EP0580098A1 - Procédé et dispositif de fondation à pieux - Google Patents

Procédé et dispositif de fondation à pieux Download PDFInfo

- Publication number

- EP0580098A1 EP0580098A1 EP93111516A EP93111516A EP0580098A1 EP 0580098 A1 EP0580098 A1 EP 0580098A1 EP 93111516 A EP93111516 A EP 93111516A EP 93111516 A EP93111516 A EP 93111516A EP 0580098 A1 EP0580098 A1 EP 0580098A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- press

- segments

- piles

- pile

- pressed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims abstract description 35

- 230000002787 reinforcement Effects 0.000 claims description 15

- 238000003825 pressing Methods 0.000 claims description 11

- 229910000831 Steel Inorganic materials 0.000 claims description 8

- 239000010959 steel Substances 0.000 claims description 8

- 239000000463 material Substances 0.000 claims 3

- 238000004382 potting Methods 0.000 claims 3

- 230000001105 regulatory effect Effects 0.000 claims 1

- 239000011150 reinforced concrete Substances 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 8

- 230000008859 change Effects 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 239000003415 peat Substances 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000002689 soil Substances 0.000 description 3

- 229910001294 Reinforcing steel Inorganic materials 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 238000009415 formwork Methods 0.000 description 2

- 239000011435 rock Substances 0.000 description 2

- 239000004576 sand Substances 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 238000004873 anchoring Methods 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 238000009412 basement excavation Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000003651 drinking water Substances 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000003673 groundwater Substances 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000009418 renovation Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D27/00—Foundations as substructures

- E02D27/32—Foundations for special purposes

- E02D27/48—Foundations inserted underneath existing buildings or constructions

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D35/00—Straightening, lifting, or lowering of foundation structures or of constructions erected on foundations

Definitions

- the invention relates to a method according to claim 1 and an apparatus for performing the method according to claim 13.

- Pile foundations are required in a wide variety of construction areas.

- driven piles have been known for thousands of years.

- the historic pile dwellings are built on ram piles.

- the cutting head of a pipe cuts into the ground.

- the pipe has a dual function. On the one hand, it serves to cut into the ground, on the other hand it acts like a formwork or a well wall in relation to the surrounding ground, ie the surrounding ground is physically completely separated from the ground inside the pipe.

- the inside of the pipe can now be dredged with suitable excavators, so-called fall excavators. In the resulting cavity is then a in the usual way Reinforced steel reinforcement and the entire cavity filled with concrete.

- the combined drilling and excavation equipment used for this purpose is usually several tons heavy and must be very high in order to have a suitable fall height for the fall excavator.

- bored piles unlike rammed piles, which compact the surrounding ground in the area of the piles, bored piles have a relatively small effect on the physics of the surrounding soil and the existing layers are penetrated without any significant change. This puncture can lead to various consequences. If, for example, a deeper water-bearing earth layer with a higher pressure is separated by a barrier layer from a higher water-bearing or non-water-bearing earth layer with lower pressure ratios, the drilling process along the cutting tube can cause water to rise from the lower water-bearing layer due to the higher pressure and the change earth physics there.

- Contaminated water flows near the surface can be mixed with deeper lying drinking water flows in an undesired manner etc.

- a significant disadvantage of both the bored pile foundation and the driven pile foundation results from the space required by the drill or ram to insert the piles, making it impossible to insert several adjacent piles at the same time.

- the press pile should have the properties of a solid column.

- the segments are not connected to one another with tensile strength.

- a statically calculable column cannot be realized in this way. This is particularly disadvantageous if the load-bearing layer is far below the level of the building foundation and / or if the subsoil settles due to the lowering of the groundwater level.

- the maximum press-in depth is also limited in the prior art due to the skin friction on the press pile which occurs with increasing press-in depth.

- the invention has for its object to provide a method and create an apparatus for performing the method, whereby the disadvantages of the prior art are avoided.

- the invention adopts the knowledge that a large number of pressed pile segments must be arranged one above the other on soft ground and that these must be connected to one another in a tensile manner by appropriate measures in order to create a statically calculable column on which the building ultimately stands.

- Another consideration that led to the creation of the invention is based on the fact that with increasing press-in depth, the skin friction on the outer surfaces of the already pressed-in segments becomes so great that a large part of the press-pressure is thereby absorbed and the seat pressure of the lowermost segment is too low to make it go deeper. It is therefore provided that one or more further segments with a smaller cross section are telescopically pressed out of the lowest segment.

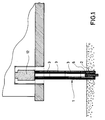

- FIG. 1 shows a partially sectioned illustration of a press pile 1 and a press 12, as well as parts of the building to be lifted and the subsurface. Below a load-bearing outer wall, only as much space had to be created as the press 12 and a press pile segment 2 or 3 require in space.

- the reaction force to apply the pressure is applied by the weight of the building. It is imperative that the reaction force from the weight of the building must be greater than that from the resistance of the ground at the time the pile is founded Reactive power, otherwise the building would be lifted at this point.

- the reaction force for the introduction of a single (or fewer) press piles 1 can be applied by the building. If, after completion of the foundation of all press piles 1, a lifting element is pressurized on each press pile 1, the entire building rises. In this way, the same hydraulic elements can advantageously be used first for the introduction of the press piles 1 and then for the lifting of the building.

- the press pile 1 as a whole is therefore not further pressed in according to the invention, but inner segments with a smaller cross section described in more detail in FIG .

- the various inner segments can be extended telescopically, the next smaller inner segments each being extended further when the peak pressure or the jacket friction has exceeded a predetermined value.

- the uppermost inner segments can be very thin-walled and made of steel, for example.

- FIG. 2 shows a press pile 1, which is composed of an initial segment 2 and any number of subsequent segments 3.

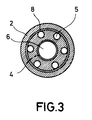

- segments 2, 3 there are several axially extending recesses.

- a large recess 4 runs directly centrally, several smaller reinforcement recesses 5 are arranged concentrically around the central axis of the segment.

- the reinforcement recesses in the starting segment 2 are designed as blind holes.

- An inner segment 6 is located within the recess 4.

- the underside of the press pile 1 is thus closed, and separating layers in the subsurface can be punctured, without the risk that the earth's physics of the individual layers are changed by compensating processes, for example water movements.

- a reinforcing steel 7 inserted into a reinforcement recess 5 is drawn as an example for all other reinforcement recesses 5.

- the reinforcement recesses 5 In order to enable a continuous insertion of the reinforcement steels 7, the reinforcement recesses 5 must be aligned over the entire length of the column 1, which is known to consist of a large number of subsequent segments 3.

- the alignment can take place, for example, by visual inspection when the next following segment 5 is placed on it, or it can be forcibly carried out by coding on the top and bottom sides of the press pile segments 2, 3.

- Such coding can be implemented, for example, in the form of grooves and corresponding projections. For the sake of clarity, the projections and grooves are not shown in this illustration.

- the individual press pile segments 2, 3 each have a helical reinforcement 8 made of steel. Due to the combination of spiral reinforcement 8, the reinforcing steel 7 passing through and the reinforcement recesses 5 poured with concrete, the press piles 1 according to the invention receive a non-positive connection and the predictable statics of a column.

- the inner segment 6 can be pressed telescopically out of the press pile 1. Because the inner segment 6 has a significantly smaller cross-section, the inner segment 6 can achieve a significantly higher surface pressure due to the building weight acting on the press pile 1.

- a press is used which only presses on the inner segment 6. This is particularly advantageous if, for example, the entire press pile 1 has penetrated the poorly load-bearing layers of the subsurface and stands on a load-bearing gravel layer. then the pressure on the inner segment 6 can "extend" it telescopically from the press pile 1 and thus bring about an improved anchoring of the press pile 1, which stands on the gravel layer, in this gravel layer.

- FIG. 3 shows a section along the section line II-II from FIG. 1, the position of the centrally running recess and the concentrically arranged reinforcement recesses can be clearly seen.

- FIG. 9 An embodiment for an application in which the original foundation has to be reinforced is shown in FIG.

- reinforcement is carried out by an auxiliary foundation 9 attached below the foundation.

- the soil beneath the foundations is removed at certain points near the load-bearing wall under which a press pile 1 will later be placed, inside or outside the building, and continuously or relatively continuously by an armored or non-armored person Concrete to be replaced.

- a plurality of tension struts 10 are anchored in the auxiliary foundation 9 thus created.

- the free ends of the tension struts 10 protruding from the auxiliary foundation 9 are connected to a stable supporting frame 11.

- the press 12 is supported on this support frame 11.

- FIG. 1 A schematic representation of a possible arrangement of a plurality of press piles 1/1 .. 1/16 under the outer walls of a building is shown in FIG.

- a partial amount of the press piles is pressurized to insert the press piles.

- the second, fourth, sixth, etc. press piles 1/2, 1/4, 1/6, ... are inserted.

- any other distribution is also conceivable, only the principle is to be explained here, namely, when inserting the press piles, alternately loading only a subset of all press piles used later for lifting.

- the method according to the invention further provides not to first bring one or more press piles all the way down to the load-bearing layer, but rather to insert all press piles approximately equally deep in the individual phases.

- the first segments of the first press pile group are pressed in, then the initial segments of the second press pile group are pressed in.

- the individual indentation steps are very small. They are preferably in the range of a few millimeters.

- the second segments of the first press pile group are pressed in, then the second segments of the second press pile group.

- the pressing in of the pile segments 2, 3 is carried out under computer control by a control unit 13, the pressing speed being kept constant for each pressing pile and the pressing pressure being stored as a function of the pressing depth.

- the respective press pile When the next following segment is put on, the respective press pile is relieved.

- the elastic part of the settlement is determined from the relief movement. The smaller this elastic part is, the closer the starting segment of the press pile 1 is to a load-bearing layer.

- press piles (1/1 to 1/16) in a first step all press piles (1/1 to 1/16) can be pressed in simultaneously, and in a second step when pressing in the press piles (1/1 to 1/16) alternately a first subset of press piles ( 1/1, 1/3, 1/5, ..) and a second subset (1/2, 1/4, .1 / 6, ..) or vice versa.

- This enables an optimal adaptation to the local soil conditions.

- the forces opposing the individual press piles are also checked when they are pressed in. If the press-in force is not the same, readjustment is carried out via the press-in path, so that a force transmission is evenly distributed over all press piles.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Placing Or Removing Of Piles Or Sheet Piles, Or Accessories Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4224042 | 1992-07-21 | ||

| DE19924224042 DE4224042A1 (de) | 1992-07-21 | 1992-07-21 | Verfahren und Vorrichtung zur Pfahlgründung |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0580098A1 true EP0580098A1 (fr) | 1994-01-26 |

Family

ID=6463760

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93111516A Withdrawn EP0580098A1 (fr) | 1992-07-21 | 1993-07-18 | Procédé et dispositif de fondation à pieux |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0580098A1 (fr) |

| DE (1) | DE4224042A1 (fr) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2144111C1 (ru) * | 1999-07-20 | 2000-01-10 | Кушнарев Сергей Михайлович | Способ усиления фундамента здания |

| DE19917253A1 (de) * | 1999-04-16 | 2000-11-02 | Hock Berghaus Kay | Verfahren zur Herstellung biegesteifer Pfähle direkt unter vorhandenen Fundamenten bei beengtem Arbeitsraum |

| KR100621669B1 (ko) | 2006-05-23 | 2006-09-07 | 주식회사고려이엔시 | 압입체를 이용한 구조물 인상 및 기초보강 공법 |

| RU2319809C1 (ru) * | 2006-08-01 | 2008-03-20 | Федеральное государственное унитарное предприятие "Проектно-изыскательский институт "Фундаментпроект" | Способ усиления фундаментов существующих зданий и сооружений |

| RU2320818C1 (ru) * | 2006-07-06 | 2008-03-27 | Федеральное государственное образовательное учреждение высшего профессионального образования Кубанский государственный аграрный университет | Фундамент мелкого заложения для надстраиваемых зданий |

| RU2352722C1 (ru) * | 2007-11-27 | 2009-04-20 | Общество с ограниченной ответственностью "Специализированная фирма "Фундатор" | Способ усиления фундамента здания |

| KR101195236B1 (ko) | 2012-07-31 | 2012-11-06 | 박영수 | 티형 지지강재를 이용한 구조물 인상공법 |

| ITMI20120916A1 (it) * | 2012-05-28 | 2013-11-29 | Setten Genesio S P A | Metodo per la sospensione temporanea di edifici esistenti per la realizzazione di sottofondazioni/sottocostruzioni di detti edifici. |

| RU2581853C1 (ru) * | 2015-03-11 | 2016-04-20 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ возведения свайного фундамента |

| RU2626479C1 (ru) * | 2016-08-03 | 2017-07-28 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ возведения фундамента |

| RU2633619C1 (ru) * | 2016-07-06 | 2017-10-16 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ усиления фундамента при реконструкции |

| RU2660153C1 (ru) * | 2017-10-05 | 2018-07-05 | Акционерное общество "Научно-исследовательский центр "Строительство", АО "НИЦ "Строительство" | Способ устройства свайно-плитного фундамента и свайно-плитный фундамент, возведенный этим способом |

| RU2667163C2 (ru) * | 2015-12-30 | 2018-09-17 | Федеральное государственное бюджетное учреждение науки Институт прикладной механики Российской академии наук (ИПРИМ РАН) | Способ возведения комбинированного фундамента (свайно-плитного, свайно-ленточного, свайно-столбчатого) |

| RU2691799C1 (ru) * | 2018-02-12 | 2019-06-18 | Виктор Дмитриевич Ирхин | Клавишный плоский фундамент |

| CN114108678A (zh) * | 2021-11-19 | 2022-03-01 | 浙江省送变电工程有限公司 | 一种变电站地基加固的锚杆静压桩施工方法 |

| CN116988504A (zh) * | 2023-08-22 | 2023-11-03 | 中铁四局集团有限公司 | 一种内框架柱承台桩基逆作法施工方法 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19949562A1 (de) * | 1999-10-14 | 2001-04-19 | Gerhard Lueck Strasen Und Tief | Fundamentplattenhalte- und -hebevorrichtung und Verfahren zum Halten und Heben von Fundamentplatten |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB382586A (en) * | 1932-06-15 | 1932-10-27 | John Fillans Barr | Improvements in and relating to concrete piles |

| FR779051A (fr) * | 1933-12-20 | 1935-03-29 | Pieux Simplex Super Soc D | Procédé et dispositif pour l'exécution des pieux statiques |

| GB1340355A (en) * | 1970-03-13 | 1973-12-12 | Internaational Tech Handelsond | Method and apparatus for making a bore hole in the ground |

| GB2162224A (en) * | 1984-07-27 | 1986-01-29 | Pilecon Engineering Sdn Bhd | Underpinned driven piles |

| EP0413422A1 (fr) * | 1989-06-22 | 1991-02-20 | Yuan-Ho Lee | Procédé de fondation |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3209182A1 (de) * | 1982-03-13 | 1983-09-15 | Rudolf 5112 Baesweiler Schaffrath | Verfahren zum abstuetzen von bauwerken bei nachlassender reaktionskraft des baugrundes |

| DE3729917A1 (de) * | 1987-09-07 | 1989-03-16 | Erka Pfahl Gmbh & Co Kg | Verfahren zum anheben von bauwerken mittels presspfaehlen |

| US4936062A (en) * | 1989-08-09 | 1990-06-26 | Golston S Webb | Rebar tie holder |

-

1992

- 1992-07-21 DE DE19924224042 patent/DE4224042A1/de not_active Withdrawn

-

1993

- 1993-07-18 EP EP93111516A patent/EP0580098A1/fr not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB382586A (en) * | 1932-06-15 | 1932-10-27 | John Fillans Barr | Improvements in and relating to concrete piles |

| FR779051A (fr) * | 1933-12-20 | 1935-03-29 | Pieux Simplex Super Soc D | Procédé et dispositif pour l'exécution des pieux statiques |

| GB1340355A (en) * | 1970-03-13 | 1973-12-12 | Internaational Tech Handelsond | Method and apparatus for making a bore hole in the ground |

| GB2162224A (en) * | 1984-07-27 | 1986-01-29 | Pilecon Engineering Sdn Bhd | Underpinned driven piles |

| EP0413422A1 (fr) * | 1989-06-22 | 1991-02-20 | Yuan-Ho Lee | Procédé de fondation |

Cited By (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19917253A1 (de) * | 1999-04-16 | 2000-11-02 | Hock Berghaus Kay | Verfahren zur Herstellung biegesteifer Pfähle direkt unter vorhandenen Fundamenten bei beengtem Arbeitsraum |

| RU2144111C1 (ru) * | 1999-07-20 | 2000-01-10 | Кушнарев Сергей Михайлович | Способ усиления фундамента здания |

| KR100621669B1 (ko) | 2006-05-23 | 2006-09-07 | 주식회사고려이엔시 | 압입체를 이용한 구조물 인상 및 기초보강 공법 |

| WO2007136152A1 (fr) * | 2006-05-23 | 2007-11-29 | Korea Engineering & Consultant Co., Ltd | Composes induisant une differenciation des myoblastes ou des fibres musculaires en cellules neuronales, composition pharmaceutique comprenant ces composes, procede permettant d'induire une differenciation en neurones et procede de criblage visant a identifier d'autres composes induisant une differenciation en neurones |

| RU2320818C1 (ru) * | 2006-07-06 | 2008-03-27 | Федеральное государственное образовательное учреждение высшего профессионального образования Кубанский государственный аграрный университет | Фундамент мелкого заложения для надстраиваемых зданий |

| RU2319809C1 (ru) * | 2006-08-01 | 2008-03-20 | Федеральное государственное унитарное предприятие "Проектно-изыскательский институт "Фундаментпроект" | Способ усиления фундаментов существующих зданий и сооружений |

| RU2352722C1 (ru) * | 2007-11-27 | 2009-04-20 | Общество с ограниченной ответственностью "Специализированная фирма "Фундатор" | Способ усиления фундамента здания |

| ITMI20120916A1 (it) * | 2012-05-28 | 2013-11-29 | Setten Genesio S P A | Metodo per la sospensione temporanea di edifici esistenti per la realizzazione di sottofondazioni/sottocostruzioni di detti edifici. |

| EP2669438A1 (fr) * | 2012-05-28 | 2013-12-04 | Setten Genesio S.p.A. | Procédée de reparation d'un bâtiment |

| KR101195236B1 (ko) | 2012-07-31 | 2012-11-06 | 박영수 | 티형 지지강재를 이용한 구조물 인상공법 |

| RU2581853C1 (ru) * | 2015-03-11 | 2016-04-20 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ возведения свайного фундамента |

| RU2667163C2 (ru) * | 2015-12-30 | 2018-09-17 | Федеральное государственное бюджетное учреждение науки Институт прикладной механики Российской академии наук (ИПРИМ РАН) | Способ возведения комбинированного фундамента (свайно-плитного, свайно-ленточного, свайно-столбчатого) |

| RU2633619C1 (ru) * | 2016-07-06 | 2017-10-16 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ усиления фундамента при реконструкции |

| RU2626479C1 (ru) * | 2016-08-03 | 2017-07-28 | Федеральное государственное автономное образовательное учреждение высшего образования "Сибирский федеральный университет" | Способ возведения фундамента |

| RU2660153C1 (ru) * | 2017-10-05 | 2018-07-05 | Акционерное общество "Научно-исследовательский центр "Строительство", АО "НИЦ "Строительство" | Способ устройства свайно-плитного фундамента и свайно-плитный фундамент, возведенный этим способом |

| RU2691799C1 (ru) * | 2018-02-12 | 2019-06-18 | Виктор Дмитриевич Ирхин | Клавишный плоский фундамент |

| CN114108678A (zh) * | 2021-11-19 | 2022-03-01 | 浙江省送变电工程有限公司 | 一种变电站地基加固的锚杆静压桩施工方法 |

| CN114108678B (zh) * | 2021-11-19 | 2023-08-22 | 浙江省送变电工程有限公司 | 一种变电站地基加固的锚杆静压桩施工方法 |

| CN116988504A (zh) * | 2023-08-22 | 2023-11-03 | 中铁四局集团有限公司 | 一种内框架柱承台桩基逆作法施工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE4224042A1 (de) | 1994-02-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69215811T2 (de) | Kurze pfeiler aus agglomerat und verfahren und vorrichtung zur herstellung derselben | |

| EP0580098A1 (fr) | Procédé et dispositif de fondation à pieux | |

| CH650542A5 (de) | Verfahren zur herstellung einer sekantenwand aus betonpfaehlen und nach dem verfahren hergestellte sekantenwand. | |

| DE2403988A1 (de) | Verfahren zum herstellen oder stabilisieren eines fundaments unter verwendung von in den boden ragenden pfaehlen | |

| DE3889631T2 (de) | Verfahren und Einrichtung zur Einstellung eines Fundamentes durch Bildung einer aus dem Boden selbst bestehenden Vermassung. | |

| DE2147051A1 (de) | Verfahren zum herstellen eines druckpfahles im boden | |

| DE10239278B4 (de) | Gründung für Wasserbauwerke | |

| EP0788572B1 (fr) | Procede de reprise en sous-oeuvre de batiments | |

| EP2925934B1 (fr) | Procédé de fabrication d'un pieu | |

| DE69938438T2 (de) | Ein in beton eingebetteter rundpfahl und pfahlrammmethode | |

| DE102007003085B4 (de) | Verfahren zur Herstellung einer Dichtwand mit optimierten Betonfertigteilen | |

| DE19941302A1 (de) | Vorrichtung und Verfahren zur Herstellung von im Boden versenkten Tragsäulen | |

| DE102010024607B4 (de) | Gründungspfahl sowie Verfahren zu seiner Herstellung | |

| DE19740032C2 (de) | Vorrichtung zur Verankerung eines Bewehrungsstabes und Verfahren zur Verankerung einer Dichtsohle | |

| DE102021116487B3 (de) | Geotextilummantelte Flüssigbodensäulen | |

| EP0340599B1 (fr) | Dalle de fond ajustable pour hauts bâtiments ainsi que méthode pour sa réalisation | |

| DE4035646A1 (de) | Verfahren zum eintreiben von tragelementen in den boden | |

| DE102004040191B4 (de) | Verfahren zur Herstellung von Führungselementen | |

| DE2335378A1 (de) | Verfahren und vorrichtung zum abteufen von schachtbauwerken | |

| DE102005008679A1 (de) | Verfahren zur Herstellung von Rammpfählen mit mindestens einem doppelwandigen Rammrohr | |

| BE1030398B1 (de) | Fundamentplatten-Bewehrungsvorrichtung zum Aufbauen eines speziell für ein Photovoltaikanlagen-Fundament anwendbaren Pfahls | |

| DE306750C (fr) | ||

| DE2105432C3 (de) | Verfahren zur Herstellung eines in Längsrichtung vorgespannten Verbundpfahles | |

| DE19726240C1 (de) | Unterfangung und/oder Abdichtung von im Grundwasser stehenden Behältern | |

| DE4439116A1 (de) | Ortbetonpfahl und Verfahren zu seiner Herstellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE DK FR IT LU NL |

|

| 17P | Request for examination filed |

Effective date: 19940726 |

|

| 17Q | First examination report despatched |

Effective date: 19950529 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19951209 |