EP0803304A2 - Creuset de maintien à préchambre en graphite ou métal - Google Patents

Creuset de maintien à préchambre en graphite ou métal Download PDFInfo

- Publication number

- EP0803304A2 EP0803304A2 EP97100045A EP97100045A EP0803304A2 EP 0803304 A2 EP0803304 A2 EP 0803304A2 EP 97100045 A EP97100045 A EP 97100045A EP 97100045 A EP97100045 A EP 97100045A EP 0803304 A2 EP0803304 A2 EP 0803304A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- crucible

- holding

- metal

- antechamber

- graphite

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B14/00—Crucible or pot furnaces

- F27B14/08—Details specially adapted for crucible or pot furnaces

- F27B14/10—Crucibles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D41/00—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like

- B22D41/04—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like tiltable

- B22D41/05—Tea-pot spout ladles

Definitions

- the invention relates to a holding crucible with a prechamber made of graphite or metal for molten metals with holding temperature fittings between 700 o C and 1000 o C.

- metals or metal alloys are premelted at the temperatures mentioned - generally aluminum alloys - in so-called premelting furnaces and heated to the desired temperature.

- Such premelting furnaces are mainly heated with oil or gas. If there is a greater need for liquid aluminum alloys, induction furnaces are used. Aluminum alloys require special maintenance.

- the hydrogen bubbles can make themselves unpleasantly noticeable as the smallest voids.

- the further sensitivity is the strong affinity of aluminum or aluminum alloys for oxygen.

- Aluminum and its alloys oxidize very easily and on every occasion, especially where oxygen or oxygen compounds are nearby.

- Aluminum oxides are formed. This fault formation is particularly pronounced in liquid aluminum alloys. The oxides then appear as oxide skins and float in the melt in order to then deposit on the grain boundaries when the castings solidify later.

- melts can be cleaned relatively easily, both from the hydrogen and from the oxides.

- the most intensive, fastest and most complete cleaning of the melt is carried out by blowing chlorine gas into the melt.

- this method has the disadvantage of being extremely polluting, so that it is only used in the toughest cases. Otherwise, cleaning salts are used to clean the melt, but they also release small amounts of chlorine gas for more intensive cleaning.

- the melt in the premelting furnace can be cleaned relatively well, even with chlorine gas, since nobody works on a premelting furnace as a caster. Suitable protective measures can easily be taken.

- the object of the invention is now to significantly reduce oxide formation when transferring the premelt into the crucible of the holding furnaces.

- the crucibles are almost the same in shape for both holding furnaces and premelting furnaces, but differ in capacity.

- the crucibles have a circular, elongated shape and are at least domed in the base area.

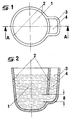

- the holding crucible (1) Fig.1 inform of a graphite crucible has a uniform course in the upper region with respect to the end of the wall thickness.

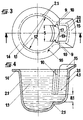

- a holding crucible made of metal (1.1) Fig. 3,4 is usually made of cast iron or cast iron - in exceptional cases also as cast steel.

- FIGS. 3 and 4 Another solution is shown graphically in FIGS. 3 and 4.

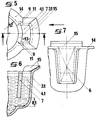

- the crucible wall (2.1) Fig. 3, 4 is left free at any circumferential point on the long side up to a certain length, in the width corresponding to the interior space dimension (5), Fig. 3 of the pre-chamber (4.1), A connecting separator (7) Fig. 5,6,8 is later inserted into this clearance (6) Fig. 7.

- the crucible wall (2.1) Fig.3 has reinforcements (9) Fig.3,4 in the area of the molded pre-chamber (3.1), in which longitudinal grooves (10) Fig.3.4 are provided, in which the longitudinal ribs (11) Fig.5.8 of the connecting separating piece (7) engage in a holding manner.

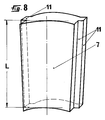

- the length (L) Fig. 8 of the connecting: separating piece (7) Fig. 8 is dimensioned such that after the connecting separating piece (7) has been fully inserted into the recess (6) Fig. 7, a connecting opening (8.1) Fig. 4, 6 between the crucible interior (12) Fig. 3.5 and the pre-chamber interior (13) Fig. 3.5 remains.

- the upper edge of the crucible is provided with a circumferential crucible edge (14) Fig. 3, 4, 5, 7 to reinforce and prevent the risk of breakage.

- the crucible rim (14) has one in the area of the antechamber inclined abbreviation (15) Fig. 3, 4, 5, 6, 7 to shield liquid metal to be introduced.

- graphite crucibles In graphite crucibles, graphite conducts heat well, but metal transfers heat even better. In the case of graphite crucibles, the thermal conductivity drops relatively quickly, since graphite crucibles become refractory over time. A graphite crucible must therefore be replaced after about 6 to 8 weeks for cost reasons.

- a metal crucible loses the thermal conductivity insignificantly, and the durability and usability can be 1 to 2 years. These circumstances clearly speak for the use of metal crucibles.

- aluminum and aluminum alloys have the property of dissolving iron. Iron is then found in the mixed crystals and becomes very brittle from a certain percentage of aluminum alloys.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Crucibles And Fluidized-Bed Furnaces (AREA)

- Carbon And Carbon Compounds (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29600045U DE29600045U1 (de) | 1996-01-03 | 1996-01-03 | Warmhaltetiegel mit Vorkammer aus Graphit oder Metall |

| DE9600045U | 1996-01-03 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0803304A2 true EP0803304A2 (fr) | 1997-10-29 |

| EP0803304A3 EP0803304A3 (fr) | 1999-06-16 |

Family

ID=8017642

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97100045A Withdrawn EP0803304A3 (fr) | 1996-01-03 | 1997-01-03 | Creuset de maintien à préchambre en graphite ou métal |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0803304A3 (fr) |

| DE (1) | DE29600045U1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005095027A1 (fr) * | 2004-04-01 | 2005-10-13 | Outokumpu Technology Oyj | Bac de coulee et procede de coulee d'anodes en cuivre |

| CN100381228C (zh) * | 2005-03-17 | 2008-04-16 | 日矿金属株式会社 | 阳极铸造用计量锅 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19831296C2 (de) * | 1998-07-13 | 2002-05-16 | Vesuvius Becker & Piscantor Gr | Warmhaltetiegel |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE30339C (de) * | L. DILL in Frankfurt a. M | Pfanne für schlackenfreien Gufs | ||

| DE428653C (de) * | 1925-02-08 | 1926-05-08 | Hugo Wachenfeld | Hilfsvorrichtung fuer Giesspfannen |

| GB578977A (en) * | 1944-06-23 | 1946-07-18 | Stone J & Co Ltd | Improvements in the treatment of magnesium base alloys and the production of pressure die-castings therefrom |

| GB618563A (en) * | 1946-11-04 | 1949-02-23 | Stone Fry Magnesium Ltd | Improvements relating to the production of pressure die castings from magnesium basealloys |

| US2621916A (en) * | 1949-12-19 | 1952-12-16 | William L Wilbert | Crucible or melting pot |

| DE1907107U (de) * | 1964-08-14 | 1964-12-23 | Bbc Brown Boveri & Cie | Kippbarer induktionstiegelofen. |

-

1996

- 1996-01-03 DE DE29600045U patent/DE29600045U1/de not_active Expired - Lifetime

-

1997

- 1997-01-03 EP EP97100045A patent/EP0803304A3/fr not_active Withdrawn

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005095027A1 (fr) * | 2004-04-01 | 2005-10-13 | Outokumpu Technology Oyj | Bac de coulee et procede de coulee d'anodes en cuivre |

| EA008872B1 (ru) * | 2004-04-01 | 2007-08-31 | Отокумпу Текнолоджи Оюй | Литейный желоб и способ литья медных анодов |

| CN100553824C (zh) * | 2004-04-01 | 2009-10-28 | 奥图泰有限公司 | 浇注槽、出口砖和铸造铜阳极用的方法 |

| CN100381228C (zh) * | 2005-03-17 | 2008-04-16 | 日矿金属株式会社 | 阳极铸造用计量锅 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE29600045U1 (de) | 1996-02-29 |

| EP0803304A3 (fr) | 1999-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1109640A1 (fr) | Recipient metallurgique | |

| EP0803304A2 (fr) | Creuset de maintien à préchambre en graphite ou métal | |

| EP0181853B1 (fr) | Brique pour lavage au gaz pour fours et récipients métallurgiques | |

| AT509787B1 (de) | Wassergekühlter deckel für ein feuerfest zugestelltes behandlungsgefäss für metallschmelzen | |

| DE69700847T2 (de) | Kühlungspaneel für Elektrolichtbogenöfen | |

| DE69407992T2 (de) | Kompakte pfanne zur behandlung von metallschmelze | |

| DE1206553B (de) | Ofen zum Schmelzen von Glas oder aehnlichen Produkten und Verfahren zum Betrieb des Ofens | |

| DE2656929A1 (de) | Nickel-chrom-legierung | |

| DE1939653C3 (de) | Wassergekühlte Stranggießkokille | |

| DE2717641C3 (de) | Kühlelement für einen metallurgischen Ofen, insbesondere für einen Hochofen | |

| DE1083509B (de) | Elektrischer Mehrkammer-Schmelzofen zum Einschmelzen von Metallen mit einer Schmelzkammer und einer Warmhalte- und Entnahmekammer | |

| DE3805334A1 (de) | Feuerfestes verschleissteil fuer den ausguss an metallurgischen behaeltern sowie angiessschutzhuelse fuer ein derartiges verschleissteil | |

| EP1088112B1 (fr) | Cuve a refroidissement a eau pour le traitement sous vide d'acier liquide | |

| DE3248104C2 (de) | Tiegel zum Schmelzen und Gießen von Dentallegierungen | |

| DE10249333B4 (de) | Metallurgisches Schmelzgefäß | |

| DE2218865A1 (de) | Reiter fuer waermguttraeger in industrieoefen | |

| DE10062308B4 (de) | Gefäß für Metallschmelzen, insbesondere Transportgefäß, zum Beispiel Stahlgießpfanne | |

| DE490025C (de) | Lichtbogenwiderstandsofen | |

| DE972075C (de) | Schwenkbarer Schachtofen, insbesondere zum Einschmelzen von Leichtmetallschrott | |

| DE2121746A1 (en) | Cooled channel cleaning tool - for low frequency induction - melting furnaces | |

| DE2719166C3 (de) | Kühlelement für einen metallurgischen Ofen | |

| DE4130590C2 (de) | Entgasungsgefaess fuer die vakuumbehandlung von fluessigem stahl | |

| DE3827074A1 (de) | Verfahren und vorrichtung zur vermeidung der verdampfverluste von legierungselementen beim elektronenstrahlschmelzen | |

| DE1802197C (de) | Induktionsrinnenofen zur Behandlung von Metallschmelzen | |

| DE8622452U1 (de) | Gasspülstein |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT DE IT |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT DE IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT DE IT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19991210 |