EP0656311B1 - Procédé pour plier et/ou relier des bandes de papier - Google Patents

Procédé pour plier et/ou relier des bandes de papier Download PDFInfo

- Publication number

- EP0656311B1 EP0656311B1 EP94117903A EP94117903A EP0656311B1 EP 0656311 B1 EP0656311 B1 EP 0656311B1 EP 94117903 A EP94117903 A EP 94117903A EP 94117903 A EP94117903 A EP 94117903A EP 0656311 B1 EP0656311 B1 EP 0656311B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- folding

- visible

- assigned

- distance

- applicator head

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/30—Folding in combination with creasing, smoothing or application of adhesive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B15/00—Details of spraying plant or spraying apparatus not otherwise provided for; Accessories

- B05B15/60—Arrangements for mounting, supporting or holding spraying apparatus

- B05B15/68—Arrangements for adjusting the position of spray heads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/22—Longitudinal folders, i.e. for folding moving sheet material parallel to the direction of movement

Definitions

- the invention relates to a method for folding at least one paper web and / or connecting at least two paper webs along a common one Folding and / or stitching line, along which by means of at least one application head is a linear one Liquid application in the form of folding aid liquid and / or glue is applied, and further relates to one particularly suitable for carrying out this method Contraption.

- a liquid is indeed from EP 0 116 273 A1 known that contains pigments that are only visible are when they are assigned visualization means get abandoned. However, this known liquid serves only invisible under normal light Mark valuable objects. A control of the Order item is not necessary here and also not intended.

- This task is related to that in the preamble of claim 1 specified by the method Characteristic of claim 1 and in connection with the specified in the general term of claims 4 and 6 Devices by the characterizing part of claims 4 or 6 solved.

- the measures according to the invention allow for the first time reliable control of the position of a Folding aid liquid or glue application and thus for the first time an error-dependent re-adjustment of the Application facility, thereby avoiding Production errors is very much supported. Since all of this accomplished with the help of a simple measuring process can result in a high Ease of use and thus a total excellent economy.

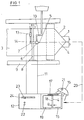

- the longitudinal folding device on which FIG. 1 is based consists of one arranged over two folding rollers 1 Funnel folding device 2, via which a printed Paper web 3 drawn to achieve a longitudinal fold becomes.

- the web is by means of a cross cutting device divided into sections, which can be subjected to a further folding process.

- a folding aid liquid applied to facilitate the by means of the funnel folding device 2 longitudinal fold to be carried out on the paper web 3 along a line 4, which with the folding process the through the gap between the folding rollers 1 and the Funnel nose of the funnel folding device 2 generated Fold line coincides. Due to the folding aid liquid, the papermaterial should be softened along the fold line, so that an exact, sharp-edged fold can be achieved.

- the folding aid liquid can be or as here, applied without contact by means of a nozzle 5 become.

- the nozzle 5 is on an application head 6 added by means of an associated holder 7 is mounted on a cross member 8, which on the frame side walls 9 of the folder superstructure or the Folding machine upstream printing machine is attached.

- the one with switching elements for opening and closing the nozzle 5 The application head 6 is provided with a feed line 10 Folding aid liquid supplied.

- the switching elements of the application head 6 are by means of a control line 11 from a control panel 12 remotely controllable.

- the position of the nozzle 5 is by moving accordingly of the holder 7 along the cross member 8 above the Width of the web 3 adjustable. In simple cases this setting is done manually.

- the control panel 12 provided from remote-controlled actuating device 13, which can be controlled via a control line 14.

- Heated tap water can be used as a folding aid Find use. With absorbent paper, such as newsprint etc., heating to about 30 ° C is sufficient. You can work at a higher temperature for problem papers become. In particularly stubborn cases, the Water chemicals are added.

- Color pigments can be used for this purpose UV light become visible. The visualization becomes therefore only a UV lamp is required. This is a check whether the through the folding aid liquid generated line 4 coincides with the fold line or not possible by making line 4 visible. The fold line is visible anyway. A possibly existing one Distance can thus be measured.

- a measuring table in the exemplary embodiment shown 15 provided to which a visualization means, here in the form of a UV lamp 16 which can be switched on and off, assigned.

- the measuring table 15 is right next to it here the control panel 12 is arranged.

- a length scale 17 is provided, with the help of a any distance a between the visible Folding line 18 and that with the help of the switched on UV lamp 16 folding aid liquid line 4 made visible one placed on the measuring table 15, unfolded here Folded product 19 can be made visible.

- the length scale 17 can, as here, permanently installed or loosely arranged.

- the UV lamp 16 can be switched on and off with a switch button 21 be provided.

- the application head 6 is then by appropriate Control of the actuator 13 with assigned control buttons 22 provided control panel 12 by the same amount, i.e. also by the distance a, adjusted.

- the application head 6 is here in the area of the control panel 12 also a length scale 23 is provided, which is an adjustable synchronously with the application head 6 Pointer 24 is assigned.

- this analog Travel display could of course also be a digital one Ad provided. It would also be conceivable the length scale 17 of the measuring table 15 an automatic Assign scanning device through which the control device 13 can be controlled automatically.

- Two or more are used to form stapling products Sheets laid on top of each other before folding, together folded and glued along the fold line. Subsequently is such a strand package through cross sections in divided individual products. With such a Production is on the top train overlapped webs before folding along the Fold line glue applied.

- This can be a watery one Have consistency.

- A can be used to apply the glue similar or the same as that related to the above Figure 1 dispenser 6 arranged and built order head is used. Often application heads are used, with which alternative Folding aid liquid or glue can be applied. When applying glue, the Application head 6 depending on the location of the Glue application.

- the line-shaped liquid application for example the glue application, up to date To scan paper web 3.

- the one that acts as a pigment carrier here Lane 3 is in the area of the line Glue application by means of a light source, in the case afterglow pigments, by means of a flash device and in the case of no afterglow, with exposure only cutting pigments, using a Exposure device, such as a UV lamp, applied and scanned by means of an associated sensor.

- the circuit of the sensor is therefore such that a Output signal to control an alarm device and / or generated to adjust the application head 6 if the sensor after activating the Visualization source receives no light signal.

Landscapes

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

- Treatment Of Fiber Materials (AREA)

- Coating Apparatus (AREA)

Claims (6)

- Procédé pour plier au moins une bande de papier et/ou assembler au moins deux bandes de papier le long d'une ligne de pliage et/ou d'assemblage le long de laquelle est effectué, au moyen d'au moins une tête à enduction (6), une application linéaire de liquide sous forme d'un liquide auxiliaire de pliage et/ou de colle, caractérisé en ce que des pigments sont ajoutés au liquide utilisé, ces pigments étant invisibles à la lumière normale et visibles lorsqu'ils sont exposés à des produits révélateurs, et en ce que l'application du liquide (4) est rendue visible sur au moins une des bandes de papier (3) et que sa distance (a) de la position souhaitée (18) est mesurée pour l'établissement d'une cote permettant de régler la position de la tête à enduction (6).

- Procédé selon la revendication 1, caractérisé en ce que la distance (a) est mesurée sur le produit fini.

- Procédé selon la revendication 1, caractérisé en ce que la distance (a) est surveillée en continu et qu'en fonction de cela est commandé un dispositif de réglage (13) affecté à la tête à enduction (6).

- Dispositif pour la mise en oeuvre du procédé selon l'une des revendications précédentes, comportant au moins une tête à enduction (6) qui est positionnée sur un support (7) réglable au moyen d'un dispositif de réglage (13), de préférence à commande à distance, caractérisé en ce qu'une table de mesure (15) équipée d'une graduation (17) est prévue, sur laquelle un produit (19) peut être placé et qui est munie de produits révélateurs, de préférence sous forme d'une lampe à U.V. (16) à commutateur marche/arrêt et en ce que le dispositif de réglage (13) affecté à la tête à enduction (6) peut être activé durant le service et qu'un dispositif indicateur (23, 24) affichant la distance de réglage est prévu.

- Dispositif selon la revendication 4, caractérisé en ce que la table de mesure (15) est placée à côté d'un pupitre de commande (12) avec des dispositifs (22) pour la commande à distance du dispositif de réglage (13) et de préférence un dispositif indicateur (23, 24) pour afficher la distance de réglage.

- Dispositif pour la mise en oeuvre du procédé selon la revendication 3, caractérisé par au moins une source révélatrice affectée à un support mobile de pigments et au moins un détecteur réglé sur celui-ci par lequel en cas d'absence d'une réception de lumière est généré un signal de sortie pour commander une installation d'alarme et/ou le réglage de la tête à enduction.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4033470 | 1990-10-20 | ||

| DE4033470A DE4033470C1 (fr) | 1990-10-20 | 1990-10-20 | |

| EP91117624A EP0486812B1 (fr) | 1990-10-20 | 1991-10-16 | Procédé et dispositif pour appliquer un liquide sur un matériau |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91117624A Division EP0486812B1 (fr) | 1990-10-20 | 1991-10-16 | Procédé et dispositif pour appliquer un liquide sur un matériau |

| EP91117624.6 Division | 1991-10-16 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0656311A2 EP0656311A2 (fr) | 1995-06-07 |

| EP0656311A3 EP0656311A3 (fr) | 1997-05-28 |

| EP0656311B1 true EP0656311B1 (fr) | 1999-03-10 |

Family

ID=6416757

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91117624A Expired - Lifetime EP0486812B1 (fr) | 1990-10-20 | 1991-10-16 | Procédé et dispositif pour appliquer un liquide sur un matériau |

| EP94117903A Expired - Lifetime EP0656311B1 (fr) | 1990-10-20 | 1991-10-16 | Procédé pour plier et/ou relier des bandes de papier |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91117624A Expired - Lifetime EP0486812B1 (fr) | 1990-10-20 | 1991-10-16 | Procédé et dispositif pour appliquer un liquide sur un matériau |

Country Status (2)

| Country | Link |

|---|---|

| EP (2) | EP0486812B1 (fr) |

| DE (3) | DE4033470C1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19711948C2 (de) | 1997-03-21 | 1999-05-20 | Roland Man Druckmasch | Vorrichtung in einer Druckmaschine zum Aufbringen von Leim |

| EP1110749A1 (fr) * | 1999-12-22 | 2001-06-27 | Grapha-Holding Ag | Procédé pour réaliser des livres à partir de cahiers reliés, brochures et analogues |

| DE10328805A1 (de) * | 2003-06-26 | 2005-01-13 | Heidelberger Druckmaschinen Ag | Vorrichtung zum Längsauftragen von Klebstoff in einem Falzapparat |

| DE102004058170A1 (de) * | 2004-12-02 | 2006-06-08 | Man Roland Druckmaschinen Ag | Druckmaschine und Verfahren zum Falzen eines Bedruckstoffs |

| DE202007004411U1 (de) * | 2007-03-22 | 2008-07-24 | Planatol Klebetechnik Gmbh | Auftragsvorrichtung mit Markiervorrichtung |

| DE102009006992A1 (de) | 2009-01-31 | 2010-08-05 | Kolbus Gmbh & Co. Kg | Vorrichtung zum Auftragen einer Flüssigkeit entlang einer Biegelinie |

| DE102015107153A1 (de) | 2015-05-07 | 2016-11-10 | Manroland Web Systems Gmbh | Gedruckte Falzhilfe |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3839637A (en) * | 1972-03-22 | 1974-10-01 | A Willis | Textile guiding and measuring indicia |

| DE3307622A1 (de) * | 1983-01-14 | 1984-07-19 | Karl-Heinz 6000 Frankfurt Brück | Markierungsmittel fuer textilien, insbesondere fuer teppiche, und verfahren zu deren herstellung und anwendung |

| DE3721875A1 (de) * | 1987-07-02 | 1989-01-12 | Gema Ransburg Ag | Verfahren und einrichtung fuer eine pulverspruehbeschichtungsanlage |

| DE3740046A1 (de) * | 1987-10-23 | 1989-05-03 | Kotterer Grafotec | Verfahren und vorrichtung zum falzen einer papierbahn |

-

1990

- 1990-10-20 DE DE4033470A patent/DE4033470C1/de not_active Expired - Fee Related

-

1991

- 1991-10-16 DE DE59106477T patent/DE59106477D1/de not_active Expired - Lifetime

- 1991-10-16 DE DE59109107T patent/DE59109107D1/de not_active Expired - Lifetime

- 1991-10-16 EP EP91117624A patent/EP0486812B1/fr not_active Expired - Lifetime

- 1991-10-16 EP EP94117903A patent/EP0656311B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0656311A2 (fr) | 1995-06-07 |

| EP0486812A3 (en) | 1992-10-07 |

| EP0656311A3 (fr) | 1997-05-28 |

| EP0486812B1 (fr) | 1995-09-13 |

| DE59109107D1 (de) | 1999-04-15 |

| DE59106477D1 (de) | 1995-10-19 |

| DE4033470C1 (fr) | 1992-04-02 |

| EP0486812A2 (fr) | 1992-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3114056C2 (fr) | ||

| DE2557551C2 (de) | Verfahren und Vorrichtung zum Auftragen von Flüssigkeiten, insbesondere von flüssigen Klebstoffen auf bahnförmiges Material | |

| EP0131241B1 (fr) | Procédé et dispositif de saisie de marques opposées sur une bande de matériau mobile, pourvue d'un décor imprimé, par des moyens photoélectriques | |

| EP0243756A1 (fr) | Procédé et dispositif pour guider une bande mouvante | |

| DE2703356A1 (de) | Vorrichtung zur ermittlung von passmarken in den freien teilen einer spur, die durch freie und belegte teile sich wiederholender muster auf einer bewegten bahn verlaeuft | |

| DE3015159A1 (de) | Verfahren und vorrichtung zum einstellen eines druckmusters auf ein material | |

| EP1867488B1 (fr) | Procédé pour décorer la surface de pièces | |

| DE2533566B2 (de) | Bahnförmiger Zwischenbildträger und Verfahren und Vorrichtung zu seiner Herstellung | |

| EP0656311B1 (fr) | Procédé pour plier et/ou relier des bandes de papier | |

| DE1906939A1 (de) | Verfahren und Vorrichtung zum Herstellen einer Stossverbindung zwischen den Enden zweier Kartonbahnen | |

| DE2121277C2 (de) | Vorrichtung zum Auslegen einer einen Längsstreifen aufweisenden Stoffbahn | |

| EP0436826A2 (fr) | Dispositif de changement de rouleaux pour une machine d'impression | |

| DE1903551C3 (de) | Vorrichtung zum Zerteilen eines fortlaufenden, mit sich wiederholenden Prägungen versehenen Materialbandes in einzelne Platten | |

| DE19711948C2 (de) | Vorrichtung in einer Druckmaschine zum Aufbringen von Leim | |

| DE3900619C2 (fr) | ||

| DE1803179A1 (de) | Einrichtung zum Regeln der seitlichen Lage einer laufenden Materialbahn | |

| DE2035129A1 (de) | Verfahren und Vorrichtung zur Kontrolle aufeinander abgestimmter Arbeitsablaufe von Maschineneinheiten | |

| EP0860276A1 (fr) | Procédé et dispositif de contrÔle de qualité | |

| EP0436825A2 (fr) | Changeur de rouleau pour une machine d'impression | |

| DE102004049017B4 (de) | Verfahren zur Steuerung des Beginns eines Markier- und Schneidevorganges einer Lasereinheit von Feldern aus einer Materialbahn | |

| DE2843269A1 (de) | Verfahren und vorrichtung zur steuerung von flaemmaschinen zum abflaemmen von oberflaechen, insbesondere von brammen | |

| DE4117404C1 (fr) | ||

| DE4008044C2 (fr) | ||

| DE1233686B (de) | Vorrichtung zum Anschliessen des Anfangs einer neuen Bahn an das Ende einer ablaufenden Werkstoffbahn aus Papier, Karton, Kunststoff- und/oder Metallfolien | |

| DE2208756C3 (de) | Spannmaschine für Warenbahnen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19950131 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 486812 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GRAFOTEC GMBH |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19980727 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BALDWIN GRAFOTEC GMBH |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 486812 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB SE |

|

| REF | Corresponds to: |

Ref document number: 59109107 Country of ref document: DE Date of ref document: 19990415 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990519 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020827 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020828 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20021024 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031017 |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20031016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20101111 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59109107 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59109107 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20111017 |