperature of 120 ° C.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

- a tubular cotton lining material weight about 330 g / m 2 , is passed through a padding chassis and with an aqueous liquor consisting of 50 g / l of a reactive dye of the formula 20 g / l soda and 2 g / l of an anionic wetting agent, padded with a liquor absorption of 90% at a temperature of 20 ° C.

- the impregnated product is introduced into a fixing unit described above at a speed of 20 m / min and fixed for 4 minutes at 70 ° C. wet temperature and 120 ° C. drying temperature.

- the colored strand of goods then leaves the fusing unit with a residual moisture content of approx. 15%.

- the goods can then be docked or post-treated using customary methods.

- the product is characterized by a very uniform product appearance and a smooth Surface and is free of creases.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Coloring (AREA)

- Treatment Of Fiber Materials (AREA)

Abstract

Description

Nach Imprägnierung der Warenbahn mit einer Farbstofflösung mit einer Flottenaufnahme von 110 bis 120% wird das Material in sogenannte Booster, in denen die Ware nochmals mit einer Chemikalienflotte beladen wird, eingefahren, anschließend aufgeblasen und damit in den bugfreien Zustand überführt. Zur Fixierung wird die Ware gleichzeitig in einer Sattdampfatmosphäre gehalten. Man nutzt dabei den Vorteil der Ballonbildung im Dämpfer erst, nachdem das notwendige Fixieralkali auf das Material aufgebracht wurde. Bei dieser Naß-in-naß-Arbeitsweise ist die Fixierausbeute der Reaktivfarbstoffe deutlich niedriger als unter Ausziehbedingungen. Tiefe Farbnuancen sind nicht zu realisieren. Aufgrund des hohen Feuchtegehaltes der Warenbahn, der Bedingungen des Aufblasens und der Fixierung kommt es bei dieser Verfahrensweise zu einer Zweiseitigkeit der Färbung und zu Ablauferscheinungen. Dieses Verfahren hat sich daher nur in wenigen Produktionsstätten für die Erzeugung heller Farbtöne etabliert.

Eine geeignete Meß- und Regelvorrichtung zur Einstellung definierter Luftfeuchtigkeiten und Trockentemperaturen besteht z.B. aus einem Psychrometer (5), einem Dampfinjektionsventil (6) und einem Umlüfter (10). Der durch das Psychrometer gemessene Luftfeuchtigkeitswert (Ist-Wert) wird in ein digitales Signal umgewandelt und mit dem vorgegebenen Soll-Wert verglichen. Nach einer computergestützten Auswertung der Meßwerte werden durch eine geeignete Regeltechnik die Luft- oder Frischdampfzufuhr so betätigt, daß sich das Kammerklima entsprechend den gewünschten Bedingungen einstellt.

Claims (14)

- Verfahren zum kontinuierlichen Färben von cellulosischen Rundstrick- oder Rundwirkwaren, dadurch gekennzeichnet, daß man den Warenstrang mit einer wäßrigen Flotte, die einen oder mehrere gelöste und/oder dispergierte Farbstoffe, gegebenenfalls erforderliches Fixieralkali und gegebenenfalls weitere Hilfsmittel enthält, bei einer Temperatur zwischen 20 und 95°C imprägniert, abquetscht und anschließend ohne Zwischentrocknung in eine Vorrichtung einführt, in der der Warenstrang faltenfrei geöffnet und der Farbstoff in einem ungesättigten Wasserdampf-Luft-Gemisch von 100 bis 160°C bei einer sich einstellenden Naßtemperatur der feuchten Ware zwischen 50 und 95°C fixiert wird und die Fixierzeit mindestens 20 Sekunden beträgt.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, daß das ungesättigte Wasserdampf-Luft-Gemisch eine Temperatur von 110 bis 130°C hat.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß sich eine Naßtemperatur der feuchten Ware von 60 bis 80°C einstellt.

- Verfahren nach mindestens einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß die Fixierzeit 40 bis 240 Sekunden, insbesondere 60 bis 180 Sekunden, beträgt.

- Verfahren nach mindestens einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß das Wasserdampf-Luft-Gemisch aus 10 bis 80 Vol-%, vorzugsweise 15 bis 35 Vol.-%, Wasserdampf besteht.

- Verfahren nach mindestens einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß die Ware mit einer Geschwindigkeit geführt wird, die über die gemessene Restfeuchte der Ware nach Austritt aus der Fixiervorrichtung geregelt wird.

- Verfahren nach mindestens einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß der Feuchtigkeitsgehalt bei Beendigung des Fixiervorgangs 10 bis 25 Gew.-%, bezogen auf das Warengewicht, beträgt.

- Verfahren nach mindestens einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß die Rundstrick- oder Rundwirkware aus Baumwolle, aus Regeneratcellulose, aus mit aminogruppenhaltigen Verbindungen modifizierten Cellulosefasern oder aus einem Gemisch der genannten Fasern mit Polyesterfasern besteht.

- Verfahren nach mindestens einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, daß die Imprägnierung des Warenstrangs durch ein einstufiges Klotzverfahren erfolgt.

- Verfahren nach mindestens einem der Ansprüche 1 bis 9, dadurch gekennzeichnet, daß der Farbstoff ein faserreaktiver Farbstoff, Säurefarbstoff, Direktfarbstoff, Schwefelfarbstoff oder Küpenfarbstoff ist.

- Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- oder Rundwirkwaren, bestehend im wesentlichen aus einer Imprägniervorrichtung für den zu färbenden textilen Warenstrang und einem Fixieraggregat,das aus einer Fixierkammer, die mindestens einen Schlauchstabilisator enthält, und einer Meß- und Regelvorrichtung zur Einstellung definierter Luftfeuchtigkeits- und Temperaturbedingungen in der Fixierkammer besteht.

- Vorrichtung nach Anspruch 11, dadurch gekennzeichnet, daß zwei oder mehrere Schlauchstabilisatoren hintereinander angeordnet sind.

- Vorrichtung nach Anspruch 12, dadurch gekennzeichnet, daß sich zwischen zwei Schlauchstabilisatoren eine Umlenkrolle oder -walze mit eigenem Antrieb befindet.

- Vorrichtung nach mindestens einem der Ansprüche 11 bis 13, dadurch gekennzeichnet, daß die Meß- und Regelvorrichtung aus einem Psychrometer, einem Dampfinjektionsventil, Abluftklappe, Frischluftzufuhr und einem Umlüfter besteht.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19709899 | 1997-03-11 | ||

| DE19709899A DE19709899A1 (de) | 1997-03-11 | 1997-03-11 | Verfahren und Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren und ihren Mischungen mit Synthesefasern |

| US09/037,443 US5951717A (en) | 1997-03-11 | 1998-03-10 | Process and apparatus for continuous dyeing of cellulosic circular knits |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0864683A2 true EP0864683A2 (de) | 1998-09-16 |

| EP0864683A3 EP0864683A3 (de) | 1999-10-20 |

Family

ID=26034704

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98103994A Withdrawn EP0864683A3 (de) | 1997-03-11 | 1998-03-06 | Verfahren und Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5951717A (de) |

| EP (1) | EP0864683A3 (de) |

| JP (1) | JPH10317269A (de) |

| CN (1) | CN1198490A (de) |

| DE (1) | DE19709899A1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103397538A (zh) * | 2013-08-12 | 2013-11-20 | 山东汇泉工业有限公司 | 还原染料冷堆法染色工艺 |

| CN105839428A (zh) * | 2016-05-06 | 2016-08-10 | 吴江福华织造有限公司 | 一种新型尼龙包覆纱纬弹皱感面料的染整工艺 |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE50013624D1 (de) * | 1999-05-28 | 2006-11-30 | Moenus Textilmaschinen Gmbh | Verfahren zur kontinuierlichen Behandlung einer textilen Warenbahn mit Dampf zum Fixieren von Reaktivfarbstoff auf nativen Fasern |

| US7033403B2 (en) * | 2002-12-27 | 2006-04-25 | Sara Lee Corporation | Spray dyeing of garments |

| US7931700B2 (en) * | 2002-12-27 | 2011-04-26 | Hbi Branded Apparel Enterprises, Llc | Composition for dyeing of cellulosic fabric |

| US7931699B2 (en) * | 2002-12-27 | 2011-04-26 | Hbi Branded Apparel Enterprises, Llc | Compositions for spray dyeing cellulosic fabrics |

| US7799097B2 (en) * | 2003-06-23 | 2010-09-21 | Hbi Branded Apparel Enterprises, Llc | Processes for spray dyeing fabrics |

| US8814953B1 (en) | 2003-06-23 | 2014-08-26 | Hbi Branded Apparel Enterprises, Llc | System and method for spray dyeing fabrics |

| US20060265816A1 (en) * | 2003-06-23 | 2006-11-30 | Michael Abbott | Formers for spray dyeing garments |

| DE10349435A1 (de) * | 2003-10-21 | 2005-06-16 | Dystar Textilfarben Gmbh & Co Deutschland Kg | Verfahren zur kontinuierlichen Färbung von Geweben aus cellulosischen Fasern und Mischgeweben enthaltend cellulosische Fasern |

| CN100362056C (zh) * | 2005-02-05 | 2008-01-16 | 明德国际仓储贸易(上海)有限公司 | 黑色墨水染料组成物 |

| CN108085899A (zh) * | 2018-01-31 | 2018-05-29 | 杭州航民美时达印染有限公司 | 一种腈纶纤维与棉纤维混纺阻燃面料的连续式平幅印染工艺 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3206895A1 (de) * | 1982-02-26 | 1983-09-15 | Hoechst Ag, 6230 Frankfurt | Verfahren zum kontinuierlichen faerben von textilen warenbahnen |

| DE3422759A1 (de) * | 1984-06-20 | 1986-01-02 | Basf Ag, 6700 Ludwigshafen | Verfahren zur beseitigung der bugmarkierung bei maschenware in schlauchform sowie eine vorrichtung zur durchfuehrung des verfahrens |

| DE3619853A1 (de) * | 1986-06-12 | 1987-12-17 | Brueckner Apparatebau Gmbh | Verfahren und vorrichtung zum faerben von schlauchware mit reaktivfarbstoffen |

| DE3742597A1 (de) * | 1987-12-16 | 1989-06-29 | Brueckner Apparatebau Gmbh | Verfahren und vorrichtung zur diskontinuierlichen nassbehandlung von gestricktem oder gewirktem textilgut |

-

1997

- 1997-03-11 DE DE19709899A patent/DE19709899A1/de not_active Withdrawn

-

1998

- 1998-03-06 EP EP98103994A patent/EP0864683A3/de not_active Withdrawn

- 1998-03-10 CN CN98108043.XA patent/CN1198490A/zh active Pending

- 1998-03-10 US US09/037,443 patent/US5951717A/en not_active Expired - Fee Related

- 1998-03-10 JP JP10075050A patent/JPH10317269A/ja not_active Withdrawn

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103397538A (zh) * | 2013-08-12 | 2013-11-20 | 山东汇泉工业有限公司 | 还原染料冷堆法染色工艺 |

| CN103397538B (zh) * | 2013-08-12 | 2016-01-20 | 山东汇泉工业有限公司 | 还原染料冷堆法染色工艺 |

| CN105839428A (zh) * | 2016-05-06 | 2016-08-10 | 吴江福华织造有限公司 | 一种新型尼龙包覆纱纬弹皱感面料的染整工艺 |

| CN105839428B (zh) * | 2016-05-06 | 2019-06-25 | 吴江福华织造有限公司 | 一种尼龙包覆纱纬弹皱感面料的染整工艺 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1198490A (zh) | 1998-11-11 |

| DE19709899A1 (de) | 1998-09-17 |

| US5951717A (en) | 1999-09-14 |

| JPH10317269A (ja) | 1998-12-02 |

| EP0864683A3 (de) | 1999-10-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0699797B1 (de) | Ausziehfärbeverfahren für Schwefelfarbstoffe | |

| DE2713800C2 (de) | Verfahren zur Indigo-Färbung von Kettfäden aus Baumwoll-Spinngarnen | |

| EP0864683A2 (de) | Verfahren und Vorrichtung zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren | |

| EP0078022A1 (de) | Verfahren zum Behandeln von Textilgut in Jet-Färbeanlagen | |

| EP1063337A2 (de) | Verfahren und Vorrichtung zur kontinuierlichen Wärmebehandlung einer textilen Warenbahn, insbesondere zum Farbfixieren | |

| DE3206895A1 (de) | Verfahren zum kontinuierlichen faerben von textilen warenbahnen | |

| EP0166316A1 (de) | Verfahren zur Beseitigung der Bugmarkierung bei Maschenware in Schlauchform sowie eine Vorrichtung zur Durchführung des Verfahrens | |

| DE19749212A1 (de) | Verfahren zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren mit Reaktivfarbstoffen | |

| EP0320701B1 (de) | Verfahren und Vorrichtung zur diskontinuierlichen Nassbehandlung von gestricktem oder gewirktem Textilgut | |

| CH688908GA3 (de) | Vorrichtung und Verfahren fuer das kontinuierliche Faerben von Maschenware in Schlauchform. | |

| DE2215249C3 (de) | Verfahren zum kontinuierlichen Färben von hochwertigen Polyesterfasern | |

| DE19629985B4 (de) | Verfahren zum kontinuierlichen Färben von cellulosehaltigem Garn mit Indigo in einem einzigen Zug | |

| DE4227507A1 (de) | Verfahren und Vorrichtung zum kontinuierlichen Färben von Kettgarnen | |

| KR19980080062A (ko) | 원통형 셀룰로즈 니트의 연속 염색 방법 및 장치 | |

| DE2713166C2 (de) | Verfahren zum kontinuierlichen Färben von bahnförmigen Textilmaterialien | |

| WO2001034893A1 (de) | Verfahren und aggregat zur vorbehandlung, farbgebung und ausrüstung von textilen flächengebilden | |

| DE3045647A1 (de) | Verfahren zum kontinuierlichen faerben von kettgarnen nach dem prinzip des flachfaerbens und vorrichtung zur durchfuehrung des verfahrens | |

| DE2214714A1 (de) | Verfahren und vorrichtung zum impraegnieren und trocknen von textilmaterial | |

| DE1460722C (de) | Verfahren zum Veredeln von Stoffbahnen, bei dem ein Gewebe in Richtung der einen Fadenschar stark gespannt und in Richtung der anderen Fadenschar entlastet wird | |

| DE2406257C3 (de) | Verfahren zum kontinuierlichen Färben von bahnförmigem Textilgut aus Cellulosefasern mit Reaktivfarbstoffen | |

| DE1610951C3 (de) | Verfahren zum Fixieren von Farbstoffen | |

| DE2409727C3 (de) | Verfahren zum Färben von synthetische Fasern enthaltenden textlien Wickelkörpern | |

| DE906927C (de) | Verfahren zum Bedrucken bzw. Faerben von nicht aus Cellulose bestehenden Fasern mit Kuepenfarbstoffen | |

| DE1619607A1 (de) | Verfahren zum Faerben von Textilmaterialien | |

| DE19708972A1 (de) | Zusammensetzung und Verfahren zum kontinuierlichen Färben mit Küpenfarbstoff |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE GB IT LI NL PT |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000420 |

|

| AKX | Designation fees paid |

Free format text: AT CH DE GB IT LI NL PT |

|

| 17Q | First examination report despatched |

Effective date: 20020409 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20020820 |