EP0634813B1 - Bloc de distribution - Google Patents

Bloc de distribution Download PDFInfo

- Publication number

- EP0634813B1 EP0634813B1 EP94106797A EP94106797A EP0634813B1 EP 0634813 B1 EP0634813 B1 EP 0634813B1 EP 94106797 A EP94106797 A EP 94106797A EP 94106797 A EP94106797 A EP 94106797A EP 0634813 B1 EP0634813 B1 EP 0634813B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- distributor strip

- conductor

- strip according

- current bar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2675—Electrical interconnections between two blocks, e.g. by means of busbars

Definitions

- the invention relates to a distribution strip with a plurality of side-by-side, Conductor connections comprising conductor rail pieces according to the preamble of the claim 1.

- Distribution strips of the generic type are used for supply and control-related connection of electrical components such as Voltage sources and signal receivers used. You can use it for this purpose used, for example, to build initiator terminal blocks be, as set out for example in EP 0 222 030 A2. In this reference is carried out that the supply lines of a voltage source two distribution strips located in an initiator terminal block and the supply voltage from there via internal cross-connection strips distributed over several connecting terminals arranged side by side to which in turn supply lines, for example from initiators for electrical Signal receivers can be connected. Building the for this application distribution strips used is relatively complex, since between the Busbar pieces of the conductor connections and the components for the actual Cross distribution of electrical power additional components such as Spacers must be available, with each current transition between the components naturally have a contact resistance.

- the object of the present invention is therefore to provide a distributor strip of the generic type To create kind in which the transverse distribution of the electrical power with conceivably low design and assembly costs, especially to achieve the smallest row widths to ensure more compact Types of conductor connections is important.

- the solution according to the invention consists in the spatial assignment of the functional elements the conductor rail pieces and the arrangement of the functional areas of the Busbar pieces within the conductor connections, primarily related to the Direction of the individual conductor connections.

- the track parts consist of a first section of two lateral, opposite and central via a connecting plate U-shaped spring contact legs, on one side of the connecting plate at its free ends the socket contact form.

- a connection level formed for inserting a conductor into the conductor connection, the Connection level, the connecting plate and the socket contact essentially perpendicular to the direction of connection of the conductor connections in a spatial row one above the other are arranged.

- the spring contact legs form with the connecting plate a structural unit, the main extension of the spring contact legs perpendicular is aligned with the direction of connection of the conductor connections.

- the plug contact elements form the side by side stringing of Conductor connections to a distribution strip by locking a plug contact in a socket contact automatically an electrical connection, so that an additional Check during assembly to ensure that all cross connections of the Cross distribution have been produced.

- the plug connection of the busbar pieces of the individual conductor connections these can be made into distribution strips any length, that is, join any number of conductor connections.

- distribution strips can be set up for any purpose, which in turn for example for the construction of initiator terminal blocks with any number of poles Find use.

- the space required can be due to the arrangement of the track pieces reduce significantly perpendicular to the direction of the row, since the connector tabs a plug contact element directly between the essentially on both sides the insertion space of the socket contact arranged spring contact leg intervention.

- the conductor to be connected to the conductor connection is, for example, via a clamping spring directly with the associated section of the busbar piece of the corresponding conductor connection. Plug and socket contact are thus made in one piece, which lowers the manufacturing costs and simplifies assembly. Since the connection level of the conductor connection is easily accessible from above is, in addition to the connection option already mentioned, via a clamping spring also realize all other usual types of connection of the conductor connection.

- the direction of insertion of the conductors lies contacts in the conductor connections and the plug-in spaces of the sockets essentially in a plane that is perpendicular to the direction of connection of the conductor connections is aligned.

- the connector tab is on the free End of a spring contact leg of a busbar piece parallel to it Arranged end edge, the connector tab in the direction of the opposite Spring contact leg is cranked so that its median plane with the middle between the middle plane located between the two spring contact legs.

- the plug tab from one of the spring contact legs be bent by simple bending operations, which in turn is better Contact behavior and lower assembly costs ensures.

- one of the plug contact elements as a socket contact offers the possibility of the socket part from several directions, for example from the side or to contact from below. Because the socket contact of the first conductor connection a distribution strip for the connection to the next track or to If the structure of the total conductor rail is not required, there is the option here to a printed circuit board arranged under the conductor connections if necessary to create additional connection possibility.

- the socket contact of the individual track piece both from below and which is also accessible from the side can be fed into the distribution strip for power supply

- Arrange additional contact surfaces on the socket contact, both in the Engage the socket contact as well as on the side of the outer surface of the socket contact can make an electrical connection, as is a U-shaped Cable contact for making electrical connections at the socket contact possible.

- the fork-shaped contact has the advantage that a current feed can in principle be done at any point on the distributor strip from below. Especially With limited space, a special feed terminal can be used save on.

- an initiator terminal block provides that two distribution strips in one Basic housing of an initiator terminal block, which can be fixed on the mounting rail is arranged.

- the connection to the basic housing is made using detachable plug-in attachments, so that the distributor strips are easy and easy to install in the initiator terminal block can be regrouped.

- Possibilities of an advantageous simple coding of the invention Distribution strip in particular the often necessary grounding of Busbar connections appear very easy to implement. Because of the accessibility the busbar pieces from below is a connection of the distribution strip to the the mounting rail carrying the earth potential can be implemented without problems.

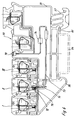

- FIG. 1 shows a distributor strip, designated in its entirety by 1, which consists of three side-by-side conductor connections labeled I-III 2 exists.

- a conductor rail piece is located in the housing 10 of each conductor connection 4, which each interlock with the aid of their plug contact elements 5.

- the structure of a conductor connection 2 is illustrated with the aid of the sectional diagram in FIG. 2.

- the busbar piece 4 In the middle of the conductor connection housing 10 there is in turn the busbar piece 4 recognizable.

- a clamping spring 14 is arranged, which serves the conductor 3 from above into the insertion funnel Introduce 13 of the conductor connection housing 10, under the busbar piece 4 to pull and fix there by clamping spring force.

- At the top of the conductor connection housing 10 is located on the side next to the insertion funnel 13 an assembly opening 15 through which an actuation of the clamping spring 14 for the Assembly process of the conductor 3 is possible.

- Each conductor connection housing has a side wall connecting cams 12 in position and size with corresponding Connection bores 11 on the opposite side surface of the conductor connection housing 10 corresponds, so that when connecting conductor connections in a row 2 these together by the engagement of the connecting cams 12 in the corresponding connection bores 11 of the adjacent conductor connection 2 are set.

- Each busbar piece 4 has a U-shaped base body 21, which consists of two spring contact legs 23 and 24 and a connecting plate 25 connecting them.

- the clamping spring 14 is shown on the outside of the spring contact leg 24 is attached. It has on its holding tab 22 facing Side an opening 30 and is shaped so that it has a spring force in the direction of the arrow F is generated. Since the retaining tab 22 protrudes through the opening 30, the Movement of the free leg 32 of the clamping spring 14 in the direction of arrow F is limited. If a counterforce is exerted on the edge 31 of the clamping spring 14, then her free leg 32 moves with the opening 30 against the arrow F downwards, so that in the interior of the U-shaped base body 21 of the busbar piece 4 a connecting wire can be inserted.

- FIGS. 1 and 2 is a way of contacting the busbar from the underside of conductor connection 2 via the socket contact 26 shown.

- the exemplary embodiment shows a solder contact 42, which is electrically connected to a circuit board 41 and on its the circuit board 41 opposite end has a contact plate 43 which through an opening 44th at the bottom of the conductor connection housing 10 in the socket contact 26 of the Busbar piece 4 engages.

- a solder contact 42 which is electrically connected to a circuit board 41 and on its the circuit board 41 opposite end has a contact plate 43 which through an opening 44th at the bottom of the conductor connection housing 10 in the socket contact 26 of the Busbar piece 4 engages.

- FIG. 4 shows a possibility of contacting the socket 26 to reach around on the outside by a fork contact 40.

- the fork contact 40 is electrically connected to a circuit board 41 like the solder contact 42 described above and engages from below the sockets contact 26, the conductor connection housing 10 in this case an adequately dimensioned cutout 45 on its Has underside.

- a distributor 1 attack if the corresponding cutout 45 in the conductor connection housing 10 Inclusion of the fork parts of the contact encompassing the contacts 26 on the side 40 is present.

- a distribution strip of the type according to the invention can thus be Position as desired over a fork contact 40 arranged in a printed circuit board 41.

- a fork contact 40 arranged in a printed circuit board 41.

- an otherwise necessary feed connection is eliminated, what is particularly advantageous when space is limited.

- Initiator terminal blocks are commonly used made up of individual initiator terminal blocks, in FIG. 5 is an example an initiator terminal block in cross section with three distribution strips according to the invention belonging conductor connections 2 shown.

- An initiator terminal block sets initiator terminal blocks arranged side by side perpendicular to the plane of the drawing 50 together, perpendicular to the plane of the drawing shown with each other are fixed on a common standardized mounting rail 54.

- Through the Lining up the initiator terminal blocks 50 inevitably also results a series of individual conductor connections 2 to distribution strips, which in Figure 5 are designated 1, II and III.

- the initiator series terminal 50 has one Terminal housing 51 made of insulating material, which with detachable webs 80 for detachable Fixing the conductor connection housing 10 provided in the terminal housing 51 is. These receiving webs 80 have small beads 81 which correspond to Engage recesses 82 of the conductor connection housing. Because of this design ensures that the conductor connections 2 are interchanged within a terminal block can be to z. B. convert a PNP arrangement into an NPN arrangement.

- the busbars of the individual distribution strips I, II and III offer when in use in initiator terminal blocks, of course, the possibility of contacting from the underside of the conductor connection housing 10.

- Figure 5 with the help of such Contacting a connection of the busbar of the distribution strip 3 with the Carrier rail 54 shown to build a PE distribution strip.

- the connection is made through the contact bracket 58, through the insertion funnel 53 of the conductor housing 10 engages in a socket contact of the busbar of the distribution strip 3. Since the Contact bracket 58 penetrates contact in the sockets, the contact must necessarily at the beginning of the distribution strip, as there is a free socket contact here is.

- the contact bracket 58 is riveted to a transmission plate 59 which in Initiator terminal housing 51 is fixed and touches the mounting rail 54, so that the appropriate electrical connection is established.

- the definition of the initiator terminal housing 51 on the mounting rail 54 is usually done by two housing feet 56 and 57, the angled holding leg 61 of the mounting rail 54 reach around.

- an initiator terminal block is shown in which the switching state of the Initiator is displayed via a control LED 70.

- the contact plate 72 is part of a contact angle 71 that over a wire bridge 73 and a resistor 74 is connected to the control LED 70.

- the contact plate 72 is not like that in FIG. 5 described contact bracket 58 in the middle of a socket contact the busbar Distribution strip engages, but one of the spring contact legs of the socket contact 26 touched on the side.

- the contact plate 72 is via the insertion funnel 76 so positively driven that a contact other than the side contact of the socket contact not possible.

Landscapes

- Connections Arranged To Contact A Plurality Of Conductors (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Ceramic Products (AREA)

- Connector Housings Or Holding Contact Members (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

Claims (13)

- Barre de distribution comportant plusieurs raccords de conducteur (2) à monter en série les uns à côté des autres, contenant des pièces de rail conducteur (4), avec des éléments de contact à enfichage (5), qui contiennent chacun une languette de connecteur (27) et un contact à douille (26), la languette de connecteur (27) s'engageant, pour la distribution transversale de puissance électrique, dans le contact à douille (26) d'une pièce de rail conducteur (4) voisine

caractérisée en ce queune première portion (21) de chaque pièce de rail conducteur (4) présente deux branches de contact à ressort (23, 24) se faisant face et reliées entre elles au centre par une tôle de liaison (25), qui forment le contact à douille (26) à leurs extrémités libres sur un côté de la tôle de liaison (25),une deuxième portion de chaque pièce de rail conducteur (4) forme un plan de raccordement, pour l'enfichage d'un conducteur dans le raccord de conducteur (2), sur le côté de la tôle de liaison (25) faisant face au contact à douille (26) etle plan de raccordement, la tôle de liaison (25) ainsi que le contact à douille (26) sont superposés dans un montage en série spatial, perpendiculairement à la direction de montage en série des raccords de conducteurs (2). - Barre de distribution selon la revendication 1, caractérisée en ce que la direction d'enfichage des conducteurs (3) dans les raccords de conducteur (2) ainsi que les espaces d'enfichage des contacts à douille (26) se situent sensiblement dans un plan perpendiculaire à la direction de montage en série des raccords de conducteurs (2).

- Barre de distribution selon l'une des revendications précédentes, caractérisée en ce que la languette de connecteur (27) est disposée à l'extrémité libre de l'une des branches de contact à ressort (24) d'une pièce de rail conducteur (4) parallèlement à son arête terminale, la languette de connecteur (27) étant coudée en direction de la branche de contact à ressort (23) opposée, de manière que son plan médian coïncide avec le plan médian se trouvant au milieu entre les deux branches de contact à ressort (23, 24).

- Barre de distribution selon la revendication 3, caractérisée en ce que la branche de contact à ressort (23), non pourvue de la languette de connecteur (27), est coudée en direction de la branche de contact à ressort (24) opposée.

- Barre de distribution selon la revendication 1, caractérisée en ce que des ressorts de serrage (14) sont disposés sur les rails conducteurs (4) des raccords de conducteur (2), en vue de la fixation des conducteurs (3) sur les pièce de rail conducteur (4).

- Barre de distribution selon l'une au moins des revendications précédentes, caractérisée en ce qu'une surface de contact (43) supplémentaire est prévue pour l'alimentation en courant de la barre de distribution (1) au contact à douille (26) d'une pièce de rail conducteur (4).

- Barre de distribution selon la revendication 6, caractérisée en ce que la surface de contact (43) s'engage dans le contact à douille (26).

- Barre de distribution selon la revendication 6, caractérisée en ce que la surface de contact a la forme d'un contact à fourche (40) en U, qui entoure le contact à douille (26).

- Barre de distribution selon la revendication 6, caractérisée en ce que la surface de contact est conformée en languette de contact, qui est électriquement reliée à l'une des surfaces extérieures tournées à l'opposé l'une de l'autre des branches de contact à ressort (23, 24).

- Barre de distribution selon l'une au moins des revendications précédentes, caractérisée en ce que les barres de distribution sont disposées dans un boítier de base (51) d'un bloc à bornes d'initiateur fixé sur un rail de support (54).

- Barre de distribution selon la revendication 10, caractérisée en ce qu'une pièce rail conducteur (4) de la barre de distribution (1) est reliée électriquement au rail de support (54) du bloc à bornes d'initiateur.

- Barre de distribution selon la revendication 11, caractérisée en ce que pour la liaison électrique avec le rail de support (54), un étrier de contact (58) s'engage dans le contact à douille (26) d'une pièce de rail conducteur (4) de la barre de distribution (1).

- Barre de distribution selon la revendication 10, caractérisée en ce que dans le boítier de base (51) sont prévues des fixation à enfichage (80, 81) pour la liaison démontable de la barre de distribution (1) et du boítier de base (51).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4324061 | 1993-07-17 | ||

| DE4324061A DE4324061C3 (de) | 1993-07-17 | 1993-07-17 | Verteilerleiste |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0634813A2 EP0634813A2 (fr) | 1995-01-18 |

| EP0634813A3 EP0634813A3 (fr) | 1995-09-13 |

| EP0634813B1 true EP0634813B1 (fr) | 1999-01-20 |

Family

ID=6493107

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94106797A Expired - Lifetime EP0634813B1 (fr) | 1993-07-17 | 1994-04-30 | Bloc de distribution |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0634813B1 (fr) |

| AT (1) | ATE176093T1 (fr) |

| DE (2) | DE4324061C3 (fr) |

| ES (1) | ES2126669T3 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1291976A1 (fr) | 2001-09-05 | 2003-03-12 | Weidmüller Interface GmbH & Co. | Barette à bornes avec contacts autodénudants et dispositif de connexion |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19630860C1 (de) * | 1996-07-31 | 1997-10-16 | Gerd Conrad | Reihenklemme, insbesondere Initiatoren-Aktoren-Klemme |

| DE19651962A1 (de) * | 1996-12-13 | 1998-06-18 | Siemens Ag | Kaskadierbares Kontaktsystem mit Unterbrechungs- und Einspeisemöglichkeit an jedem Kontaktelement |

| DE19718996C1 (de) * | 1997-05-06 | 1998-06-04 | Phoenix Contact Gmbh & Co | Elektrisches oder elektronisches Gerät |

| DE19832593C1 (de) * | 1998-07-09 | 2000-01-05 | Gerd Conrad | Initiatoren-Aktoren-Klemme |

| DE19851566A1 (de) * | 1998-11-09 | 2000-05-11 | Grote & Hartmann | Potentialverteiler |

| ATE304741T1 (de) * | 2000-03-04 | 2005-09-15 | Conrad Gerd | Brücke für eine elektrische etagenklemme |

| DE20004475U1 (de) | 2000-03-10 | 2001-07-19 | Weidmüller Interface GmbH & Co., 32758 Detmold | Reihenklemme mit Schirmanschlußelement |

| DE10030610A1 (de) * | 2000-06-21 | 2002-01-03 | Abb Patent Gmbh | Installationsverteiler |

| DE10054260A1 (de) * | 2000-11-02 | 2002-05-29 | Vera Feistkorn | Verbindungsvorrichtung für elektrische Leiter zum Auflöten auf Platinen |

| FR2875671B1 (fr) | 2004-09-23 | 2010-02-26 | Hager Electro Sas | Boitier modulaire |

| DE102011052964B4 (de) | 2011-08-24 | 2019-01-31 | Phoenix Contact Gmbh & Co. Kg | Elektrisches Kontaktelement zur Querrangierung zwischen E/A-Modulen |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1205603B (de) * | 1960-02-05 | 1965-11-25 | Josef Eisert | Bruecke zur leitenden Verbindung von mehreren benachbarten Schaltanlagen-Reihenklemmen |

| FR2504610A1 (fr) * | 1981-04-24 | 1982-10-29 | Telemecanique Electrique | Systeme de distribution par voie electrique de signaux de commande pneumatique |

| EP0222030B1 (fr) * | 1985-11-09 | 1989-06-21 | C.A. Weidmüller GmbH & Co. | Bloc de connexion pour initiateur |

| DE3704784A1 (de) * | 1986-07-15 | 1988-05-26 | Wieland Elektrische Industrie | Elektrische anschluss- und/oder verbindungsklemme, insbesondere zum anschluss von initiatoren |

| US4931024A (en) * | 1989-09-13 | 1990-06-05 | Hubbell Incorporated | Contact clip for wiring devices |

| ES2056348T3 (es) * | 1989-11-27 | 1994-10-01 | Bticino Spa | Conjunto de elementos de construccion para facilitar la conexion electrica simultanea de varios interruptores automaticos modulares. |

| DE4014048A1 (de) * | 1990-04-28 | 1991-10-31 | Wago Verwaltungs Gmbh | Elektrische verbindungsklemme |

| DE4019130C2 (de) * | 1990-06-13 | 2000-03-23 | Wago Verwaltungs Gmbh | Stockwerksklemme für elektrische Leiter |

| DE4237733C1 (de) * | 1992-11-09 | 1993-12-23 | Weidmueller Interface | Schraubenlose Anschlußklemme für elektrische Leiter |

-

1993

- 1993-07-17 DE DE4324061A patent/DE4324061C3/de not_active Expired - Fee Related

-

1994

- 1994-04-30 ES ES94106797T patent/ES2126669T3/es not_active Expired - Lifetime

- 1994-04-30 AT AT94106797T patent/ATE176093T1/de not_active IP Right Cessation

- 1994-04-30 EP EP94106797A patent/EP0634813B1/fr not_active Expired - Lifetime

- 1994-04-30 DE DE59407680T patent/DE59407680D1/de not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1291976A1 (fr) | 2001-09-05 | 2003-03-12 | Weidmüller Interface GmbH & Co. | Barette à bornes avec contacts autodénudants et dispositif de connexion |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE176093T1 (de) | 1999-02-15 |

| DE59407680D1 (de) | 1999-03-04 |

| EP0634813A3 (fr) | 1995-09-13 |

| ES2126669T3 (es) | 1999-04-01 |

| DE4324061C3 (de) | 2001-06-21 |

| DE4324061A1 (de) | 1995-01-19 |

| EP0634813A2 (fr) | 1995-01-18 |

| DE4324061C2 (de) | 1996-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4438802C1 (de) | Verteilerleisten mit Querverteilung der elektrischen Leistung (II) | |

| EP0726622B1 (fr) | Dispositif de distribution électrique | |

| EP0789427B1 (fr) | Connecteur pour plaque de circuit imprimé | |

| EP0123822B1 (fr) | Connecteur transversal pour bornes alignées | |

| DE102005040657A1 (de) | Elektrische Anschlussklemme | |

| DE69719025T2 (de) | Ansteckbare elektrische anschlussleiste | |

| DE2525641A1 (de) | Vorrichtung zum gleichzeitigen einsetzen jedes leitungsdrahts von zwei elektrischen leitungsdrahtgruppen in einen schlitz eines einzelnen elektrischen kontakts eines elektrischen verbinders | |

| EP0634813B1 (fr) | Bloc de distribution | |

| DE2045474C3 (de) | Kabelanschlußvorrichtung mit Steckkontakten | |

| DE69204773T2 (de) | Kontaktleister, insbesondere für Telefon- oder Datenleitungen. | |

| EP1117158B1 (fr) | Dispositif de blindage de fixation d'élements de raccordement | |

| DE3730662A1 (de) | Anschlussvorrichtung der fernmeldetechnik | |

| DE2128954A1 (de) | Elektrische Steckverbindung | |

| DE2714158C3 (de) | Anschlußvorrichtung für ein vieladriges Rundkabel | |

| DE2644296A1 (de) | Dreireihiger leitungsstecker mit sogenannten kontaktgabeln zum anschliessen von flachbandkabeln | |

| EP0921611B1 (fr) | Prise et interrupteur pour le secteur | |

| DE69411294T2 (de) | Anschlussblock für elektrisches Geräte und Leistungsumformer mit einem derartigen Anschlu block | |

| DE10157099B4 (de) | Elektrischer Verbinder für die Datentechnik | |

| DE29614725U1 (de) | Steckeinrichtung | |

| EP3923417B1 (fr) | Boîte de dérivation | |

| DE10223867B4 (de) | Leiterplatten-Prüfeinheit | |

| DE1590020A1 (de) | Elektrische Vielfachstecktafel(Programmiertafel) | |

| EP1585195B1 (fr) | Dispositif de barre omnibus | |

| DE29823911U1 (de) | Auf einer Sammelschiene befestigte, elektrisch miteinander verbundene Stromabnehmer | |

| DE29916602U1 (de) | Elektrischer Steckverteilerblock |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19960301 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19980730 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 176093 Country of ref document: AT Date of ref document: 19990215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990129 |

|

| REF | Corresponds to: |

Ref document number: 59407680 Country of ref document: DE Date of ref document: 19990304 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2126669 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: WAGO KONTAKTTECHNIK GMBH Effective date: 19991020 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBO | Opposition rejected |

Free format text: ORIGINAL CODE: EPIDOS REJO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAE | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOS REFNO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 20041027 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090416 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20120425 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20130418 Year of fee payment: 20 Ref country code: CH Payment date: 20130422 Year of fee payment: 20 Ref country code: DE Payment date: 20130419 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20130515 Year of fee payment: 20 Ref country code: IT Payment date: 20130424 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59407680 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20140429 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140501 |