EP0802552B1 - Elektrischer Schalter mit Unterspannungsauslösung - Google Patents

Elektrischer Schalter mit Unterspannungsauslösung Download PDFInfo

- Publication number

- EP0802552B1 EP0802552B1 EP97106350A EP97106350A EP0802552B1 EP 0802552 B1 EP0802552 B1 EP 0802552B1 EP 97106350 A EP97106350 A EP 97106350A EP 97106350 A EP97106350 A EP 97106350A EP 0802552 B1 EP0802552 B1 EP 0802552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- switch

- magnet armature

- switch according

- switching element

- fixing slide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H83/00—Protective switches, e.g. circuit-breaking switches, or protective relays operated by abnormal electrical conditions otherwise than solely by excess current

- H01H83/12—Protective switches, e.g. circuit-breaking switches, or protective relays operated by abnormal electrical conditions otherwise than solely by excess current operated by voltage falling below a predetermined value, e.g. for no-volt protection

Definitions

- the invention relates to an electrical switch with the features of the preamble of claim 1.

- Such switches are known from DE-A-4 341 214 and from DE-A-3 340 250. These switches work with a magnetic circuit for electromagnetic Undervoltage release together. If the monitored voltage drops below one determined value, the magnetic circuit is opened and consequently one manually operated switching element transferred to its off position. In this switch-off position the circuit of the electrical switch is interrupted.

- the Switching element is coupled to the movable magnet armature of the magnetic circuit in such a way that when the switching element is in the switched-off position, the magnetic circuit is automatically closed again. As a result, the magnetic circuit is also without The presence of the required minimum voltage is closed again.

- the electromagnet therefore only needs to be closed with a magnetic circuit for the magnet armature generate the required holding force. This holding force is much smaller than the attraction force to close the magnetic circuit when it is back Tension.

- a disadvantage of the known switches is the complex coupling between the switching element and the magnet armature.

- the switching movement of the Switching device from its on position to its off position is over transfer complex rocker arm designs to the magnetic armature.

- This Coupling complicates the manufacture of the undervoltage release necessary components and increases manufacturing costs also allow the complicated rocker arm designs are only relatively small Power transmission between the switching element and the magnet armature.

- Already minor Signs of wear and tear of these swivel levers can make the proper Interfering with the operation of the undervoltage release.

- individual coupling components could be dimensioned stronger become.

- this has an increased space requirement for the switch housing and / or a housing provided for the magnetic circuit.

- the invention has for its object an electrical switch of the beginning to improve the type mentioned in terms of construction and safety.

- the switching element only has to be proportionate Apply small forces to keep the magnet armature in its tightened position To move the position on the magnetic core and fix it there.

- the good power transmission caused by the fixing slide from the switching element to the Magnetic anchors also favor a simple construction of the Switching element and its stability during the operating life of the switch.

- the fixing slide is preferably mounted displaceably on the housing side, as a result of which Wrong movements and faulty power transmissions between the switching element and Magnetic armatures can be reliably avoided.

- the voltage connected to the electromagnet and to be monitored is in a preferred embodiment, the mains voltage for the circuit of the electrical switch.

- the electromagnet can also be connected to another Voltage must be connected.

- the electromagnet is connected to two phases of a multi-phase power system.

- the undervoltage unit is preferably used with a bipolar switch combined

- the electrical switch is in a preferred Embodiment designed as an overcurrent protection switch and each has this Phase a corresponding overcurrent trip element, especially one on one Switch lock of the circuit breaker acting bimetal strips.

- the undervoltage unit with the magnetic circuit can be in the switch housing be installed or integrated in a separate housing, which by suitable fasteners is coupled to the switch housing.

- the coil connections of the electromagnet are preferably via a Rectifier with the contact connections connected to the voltage to be monitored the undervoltage unit electrically connected.

- the switching element is a two-armed rocker switch formed, which is pivotally mounted on the switch housing. While the pivoting of the rocker switch into its off position becomes its pivoting movement converted directly into a translational movement of the fixing slide.

- the switching element is in the form of one or two push buttons trained, which pressurizes the user to operate them manually and thereby be slowly shifted.

- the Longitudinal movement of the push button parallel to the translational movement of the fixing slide, so that the push button and the fixing slide are particularly easily coupled can be

- the magnetic circuit is opened and the automatic sequence is repeated Turning off the switch and closing the magnetic circuit started. This automatic sequence when attempting to transfer the switching element to its switch-on position helps to ensure that the safety requirements for the Switches are met.

- the fixing slide and the switching element are preferably in such a manner with one another connected that the fixing slide from the switching element in its on position is decoupled.

- the fixing slide and the magnet armature are opposite the switching element is freely movable. This free mobility ensures reliable release of the switch in the event of undervoltage. Moreover supports the decoupling of the switching element and the fixing slide the aforementioned Sequence of events when trying to switch the switching element in spite of undervoltage Switch to the on position.

- the fixing slide has one transverse to it Movement direction extending shoulder on.

- undervoltage i.e. if the magnet armature falls off, the fixer slide is moved and acted upon a switch lock connected to the switching element.

- the key switch is to open and close a switching contact of the circuit between a Contact opening position and a contact closing position movable and transfers the switching element to its switch-off position when the switching contact is opened.

- the fixing slide ensures that undervoltage is triggered a technically simple automatic sequence for interrupting the circuit and closing the magnetic circuit again. For triggering this automatic sequence, i.e. the application of the key switch, apart from the fixing slide itself, no other components are necessary. This supports a space-saving and technically simple construction of the electrical Switch and the undervoltage unit.

- a spring element In a preferred embodiment is between the fixing slide and the Magnetic armature arranged a spring element. Its spring force can be production-related Dimensional tolerances and deviations of the switching element, the fixing slide and compensate for the magnetic tank, thereby ensuring the safe operation of the switch. Due to the balancing effect of the spring element is also the part of the committee in the production of the aforementioned Components lower, which also reduces the manufacturing costs of the electrical Switch and the undervoltage unit can be further reduced.

- the compensating spring element is preferably in the form of an arched spring washer formed with a concave side facing the magnet armature.

- the spring element is supported on the magnetic armature, in particular on its the face facing the fixing slide, and is therefore without additional Aids between the fixing slide and the magnetic armature are fixed above

- the spring washer between the fixing slide and magnetic armature can be integrated in a space-saving manner and ensures particularly effective transmission the spring force on the fixing slide in its direction of displacement.

- the magnet armature with the fixing slide captively connected. This creates a mechanically particularly stable drive coupling between the two components. Faulty functional processes to open and close the magnetic circuit are therefore a priori avoided.

- the captive coupling is e.g. through a positive or realized a material connection.

- the coupling can be rigid or movable his.

- the magnet armature is approximately transverse to it the end face facing the fixing slide is penetrated by an anchor slot.

- This anchor slot takes a fixing pin arranged on the fixing slide on.

- the fixing pin is preferably an integral part of the fixing slide and thereby supports a mechanically stable coupling between the Fixing slide and the magnetic anchor.

- the fixing pin according to Art a positive connection with the magnet armature connected and simplified thereby the assembly of the components.

- the fixing pin penetrates the fixing slide forth the magnet armature in the direction of the contact surface facing the magnetic core of the magnet armature.

- the fixing pin engages there in an advantageous manner Design the slot edge of the anchor slot.

- a crossbar is formed, which is in the assembled state of the fixing pin the slot edge of the anchor slot on the contact surface

- the fixer pin and its associated crossbar are particularly good T-shaped.

- the anchor slot is cross-shaped with two intersecting, longitudinal slits of different lengths.

- the two longitudinal slots are dimensioned in such a way that the T-shaped fixing pin is first inserted into the longer longitudinal slot used and with the crossbar through this longitudinal slot is passed through and then rotated by 90 ° into the shorter longitudinal slot snaps into place. In this way, the fixer slide is additionally secured against rotation mounted on the magnet armature and thus even better against unwanted changes in position protected

- the fixing pin is in an additional Function as a centering and fixing element effective for this spring element. Without further aids, this spring element is held captive on the fixing pin

- the spring element is designed, for example, as a coil spring and surrounds the Locating pin with a small radial distance. This is designed as a spring washer Spring element transversely to the plane of the disc from a slot for receiving the fixing pin enforced and thereby also stored captive.

- the direction of displacement is of the fixing slide in a preferred embodiment in parallel for the direction of the magnet armature.

- the direction of displacement is preferably of the fixing slide at the same time in the plane of movement of the switching element on

- the plate level about the direction of displacement and a transverse direction extending across it is.

- This simple shape allows the fixing slide to be manufactured as cheap mass-produced items.

- This fixing slide is advantageous as a stamped part Can also be made from a suitable plastic or metal the plate shape of the fixing slide further miniaturizes the switch and / or the undervoltage unit.

- the one carrying the coil of the electromagnet Coil body at least two over the pole face of the magnetic core in the direction of drop protruding from the magnet armature and running approximately in the direction of the waste Leaders on.

- These guide bars are opposite one another arranged and flank the magnet armature laterally as a movement guide.

- the magnet armature in the direction of the fall and in the direction performs controlled movements in its tightened position. This contributes to this in that the components of the electrical drive coupled together Switch and the undervoltage unit no undesirable changes in position exhibit.

- these guideways are indirect as a movement guide effective for the locking slide coupled to the magnetic armature.

- the guide webs are an integral part of the bobbin, which is injection molded or cast from a suitable plastic is.

- Stop lugs are transverse to the direction of waste of the magnet armature and are directed towards each other. These are preferably Stop lugs are an integral part of the guide bars and are therefore manufactured easy to manufacture.

- the electromagnet of the magnetic circuit a horseshoe-like or U-shaped magnetic core.

- the freeers of the two U-legs of the magnetic core each have a pole face, which when closed Magnetic circuit contacted with the contact surface of the magnet armature are.

- the coil body carrying the coil of the electromagnet is in the In order to make the electromagnet easy to assemble in several parts to be able to accommodate the magnetic core.

- the bobbin it is advantageous to use the bobbin to be formed in two parts with the division plane as the symmetry plane in this The case for the assembly of the bobbin is the manufacture of a single one Component necessary. This takes into account a production-oriented and inexpensive Manufacture of the electromagnet.

- the magnetic core is fixed to the coil body.

- the U level of the horseshoe lies

- the magnetic core is approximately in the division plane of the bobbin.

- the magnetic core without additional Fixing agent between the two partial bodies acting as clamping jaws of the bobbin fixed.

- the two partial bodies e.g. by mutual locking, locking or the like. captive connected with each other. This connection facilitates further assembly of the electromagnet and the magnetic core as a compact unit

- a separate device housing is preferably for the undervoltage unit intended.

- the coil body of the electromagnet is in this device housing used and conveniently releasably fixed there.

- the bobbin carries several spring hooks, which project beyond an insertion opening of the device housing when installed and correspond with corresponding locking recesses in the circuit breaker housing. There is therefore no need for any additional fasteners on the device housing for mounting on the switch housing.

- the device housing can therefore be particularly cost-saving, for example as a rectangular receiving shaft or the like. Taking into account the spring hooks on the bobbin on the other hand, the cost is not so important because of the coil body anyway the shape of the magnetic core and possibly the Guide bars for the magnet armature must be taken into account.

- the switch housing is preferably in an additional Sealing function used.

- the ones with the spring hooks cooperating locking recesses arranged such that an outer surface of the switch housing with the spring hooks locked, the insertion opening of the device housing automatically covers.

- the electrical switch is a two-pole overcurrent protection switch 1 - below in short: "Circuit breaker 1" - trained. Its made of insulating plastic Switch housing 2 has a rectangular housing opening 3, which by a switching element in the form of a two-armed rocker switch 4 In Fig. 1, the rocker switch 4 is in its on position, in which the Circuits of the two phases of the circuit breaker 1 are closed. The Switch rocker 4 is between its switch-on position and one that interrupts the circuits Switch-off position can be swiveled. On the two narrow sides the switch housing 2 are two resilient housing hooks 5, of which only three housing hooks 5 are visible in FIG. They serve the Attachment of the circuit breaker 1 in a front panel, not shown here.

- the rocker switch 4 acts with a switch lock or a switching mechanism Open and close switching contacts of the circuits and with a magnetic Circuit for electromagnetic undervoltage release together

- the magnetic circuit is part of an undervoltage device 6, the Device housing 7 is mounted in the mounting position on the switch housing 2.

- the basic construction and operation of the circuit breaker 1 is in DE-C-2 928 277.

- the rocker switch 4 is on a housing-fixed Swivel axis 8 pivotally mounted (Fig. 3).

- a coupling cam 10 is attached, which runs transversely to the pivoting plane of the rocker switch 4, a cam track 11 penetrates a latch lever 12 (Fig. 3).

- the latch lever 12 is supported with a support nose 13 arranged at its one free end on a lever arm 14 of a two-armed arm running approximately vertically in the plane of the drawing Release lever 15 from.

- the trigger lever 15 is by means of an axle mount 16 on a housing axis running parallel to the pivot axis 8 pivoted.

- the rocker switch 4 and the switch lock of the circuit breaker 1 are with the magnetic circuit of the undervoltage device 6 is particularly illustrative in FIG shown fixing slide 24 coupled together.

- the principle of operation the coupling will be described in detail later.

- the fixing slide 24 is in the Installation state within the switch housing 2 and the device housing 7 linearly movable or displaceable.

- the displacement direction 25 runs in the direction its longitudinal extent

- the fixing slide 24 is a plate-like component, the Plate level through the direction of displacement 25 and a transverse to it Transverse direction 26 is spanned.

- the fixing slide 24 has one in the transverse direction 26 extending contact shoulder 27, which when the magnetic circuit opens the trigger arm 17 of the trigger lever 15 acts counterclockwise and thereby moves the key switch into its contact opening position (Fig. 4). In this contact opening position of the key switch is the Circuit broken.

- the magnetic circuit contains a plate-shaped magnet armature 28 and a horseshoe-like, d h a U-shaped magnetic core 29.

- the two U-legs of the Magnetic core 29 are connected to each other by a connecting yoke 30 and each have a pole face 31 at their free ends.

- the pole faces 31 are with a closed magnetic circuit directly with a contact surface facing them 32 of the magnet armature 28 contacted.

- Magnetic armatures 28 are at right angles to the direction of displacement 25 in the assembled state the fixing slide 24 is arranged.

- the magnet armature 28 is by a over the support edge 40 in the direction of displacement 25 protruding fixing pin 42 with the fixing slide 24 captive connected.

- the fixing pin 42 which is T-shaped in cross section, has at its end Magnetic armature 28 facing free end extending in the transverse direction 26 Cross bar 43 on.

- the fixing pin passes through 42 in the direction of displacement 25 a central disc longitudinal slot 44 the spring washer 39 and a cross-slot-shaped armature slot 45 of the magnet armature 28.

- the anchor slot 45 is through a first longitudinal slot and one intersecting, shorter longitudinal slot is formed for assembly the cross bar 43 passed through the longer longitudinal slot of the anchor slot 45. Does that stick out?

- the fixing slide 24 is 90 ° rotated so that the fixing pin 42 in the shorter longitudinal slot of the anchor slot 45 snaps into place.

- the crossbar 43 engages behind the slot edge of the anchor slot 45 and is pressed by the spring washer 39 against the supporting edge 40 pressed against the contact surface 32 With the help of the fixing pin 42 are the fixing slide 24, the spring washer 39 and the magnet armature 28 mechanically stable connected.

- the bobbin 37 shown in two parts in FIG. 2 carries one in FIGS. 4-6 schematically illustrated coil 46.

- the two partial bodies 37 'of the coil body 37 each carry two approximately in the direction of movement of the magnet armature 28 extending guide webs 47

- the guide webs 47 are in one piece on the Coil body 37 formed and protrude in the assembled state of the magnetic circuit beyond the pole faces 31 in the direction of drop of the armature 28.

- a boardwalk 47 of the partial body 37 ' is aligned in the transverse direction 26 with a guide web 47 of the second partial body 37 'These two aligned guide webs 47 flank the magnet armature 28 on both sides and thereby force a linear movement of the magnet armature 28 in the direction of displacement 25 around the movement

- a second pair of two guide bars with parallel spacing 47 integrally formed on the coil body 37 The facing the fixing slide 24 Free ends of the guide webs 47 have a stop lug 48 for limitation of the path of the falling magnet armature 28.

- the stop lugs 48 of the two in the transverse direction 26 together aligned guide webs 47 directed towards each other and act on the Face 33 of the falling armature 28 (Fig. 4).

- the division plane of the coil former 37 is also its plane of symmetry, since the two partial bodies 37 'and 37' are identical. Here lies the U-plane of the magnetic core 29 approximately in the parting plane of the coil former 37 a.

- the partial body 37 ' has an opening with the magnetic core 29 facing receiving groove 49. This receiving groove 49 is in the direction of displacement 25 limited by a plurality of groove webs 50.

- the two partial bodies 37 ' are directed towards one another in the transverse direction 26 and take the connecting yoke 30 of the with their grooves 49 Magnetic core 29 approximately form-fitting between them. This is the magnetic core 29 mechanically stably fixed to the bobbin 37

- each partial body 37 ' there are also two transverse to the plane of movement of the fixing slide 24 spaced apart spring hooks 50 are formed.

- the assembled bobbin 37 passes through an insertion opening 51 through along an insertion direction 52 into the cuboid device housing 7 used and locked with the device housing 7.

- the insides of the two transversely to the plane of movement of the fixing slide 24 extending side walls of the device housing 7 two mounting grooves each 53, of which only the one in FIG. 2 due to the perspective representation two mounting grooves 53 of one side wall are visible.

- the two assembly grooves 53 of each side wall run at a parallel distance in the direction of insertion 52. They correspond to corresponding mounting webs 54 of the partial body 37 '.

- the level of these guide webs 54 is through the direction of insertion 52 and Transverse direction 26 spanned. They allow easy assembly and exact Positioning of the electromagnet in the device housing 7.

- the two are parallel to Plane of movement of the fixing slide 24 extending side walls of the device housing 7 each penetrated by two locking holes 55

- These locking holes 55 correspond with appropriately trained and molded on the partial bodies 37 ' Lugs 56 (Fig. 2).

- the spring hooks 50 protrude beyond the insertion opening 51 of the device housing 7 also.

- the insertion opening 51 is in the locked position of the spring hook 50 of the device housing 7 from one arranged in the area of the switch bottom side 23 Cover wall 58 of the switch housing 2 automatically sealed to the outside.

- the fixing slide 24 connected to the magnet armature 28 projects beyond the insertion opening 51 of the device housing 7 also.

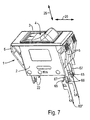

- the coil connections 61 of the coil 46 are via a bridge rectifier 62 with two device connection contacts connected to the voltage to be monitored 63 'or 63 "of the undervoltage device 6 electrically connected (Fig. 1, Fig. 7). It is also in the electrical circuit between the bridge rectifier 62 and the device connection contacts 63 'or 63 "a series resistor 64 used.

- the bridge rectifier 62 is in the assembled state between a resilient clamp arm 59 and the partial body 37 'captively clamped.

- two device connection contacts 63 protrude in the direction of insertion 52 beyond the device housing 7 (Fig. 1,2,3,5,6) and are with the monitoring voltage - not shown here - directly electrically connected.

- two device connection contacts 63 "are complete arranged within the device housing 7 (Fig. 4, Fig. 7).

- this embodiment is the undervoltage device 6 directly with connections of the circuit breaker 1 electrically connected

- the circuit breaker 1 facing Free ends of the device connection contacts 63 "as flat contact tongues 65 educated.

- contact tongues 65 correspond to in the direction of displacement 25 extending contact slots 66 of two switch connection contacts 67 To the two switch connection contacts 67 is not shown here Aids connected to the power supply line, especially screwed on two contact slots 66 are dimensioned such that when attaching the Undervoltage device 6 on the circuit breaker 1, the contact tongues 65 in the contact slots 66 intervene and from these with the necessary electrical contact pressure be clamped.

- the slide free end 60 is of the Switch rocker 4 decoupled and freely movable relative to the rocker switch 4 (Fig. 3)

- the magnet armature 28 is therefore by the spring pressure of the coil spring 34 in the downward direction, i.e. printed in the direction of the rocker switch 4.

- FIG. 8 shows a further embodiment of the circuit breaker 1 with two push buttons 69, 69 'shown as a switching element.

- Functionally identical components are in Fig.8 provided with the same reference numerals as in Fig.1 to Fig.7

- the two Push buttons 69, 69 'for switching the circuit are in the direction of displacement 25 displaceable and form-fit each have a guide recess 70, 70 '.

- the two guide recesses 70, 70 ' are part of one formed on the switch housing shaft-like guide attachment 71.

- Der Guide attachment 71 is also part of the switch housing 2 surrounding mounting panel 72 which 25 in the displacement direction is penetrated by two circular mounting holes 73.

- the mounting holes 73 are used to hold suitable fasteners, e.g. Screws, with whose help the circuit breaker 1 is fixed in place at the installation site.

- the mechanical coupling of the two push buttons 69, 69 'to one another Switching the circuit can in principle in the known from WO-A-9407255 Way.

- the fixing slide 24, not shown in Fig. 8 is with the Push button 69 coupled in such a way that in the off position of the circuit breaker 1 or the push button 69 of the fixing slide 24 the position shown in FIG. 5 occupies.

- the slide free end 60 is preferably in a hood-like Receiving opening of the push button 69 and from this in Direction of the magnetic core 29 is pressurized.

- the embodiment shown is only a single push button as a switching element provided and coupled in a suitable manner with the fixing slide 24.

Landscapes

- Breakers (AREA)

- Tumbler Switches (AREA)

Description

- Fig. 1

- eine perspektivische Darstellung eines Überstromschutzschalters mit einem daran befestigten Unterspannungsgerät,

- Fig. 2

- eine Explosionsdarstellung wesentlicher Bauteile des Unterspannungsgeräts gemäß Fig. 1,

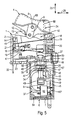

- Fig 3

- eine teilweise geschnittene Seitenansicht wesentlicher Bauteile des Überstromschutzschalters und des Unterspannungsgerätes gemäß Fig. 1, mit geschlossenem Magnetkreis und einem Schaltorgan in Einschaltstellung,

- Fig. 4

- die Seitenansicht gemäß Fig. 3 bei geöffnetem Magnetkreis und noch in Einschaltstellung befindlichem Schaltorgan,

- Fig. 5

- die Seitenansicht gemäß Fig. 3 mit dem Schaltorgan in Ausschaltstellung und mit erneut geschlossenem Magnetkreis,

- Fig. 6

- eine Seitenansicht des Unterspannungsgerätes gemäß Pfeilrichtung VI in Fig. 5,

- Fig. 7

- die perspektivische Darstellung des Überstromschutzschalters gemäß Fig. 1 mit einer weiteren Ausführungsform von Gerätekontaktanschlüssen des Unterspannungsgerätes zum elektrischen Anschluß an eine Spannung.

- Fig.8

- eine perspektivische Darstellung eines zwei Druckknöpfe als Schaltorgan enthaltenden Uberstromschutzschalters mit einem daran befestigten Unterspannungsgerät.

- 1

- Überstrom schutzschalter

- 2

- Schaltergehause

- 3

- Gehäuseöffnung

- 4

- Schaltwippe

- 5

- Gehäusehaken

- 6

- Unterspannungsgerät

- 7

- Gerätegehäuse

- 8

- Schwenkachse

- 9

- Wirkende

- 10

- Kopplungsnocken

- 11

- Nockenbahn

- 12

- Verklinkungshebel

- 13

- Stütznase

- 14

- Verklinkungsarm

- 15

- Auslösehebel

- 16

- Achsaufnahme

- 17

- Auslösearm

- 18

- Kontaktfeder

- 19

- Schaltkontakt

- 20

- Festkontakt

- 21

- Befestigungsende

- 22

- Kontaktzunge

- 23

- Schalterbodenseite

- 24

- Fixierschieber

- 25

- Verschieberichtung

- 26

- Querrichtung

- 27

- Anlageschulter

- 28

- Magnetanker

- 29

- Magnetkern

- 30

- Verbindungsjoch

- 31

- Polfläche

- 32

- Kontaktfläche

- 33

- Stirnfläche

- 34

- Schraubenfeder

- 35

- Zentrierdorn

- 36

- Stutzlager

- 37

- Spulenkörper

- 37'

- Teilkörper

- 38

- Lagernut

- 39

- Federscheibe

- 40

- Stutzkante

- 41

- Scheibenkante

- 42

- Fixierzapfen

- 43

- Quersteg

- 44

- Scheibenlängsschlitz

- 45

- Ankerschlitz

- 46

- Spule

- 47

- Führungssteg

- 48

- Anschlagnase

- 49

- Aufnahmenut

- 50

- Federhaken

- 51

- Einsetzöffnung

- 52

- Einsetzrichtung

- 53

- Montagenut

- 54

- Montagesteg

- 55

- Rastloch

- 56

- Rastnase

- 57

- Raststeg

- 58

- Deckwand

- 59

- Klemmausleger

- 60

- Schieberfreiende

- 61

- Spulenanschluß

- 62

- Brückengleichrichter

- 63',63"

- Geräteanschlußkontakt

- 64

- Vorwiderstand

- 65

- 5 Kontaktzunge

- 66

- Kontaktschlitz

- 67

- Schalteranschlußkontakt

- 68

- Betätigungsseite

- 69,69'

- Druckknopf

- 70.70'

- Führungsaussparung

- 71

- Führungsaufsatz

- 72

- Montageblende

- 73

- Montageloch

Claims (16)

- Elektrischer Schalter (1) mit einem zwischen Einschalt- und Ausschaltstellung beweglichen Schaltorgan (4,69) zum Schalten eines Stromkreises und mit einem magnetischen Kreis (28,29) zur elektromagnetischen Unterspannungsauslösung, wobei bei Unterspannung der sich öffnende Magnetkreis (28,29) das Schaltorgan (4,69) in seine Ausschaltstellung überführt und wobei das in seine Ausschaltstellung überführte Schaltorgan (4,69) den Magnetkreis (28,29) wieder schließt,

gekennzeichnet durch

einen das Schaltorgan (4,69) mit dem Magnetanker (28) koppelnden linearbeweglichen Fixierschieber (24) zum Fixieren des Magnetankers (28) am Magnetkern (29) in Ausschaltstellung des Schaltorgans (4,69). - Schalter nach Anspruch 1

dadurch gekennzeichnet, daß der Fixierschieber (24) von dem in Einschaltstellung befindlichen Schaltorgan (4,69) entkoppelt ist - Schalter nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß der Fixierschieber (24) eine quer zur Verschieberichtung (25) verlaufende Anlageschulter (27) aufweist, welche bei abfallendem Magnetanker (28) ein mit dem Schaltorgan (4,69) verbundenes Schaltschloß (12,15) zum Öffnen eines Schaltkontaktes (19) des Stromkreises und zur Überführung des Schaltorgans (4,69) in seine Ausschaltstellung beaufschlagt. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

gekennzeichnet durch

ein zwischen Fixierschieber (24) und Magnetanker (28) angeordnetes Federelement (39) zur Einstellung des Fixierschiebers (24) zwischen Schaltorgan (4,69) und Magnetanker (28). - Schalter nach Anspruch 4,

gekennzeichnet durch

eine sich am Magnetanker (28) abstützende und bogenartig gewölbte Federscheibe (39), welche konkavseitig dem Magnetanker (28) zugewandt ist. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

dadurch gekennzeichnet, daß der Magnetanker (28) mit dem Fixierschieber (24) unverlierbar verbunden ist. - Schalter nach Anspruch 6,

dadurch gekennzeichnet, daß der Magnetanker (28) einen Ankerschlitz (45) zur Aufnahme eines am Fixierschieber (24) angeordneten Fixierzapfens (42) aufweist, der einen Schlitzrand des Ankerschlitzes (45) hintergreift. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

dadurch gekennzeichnet, daß die Verschieberichtung (25) des Fixierschiebers (24) parallel zur Abfallrichtung des Magnetankers (28) verläuft und/oder in der Bewegungsebene des Schaltorgans (4,69) einliegt. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

gekennzeichnet durch

einen plattenartigen Fixierschieber (24). - Schalter nach einem oder mehreren der vorhergehenden Anspruche,

dadurch gekennzeichnet, daß der die Spule (40) des Elektromagneten tragende Spulenkörper (37) mindestens zwei über die Polfläche (31) des Magnetkerns (29) in Abfallrichtung des Magnetankers (28) hinausstehende Führungsstege (47) aufweist, welche einander gegenüberliegend den Magnetanker (28) als Bewegungsführung seitlich flankieren. - Schalter nach Anspruch 10,

dadurch gekennzeichnet, daß die Fuhrungsstege (47) jeweils eine quer zur Abfallrichtung aufeinander zu gerichtete Anschlagnase (48) tragen. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

dadurch gekennzeichnet, daß der Magnetanker (28) zum Schließen des Magnetkreises mit den beiden Polflächen (31) eines hufeisenartigen Magnetkerns (29) kontaktiert ist. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

dadurch gekennzeichnet, daß der die Spule (40) des Elektromagneten tragende Spulenkörper (37) zweiteilig ist mit der Teilungsebene als Symmetrieebene. - Schalter nach den Ansprüchen 12 und 13,

dadurch gekennzeichnet, daß die U-Ebene des hufeisenartigen Magnetkerns (29) etwa in der Teilungsebene des Spulenkörpers (37) einliegt. - Schalter nach einem oder mehreren der vorhergehenden Ansprüche,

dadurch gekennzeichnet,daß der die Spule (40) des Elektromagneten tragende Spulenkörper (37) in ein Gerätegehause (7) eingesetzt und dort fixiert ist unddaß der Spulenkörper (37) Federhaken (50) trägt, welche im Montagezustand über eine Einsetzöffnung (51) des Gerätegehäuses (7) hinausragen und mit entsprechenden Rastaussparungen (57) des Schaltergehäuses (2) korrespondieren - Schalter nach Anspruch 15,

dadurch gekennzeichnet, daß die Einsetzöffnung (51) des Gerätegehäuses (7) in Raststellung der Federhaken (50) von einer Deckwand (58) des Schaltergehäuses (2) nach außen abgedichtet ist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29724577U DE29724577U1 (de) | 1997-04-17 | 1997-04-17 | Elektrischer Schalter mit Unterspannungsauslösung |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29607027U | 1996-04-18 | ||

| DE29607027 | 1996-04-18 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0802552A2 EP0802552A2 (de) | 1997-10-22 |

| EP0802552A3 EP0802552A3 (de) | 1999-03-10 |

| EP0802552B1 true EP0802552B1 (de) | 2001-11-21 |

Family

ID=8022750

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97106350A Expired - Lifetime EP0802552B1 (de) | 1996-04-18 | 1997-04-17 | Elektrischer Schalter mit Unterspannungsauslösung |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5834996A (de) |

| EP (1) | EP0802552B1 (de) |

| JP (1) | JP3754796B2 (de) |

| DE (1) | DE59705433D1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7722444B2 (en) | 2005-05-13 | 2010-05-25 | Black & Decker Inc. | Angle grinder |

| DE102009025514A1 (de) | 2009-06-19 | 2010-12-30 | Ellenberger & Poensgen Gmbh | Steuerverfahren zur Auslösung eines elektronischen Schutzschalters |

| DE202010018176U1 (de) | 2009-06-19 | 2014-07-08 | Ellenberger & Poensgen Gmbh | Elektronischer Schutzschalter |

| US10818450B2 (en) | 2017-06-14 | 2020-10-27 | Black & Decker Inc. | Paddle switch |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19919331A1 (de) * | 1999-04-28 | 2000-11-02 | Ellenberger & Poensgen | Unterspannungsauslöser |

| US6613995B1 (en) | 2002-01-04 | 2003-09-02 | Reliance Controls Corporation | Switch having stabilizing protrusions to facilitate mounting thereof |

| WO2011015230A1 (en) * | 2009-08-04 | 2011-02-10 | Abb Ab | A low-voltage contactor |

| USD938369S1 (en) * | 2019-10-21 | 2021-12-14 | Ellenberger & Poensgen Gmbh | Combined electrical switch with mounting plate |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4019097A (en) * | 1974-12-10 | 1977-04-19 | Westinghouse Electric Corporation | Circuit breaker with solid state passive overcurrent sensing device |

| US4034266A (en) * | 1975-08-29 | 1977-07-05 | Westinghouse Electric Corporation | Electric wall receptacle with ground fault protection |

| CH614069A5 (de) * | 1977-03-31 | 1979-10-31 | Weber Ag Fab Elektro | |

| DE2928277C2 (de) * | 1979-07-13 | 1983-12-01 | Ellenberger & Poensgen Gmbh, 8503 Altdorf | Kombinierbarer zweipoliger Überstromschutzschalter |

| DE3114717C2 (de) * | 1981-04-11 | 1987-04-30 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | Unterspannungsauslöser für einen Leitungsschutzschalter |

| DE3424089A1 (de) * | 1983-08-19 | 1985-03-07 | Weber AG Fabrik elektrotechnischer Artikel und Apparate, Emmenbrücke | Druckknopfbetaetigter ueberstromschalter |

| DE3340250A1 (de) * | 1983-11-08 | 1985-05-15 | Heinrich Kopp Gmbh & Co Kg, 8756 Kahl | Fehlerstromschutzschalter(-teil) mit unterspannungsausloesung |

| DE4003744A1 (de) * | 1990-02-08 | 1991-08-14 | Klinger & Born Gmbh | Drehschalter |

| CH680174A5 (de) * | 1990-05-23 | 1992-06-30 | Weber Ag | |

| DE59306131D1 (de) * | 1992-09-19 | 1997-05-15 | Ellenberger & Poensgen | Druckknopfbetätigter schutzschalter |

| DE59402333D1 (de) * | 1993-03-17 | 1997-05-15 | Ellenberger & Poensgen | Geräteschalter mit integriertem Überstromschutz |

| DE4341214C2 (de) * | 1993-12-03 | 1996-11-07 | Kloeckner Moeller Gmbh | Auslöseeinheit für Leistungs- oder Schutzschalter |

-

1997

- 1997-04-15 US US08/843,398 patent/US5834996A/en not_active Expired - Lifetime

- 1997-04-17 DE DE59705433T patent/DE59705433D1/de not_active Expired - Lifetime

- 1997-04-17 EP EP97106350A patent/EP0802552B1/de not_active Expired - Lifetime

- 1997-04-18 JP JP10212397A patent/JP3754796B2/ja not_active Expired - Fee Related

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7722444B2 (en) | 2005-05-13 | 2010-05-25 | Black & Decker Inc. | Angle grinder |

| US8087977B2 (en) | 2005-05-13 | 2012-01-03 | Black & Decker Inc. | Angle grinder |

| US8087976B2 (en) | 2005-05-13 | 2012-01-03 | Black & Decker Inc. | Trigger assembly for angle grinder |

| DE102009025514A1 (de) | 2009-06-19 | 2010-12-30 | Ellenberger & Poensgen Gmbh | Steuerverfahren zur Auslösung eines elektronischen Schutzschalters |

| DE202010018176U1 (de) | 2009-06-19 | 2014-07-08 | Ellenberger & Poensgen Gmbh | Elektronischer Schutzschalter |

| US10818450B2 (en) | 2017-06-14 | 2020-10-27 | Black & Decker Inc. | Paddle switch |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59705433D1 (de) | 2002-01-03 |

| US5834996A (en) | 1998-11-10 |

| JPH1040779A (ja) | 1998-02-13 |

| JP3754796B2 (ja) | 2006-03-15 |

| EP0802552A3 (de) | 1999-03-10 |

| EP0802552A2 (de) | 1997-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69808446T2 (de) | Auslösemechanismus für überlastrelais | |

| EP0543208B1 (de) | Schutzschalter mit Schaltwippe | |

| EP0317660B1 (de) | Schütz | |

| EP0185107B1 (de) | Motorschutzschalter | |

| DE3874168T2 (de) | Fernbetaetigter ein-/aus-schutzschalter. | |

| EP0563774A2 (de) | Fernsteuerbarer Schutzschalter | |

| DE1256300B (de) | Schaltschuetz | |

| EP0033841B1 (de) | Relais | |

| DE3880659T2 (de) | Schutzgerät für elektrische Anlagen. | |

| EP0802552B1 (de) | Elektrischer Schalter mit Unterspannungsauslösung | |

| DE3713537A1 (de) | Umkehr-schaltvorrichtung mit ueberstromschutz | |

| DE69218025T2 (de) | Elektromechanisches Schaltgerät mit frontalem Zusatzbauteil | |

| DE3539976A1 (de) | Abschaltvorrichtung mit fernsteuerung der oeffnung und schliessung ihrer kreise | |

| EP0303965A2 (de) | Elektrisches Schaltgerät | |

| WO1999054897A1 (de) | Schaltgerät mit einer schaltkammer-baugruppe | |

| DE1465705B1 (de) | Elektrischer Schnappschalter mit Drueckerhebel | |

| DE4233918B4 (de) | Elektrischer Schalter mit Stromüberwachung | |

| EP0036432B2 (de) | Schütz, insbesondere Leistungs- oder Steuer- oder Starter-Schütz | |

| DE69022333T2 (de) | Mit einem Trennelement ausgestattete Lastschalter oder modulare Schalter. | |

| DE4213729C2 (de) | Schutzschalter, insbesondere Motorschutzschalter | |

| DE721862C (de) | Selbstschalter, insbesondere Trennschutzschalter | |

| EP0188482B1 (de) | Schaltschloss | |

| DE69509704T2 (de) | Schaltschutz mit Rasteinrichtung für Schienenmontage | |

| DE102006036194B4 (de) | Schaltvorrichtung mit Schaltstellenpaar | |

| EP0145946B1 (de) | Leitungsschutzschalter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19990408 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010531 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. PATENTANWAELTE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REF | Corresponds to: |

Ref document number: 59705433 Country of ref document: DE Date of ref document: 20020103 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020216 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: ELLENBERGER & POENSGEN GMBH Free format text: ELLENBERGER & POENSGEN GMBH#INDUSTRIESTRASSE 2-8#D-90518 ALTDORF (DE) -TRANSFER TO- ELLENBERGER & POENSGEN GMBH#INDUSTRIESTRASSE 2-8#D-90518 ALTDORF (DE) |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150423 Year of fee payment: 19 Ref country code: CH Payment date: 20150422 Year of fee payment: 19 Ref country code: DE Payment date: 20150428 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150423 Year of fee payment: 19 Ref country code: FR Payment date: 20150422 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59705433 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160417 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20161230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160502 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160417 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160417 |