EP0756739B1 - Etikett, insbesondere für die befestigung an der innenseite eines kraftfahrzeugfensters - Google Patents

Etikett, insbesondere für die befestigung an der innenseite eines kraftfahrzeugfensters Download PDFInfo

- Publication number

- EP0756739B1 EP0756739B1 EP95917346A EP95917346A EP0756739B1 EP 0756739 B1 EP0756739 B1 EP 0756739B1 EP 95917346 A EP95917346 A EP 95917346A EP 95917346 A EP95917346 A EP 95917346A EP 0756739 B1 EP0756739 B1 EP 0756739B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- printed

- film

- label

- adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F3/00—Labels, tag tickets, or similar identification or indication means; Seals; Postage or like stamps

- G09F3/02—Forms or constructions

- G09F3/0291—Labels or tickets undergoing a change under particular conditions, e.g. heat, radiation, passage of time

- G09F3/0292—Labels or tickets undergoing a change under particular conditions, e.g. heat, radiation, passage of time tamper indicating labels

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F3/00—Labels, tag tickets, or similar identification or indication means; Seals; Postage or like stamps

- G09F3/08—Fastening or securing by means not forming part of the material of the label itself

- G09F3/18—Casings, frames or enclosures for labels

- G09F3/20—Casings, frames or enclosures for labels for adjustable, removable, or interchangeable labels

- G09F3/203—Casings, frames or enclosures for labels for adjustable, removable, or interchangeable labels specially adapted to be attached to a transparent surface, e.g. the window of a car

Definitions

- the invention relates to a label.

- labels are, for example, on walls attached to an indication of the importance of the wall or one of it to give enclosed content. It is also known to have labels with their label side to be attached to the inside of glass panes so that the lettering is readable through the glass pane.

- DE-GM 1 904 346 describes a label and its manufacture, which consists of layers arranged one above the other is built up. These are: a plastic film, a layer of transparent lacquer, a layer with a print and a metal layer.

- the label can be provided with adhesive on the top or bottom and can be used as an inner or outer window sticker.

- a laminate is known from US Pat. No. 4,246,307 which indicates detachment attempts, for example through die cuts in a transparent top layer, which creates the laminate becomes severable and destructible when attempting to remove it.

- the surface of a back layer of the laminate can be reflective or luminescent if that Laminate is used as a vehicle license plate.

- the laminate has the rear layer with the license plate number, including one Layer of a pressure sensitive adhesive, including a top layer. Additional transparent layers can be interposed.

- the invention has for its object to provide a new label that is forgery-proof and can only be detached from its base in such a way that the detachment is visible becomes.

- This object is achieved by the invention defined in claim 1. Training the invention are characterized in the subclaims.

- a preferred area of application of the label according to the invention is the future Europe-wide motor vehicle license plate.

- This Europe-wide license plate is supposed to be on the inside the rear window and / or front window of a motor vehicle are attached and certain region indicators, such as the German flag, a letter and sequence of numbers and a city badge with the date of approval or similar. visible and be largely secured against forgery and removal.

- the invention is that a base laminate or a reflective Layer with one or more printed and / or printable layers, one transparent, white or colored layer and / or one on one surface connected to a unit with a cover film provided on a glass adhesive are.

- the printed film or the printed layers of the label are with an illustration, especially a flag, printed in multi-color printing, preferably on the back of the film.

- the laminate layers are dimensioned so that the printed Flag appears in 3D.

- the printable film on the label is made up of letters and / or numbers Motor vehicle registration number of the motor vehicle printed for which the label is determined. Between the base laminate and the printed or printable film a protective film can be provided on the label in the area of printability, that keeps the printable part accessible for printing or stamping and after removal, the non-detachable connection of the surfaces allows. It can also be provided a printed main sign with an additional sign can be provided. The additional label can be used with the vehicle-specific data be printed.

- the edge of the cover film is colored, especially with Symbols printed and covered with such an adhesive that with violent solution part of the color and / or symbols from the glass adheres to the glass and another part Part of the cover film.

- the visibility of the damage can be improved if the part that adheres to the glass is strip-like or checkerboard-like.

- a silicone layer or between the printed layer and adhesive Sealing applied in the form of a strip or checkerboard.

- the one that connects the laminate layers and / or the label is preferably on the glass fixing glue a void glue.

- the detectability of damage can be further improved if colors and / or the adhesive are such that they are exposed to the effects of temperature Change hue. A detachment of the label with a hair dryer or the like is immediately recognizable.

- the attachment point of the label remains with an additional measure violent removal of the label visible.

- the label with the glass pane connecting glue is soluble in itself with solvents. But on the glass when the label is peeled off, residual paint adheres to it, preventing it from solvents protect and make it solvent-resistant together with the printing inks. The part of the colored printing remaining on the label is liable due to the silicone layer not on the adhesive, but on the label.

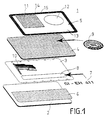

- FIG. 1 shows an exploded view of a label 1 with a plurality of laminate layers 2, 3, 4, 5 and a protective film 6 for maintaining the accessibility of an area 8 which can be printed with a motor vehicle license plate 7 and with a city badge which can be inserted into one of the laminate layers 4, 5 9 shown.

- the materials customary for label production are essentially suitable for the laminate layers.

- the protective film 6 is initially provided in a partial area. she prevents the laminate layers 2 and 3 from sticking together as intended in the area of the protective film 6.

- the protective film 6 covers the area 8 from below Layer 3 with the dimension and required for the motor vehicle license plate 7 is removably attached there.

- the base laminate layer 2 is printed or printable Film covered as layer 3.

- the film 3 is preferably on the back, that is, the side facing layer 2, with a symbol 10, in particular one Flag, printed in multicolor. When printing on the back of the film 3 should the film should be transparent to allow a view from the front.

- the non-visible adhesive that connects the two laminate layers 2 and 3 dimensioned so that he the two laminate layers 2 and 3 after completion of the printing or stamping the motor vehicle license plate 7 against forgery completes.

- a temperature Color change occurs. It is immediately recognizable whether a fake or just attempting to remove the label for counterfeit use on others Job was undertaken.

- a temperature-responsive Foil layer and / or color layer used.

- the print image is translucent if provided a print on the back of the film 3.

- the label 7 can with a Thermal transfer printer can be printed on the film 3. When temperature is applied the color of the vehicle license plate in the area 8 then of the brightly transparent Color into a dark color.

- the printable film 3 is covered by a transparent laminate layer 4 and also glued to this.

- a top laminate layer 5 attached, which is glued to the bottom with the layer 4 and on its top is provided with an adhesive that the finished label 1 with a not shown Glass pane of the motor vehicle makes connectable.

- the adhesive is in contact with Color residues are solvent-resistant and can be removed by violently removing the label 1 do not easily remove from the glass pane. The former location is therefore still visible for a long time.

- acrylic paint and acrylic adhesive are used.

- the acrylate adhesive has document character, i. H. it adheres firmly and securely on the glass and at the same time seals the surface of layer 5 of the label 1.

- the adhesive residue on the glass pane after the label has been torn off are very resistant due to the acrylic paint on the adhesive residue against solvents. Removing the remains of the torn label from the glass pane is by scraping with the help of a knife blade, for example or the like and a subsequent washing with a solvent possible.

- Transparent windows 11, 12, 13 are provided in the white or colored cover layer 5, by the symbol 10, the motor vehicle license plate 7 and the city badge 9 are visible.

- the window 11 for the symbol 10 causes together with the Presentation of the print and the further transparent film 4 a 3D effect for the symbol 10.

- the print is intended, for example, so that the symbol 10 is shown twice with a parallel shift.

- the print image is strip-shaped intended.

- the film of the window 11 over the layer 4 is in place of the Printed with the symbol 10 also striped, for example transparent with black stripes.

- the stripes of the print are colorless or white.

- the width the black and the colorless or white stripe is chosen the same.

- the window 12 for the city badge 9 can be a transparent film if the City badge is attached to layer 3 or behind layer 4. But it is also possible to see the city badge 9 through a window 12 in the form of an opening of layer 5 to stick to layer 4. Instead of windows 11, 12, 13, the entire Layer 5 be made transparent. For the 3D effect of the symbol 10 can on a correspondingly adapted film between the layers 3 at the desired location and 4 are inserted.

- the top layer 5 is from the top with a blue border 14 with Euro stars 15 printed.

- the label 1 has been torn off the glass pane, it remains on the glass pane and on the top of the torn label different color components, that mark the glass plate with theft indicator as well for the possibly reused label 1, the previous theft is visible do.

- the color varnish can be applied to the layer 5 in the form of a strip or a checkerboard pattern. The adhesive then adheres well and sometimes not so well to layer 5. Or that Color adheres to the layer in a stripe-like, checkerboard pattern or other way Pattern-like strong and weak on layer 5 and on the adhesive on the Layer 5.

- the color adheres strongly to layer 5 in strips or as a pattern on layer 5, i.e. on the torn label 1.

- the color remains weakly adhering to layer 5 and strongly adhering to the adhesive of layer 5 with the glue on the glass pane.

- acrylic paint the result is already mentioned effect of the solvent-resistant adhesive on the disc of the Motor vehicle.

- a so-called void glue is used as the glue, which glues the one he glued Material, here layers 2-5 or layers of color, destroyed so that they separation are no longer reusable.

- the one with the adhesive Layer 5 can be added to layer 4 and provided with a protective layer will.

- the adhesive can also be a transfer adhesive that is laminated onto layer 4 becomes.

- the bottom laminate layer 2 can be made of soft PVC or acrylate.

- the printed one Layer 3 is preferably provided from a transparent rigid PVC.

- the top layer 5 is advantageous with a protective film made of silicone paper or from a other removable plastic. Those used between layers 2 through 5 Glue should seal the individual layers tightly together. The choice of the respective adhesive depends on the materials used for the layers.

- Figure 2 shows a plan view of a completed label 1 in the correct representation with clearly visible symbol 10, the flag, with the motor vehicle license plate 7 on a light background and with the blue, continuous edge 14 with the small euro stars 15.

- the stars 15 are preferably yellow.

- FIG. 3 shows the view of a label 1 torn off the glass pane. Only blue stripes 141 are visible with stars 151 in between. The stripes arranged around stars 151 have remained on the glass pane. Instead of the stripes, however, other patterns, as already described for FIG. 1, could also arise when the label is torn off the pane, for example a checkerboard or another fantasy pattern.

- the field of the motor vehicle license plate 7 has become dark due to possible temperature supply, and the license plate 7 may no longer be readable. The temperature could have been supplied, for example, by attempting to remove it with a hair dryer or steam. So the label cannot be removed by heat. Finally, it is also not possible to reuse labels from burnt-out or scrapped motor vehicles.

- Figure 4 shows an exploded view of another structure of the layers.

- the base laminate 2 is white or colored and can be designed to be temperature-reactive, for example as an alternative to the temperature-reactive color.

- the layer 3 printed with the symbol 10 from the rear, which is directed toward the layer 2, is attached to the layer 2.

- the Euro stars 15 are printed from the back on the edge of layer 3.

- the print is multi-colored. It can also extend over the entire layer 3.

- the layer 3 is in turn covered with a transparent layer 4.

- This layer 4 is provided with a security punch 16. This security punch 16 of the transparent layer 4 makes it more difficult to tear off the entire label from a pane. It can take any form.

- the security punching 16 can also be in the layer 2 , the base laminate.

- the printable layer 31 is inserted on the transparent layer 4 from its front, which faces the layer 5 arranged above it. It is provided with the city badge 9 that has already been printed in and the blue border on the circumferential edge with cutouts for the stars 15. After completion of the label 1, it is provided with the motor vehicle license plate.

- the approval badge or city badge 9 is provided as a black screen print on layer 31.

- the cover layer 5 consists of a crystal-clear adhesive 20 which is separated from the inscription field 8 of the layer 31 by the protective film 6 which can be peeled off from the adhesive layer 20 and thus enables the motor vehicle license plate 7 to be imprinted on the already prepared labels.

- the protective film 6 is preferably a silicone film.

- the vehicle registration number 7 is printed on the front of the layer 31.

- the adhesive layer 20 with film 5 then seals the area 8 from above.

- the adhesive layer 20 has, for example, a carrier film 5, on the back of which is provided with the corresponding adhesive 20, for example a void adhesive.

- the adhesive 20 can also be applied to the layer 31 first.

- the protective film 5 is removably attached to the adhesive layer until the label is adhered to a glass pane or the like.

- the protective film 6 on the area 8 of the layer 31 is contained in the ready-to-sell label.

- the labels are resold at the vehicle registration offices. Only then are the corresponding motor vehicle license plates 7 printed in the area 8, the film 6 removed and the area 8 closed with the film 5 by the adhesive layer 20 and thereby sealed. The film 5 is then removed to stick to the glass pane.

- the 3D marking of the symbol 10 prevents the simple copying of the Labels 1.

- the same can be a UV luminescent color as for banknotes is used, whereby authenticity is identified by UV lamps can.

- the printed city badge ensures a limited usability of possibly stolen, not yet labeled labels. After about one theft certain amount of blank labels from a motor vehicle authority can then specifically searched for vehicles with a corresponding badge and / or the Badge shape can be changed for more labels.

- FIG. 5 shows a perspective view of an exploded drawing of a third embodiment of a label according to the invention.

- the base laminate 2 is arranged as the bottom layer.

- the base laminate 2 has an outer peripheral edge 241.

- This border 241 is printed with stars 151, for example yellow euro stars. It is printed from above.

- a 3D print is provided within the edge 241. This is preferably designed in four colors. The 3D print is of such a size that a labeling field 17 remains between the print and the lower edge of the base laminate 2. This is blank.

- a laminate 41 is arranged over the base laminate 2.

- the laminate 41 is, for example, white or colored. It is made of such a material and so that the 3D print of the base laminate 2 shows the desired 3D effect.

- the layer 31 is arranged above the laminate 41.

- the layer 31 is first provided with a release lacquer in the form of a pattern. Then, for example, a blue color is applied to the peripheral edge 14. Star-shaped recesses 15 are left within the blue border 14. Due to the transparency of the laminate 41, the stars 151 provided on the layer 2 can then be seen from the front, that is to say from the printed side of the layer 31.

- the city badge 9 is provided in the upper left half of layer 31.

- the area 8 which can be printed with the license plate 7 is provided below the city badge. For the layer 31, such a film is used that the area 8 can be labeled with a thermal transfer printer.

- the labels shown in FIG. 5 are produced in such a way that the layer 31 is provided with the adhesive layer 20 and the cover paper 5.

- the individual labels can still be arranged on a roll. From the open back, so the side of the layer 31 opposite the adhesive 20, the region 8 becomes with a thermal transfer printer labeled mirror image with the motor vehicle registration number 7.

- the labels can be placed one after the other on a layer 5 provided as an endless roll be fed into the printer. If the thermal transfer printer with a Cutter is equipped, the labels can then be removed individually. After labeling the back of the label by the thermal transfer printer the prepunched and prefabricated laminate films 41 and 2 on the back of the Layer 31 arranged. When attempting to peel it off from a glass sheet or the like the last-mentioned laminate films 41 and 2 are destroyed first.

- Layer 41 can therefore, for example, have a security punch 16, as shown in FIG 4 is shown.

- the separating lacquer on the layer 31 is not to the outside Edge 18 of layer 31 added in order to destroy the layer 31 to avoid the carrier layer 5.

- the 3D representation on layer 2, for example the symbol 10 can be designed as a surface print. This is special advantageous in series production, since the printing effort is due to the large Area reduced. No adjustment of the 3D representation is required.

- FIG. 6 shows a plan view of a section of an endless belt with several labels.

- a carrier film 19 is shown with three labels 1 arranged thereon.

- the labels first have a layer 31. This layer is temperature sensitive. The inscription takes place by means of a thermal transfer printer only in the bright area 8 as described in FIG. 5.

- Adhesive 20 is arranged on the surface of the layer 31 facing the carrier film 19. From this side there is also a printed image of the layer 31. On the one hand, this includes the circumferential edge 14.

- a surface-covering 3D printing 21 is provided within the area delimited by the edge.

- the area 22 for arranging the badge 9 is again provided in the upper right corner. The badge 9 can also already be printed there.

- the illustration in FIG. 6 is viewed from the back of the label in a top view of the layer 31. As a result, the 3D printing 21 appears in mirror image.

- the laminate layer 41 can have a punching 16.

- the laminate layer 2 is used to seal the label from the back.

- the provision of a white back Laminate layer 2 done by printing.

- the labeling area 8 remains free or transparent.

- the vehicle registration number can then be found there be printed.

- a backside sealing of the label 1 can also be partial in the area of the labeling field 8.

- the imagery printed on the Area 8 can thus be done by the end user. It is then in one operation possible with the mirror-image printing.

- the individual labels can either be cut from the endless belt or between the individual labels there is a perforation on the endless carrier film 19 intended to tear off the labels.

- the labels become sticky then detached from the carrier film 19 on the glass panes.

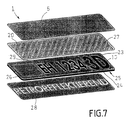

- FIG. 7 shows a perspective exploded drawing of a fourth embodiment of a label 1 according to the invention.

- the label 1 consists of a main plate 25 and an additional plate 26.

- the additional plate 26 is attached to the main plate 25 in a partial area.

- the additional label can no longer be removed from there after it has been glued to the main label.

- the main shield 25 has 3D printing 10. This is also applied to the front of the main sign, as is the additional sign 26.

- the main sign 25 can have a consecutive numbering 29. This can also contain Cyrillic letters, for example.

- the additional plate is marked with the vehicle registration number 7, the identification number, the engine number, etc.

- the main sign is after the printing with the representation 10 and the addition a transparent film with black or colored stripes to create the 3D effect and the printing with the consecutive numbering and after Providing the space for the additional shield from its rear 24 with a retroreflective Layer 28 covered as a base laminate.

- This can be glued or printed will.

- the adhesive layer is on the printed front side 23 of the main plate 25 20 added.

- the adhesive layer is built up in strips. When peeling part of the label remains on a sheet of glass to which it was glued Adhesive strips 27 on the glass pane and another part remains on the sign 25.

- the adhesive layer 20 is provided with the cover film 5. This serves to protect against premature gluing of the adhesive 20 with objects other than the corresponding Car window.

- the cover sheet 5 is attached to the main shield 25 for gluing a sheet of glass or the like.

- the retroreflective layer 28 means that the sign cannot be copied.

- the usual motor vehicle license plates are also retroreflective.

- the peripheral frame of the additional shield 26 or the entire shield 25 can be provided in different colors. For example, every year could be different Colors are used. This makes the signs according to the registration years of the motor vehicles distinguishable.

- the 3D display can also be selected differently from region to region will. On the one hand, for example, a flag 10, as in FIGS. 1 to 3 shown, be provided. On the other hand, city coats of arms or similar, regionally specific motifs can be selected.

- the main shield 25 is made, for example, from a PVC film composite. This can be approx. 470 micrometers thick and have a size of 50 x 210 mm.

- the signs can be produced as cross-cuts on rolls. By providing one Punching between the individual signs, for example a fan punch, the signs can be separated from each other and from the roll. However it is it is also possible to offer the signs individually from the outset. Then you will already separated from each other during production.

- the signs are as inner window stickers usable. In turn, a destructible document adhesive is used as the adhesive layer 20 used.

- FIG. 8 shows a section of the main plate 25 according to FIG. 7.

- the section shows the adhesive of the additional plate 26 on the main plate 25.

- the cover film 5 of the large main plate 25 is opened.

- the printed additional label 26 is applied and glued with its carrier film 30 upward on the lower left edge of the label.

- the carrier film 30 of the additional shield 26 is then removed.

- the opened cover film 5 of the main plate 25 is closed again.

- the additional shield and main shield are firmly connected.

- the main sign thus finished can then be attached to the vehicle.

- the cover film 5 is removed from the main shield and the adhesive layer 20 is exposed.

- FIG. 9 shows an endless carrier film 30 with additional signs 26.

- the carrier film 30 is partially removed from the front additional shield 26.

- the additional shield 26 has an outer peripheral edge 33. This is printed all around. The printed image is directed towards the carrier film 30. It is UV luminescent and cannot be labeled. By providing the UV-luminescent edge 33, the additional shield is forgery-proof.

- the inner area 34 of the label 26 can be printed by a thermal transfer printer with the identification and engine number or with the motor vehicle registration number. This printing is provided from the rear 35 of the additional label 26.

- the rear side 35 is the side of the additional label 26 which points away from the carrier film 30.

- the reverse side 35 of the label 26 is printed in mirror image by the thermal transfer printer.

- the additional labels 26 thus printed are either automatically cut from the roll of the carrier film 30 by the thermal transfer printer. Or a punching, for example a Laporello punching 32, is provided between the individual additional signs in the carrier film 30. As a result, the individual signs 26 can be separated from one another. Otherwise, a cutting device provided in the thermal transfer printer is advantageous.

- the additional label can also be provided with a barcode display. This is optionally readable by infrared. This means that a black code is on black surface is provided.

- the barcode display can either be in the circumferential edge 33 or provided in the central region 34 of the additional shield will.

- the additional label is also preferably highly transparent, thermal transfer printable and made of polyester.

- FIG. 10 shows an exploded perspective view of the structure of a document adhesive for an inventive label according to the previous figures.

- Layer 31 is provided as the base material.

- the layer 31 is transparent and can be printed on both sides. It can also be labeled.

- a silicone lacquer 36 is partially applied to the printed surface of the layer 31. This is done in a checkerboard fashion in FIG. Areas with and without silicone lacquer are thus formed on the layer 31.

- the adhesive layer 20 is then applied to the silicone lacquer and the layer 31. At the points where the silicone lacquer is not provided on the layer 31, the adhesive layer 20 forms a permanent, firm connection with the layer 31.

- the adhesive adheres to the silicone lacquer where the silicone lacquer is provided. Silicone varnish and adhesive can, however, be easily removed from one another.

- the cover film 5 is applied to the adhesive layer 20.

- the adhesive portions arranged on the silicone lacquer 36 remain when detached the label from a surface, for example a glass pane, on this surface.

- the printed image on the layer 31 is divided.

- a checkerboard pattern-like application of the silicone lacquer 36 remains on the layer 31 also stick a chessboard-like print image on the surface.

- the corresponding protected part of the printing of the layer 31 remains under the silicone lacquer on this layer 31.

- a seal 37 can also be applied over the silicone layer 36 to be pulled.

- the seal also has document character. By your The printed image of the layer 31 is then also separated. An attempt at manipulation becomes visible.

- FIG. 11 shows a perspective view of a 3D representation as used in the labels according to the invention. Only a schematic sketch is shown.

- An image representation 40 is provided as the bottom layer. This can be provided, for example, on the layer 31, as mentioned in the previous figure 10.

- a transparent material is applied to this image representation 40. This can be a plastic layer, for example.

- the transparent material 39 is provided with a mask 38 at least in the area of the image representation 40.

- the mask 38 is constructed from black mask lines arranged vertically. The individual lines run parallel to each other.

- a viewer 42 can only see the part of the image 40 from above, which is not covered by the mask lines of mask 38. Because of the between the viewing angle alpha lying in the two eyes of the viewer 42 is the Image representation 40 for the viewer three-dimensionally. The reason for this is that right eye sees a different picture than the left. This is indicated schematically in FIG. 11.

- the 3D representation cannot be copied, the copiers can only represent one Layer can copy from. This will only part of the between the masks copied visible image. By shadowing the mask 38 on the image 40, the entire copying area is shown in the color of the mask. This would be black in Figure 11.

- the lines of the mask 38 can also show a different color. For example they can be selected as dark blue, green, red or the like.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Vehicle Interior And Exterior Ornaments, Soundproofing, And Insulation (AREA)

- Window Of Vehicle (AREA)

- Adhesive Tapes (AREA)

- Motor Or Generator Frames (AREA)

- Body Structure For Vehicles (AREA)

- Vehicle Waterproofing, Decoration, And Sanitation Devices (AREA)

- Printing Methods (AREA)

- Power-Operated Mechanisms For Wings (AREA)

Description

- Fig. 1

- eine Explosionsansicht eines Etiketts mit den zusammenzufügenden Teilen;

- Fig. 2

- ein Etikett in unzerstörter Ansicht und

- Fig. 3

- ein Etikett in einer durch Beschädigung bewirkten Ansicht;

- Fig. 4

- eine zweite Explosionsansicht des Etiketts mit den zusammenzufügenden Teilen;

- Fig. 5

- eine dritte Explosionsansicht des Etiketts mit den zusammenzufügenden Teilen;

- Fig. 6

- eine Draufsicht auf einen Ausschnitt aus einem endlosen Trägerpapier mit drei Etiketten;

- Fig. 7

- eine vierte Explosionsansicht des Etiketts mit den zusammenzufügenden Teilen als Hauptschild,

- Fig. 8

- eine Detailansicht des Etiketts nach Fig. 7 mit einzufügendem Zusatzschild,.

- Fig. 9

- eine perspektivische Ansicht eines Ausschnittes einer Trägerfolie mit Zusatzschild,

- Fig. 10

- eine Explosionsansicht des Aufbaus eines Dokumentenklebers und

- Fig. 11

- eine perspektivische Ansicht einer 3D-Darstellung mit Blick durch die einzelnen Schichten.

Claims (15)

- Etikett, insbesondere für die Befestigung an der Innenseite eines Kraftfahrzeugfensters,

dadurch gekennzeichnet, daß ein Basis-Laminat (2, 28) mit einer oder mehreren ein- oder beidseitig bedruckten und/oder bedruckbaren Schichten (3, 31, 25, 26), einer transparenten Folie (4, 41) und/oder einer an ihrer einen Oberfläche mit einem auf Glas klebenden, lösemittelbeständigen Kleber (20) versehenen Deckfolie (5) und einer gedruckten Abbildung (10) in 3D-Darstellung oder einer flächendeckenden 3D-Bedruckung (21) über der gesamten Fläche des Etiketts versehen ist, wobei der 3D-Effekt durch Vorsehen einer transparenten Schicht (39) mit darauf vorgesehener schwarzer oder andersfarbiger Maske (38) und darunter angeordneter Bilddarstellung (40) erzielt wird, und daß eine Sicherheitsstanzung und/oder eine UV-lumineszierende Bedruckung (10, 33) und/oder eine Farbtonänderung unter Temperatureinwirkung von Farben und/ oder Kleber und/oder Folien vorgesehen ist oder sind. - Etikett nach Anspruch 1,

dadurch gekennzeichnet,

daß zwischen dem Basis-Laminat (2) oder der Deckfolie (5) und der bedruckten oder bedruckbaren Folie (3,31) im Bereich der Bedruckbarkeit eine Schutzfolie (6) vorgesehen ist, die den bedruckbaren Bereich (8) für die Bedruckung oder Stempelung zugänglich erhält und nach ihrem Entfernen die Bedruckung durch die Verbindung der Schichten (2, 3, 31, 5) versiegelt. - Etikett nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß die bedruckte Fläche der bedruckten oder bedruckbaren Schicht (3, 31, 25, 26) partiell mit einem Silikonlack (36) und darüber mit der Kleberschicht (20) versehen ist, wobei Kleberschicht (20) und bedruckte oder bedruckbare Schicht (3, 31, 25, 26) eine permanente feste Verbindung miteinander eingehen. - Etikett nach einem der Ansprüche 1 bis 3,

dadurch gekennzeichnet, daß das Etikett so mit Farbe und/oder mit Symbolen, insbesondere auf dem Rand (14), bedruckt und mit Kleber (20) bedeckt ist, daß bei gewaltsamer Lösung vom Glas ein Teil der Farbe und/oder Symbole (15) am Glas haftet und ein anderer Teil an der unter dem Kleber (20) vorgesehenen Laminat-Schicht (3, 31, 25, 26). - Etikett nach einem der Ansprüche 1 bis 4,

dadurch gekennzeichnet, daß die bedruckte Schicht (3, 31, 25) eine Folie ist und mit einer Abbildung (10) auf der Folien-Rückseite, insbesondere mit einer Fahne im Mehrfarbendruck, versehen ist. - Etikett nach einem der Ansprüche 1 bis 5,

dadurch gekennzeichnet, daß nach dem Ablösen des Etiketts von einer Glasfläche der auf dem Glas verbleibende Kleber in Verbindung mit Farbresten lösemittelbeständig ist. - Etikett nach einem der Ansprüche 1 bis 6,

dadurch gekennzeichnet, daß die bedruckbare Folie (3, 31, 25, 26) mit dem Kraftfahrzeugkennzeichen (7) des Kraftfahrzeuges bedruckt ist, für das das Etikett (1) bestimmt ist,

daß in die Deckfolie (5) ein Feld (12) für das Einsetzen oder Eindrucken einer Plakette (9), insbesondere einer Städteplakette, und/oder ein oder mehrere Sichtfenster (11, 12, 13) vorgesehen sind, wobei das Feld (12) vorzugsweise frei von Kleber ist, und

daß der Rand (14, 33) der Deckfolie (5) oder der bedruckbaren Schicht (31, 26) farbig ausgeführt ist. - Etikett nach einem der Ansprüche 1 bis 7,

dadurch gekennzeichnet, daß die Basis-Laminatschicht (2), eine Kleberschicht, die bedruckbare oder bedruckte Folie (3), eine Kleberschicht, die transparente Laminatschicht (4), eine Kleberschicht, die Deck-Laminatschicht (5) und die in Verbindung mit Farbresten lösungsmittelresistente Kleberschicht (20) übereinander vorgesehen sind, wobei in der Deck-Laminatschicht (5) vorzugsweise transparente Fenster (11, 12, 13) vorgesehen sind. - Etikett nach einem der Ansprüche 1 bis 7,

dadurch gekennzeichnet, daß die vorzugsweise temperaturreagierende Basis-Laminatschicht (2), eine Kleberschicht, die bedruckte Schicht (3), eine Kleberschicht, eine mit einer Sicherheitsstanzung (16) versehene transparente Schicht (4), eine Kleberschicht, eine von ihrer Vorderseite her bedruckbare oder bedruckte Schicht (31) und eine aus dem glasklaren Kleber (20) bestehende Deckschicht (5) oder eine mit diesem versehene Trägerfolie (5) übereinander vorgesehen sind. - Etikett nach einem der Ansprüche 1 bis 7,

dadurch gekennzeichnet, daß die bedruckte Basis-Laminatschicht (2) mit 3D-Aufdruck, eine Laminat-schicht (41) zur Erzeugung des 3D-Effekts des 3D-Aufdrucks eine in Musterform mit einem Trennlack versehene und darüber bedruckte Schicht (31) und die mit einer abziehbaren Deckfolie (5) bedeckte Kleberschicht (20) übereinander vorgesehen und miteinander verbunden sind. - Etikett nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, daß eine als Endlosband gefertigte Trägerfolie (19) mit der Kleberschicht (20), einer temperaturreagierenden Schicht (31), der Laminatschicht (41) zur Erzeugung des 3D-Effekts und/ oder der Basis-Laminatschicht (2) versehen ist. - Etikett nach Anspruch 11,

dadurch gekennzeichnet, daß eine Querstanzung oder eine Leporellostanzung der Trägerfolie (19) zwischen den Etiketten ein Trennen der Etiketten voneinander ermöglicht. - Etikett nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet,

daß ein Hauptschild (25) und ein Zusatzschild (26) miteinander verbindbar vorgesehen sind. - Etikett nach Anspruch 13,

dadurch gekennzeichnet,

daß das Hauptschild eine retroreflektierende Schicht (28), eine Nummerierung (29) und eine 3D-Bedruckung (10) aufweist, und daß das Zusatzschild sehr dünn und beschriftbar ist, auf der Sichtseite des Hauptschilds (25) angeordnet und mit dem Kleber (20) zusammen zerstörbar ist. - Etikett nach Anspruch 14,

dadurch gekennzeichnet,

daß das Zusatzschild (26) durch den Endanwender oder die Kraftfahrzeugbehörde mit Daten, insbesondere der Fahrgestellnummer des Fahrzeugs, dem Versicherungsnachweis, den Zulassungsdaten oder dergleichen, manuell oder automatisch bedruckbar ist, einen UV-lumineszierenden Rand (33) aufweist und mit UV-lumineszierenden Farben versehen ist.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4414149 | 1994-04-22 | ||

| DE4414149A DE4414149A1 (de) | 1994-04-22 | 1994-04-22 | Etikett, insbesondere für die Befestigung an der Innenseite eines Kraftfahrzeugfensters |

| PCT/EP1995/001506 WO1995029474A1 (de) | 1994-04-22 | 1995-04-21 | Etikett, insbesondere für die befestigung an der innenseite eines kraftfahrzeugfensters |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0756739A1 EP0756739A1 (de) | 1997-02-05 |

| EP0756739B1 true EP0756739B1 (de) | 1998-10-28 |

Family

ID=6516208

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95917346A Expired - Lifetime EP0756739B1 (de) | 1994-04-22 | 1995-04-21 | Etikett, insbesondere für die befestigung an der innenseite eines kraftfahrzeugfensters |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0756739B1 (de) |

| AT (1) | ATE172809T1 (de) |

| AU (1) | AU2345395A (de) |

| DE (2) | DE4414149A1 (de) |

| DK (1) | DK0756739T3 (de) |

| ES (1) | ES2123978T3 (de) |

| PL (1) | PL178849B1 (de) |

| WO (1) | WO1995029474A1 (de) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2742906B1 (fr) * | 1995-12-22 | 1998-03-06 | Hologram Ind Sarl | Etiquette de marquage securisee notamment pour vehicule automobile |

| DE19607606A1 (de) * | 1996-02-29 | 1997-09-04 | Abb Patent Gmbh | Verfahren und Sicherung eines Produktes gegen identischen unberechtigten Nachbau |

| DE19654847A1 (de) * | 1996-04-20 | 1997-10-23 | Gsi Ges Fuer Systemtechnik Und | Vorrichtung zur Vornahme von Transaktionen im elektronischen Zahlungsverkehr |

| FR2757984B1 (fr) | 1996-12-30 | 1999-03-26 | Hologram Ind Sarl | Systeme de marquage securise personnalisable |

| AU695736B3 (en) * | 1998-02-10 | 1998-08-20 | Versari International Limited | A form incorporating a self-adhesive label |

| US6372341B1 (en) | 1998-04-27 | 2002-04-16 | 3M Innovative Properties Company | Tampa-indicating article for reusable substrates |

| DE10020556C2 (de) * | 2000-04-27 | 2002-11-21 | Witte Plusprint Druckmedien Gm | Plakette, insbesondere Zulassungs-, Prüf-, Siegel-, oder Mautplakette, für Kraftfahrzeuge |

| ES2238880B1 (es) * | 2002-04-15 | 2007-05-01 | Industrias Samar't, S.A. | Disposicion identificadora para vehiculos. |

| DE202008007984U1 (de) * | 2008-06-17 | 2008-08-14 | Schröder, Franz-Anton | Identifikationsmittel mit einer Produktidentifikationskennung |

| DE102009005970A1 (de) * | 2009-01-23 | 2010-07-29 | J.H. Tönnjes E.A.S.T. GmbH & Co. KG | Kennzeichen, vorzugsweise Kraftfahrzeugkennzeichen, sowie Verfahren zur Herstellung desselben |

| DE102010055794B4 (de) * | 2010-12-23 | 2013-03-21 | Kurt Koch | Aufbewahrungseinrichtung |

| CA3109519A1 (en) * | 2018-08-13 | 2020-02-20 | Ccl Industries Inc. Corporation Canada | Diy badge talker |

| US12387624B2 (en) * | 2023-03-08 | 2025-08-12 | Studio Eight LLC | Label and beverage container with label attached |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1904346U (de) * | 1963-05-18 | 1964-11-12 | Helmuth Schmoock | Etikett. |

| US3631617A (en) * | 1969-10-27 | 1972-01-04 | Avery Products Corp | Tamperproof label construction |

| US4246307A (en) * | 1977-12-23 | 1981-01-20 | Trautwein Hansjoerg | Tamper-proof laminated sticker or card |

-

1994

- 1994-04-22 DE DE4414149A patent/DE4414149A1/de not_active Withdrawn

-

1995

- 1995-04-21 AT AT95917346T patent/ATE172809T1/de not_active IP Right Cessation

- 1995-04-21 PL PL95316851A patent/PL178849B1/pl unknown

- 1995-04-21 DE DE59504080T patent/DE59504080D1/de not_active Expired - Fee Related

- 1995-04-21 WO PCT/EP1995/001506 patent/WO1995029474A1/de not_active Ceased

- 1995-04-21 EP EP95917346A patent/EP0756739B1/de not_active Expired - Lifetime

- 1995-04-21 ES ES95917346T patent/ES2123978T3/es not_active Expired - Lifetime

- 1995-04-21 DK DK95917346T patent/DK0756739T3/da active

- 1995-04-21 AU AU23453/95A patent/AU2345395A/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| ES2123978T3 (es) | 1999-01-16 |

| DK0756739T3 (da) | 1999-07-12 |

| AU2345395A (en) | 1995-11-16 |

| ATE172809T1 (de) | 1998-11-15 |

| EP0756739A1 (de) | 1997-02-05 |

| WO1995029474A1 (de) | 1995-11-02 |

| PL178849B1 (pl) | 2000-06-30 |

| DE59504080D1 (de) | 1998-12-03 |

| DE4414149A1 (de) | 1995-11-02 |

| PL316851A1 (en) | 1997-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60312712T2 (de) | Farbwechselband, label, karte und spielzwischenvorrichtungen | |

| DE69800730T2 (de) | Formular das unerlaubtes lesen erkennen lässt, zur sicheren übermittlung von informationen | |

| DE102011100579B4 (de) | Fahrzeugidentifizierungsnummer-Etikett (VIN-Etikett) | |

| DE69405599T2 (de) | Sicherheitsetikett | |

| DE69927097T2 (de) | Etikett zum Verdecken von Informationen | |

| EP0756739B1 (de) | Etikett, insbesondere für die befestigung an der innenseite eines kraftfahrzeugfensters | |

| EP2505376B1 (de) | Panelanordnung zur Sichtsteuerung mit kontrastierender gefärbter Trennfolie | |

| EP0866750A1 (de) | Mit einem laserstrahl beschriftbare folie | |

| DE102008038675B4 (de) | Siegelsystem für das Zulassen sowie Um- und Abmelden von Kraftfahrzeugen | |

| US5173081A (en) | Security/protection feature business form with repositional adhesive | |

| DE4224552A1 (de) | Fälschungssicherer Kennzeichnungsträger für Kraftfahrzeuge | |

| DE102013108318B4 (de) | Etikett, insbesondere zum Abdecken von Informationen | |

| DE60220294T2 (de) | Sicherheitsvignette zum anbringen wechselnder aufschriften | |

| DE19653890A1 (de) | Etikett | |

| EP0170712B1 (de) | Sicherheitsaufkleber | |

| DE2831587B2 (de) | Fälschungssicherer Kennzeichnungsträger für Kraftfahrzeuge | |

| DE10208427B4 (de) | Klebesiegel und Träger dafür | |

| DE4338127A1 (de) | Identifikationskarte, Mitgliedskarte und dergleichen | |

| DE4314579A1 (de) | Aufkleber | |

| DE19828178A1 (de) | Hülle zur Einsiegelung eines flachen Wertgegenstandes sowie Verfahren und Vorrichtung zur Herstellung einer solchen Hülle | |

| DE19529728C1 (de) | Klebestempel, Plakette o. dgl. zur Anbringung an Dokumenten, Kraftfahrzeugen o. dgl. | |

| DE202012005364U1 (de) | Hybridkennzeichenschild für Fahrzeuge | |

| EP3726506B1 (de) | Versiegelungsfolie | |

| DE2444984A1 (de) | Bedruckbare etikettenanordnung | |

| EP0795438B1 (de) | Kennzeichnungsträger und Verfahren zu seiner Herstellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19961019 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| RAX | Requested extension states of the european patent have changed |

Free format text: LT PAYMENT 961019;SI PAYMENT 961019 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19971224 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: EHA SCHILDER & WERBETECHNIK HOFFMANN KG |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 961019;SI PAYMENT 961019 |

|

| LTIE | Lt: invalidation of european patent or patent extension | ||

| REF | Corresponds to: |

Ref document number: 172809 Country of ref document: AT Date of ref document: 19981115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER & PARTNER PATENTANWAELTE AG Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19981029 |

|

| REF | Corresponds to: |

Ref document number: 59504080 Country of ref document: DE Date of ref document: 19981203 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2123978 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 19990326 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MC Payment date: 19990401 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 19990405 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990407 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19990415 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19990421 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19990422 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19990423 Year of fee payment: 6 Ref country code: CH Payment date: 19990423 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19990426 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19990427 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19990429 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19990430 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19990119 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19990520 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000421 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000421 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000421 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000421 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000421 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000422 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 20000422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 |

|

| BERE | Be: lapsed |

Owner name: EHA SCHILDER & WERBETECHNIK HOFFMANN K.G. Effective date: 20000430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001101 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 95917346.9 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000421 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001229 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20001101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20001031 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20010425 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050421 |