EP0786366B1 - Cooling system in construction equipment - Google Patents

Cooling system in construction equipment Download PDFInfo

- Publication number

- EP0786366B1 EP0786366B1 EP97300424A EP97300424A EP0786366B1 EP 0786366 B1 EP0786366 B1 EP 0786366B1 EP 97300424 A EP97300424 A EP 97300424A EP 97300424 A EP97300424 A EP 97300424A EP 0786366 B1 EP0786366 B1 EP 0786366B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- upper rotating

- rotating structure

- control valves

- engine

- cooling system

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F9/00—Component parts of dredgers or soil-shifting machines, not restricted to one of the kinds covered by groups E02F3/00 - E02F7/00

- E02F9/08—Superstructures; Supports for superstructures

- E02F9/0858—Arrangement of component parts installed on superstructures not otherwise provided for, e.g. electric components, fenders, air-conditioning units

- E02F9/0875—Arrangement of valve arrangements on superstructures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K11/00—Arrangement in connection with cooling of propulsion units

- B60K11/06—Arrangement in connection with cooling of propulsion units with air cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K11/00—Arrangement in connection with cooling of propulsion units

- B60K11/08—Air inlets for cooling; Shutters or blinds therefor

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F9/00—Component parts of dredgers or soil-shifting machines, not restricted to one of the kinds covered by groups E02F3/00 - E02F7/00

- E02F9/08—Superstructures; Supports for superstructures

- E02F9/0858—Arrangement of component parts installed on superstructures not otherwise provided for, e.g. electric components, fenders, air-conditioning units

- E02F9/0866—Engine compartment, e.g. heat exchangers, exhaust filters, cooling devices, silencers, mufflers, position of hydraulic pumps in the engine compartment

Definitions

- the present invention relates to a cooling system for cooling an engine, a hydraulic oil tank and control valves which are all mounted mainly in construction equipment such as a hydraulic excavator or in a working vehicle.

- Fig. 6 is a sectional side view showing a part of an upper rotating structure of a small-sized excavator, which is disclosed in Japanese Utility Publication No. 32434/94.

- an air duct 3 for sucking the outside air from a lower opening 2.

- the air duct 3 surrounds at least a portion of an oil tank 4 while allowing the said portion of the tank to be positioned in an air intake clearance 5.

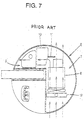

- Fig. 7 is a cutaway plan view showing the construction of an upper rotating structure 6 of a small-sized excavator which is disclosed in Japanese Patent Laid Open No. 237458/95.

- an air flow control plate 11 is provided in an engine accommodating portion 7.

- the air flow control plate 11 guides a part of cooling air which has passed an engine 8 toward a hydraulic oil tank 10 mounted in a tank accommodating portion 9.

- the air duct 3 extends past the oil tank 4 from the lower opening 2. In the central portion of interior of the upper rotating structure of the small-sized excavator, there is little margin of space, so it is very difficult to arrange the air duct 3 there in.

- the air which has passed a radiator 12 comes into abutment against the air flow control plate 11 and is partially turned back toward the engine accommodating portion 7, so that the cooling efficiency for the engine 8 is deteriorated and there is not attained a satisfactory cooling effect for the hydraulic oil tank 10.

- US 3788418 describes an excavator having a cooling system as defined in the preamble of claim 1.

- the construction equipment cooling system of the present invention comprises an upper rotating structure; an engine mounted in a rear portion of the upper rotating structure and having an engine fan; a radiator disposed in proximity to the engine fan; a hydraulic oil tank disposed beside the engine; and control valves for controlling hydraulic actuators.

- the control valves being disposed on a side of the hydraulic oil tank.

- a lower opening is formed in an underside of the upper rotating structure and below the control valves. With rotation of the engine fan, air for cooling the control valves is sucked through the said lower opening.

- a clearance is formed between an upright plate as a constituent of a frame of the upper rotating structure and the side face of the hydraulic oil tank, and the foregoing lower opening is formed below the clearance.

- the cooling system may be designed so that the air for cooling the control valves is supplied through only the aforesaid lower opening.

- the control valves may be attached to a valve stand fixed to the upper rotating structure.

- a duct may be provided on an exhaust side of the radiator, thereby allowing the air to be discharged through the duct to an exterior of the upper rotating structure.

- the air which is sucked from the lower opening with rotation of the engine fan flows along the side face of the hydraulic oil tank.

- the air passes the control valves attached to the side face of the tank. Consequently, both hydraulic oil tank and control valves are cooled by the cooling air. Additionally, it is possible to effect maintenance by utilizing the foregoing clearance and thus possible to improve the maintainability.

- Fig. 1 is a side view of a small-sized excavator equipped with a cooling system (not shown in Fig. 1) embodying the present invention.

- the reference numeral 13 denotes a lower traveling structure

- the numeral 14 denotes an upper rotating structure, which is rotatably mounted on the lower traveling structure 13.

- a working attachment 15 is mounted on a front portion of the upper rotating structure 14. The whole of the attachment 15 is not shown in Fig. 1.

- a boom cylinder 16 is a hydraulic actuator for actuating the working attachment 15.

- Left and right traveling motors 17L and 17R are mounted to the lower traveling structure 13 on the left and right sides. The right traveling motor 17R is not shown in the figure because it is located on the opposite side, or hidden side, of the left traveling motor 17L.

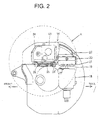

- Fig. 2 is a partially cut-away plan view showing a principal portion of the cooling system disposed in the interior of the upper rotating structure 14.

- the numeral 18 denotes a water-cooled engine

- numeral 19 denotes an engine fan

- numeral 20 denotes a radiator

- numeral 21 denotes a shroud provided on an intake side of the radiator

- numeral 22 a duct provided on an exhaust side of the radiator

- numeral 23 denotes a hydraulic oil tank

- numeral 24 denotes a fuel tank

- numeral 25 denotes control valves controlling hydraulic actuators mounted on the hydraulic excavator

- numerals 26 and 26' denote valve stands for supporting the control valves 25.

- Fig. 3 is a partially cut-away detail view of a portion indicated by the reference mark A in Fig. 2.

- the numeral 27 denotes a frame of the upper rotating structure 14

- numeral 28 denotes a longitudinally extending upright plate as a constituent of the frame 27,

- numeral 29 denotes a lower opening.

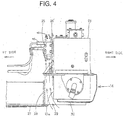

- Fig. 4 is a view as seen in the arrowed direction B-B in Fig. 3.

- numeral 30 denotes an under cover mounted on a bottom side of a rear portion of the upper rotating structure 14.

- Fig. is a view as seen in the arrowed direction C-C in Fig. 3.

- the numeral 31 denotes an opening for the engine fan 19 of which opening is formed in a rear surface of the shroud 21.

- Figs. 1 to 5 The construction of the cooling system according to the present invention will now be described with reference to Figs. 1 to 5.

- the engine 18 and the radiator 20 are mounted in the rear portion of the upper rotating structure 14.

- the hydraulic oil tank 23 is disposed on the side of the radiator 20.

- With rotation of the engine fan 19 the cooling air is sucked from only the lower opening 29 formed in the underside of the upper rotating structure 14.

- the cooling air flows through the path indicated with arrows in Fig. 3, then passes through the opening 31 for the engine fan (shown in more detail in Fig.

- control valves 25 for controlling hydraulic actuators which valves become high in temperature with increase of the hydraulic oil temperature.

- the lower opening 29 is positioned in the clearance between the upright plate 28 as a constituent of the frame 27 of the upper rotating structure and an outer surface 23a of the hydraulic oil tank 23 of which outer surface faces the central portion of the upper rotating structure 14.

- the valve stands 26 and 26' are disposed near the outer surface 23a of the tank 23 along which the cooling air flows, and the control valves 25 are secured to those valve stands 26, 26'.

- the cooling air passes the outer peripheral surfaces of the control valves 25.

- the cooling air is sucked from only the lower opening 29 of the upper rotating structure 14.

- the cooling air is introduced upward while being guided by both the upright plate 28 of the frame 27 and the outer surface 23a of the hydraulic oil tank 23 opposed to the upright plate 28.

- the structure of the lower opening 29 used in this embodiment is simple and economical, not requiring any complicated mechanism.

- the hydraulic actuator controlling valves 25 are disposed in proximity to the outer surface 23a of the tank 23, the cooling air which has been sucked in passes both the tank outer surface 23a and the outer peripheral surfaces of the control valves 25.

- the hydraulic oil tank 23 and the control valves 25 are cooled by the cooling air.

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Component Parts Of Construction Machinery (AREA)

- Cooling, Air Intake And Gas Exhaust, And Fuel Tank Arrangements In Propulsion Units (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP31398/96 | 1996-01-24 | ||

| JP3139896 | 1996-01-24 | ||

| JP03139896A JP3622316B2 (ja) | 1996-01-24 | 1996-01-24 | 建設機械の冷却装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0786366A1 EP0786366A1 (en) | 1997-07-30 |

| EP0786366B1 true EP0786366B1 (en) | 2001-08-08 |

Family

ID=12330163

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97300424A Expired - Lifetime EP0786366B1 (en) | 1996-01-24 | 1997-01-23 | Cooling system in construction equipment |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5791301A (ja) |

| EP (1) | EP0786366B1 (ja) |

| JP (1) | JP3622316B2 (ja) |

| DE (1) | DE69705971T2 (ja) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19839783B4 (de) * | 1997-09-04 | 2006-04-06 | Kubota Corp. | Steuerventilmechanismus für ein Arbeitsfahrzeug mit drehbarem Aufbau |

| US7212999B2 (en) * | 1999-04-09 | 2007-05-01 | Trading Technologies International, Inc. | User interface for an electronic trading system |

| JP2001026944A (ja) * | 1999-07-16 | 2001-01-30 | Kobelco Contstruction Machinery Ltd | 建設機械の排気系構造 |

| ITTO20020727A1 (it) * | 2002-08-14 | 2004-02-15 | Fiat Kobelco Construction Machinery Spa | Apparecchiatura di raffreddamento per un autoveicolo, in particolare per un escavatore. |

| JP3952972B2 (ja) * | 2003-03-07 | 2007-08-01 | コベルコ建機株式会社 | 建設機械の冷却装置 |

| US7451843B2 (en) * | 2003-06-16 | 2008-11-18 | Kobelco Construction Machinery Co., Ltd. | Construction machine |

| CN101076635A (zh) * | 2004-08-04 | 2007-11-21 | 洋马株式会社 | 回转式作业机械 |

| JP4515232B2 (ja) * | 2004-11-22 | 2010-07-28 | 株式会社クボタ | 旋回作業機 |

| WO2009001607A1 (ja) * | 2007-06-26 | 2008-12-31 | Hitachi Construction Machinery Co., Ltd. | 建設機械 |

| JP2009209647A (ja) * | 2008-03-06 | 2009-09-17 | Hitachi Constr Mach Co Ltd | 建設機械の熱交換装置 |

| JP5160668B2 (ja) * | 2011-06-17 | 2013-03-13 | 株式会社小松製作所 | 油圧ショベル |

| JP6229694B2 (ja) * | 2015-06-08 | 2017-11-15 | コベルコ建機株式会社 | エンジンを備えた建設機械 |

| CN106956587B (zh) * | 2017-01-20 | 2020-03-20 | 徐工集团工程机械有限公司 | 车辆动力舱及具有其的工程车辆 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3788418A (en) * | 1972-04-06 | 1974-01-29 | Caterpillar Tractor Co | System for cooling an hydraulic excavator |

| JPH0264716A (ja) * | 1988-08-30 | 1990-03-05 | Shimadzu Corp | パルスモータ式位置決め装置 |

| JPH0476930A (ja) * | 1990-07-18 | 1992-03-11 | Sumitomo Electric Ind Ltd | 半導体素子実装装置 |

| JP2580925B2 (ja) * | 1991-01-10 | 1997-02-12 | 株式会社豊田自動織機製作所 | フォークリフトのエンジンルーム |

| JPH0632434A (ja) * | 1992-07-17 | 1994-02-08 | Bando Chem Ind Ltd | ローラパイプ |

| JP2560035Y2 (ja) | 1992-09-28 | 1998-01-21 | 石川島播磨重工業株式会社 | 連続式アンローダのバケットエレベータ用駆動装置 |

| JPH07237458A (ja) | 1994-03-03 | 1995-09-12 | Kubota Corp | 作業車の原動部構造 |

| DE69603210T2 (de) * | 1995-02-17 | 2000-01-20 | Kubota Corp., Osaka | Schaufelbagger mit einer Motorhaube an welcher der Fahrersitz befestigt ist |

-

1996

- 1996-01-24 JP JP03139896A patent/JP3622316B2/ja not_active Expired - Fee Related

-

1997

- 1997-01-23 EP EP97300424A patent/EP0786366B1/en not_active Expired - Lifetime

- 1997-01-23 DE DE69705971T patent/DE69705971T2/de not_active Expired - Lifetime

- 1997-01-23 US US08/787,171 patent/US5791301A/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0786366A1 (en) | 1997-07-30 |

| JPH09202146A (ja) | 1997-08-05 |

| DE69705971T2 (de) | 2001-12-20 |

| JP3622316B2 (ja) | 2005-02-23 |

| DE69705971D1 (de) | 2001-09-13 |

| US5791301A (en) | 1998-08-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0786366B1 (en) | Cooling system in construction equipment | |

| US6922925B2 (en) | Construction machine | |

| EP0304080B1 (en) | Off-road vehicle | |

| US6092616A (en) | Cooling system for a skid steer loader | |

| EP1887147B1 (en) | Construction machine | |

| EP1091048B1 (en) | Construction machine | |

| US6257359B1 (en) | Air handling system for engines | |

| JP2008296615A (ja) | 建設機械 | |

| US4917201A (en) | Motor vehicle | |

| JPH11254976A (ja) | 建設機械の騒音低減装置並びにこの装置に用いるカバー及び排気部 | |

| JPS643777Y2 (ja) | ||

| JP3046271B2 (ja) | 走行作業機におけるエンジン等の配置機構 | |

| JP2020157895A (ja) | 作業車両 | |

| JPH07237458A (ja) | 作業車の原動部構造 | |

| EP4442911A1 (en) | Work machine | |

| WO2024143190A1 (ja) | 作業機 | |

| JP2850077B2 (ja) | 建設機械 | |

| US20230304259A1 (en) | Construction machine | |

| JPH0216022Y2 (ja) | ||

| JP3051691B2 (ja) | 走行作業機におけるエンジン等の配置機構 | |

| JP2023130211A (ja) | 建設機械 | |

| JPH09166022A (ja) | エンジンの冷却装置 | |

| JPH08312347A (ja) | エンジンにおける作動油冷却装置 | |

| JP3073332B2 (ja) | 旋回型作業車 | |

| JPH0681365A (ja) | 旋回型作業車 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19970210 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 19990526 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 69705971 Country of ref document: DE Date of ref document: 20010913 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120202 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120118 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120114 Year of fee payment: 16 Ref country code: GB Payment date: 20120118 Year of fee payment: 16 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130123 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130801 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 69705971 Country of ref document: DE Effective date: 20130801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130131 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130123 |